In today’s complex, fast-moving markets, procurement means much more than simply purchasing goods and services. It covers the entire supplier relationship, from selecting suppliers and negotiating contract terms to purchasing, paying for, and receiving goods and services. At its most basic, a procurement strategy aims to reduce operational costs and increase efficiency. But a procurement strategy that is fully aligned with an organization’s strategic business goals can also enhance competitiveness, build market share, and maximize profits. Suffice to say, any type of business can benefit from a well-thought-out procurement strategy. Here’s how to create a strategy that will complement yours.

What Is a Procurement Strategy?

A procurement strategy is a long-term plan for the acquisition of goods and services. It seeks to optimize the supply chain and streamline internal processes to ensure that the procurement process is as efficient and cost-effective as possible.

Successful procurement strategies typically share six characteristics. The first is that they bring together procurement processes under a single strategic umbrella, so that purchasing decisions are always aligned with the company’s long-term goals. The second is that they include a detailed road map covering the entire procurement process, with clearly defined tasks, responsibilities, and measurable outcomes.

The third characteristic of a successful procurement strategy is performance measurement, through the establishment of key performance indicators (KPIs) and periodic reviews that track progress and allow for course-corrections. The fourth characteristic is the use of technology to increase efficiency, improve visibility and communication, and support decision-making and risk management.

The fifth highlight of a successful procurement strategy is supplier management. Managing the supplier relationship end to end builds resilience and opens doors to new markets and opportunities for innovation. The sixth characteristic, and perhaps the most obvious, is that successful procurement strategies are cost-effective. Although there are many types of procurement strategies (discussed later), all of them aim to minimize costs and maximize profits over the long term.

Key Takeaways

- An effective procurement strategy is fully aligned with, and helps deliver on, an organization’s primary goals.

- Procurement strategies generally fall into several broad categories.

- Building a procurement strategy is a meticulous process that starts with defining the business’s procurement vision and goals.

- An effective procurement strategy can lead to more competitive pricing, better customer relationships, and higher profits.

Why Are Procurement Strategies Important?

A clear and effective procurement strategy is essential for business efficiency; without one, procurement is likely to be inconsistent and fragmented, leading to higher costs, strains in supplier relationships, and increased operational risks.

But efficiency and risk avoidance are not the only reasons to establish a procurement strategy. A procurement strategy also helps organizations develop long-term partnerships with suppliers that share their values, thus building mutual support and stability while reducing the likelihood of supply chain shocks. A procurement strategy enforces desired standards of delivery, quality, and cost-effectiveness throughout the supply chain, which can protect an organization’s reputation and help it attract loyal customers. A procurement strategy can also improve cost management by recognizing cost-saving opportunities and providing a firm basis for price negotiations with suppliers. In addition, it fosters innovation by allowing organizations to collaborate closely with suppliers to develop new products and services that enable them to compete effectively in a dynamic marketplace.

Types of Procurement Strategies

An organization’s procurement strategy should be tailored to its overall strategic goals and the environment within which it operates. That said, procurement strategies fall into a handful of broad categories, which are described below.

- Demand forecasting: Demand forecasting is the process of predicting customer demand for products or services. While a tool or technique and not a strategy in and of itself, using accurate, professional demand forecasting tools and techniques, organizations can pinpoint resource needs and plan for the timely, reliable procurement of raw materials, intermediate parts, production capacity, and administrative support. The benefits of using demand forecasting to underline a procurement strategy include more efficient production, higher revenue, and improved customer satisfaction.

- Strategic sourcing: Sourcing is the process of researching, vetting,

identifying, and selecting potential suppliers; negotiating contracts; and bringing

suppliers on board. Strategic sourcing

shifts this process from a focus on short-term cost benefits, such as selecting the

cheapest suppliers, to looking for suppliers that align with the business’s long-term

growth objectives. A procurement strategy that is mindful of strategic sourcing

incorporates four key pillars: expenditure analysis, supplier evaluation, contract

negotiation, and supplier relationship management. Purchasing decisions then naturally

fall within the framework of the strategic supplier network.

Granted, establishing long-term relationships with a carefully vetted group of suppliers may mean forgoing short-term cost savings in favor of strategic long-term relationships; but, conversely, remaining loyal to a set of reliable suppliers can help a business ride out supply chain storms. Building long-term relationships with key suppliers whose objectives and operational practices are in step with those of the business creates opportunities for product diversification and innovation. - Cost reduction: Cost reduction is often the primary objective of a

procurement strategy. Many organizations operate on thin margins, so keeping procurement

costs down can be essential for generating profits. Optimizing supply chains, choosing

suppliers with fair prices, and negotiating beneficial contract terms can significantly

lower production costs both in the short term and, more importantly, over the longer

term.

However, a procurement strategy that emphasizes cost reduction should nevertheless align with the business’s corporate values and long-term growth objectives. For example, if an organization’s strategic objective is to develop a market-leading position in green technology, a cost reduction procurement strategy that keeps production costs down by using fossil fuels when green alternatives are available is apt to conflict with the business’s stated strategic objective and make its products unacceptable to its target market. On the other hand, the initial cost of switching to green tech may be recouped over the long term through less costly energy sources. - Supplier relationship management (SRM): For many

organizations, building strong, reliable supplier networks is critical for business

success. Good relationships with suppliers can mean lower costs, resilience to adverse

events, and less risk in operations and supply chains. This is why so many

organizations put supplier

relationship management at the heart of their procurement strategy.

An SRM-focused procurement strategy prioritizes efficient organization and management of supply chains to deliver low-cost, high-quality products and services. It also includes the systematic monitoring and evaluation of supplier relationships to identify places where changes could improve business operations. - Supplier life cycle management: Although most companies prefer to forge long-term relationships with suppliers, few supplier relationships last forever. Companies can outgrow their suppliers or develop in directions that require disengagement with existing suppliers and onboarding of new ones. Suppliers, too, can progress in ways that no longer fit the strategic objectives of some of their customers. Considering these changing relationships and needs, managing the supplier life cycle is a key aspect of procurement strategy—starting with initial selection, contract negotiation, and onboarding, continuing through ongoing maintenance and evaluation, and ending with eventual disengagement and replacement.

- Strategic negotiation: Negotiating contracts is an essential part of the procurement process. Organizations can cut costs and enhance profits through the pursuit of excellence in contract negotiation. But looking beyond simple cost-cutting and profit boosts, businesses can develop a competitive edge and gain market share by building strategic relationships with suppliers that share the company’s vision, principles, and standards. Embedding strategic negotiations within a procurement strategy sets the scene for profitable and innovative collaboration well into the future.

- Risk management: Supply chain

risks

fall into four main categories: economic, environmental, political, and ethical.

Examples include, respectively: supplier bankruptcies; natural disasters; political

unrest, such as the conflict in the Middle East and Ukraine; and ethical concerns,

such

as sourcing from companies with poor labor practices.

Embedding risk management as part of an organization’s procurement strategy—particularly smaller businesses that rely on increasingly fragile international suppliers—is necessary for long-term survival. Procurement strategies should incorporate assessment, monitoring, and mitigation of supply chain risks. Assessment and monitoring can include supply chain mapping, weighted ranking, value-at-risk analysis, supplier segmentation, and other techniques that inform about and quantify potential vulnerabilities.

In terms of mitigation, supply chain risks can be eased by strategically diversifying the supplier base to eliminate “single points of failure,” shortening or reshoring supply chains, adjusting inventory management strategies to reduce reliance on just-in-time delivery in vulnerable supply chains, and building strong supplier relationships. - Supplier diversity: A procurement strategy that emphasizes the

development of a more inclusive base of suppliers can help organizations achieve

their

diversity, equality, and inclusion (DEI) objectives. At its simplest, a

diversity-oriented procurement strategy would favor small vendors over large

corporations. But encouraging diversity also means increasing the representation of

disadvantaged groups in the supply chain. Thus, a procurement strategy might

explicitly

aim to develop relationships with enterprises owned and run by women, people of

color,

people with disabilities, or people from the LGBTQ+ community.

Increasing supplier diversity offers attractive benefits for organizations. For example, it can open the door to novel business opportunities and innovation, create a more competitive supply base, increase business agility, help businesses meet their DEI or environmental, social, and governance (ESG) goals, and foster goodwill. They could then track these goals by using relevant KPIs, such as the percentage of spend to diverse suppliers or suppliers with diversity certifications. - Sustainable procurement: These days, organizations understand the

importance of supply chain sustainability. A sustainable supply chain is one that

not

only meets the business’s requirements for cost, quality, and timeliness, but it

also

seeks to protect the environment. So, for example, a manufacturer of high-end

furniture

might work with its suppliers to ensure that all the timber it uses comes from

forests

that actively reduce CO2 emissions and is harvested by people who are

paid

fair wages and have good working conditions.

A sustainable procurement strategy also defines environmental, social, and corporate governance (ESG) objectives for procurement and ensures that all purchasing decisions comply with these objectives. - Continuous improvement: However good an organization’s procurement

processes are, there’s always room for improvement. Organizations can target their

procurement strategies specifically at identifying opportunities for cutting costs,

increasing efficiency, building resilience, improving customer service, and

generating

more revenue.

Typically, a continuous improvement procurement strategy will involve constantly surveilling procurement processes to identify inefficiencies, obstacles, and risks, and taking action to eliminate or mitigate these shortcomings. A continuous improvement procurement strategy can involve rapid integration of cutting-edge technology and best practices, improving KPIs such as cycle time reduction, defect rates, and resource utilization rates. - Digital transformation: Increasingly, business success depends on

adopting digital technologies. Digitizing the entire procurement process can improve

supply chains by eliminating bottlenecks and perfecting information sharing without

compromising security. It’s likely to be particularly beneficial for organizations

exercising a demand-driven “pull” supply strategy with lean inventory, but even

those

using a more traditional “push” strategy can

glean

efficiency gains from digitizing the procurement process.

A procurement strategy focused on digitizing the procurement process typically requires a considerable investment in technology and business process redesign. The business may also need to replace suppliers and recruit and train new staff.

9 Steps to Build a Procurement Strategy

Building a procurement strategy is a meticulous process that starts by analyzing the business’s current status and ends with the production of a detailed road map that covers all aspects of the company’s procurement processes and supply chains. Here are nine essential steps needed to craft an effective procurement strategy.

-

Assess Current Procurement Processes

Assessing a procurement strategy starts with mapping the business’s existing procurement process. Determine to what extent it meets the business’s needs and supports growth objectives, identify areas where inefficiencies and poor relationships are costing the business money, and pinpoint processes that are misaligned with the business strategy. This “gap analysis” feeds into the development of a strategic procurement plan (step 3).

-

Define Procurement Goals

Once the existing processes have been mapped and assessed, the business’s procurement goals can be defined. These goals must align with and support the business’s long-term growth strategy. They might be quite different from existing objectives. For example, a business that currently focuses on keeping its procurement costs as low as possible by constantly seeking price cuts might, as part of a business strategy to achieve market dominance, switch its goal to building long-term strategic relationships with key suppliers, even if this means forgoing short-term price cuts.

-

Develop a Strategic Procurement Plan

The strategic procurement plan is the heart of a procurement strategy, in that it lays out the vision and goals for procurement and defines the processes for achieving them. It also outlines tasks to be performed, assigns key responsibilities, sets time frames for completion, establishes KPIs for measuring success, and selects tools to monitor performance. If the procurement strategy involves significant digitalization, the plan will detail the technology to be adopted, the resources needed for implementation, and the schedule for rolling it out.

In addition, the strategic procurement plan will incorporate preliminary costs for business process and technological changes, as well as an estimate of short- and long-term financial benefits. Developing this plan requires the support of key business stakeholders, such as heads of finance, operations, marketing, and customer relationships.

-

Conduct Market Research and Supplier Analysis

It’s important to find the right suppliers to help the business achieve its strategic goals. Sources, such as existing suppliers, online databases, industry reports, trade shows, and recommendations from business partners, can be tapped to put together a list of potential suppliers. Each supplier can then be evaluated. Analysis includes examining publicly available information, such as suppliers’ published statements, financial history, market reputation, reported quality of goods and services, pricing structures, and delivery schedules. The aim is to produce a short list of suppliers that will be invited to participate in the sourcing process.

-

Create a Sourcing Strategy

The sourcing strategy is a blueprint for the selection, onboarding, and management of suppliers. Creating a sourcing strategy starts with listing every business expenditure (direct and indirect) and grouping them by the nature of the goods and services involved, such as IT software and services, raw materials for manufacturing, or office equipment. For each group, a detailed pattern of spending will emerge through the examination of purchases, noting the total value and volume of purchases over an accounting period, the frequency of purchases, the average size of a transaction, whether purchases are for critical just-in-time inventory or inventory top-off, and any variation in purchase patterns, such as seasonal fluctuations. Future spending plans also need to be taken into account.

Once the spend analysis is complete and prospective suppliers identified (see step 4), the business is ready to develop an initial sourcing strategy. Depending on the nature of the expense, the appropriate process steps can be identified, and key documents for prospective suppliers—requests for information (RFIs), requests for proposal (RFPs), or requests for quotation (RFQs)—can be drafted.

At this stage, evaluation of prospective suppliers is typically more rigorous than during the analysis stage. Companies may request samples, plan site visits, and/or hold in-person meetings with prospective suppliers. Those with procurement goals aligned with ESG objectives may scrutinize prospective suppliers’ ethical practices, environmental policies, and compliance with relevant regulations and standards, while others pursuing digitization may want to evaluate suppliers’ technological capability, preparedness, and resilience.

-

Implement Procurement Technology and Tools

Deploying efficient, effective procurement technology and tools maximizes the benefits of having a procurement strategy. Procurement tools range from simple online RFI, RFP, and RFQ forms to specialist software for contract management, vendor selection, and inventory tracking. Technologies include procure-to-pay software, which integrates purchasing with accounts payable; supplier management systems, which monitor and track supplier performance and manage the supplier life cycle; compliance and risk management platforms; expenditure management and analysis tools; and comprehensive business-intelligence tools that monitor KPIs.

Some or all of these will be helpful to any procurement strategy, even if digitization is not its primary focus. So selecting the right tools and technologies, and setting up a time frame for implementing them, is a crucial step in building a procurement strategy.

-

Build and Manage Supplier Relationships

Once the company has chosen its supply partners, the focus shifts to building and managing relationships. The process begins with onboarding, then focuses on monitoring performance and managing risk, and it eventually concludes with disengagement. SRM typically requires dedicated staff and demands a significant amount of time. But it’s worth it all if it attracts and retains loyal suppliers whose goals and values align with the business’s and that can reliably deliver the performance the company needs to succeed.

-

Monitor and Evaluate Procurement Performance

Organizations can track their procurement performance through KPIs and metrics that measure efficiency, cost-effectiveness, quality, supplier relationships, and overall strategic alignment with business goals. This data-driven approach helps businesses recognize what is working, identify areas for improvement, demonstrate value to stakeholders, manage risks, and support informed overall decision-making across the supply chain decision-making across the supply chain.

Useful metrics for evaluating supply chain efficiency include total cost of ownership, which is a comprehensive analysis of all costs associated with a product or service over its entire life cycle; inventory turnover rate, which measures how often an item of stock is used or rotated over a period of time; and vendor KPIs, such as delivery lead times, communication time lags, product quality, pricing competitiveness, and compliance with negotiated terms. To evaluate the efficiency of internal processes, businesses can also monitor cycle times, purchase order accuracy, and invoice processing speed.

-

Address Risks and Compliance

However meticulously a procurement strategy is crafted, problems are inevitable. From bottlenecks in supplier selection, should the preferred supplier list be overly restrictive, to a key supplier going out of business, to external threats, such as cyberattacks and weather events, managers need to understand the risks and establish procedures to mitigate them. The procurement strategy should, therefore, include a comprehensive risk management strategy and mitigation plan that pinpoints risks, documents actions to contain them, and assigns responsibilities to staff.

For risks that could involve regulatory fines, mitigation means making sure that all staff and suppliers understand the relevant regulations and comply with them; a manual that documents compliance requirements and procedures can go a long way toward accomplishing this. Dedicated compliance staff and management may need to be recruited.

Key Components of an Effective Procurement Strategy

A procurement strategy needs to be well documented and easy to navigate if its implementation is to be successful. Key components of an effective procurement strategy include:

- A strategic statement: An effective procurement strategy starts

with a

clear statement of the business’s strategic vision for procurement. This often

consists

of a single paragraph, as in this statement from a multinational consumer goods

company:

“We have ambitious plans to deliver growth—for ourselves and our partners—whilst

doing

good for people and the planet. To achieve long-term, sustainable growth, we choose

to

partner with those who share our values.”

The company goes on to explain what this sustainable procurement strategy means for customers, staff, and suppliers. But regardless of length, the strategic statement should communicate, in clear terms, the entirety of the business’s procurement strategy. - Expected outcomes: The procurement strategy should state

exactly what

the company expects to achieve and by when. Outcomes can be financial, such as

higher

margins, or nonfinancial, such as eliminating exploitive practices from the

supply

chain. In either case, targets should be tangible and realistically achievable

within a

designated time frame.

For example, a target for a financial outcome might be to “cut cost of sales by 15% within three years.” The accompanying strategic procurement plan would outline how this is to be achieved—for example, by replacing suppliers and renegotiating contracts. A target for a nonfinancial outcome in a sustainable procurement strategy might be to “reduce direct fossil fuel use by 70% within three years.” The accompanying strategic procurement plan might then include steps, such as replacing the company fleet with electric vehicles or converting generators to solar or wind power. - Timeline and milestones: Implementing a procurement strategy means making changes in the way the business works. Whether that means IT fixes, business process redesign, or selecting and onboarding new suppliers and staff, change must be managed. So it’s wise to create a plan that lists the key tasks to be performed and identifies who is responsible for them, how long each one will take, and any interdependencies with other tasks. Identifying the set of interdependent tasks that collectively take the longest to complete—the so-called “critical path”—sets the overall timeline for the change plan.

- A tactical action plan: Implementing strategic changes is important for long-term success. But since they can take months or even years to enact, setting intermediate milestones can be useful for tracking progress and maintaining stakeholder interest. Therefore, it’s wise to have two plans when preparing a procurement strategy: the change plan that will achieve the business’s strategic goals and a tactical plan that governs smaller, perhaps temporary, changes for “quick wins.”

- Performance metrics: The most effective way for managers to

know

whether their strategies are generating the expected benefits is by quantifying

their

progress. That’s why, as previously mentioned, a procurement strategy needs to

include a

set of performance

metrics

that help managers evaluate the success of the strategy.

Once the expected outcomes and intermediate targets of the procurement strategy have been established, potential metrics to measure performance against these outcomes and targets can be identified. For example, if a goal is to bring down the cost of production by 30% over three years, financial KPIs could be set up to monitor monthly, quarterly, and yearly production costs and compare them against previous periods and year-on-year. If another goal is to improve customer retention by 20%, KPIs might monitor the volume and value of repeat sales vs. new customer sales, as well as following feedback from customer surveys. Calculating KPIs can be a heavily manual and time-consuming process, but specialty software that collects and analyzes the necessary data and reports on a range of metrics tailored to the specific needs of the business can ease the burden. The procurement strategy should identify any new software that might be needed to produce the metrics, and include a plan and time frame for its implementation. - Required tools and resources: Implementing a procurement

strategy is

resource-intensive. New staff may need to be recruited and trained and existing

staff

retrained. New suppliers may need to be selected and onboarded, and contracts

with

existing suppliers renegotiated or terminated. Business processes may need to be

mapped

and remapped. The procurement strategy must document the resource needs and

specify how

they will be found.

The same is true for necessary technologies. The procurement strategy should lay out what tools are required, along with a road map for their implementation. Technologies may include a procurement platform, a supplier management system, a compliance and risk management platform, business-intelligence and spend analysis tools, procure-to-pay software, and/or an enterprise resource planning system that ties them all together. The procurement strategy should identify and document the required tools and technologies and develop a timetable for their implementation.

Enhance Your Procurement Strategy With NetSuite

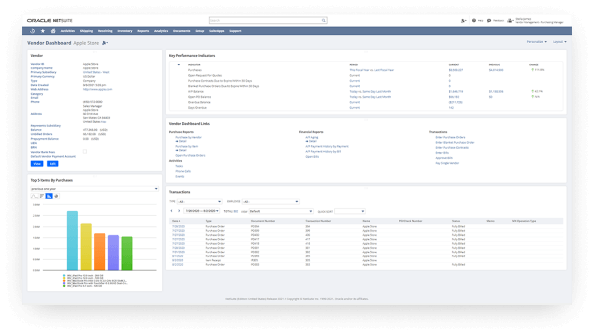

A procurement strategy will only be as effective as the software that supports it. With NetSuite Procurement, organizations can save money and time by centrally managing supplier relationships and automating key processes. NetSuite’s comprehensive platform helps businesses obtain goods and services at the best price and in a timely manner by channeling purchase orders to approved suppliers. It also simplifies recordkeeping by automatically linking procurement transactions to supplier data, delivery receipts, and invoices. All procurement-related information—from transactions and records to vendor performance and expenditures by department—is consolidated in a procurement dashboard, enabling procurement managers to see at a glance what is going on across the entire business. Using NetSuite Procurement, businesses can collaborate more closely with suppliers, negotiate better contracts, control costs, and manage risks and variances, leading to increased profitability.

A well-crafted procurement strategy, backed by stakeholders and by the right tools and technologies, can elevate business performance. Building strong supplier relationships and negotiating better contracts can cut down on costs and reduce expenditure volatility. Optimizing supply chains and streamlining procurement processes will improve customer service and solidify reputations, potentially leading to increased market share and customer retention. And by closely monitoring procurement via real-time KPIs, companies can quickly identify and address risks and variances, with minimal disruption. As cost control increases, suppliers become more dependable, and customer satisfaction rises, the business’s market position can improve and that all-important bottom line can grow.

Procurement Strategy FAQs

What is the most important step for strategic procurement?

Strategic procurement is a nine-step process that includes defining goals, developing a strategic plan, creating a sourcing strategy, building and managing supplier relationships, and implementing procurement technology. Arguably, all are important. For example, good relationships with suppliers can lead to more competitive pricing, higher quality products, and improved customer service, potentially resulting in increased revenues and greater market share.

What is the procurement strategy cycle?

The procurement strategy cycle encompasses the entire process of finding and obtaining goods and services to meet strategic objectives. It involves multiple steps, including defining strategic goals, identifying business needs, finding the right suppliers, negotiating terms, creating purchase orders, and receiving deliveries.

Where does procurement fit in an organization?

Procurement is a key aspect of supply chain management. Given its strategic importance, the department leader typically reports to the chief operating officer; or, if there is a chief procurement officer, that person reports to the chief executive officer.