Raw materials are the basic substances used to produce products. In one form or another, they have been shaping human history since the beginning of civilization, from stones fashioned into axes and animal hides tanned for clothing to silicon, gold and copper used to manufacture modern-day electronics.

Raw materials are an essential part of the supply chain, kicking off a string of inventory- and production-related processes that lead to finished, sellable goods across numerous industries. Raw materials require careful demand planning, inventory management and proper accounting for financial statement accuracy. Our comprehensive guide delivers the goods.

What Are Raw Materials?

Raw materials are the unprocessed, or minimally processed, inputs used in the production of goods, such as the steel, rubber and plastic used to manufacture cars. What’s more, they are a hot commodity: A forecast from the Institute for Supply Chain Management states that raw material prices will rise 3.2% during the first five months of 2024. That’s on the heels of a 4.1% increase in 2023 and 25% rise since 2020.

What makes up these vital materials? They are often a form of natural resources that fall into three main categories:

- Plant/tree-based: Vegetables, fruits, flowers, wood, resin, corn, grain, lumber and latex.

- Animal-based: Leather, meat, bones, milk, wool and silk.

- Mining-based: Minerals, metals, crude oil, gasoline, natural gas, various minerals and coal.

Another form of raw materials, synthetics, is created through chemical processes applied to natural resources. These synthetics include plastics, polyethylene, polypropylene, polyvinyl chloride (PVC), sulfur, chlorine ammonia and steel.

Key Takeaways

- Raw materials are foundational products that are transformed into manufactured goods.

- They can be found in nature, on farms, can be mined from the planet and even chemically produced.

- For accounting purposes, it is imperative to understand the differences between direct and indirect raw materials.

- The value of direct raw materials inventory appears as a current asset on the balance sheet.

- Many industries, such as automotive, construction and energy, are reliant on raw materials.

Raw Materials Explained

To finagle a line from Aristotle, one whole product ready for sale is greater than the sum of its raw material parts. But as any modern-day manufacturer would attest, without those parts, there would be no product. Some raw materials, such as wood and minerals, are extracted from the earth through mining and drilling. Others are grown on farms or are produced in factories using chemical processes.

But no matter the type, raw materials are rarely used in their original state. Coffee beans are a simple example: The raw beans are picked, then ground into a powder, put in a can or bag and eventually turned into a cup of latte. Another common example is crude oil. This viscous raw material doesn’t do much on its own; rather, it must be extracted before it can be transformed into the myriad petroleum-based items used every day.

Raw materials are one of three main types of inventory. They provide the foundation for the other two: works in process (WIP) and finished goods. WIPs — also known as semi-finished goods — are partially completed items not ready to be sold, as opposed to finished goods, which are done and ready for sale. Also worth noting, there are two types of raw materials: direct and indirect. (More on these following the next section.)

Accounting for Raw Materials

Efficient management of raw materials inventory is pivotal for effective financial oversight. In the realm of manufacturing accounting, raw materials are acknowledged as a business’s “critical asset,” without which the business could fail.

Raw materials are reported on a company’s balance sheet, one of three core financial statements that summarize a business’s financial standing at a particular point in time (usually the end of a specific accounting period). Raw materials are classified on the balance sheet as a current asset, meaning that the business expects to consume the inventory within a year.

The process of accounting for raw materials inventory involves monitoring and assigning value to materials that will be consumed in production. A foundational practice is the use of a “perpetual inventory system,” which facilitates real-time monitoring of raw material quantities and costs to accurately reflect the current asset value. Regular reconciliations between physical inventory counts and accounting records help pinpoint discrepancies and mitigate errors in financial reporting.

The first-in, first-out (FIFO) and weighted average cost (WAC) valuation methods are prevalent in raw materials inventory accounting. FIFO operates on the assumption that initially procured materials are the first to be used in production; the inventory’s value on the balance sheet represents the current cost of materials in stock. The WAC method computes the average cost of all materials on hand, regardless of acquisition timing. This method offers a dynamic and continuously updated valuation of raw materials, providing a purportedly more accurate reflection of their current value in inventory.

All inventory, including raw materials, should be valued at its comprehensive cost. This means its value includes the costs of shipping to the manufacturer, storage and preparation. When first procured, the typical journal entries in an accrual accounting system include a credit to cash and a debit to inventory. Debiting inventory increases current assets, and crediting cash reduces cash assets by the amount paid to the supplier.

When a manufacturer uses inventoried raw materials in production, it transfers them from raw materials inventory to WIP inventory. When the company completes its WIP items, it adds the finished items to the finished goods inventory, making them ready for sale. Raw material costs eventually hit a company’s income statement as part of cost of goods sold (COGS), noted in the period when the finished goods are sold.

Direct vs. Indirect Raw Materials

The manufacturing process for any product involves the use of direct and indirect materials. Direct raw materials are the raw inputs used during production and are directly reflected in the final product. Thus, their costs are easy to quantify, easy to allocate to individual production and production costs and easy to factor into product pricing. Examples of direct materials include clay for the manufacturing of ceramic mugs and cotton for clothing.

Direct raw materials are placed in “current assets” on a company’s balance sheet and are expensed on the income statement within COGS when the finished products are sold. Direct raw materials are typically considered variable costs, simply because the amount of material used depends on the quantities of the item being produced.

Indirect raw materials support the manufacturing process but aren’t directly linked to a specific product or are immaterial. The oil that maintains assembly machines used to put together auto parts is one example. Others include safety masks and goggles, cleaning materials, glue and other adhesives. Indirect raw materials are part of the manufacturer’s overhead costs. They can be expensed, as incurred, as operating expenses on the company’s income statement, or they can be aggregated with other indirect costs and allocated to products using a systematic and reasonable approach. Allocation is the preferred method because it yields a more comprehensive inventory valuation.

Raw Materials in the Supply Chain

A supply chain is a synchronized network of activities involved in a product’s life cycle. Generally speaking, it begins with the procurement of raw materials, which are delivered to suppliers and represent the first link in the production chain. A manufacturer subsequently purchases these materials for processing into semi-finished or finished products. Upon completion, products are stored in warehouses and distribution centers or shipped directly to wholesalers, retailers or customers.

Since raw materials are the starting point for any final product, ensuring adequate supply is critical to meeting product demand. This requires careful management: Overstocking raw materials can tie up a company’s cash and increase carrying costs. Understocking can lead to stockouts, revenue losses and customer dissatisfaction.

All of these factors point to the importance of supply chain management and the technologies that underpin them. Material resource planning (MRP) systems, for example, are useful for accurate inventory control and production management. More comprehensive enterprise resource planning, or ERP, systems include MRP functionality that is integrated with other core business processes, optimizing the entire operation, from raw material sourcing to product delivery.

Types of Raw Materials

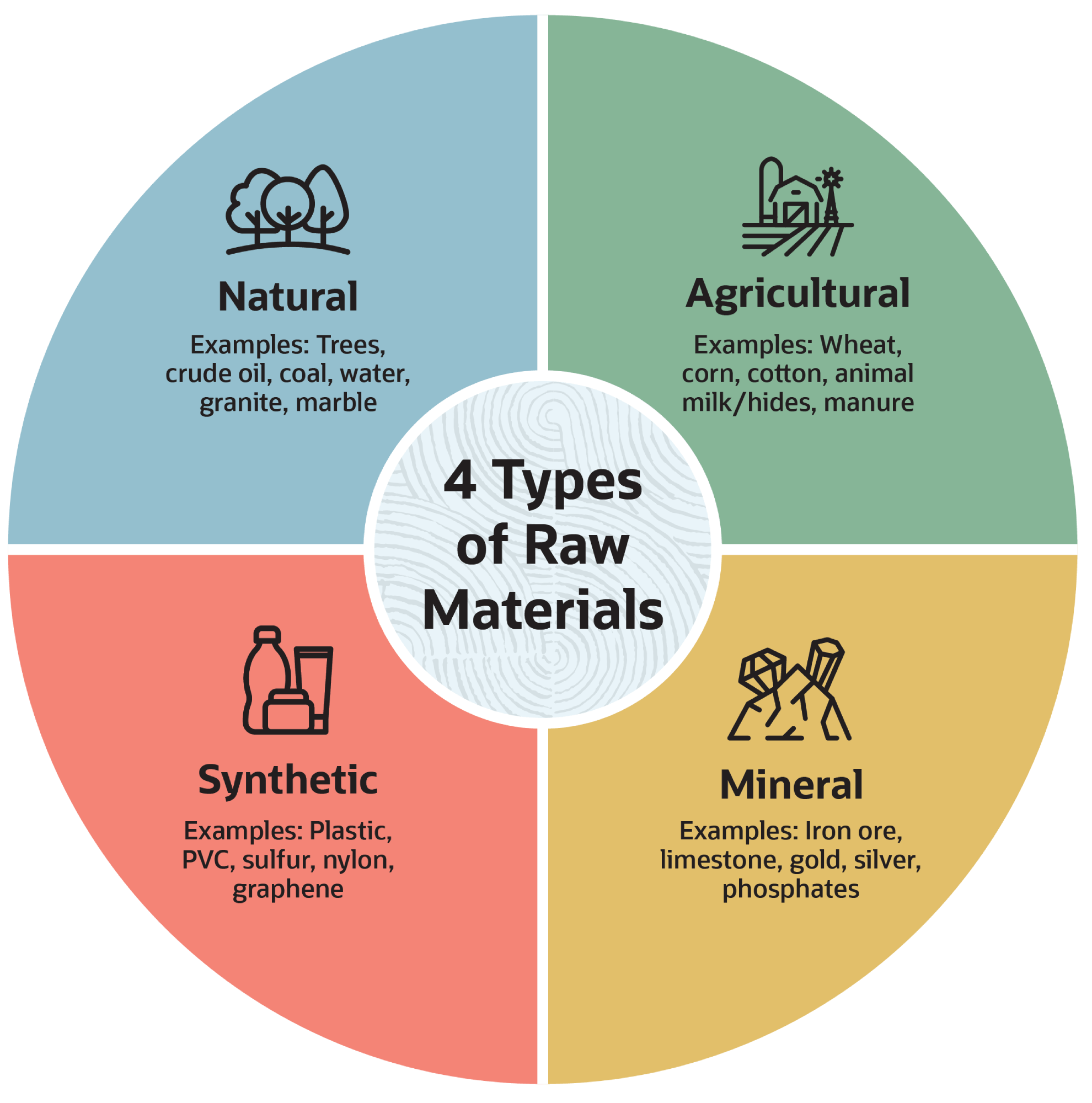

Raw materials are not just commodities; they are the essence of countless products used day in and day out by global businesses and consumers. Broadly speaking, raw materials can be classified into four categories: natural, agricultural, mineral and synthetic.

-

Natural Raw Materials

Natural raw materials come directly from the environment. Trees and plants are significant sources of natural raw materials: Natural rubber, for example, is derived from the latex of rubber trees, and cork is harvested from the bark of cork oak trees. And wood, in general, offers some of the greatest versatility among raw materials. In its various forms, such as timber and wood pulp, it is used in the production of lumber and paper.

Crude oil, a fossil fuel extracted from the earth, can be refined into many petroleum-based fuels, such as gasoline, diesel and jet fuel. It is also used in the petrochemical industry to produce plastics, synthetic fibers and chemicals. Additional fossil fuels, such as coal and natural gas, are crucial for energy production; natural gas, specifically, can be used in the chemical industry to help create hydrogen, ethane and methanol.

Some other natural raw materials include water, which is indispensable for agriculture, manufacturing processes and power generation. Salt can be used in the chemical manufacturing process and for water treatment. Natural stones, like granite, marble and limestone, are raw materials used in construction, while sand and gravel are derived from natural deposits and used for making concrete and asphalt.

-

Agricultural Raw Materials

Agricultural raw materials are derived from plants (cultivated intentionally for specific purposes) and animals. Crops, such as wheat, rice, corn and soybeans, are staple food sources that serve as the foundation for many food products from bread and pasta to cereals, sweeteners and cooking oils. Natural fibers, such as cotton and flax, are obtained from plants and used extensively in textile manufacturing for products like clothing, bedding and linen. In addition, crops such as jute are used in the production of natural fibers for packaging materials and construction. And plants like eucalyptus and pine are harvested for the production of wood pulp, which serves as a raw material for paper- and cellulose-based products.

Meanwhile, milk is an animal-based raw material used in a range of dairy products, including cheese, butter and yogurt. Animal hides and skins are used in the production of leather, while wool, a natural fiber, is widely used in the textile industry in the production of warm clothing items. Manure is also a valuable source of organic fertilizer, and some livestock provide biological materials, such as enzymes and hormones, for pharmaceuticals and biomedical research.

-

Mineral Raw Materials

Mineral raw materials are especially important to the construction and manufacturing industries. Metallic minerals include iron ore, a key ingredient in the production of steel; copper, which is widely used in electrical wiring and electronics; and aluminum (derived from bauxite), valued for its lightweight and corrosion-resistant properties.

Nonmetallic minerals also play crucial roles. Limestone is a primary raw material for cement production; gypsum is used to produce plaster and drywall; silica, derived from sand, is a key component in the glass industry; and clay is used in the production of ceramics, bricks and pottery.

Gemstones and precious metals serve aesthetic and high-value purposes. Gold is prized for its use in jewelry, as well as its application in electronics and dentistry due to its conductivity and corrosion resistance. Silver is used in various industrial applications, including photography and electrical contacts. And diamonds, beyond their role in jewelry, have industrial applications due to their hardness and, thus, used in cutting, grinding and drilling tools.

Less flashy raw materials, including phosphates, potash and nitrates, are crucial components of fertilizers. And coal, lignite and peat are often used as mineral fuel sources for various industrial processes.

-

Synthetic Raw Materials

Synthetic raw materials are derived from chemical processes, offering versatility and tailored properties for various applications. Plastics, a prominent category of synthetic materials, are derived from petrochemicals, such as crude oil and natural gas, and play a crucial role in packaging, construction, automotive components and countless consumer goods. Polyethylene, polypropylene and polyvinyl chloride (PVC) are used to manufacture plastic products and packaging.

Raw chemicals, including sulfur, chlorine and ammonia, are employed extensively in the production of other chemicals needed in industrial processes. Synthetic chemicals also play a vital role in pharmaceuticals, offering precise control over molecular structures to create medicines with targeted effects. Additionally, synthetic dyes and pigments are crucial in the textile, cosmetics and food industries.

Another material category consists of synthetic fibers, such as polyester, nylon and acrylic, which are extensively used in the textile industry for clothing, upholstery and various technical applications. Synthetic rubbers serve as essential raw materials for tires, seals and gaskets. Adhesives and coatings enhance the bonding of surfaces, protect against corrosion and provide aesthetic finishes. Polyurethane, a versatile synthetic polymer, finds applications in foam products, insulation materials and coatings.

In the realm of electronics, synthetic materials, such as semiconductors and conductive polymers, are foundational for the production of electronic devices. They make possible the creation of components, such as microchips and flexible displays, drive technological advancements and even contribute to new materials. For instance, graphene, derived from graphite, is known for being an excellent conductor of heat and electricity, while maintaining exceptional strength. It is also the building block for carbon nanotubes, which are being used in new and advanced energy storage systems, including batteries and supercapacitors, lightweight material reinforcement and as components in biosensors for medical diagnostics.

Billions of tons of raw materials are extracted from the earth every year.

Importance of Raw Materials in Various Industries

Raw materials are essential to the production processes associated with a multitude of industries. They serve as the building blocks for countless automotive parts, for example; in construction, they are integral to infrastructure and architecture. Technology and electronics tap raw materials to drive innovation, as does the energy sector, in terms of devising more efficient methods of generating power.

-

Automotive Industry

The automotive industry uses a broad range of raw materials as the foundation for manufacturing vehicles and their components. A vehicle, and its manufacturing process, is essentially a microcosm of a number of industries. Metals, such as steel and aluminum, are fundamental for constructing the chassis, body panels and other structural elements. Copper is needed in electrical wiring, and silica can be used for glass-making and other electronic components. And with the electric-vehicle market growing, more manufacturers need materials such as lithium, cobalt and nickel for the necessary batteries and other proprietary technologies.

Besides metals, plastics and rubber are used for tires, internal components and the body of the vehicle. But their uses stretch further and are often used in the vehicle interior, along with textiles and leather. The console and dashboard are primarily composed of plastics, while upholstery can be synthetic or natural.

-

Construction Industry

It’s fair to say that without raw materials, the construction industry would cease to be. For instance, concrete, which provides the literal foundation for buildings, bridges, highways and other infrastructure projects, is composed of water, aggregates and cement — which itself is produced from a mixture of the raw materials limestone and clay.

Steel, known for its strength and ductility, is used extensively in structural frameworks, beams, columns and reinforcement. It can contribute to the stability and load-bearing capacity of buildings and infrastructure, and its malleability and versatility make it suitable for diverse architectural designs and engineering requirements. Steel is primarily made through the basic oxygen steelmaking process, but there are other methods, such as using an electric arc furnace.

Additionally, lumber, derived from timber, has served as a primary material in construction for millennia. Particularly in residential and commercial building projects, wood is used for framing, flooring, roofing and interior finishes, but it also branches out to outdoor structures, like bridges and decks.

-

Technology and Electronics

Today’s electronics, in every form, rely on a variety of mined rare earth metals and precious metals. Neodymium, dysprosium and terbium, for example, are essential in the production of powerful magnets used in speakers, electric motors and hard disk drives. Europium and yttrium are used in the production of phosphors for LED technology and fluorescent lighting. Other rare metals are employed in the manufacturing of rechargeable batteries, particularly in certain types of nickel-metal hydride (NiMH) batteries used in portable electronic devices and hybrid electric vehicles.

Earth’s precious metals, including gold, silver and platinum, are also widely used. Gold is a major component in the production of electronic components and connections, due to its excellent conductivity and resistance to corrosion. It is commonly used in connectors, switches and integrated circuits within various devices, like smartphones and computers. Silver is also highly conductive and used in the manufacture of many similar devices, though its thermal conductivity properties make it suitable for applications where heat dissipation is crucial, such as in electronic components and power modules. Platinum, on the other hand, is less common in electronic devices but finds applications in certain high-temperature and corrosion-resistant electronic components.

Other raw materials used in the creation of technology and electronics include sand or, more specifically, quartz, which can be crushed to extract silica in the form of silicon dioxide. Silicon dioxide is subsequently processed to help create glass, semiconductors, many electronic components and silicon — which can be further refined to achieve the high purity required for integrated circuits, microchips and semiconductors.

-

Energy Sector

As the global energy landscape evolves, there is an increasing focus on transitioning toward cleaner and more sustainable energy sources, like solar, wind and hydroelectric power. But more traditional fuels, derived from raw materials, still play a crucial part in managing power needs for humanity. For instance, coal, a fossil fuel, is a major source of electricity generation. It is burned in power plants to produce steam, which then drives turbines connected to generators. Despite environmental concerns due to carbon dioxide emissions, coal remains a significant energy source in many regions, as well.

Another fossil fuel, natural gas is composed mainly of methane and can be burned directly in power plants to generate electricity. Natural gas is also key to the production of electricity in gas turbines and is widely used for heating, cooking and as a fuel in industrial processes.

Uranium is a raw material essential for nuclear energy production. In nuclear power plants, uranium undergoes a process called nuclear fission, which generates heat used to produce steam that drives turbines and ultimately generates electricity.

Raw Materials Examples

From the aerospace and automotive industries, where aluminum, crude oil, rubber and steel are instrumental, to agriculture, where cotton, corn, livestock and seeds drive food production, raw materials are nothing short of indispensable. But that’s just the beginning. In the worlds of chemicals and petrochemicals, crude oil, ethylene and petroleum play pivotal roles in producing plastics, synthetic fibers and fuel. In construction, several raw materials, such as concrete, gravel, limestone and steel, form the backbone of infrastructure development.

In electronics, copper, gold and rare earth metals are used for wiring, circuit boards and electronic devices. Energy production relies on resources such as coal, natural gas and uranium, while manufacturing depends on aluminum, petroleum, salt and steel.

Track and Manage Raw Materials With Inventory Management

When you weigh the burdens of high carrying costs, missed sales, cash tie-ups, operational inefficiency, unhappy customers and reduced profit margins, there is absolutely zero upside for companies that lose visibility over their inventory, whether raw materials or finished goods. Whether you’re a manufacturer, distributor or retailer, NetSuite Inventory Management can help. The solution provides a singular, real-time view of inventory across all locations that allows businesses to easily, and automatically, track what they have, plan for demand and replenish as necessary — at just the right amounts. The software also automates cycle counting, issues alerts for possible inventory shortages or overstocks and continuously monitors performance metrics. By gaining control over their inventory, businesses can better manage their cash flow and costs, while ensuring that customers have what they need, when they need it.

Raw materials are the building blocks for innovation and technological advancement. From the silicon in computer chips to the rare earth metals in smartphones, raw materials enable the development of cutting-edge technologies that shape our modern world. But they also remain important in almost every product that exists today in the analog world — from automobiles to zippers. As such, they must be carefully sourced, tracked and accounted for throughout the global supply chain.

Raw Materials FAQs

What are examples of raw materials?

Raw materials consist of a wide range of natural and synthetic substances used for the production of goods. Common examples include metals, like steel (derived from iron) and aluminum (derived from bauxite); precious metals, like diamonds; cotton and timber; minerals, such as limestone; and energy producers, including natural gas, coal and uranium.

What are natural raw materials?

Natural raw materials are sourced directly from the environment and serve as the foundation for a number of industries, operations and even civilizations. Simply put, they are any material that comes from the earth and can be processed into a usable product.

What is another term for raw materials?

Other terms for raw materials include feedstock, stock, ingredients, unprocessed materials and primary commodities (the latter in the context of the commodities market in which these materials are traded).

What is raw material vs. material?

Raw materials are a type of material. They are defined as the unprocessed, or minimally processed, substances that are used at the start of the production process and that undergo various processes to be transformed into finished goods. Materials can refer to any item in the production process.

What are 10 raw materials and their products?

Raw materials go into the creation of finished products. Examples include:

- Steel for cars

- Wood for lumber and paper

- Crude oil for gasoline and jet fuel

- Cotton for textiles

- Animal milk for dairy products

- Animal hide for leather goods

- Manure for fertilizer

- Limestone for cement

- Silicon for computer chips

- Semiconductors for electronics