As a consumer, it's frustrating to visit a store or an ecommerce website, ready to buy a specific product, only to find out it's currently unavailable. As a retailer, you want to avoid the chance of frustrating your customer that way — and having them look elsewhere for what they want. In the U.S. retail food industry alone, stockouts are estimated to cost $15 billion to $20 billion per year in lost sales, or up to 3% of total industry sales.

Stockouts can, however, be reduced — if not prevented — although the related inventory management issues are tricky to navigate. Here's a detailed discussion of stockouts, including their causes and key ways to mitigate them.

What Is a Stockout in Business?

A stockout is when a business runs out of a specific product. When this occurs, the product can't be ordered by customers, and the business has to change the product's availability status. If the company inadvertently accepts an order for an out-of-stock (OOS) item, it may have to take the painful step of informing, and disappointing, the customer or incurring excess costs on unplanned production and rush shipments to deliver orders on time. Stockouts are the opposite of overstocks, which is when there's too much inventory, low product sales and the business is in danger of having excess inventory it must eventually write off.

A business can calculate its stockout rate, or the percentage of items not available when needed for sale, by dividing the number of products not in stock by the total number of products that are in inventory and available for sale.

Stockout rate: Products not in stock / Total number of products available

The most recent available data on the retail industry's global average stockout rate places it at 8% — and nearly double that for advertised products — but is from the early 2000s. Since then, ongoing supply chain disruptions from the COVID-19 pandemic have likely driven that average rate higher.

Key Takeaways

- Stockouts, also known as out-of-stocks, happen when a business runs out of a product that a customer is ready to buy.

- Stockouts directly impact customer satisfaction and are a significant cause for negative reviews, extra costs and loss of sales or — worse — customers.

- Inventory management software is designed to solve or at least mitigate most stockout causes.

Stockouts Explained

A stockout is an event in which a product is exhausted in inventory and, therefore, unavailable to fulfill an order. Ideally, a business becomes aware of any stockouts before customers place their orders. That way, the business can head off the worst-case scenario of a customer ordering an OOS item by changing the availability status of the item on its website and any other sales channels. If the business knows when the product will be back in stock, it's important to disclose that information along with the stockout notice. That information can help customers decide whether to wait for the product or look elsewhere, and they'll appreciate receiving it. Good inventory management software can provide the necessary information and automate some or all of these processes, depending on the business's preferences — but even better would be to know when you're running low and reorder in advance.

If the business becomes aware that a product is out of stock after a customer orders it, you should check all locations to ensure that you can't fulfill the order from another location or selling channel. But if not, the customer care team should reach out to the customer to let them know. How the customer responds will vary: The best-case result would be for the customer to place their entire order on hold until the OOS item becomes available. That way the business doesn't have to incur the cost of shipping the product separately. But even if the customer wants their order delivered in two shipments, at least the business has retained the sale. Other scenarios include the customer dropping the product from their order to buy from another company or, worst-case scenario, canceling their entire order. When that happens, the business may never recover that customer.

Stockouts almost always cause customer satisfaction to drop. That's why it's so essential to know the causes of stockouts and the best ways to prevent them.

What Causes Stockouts?

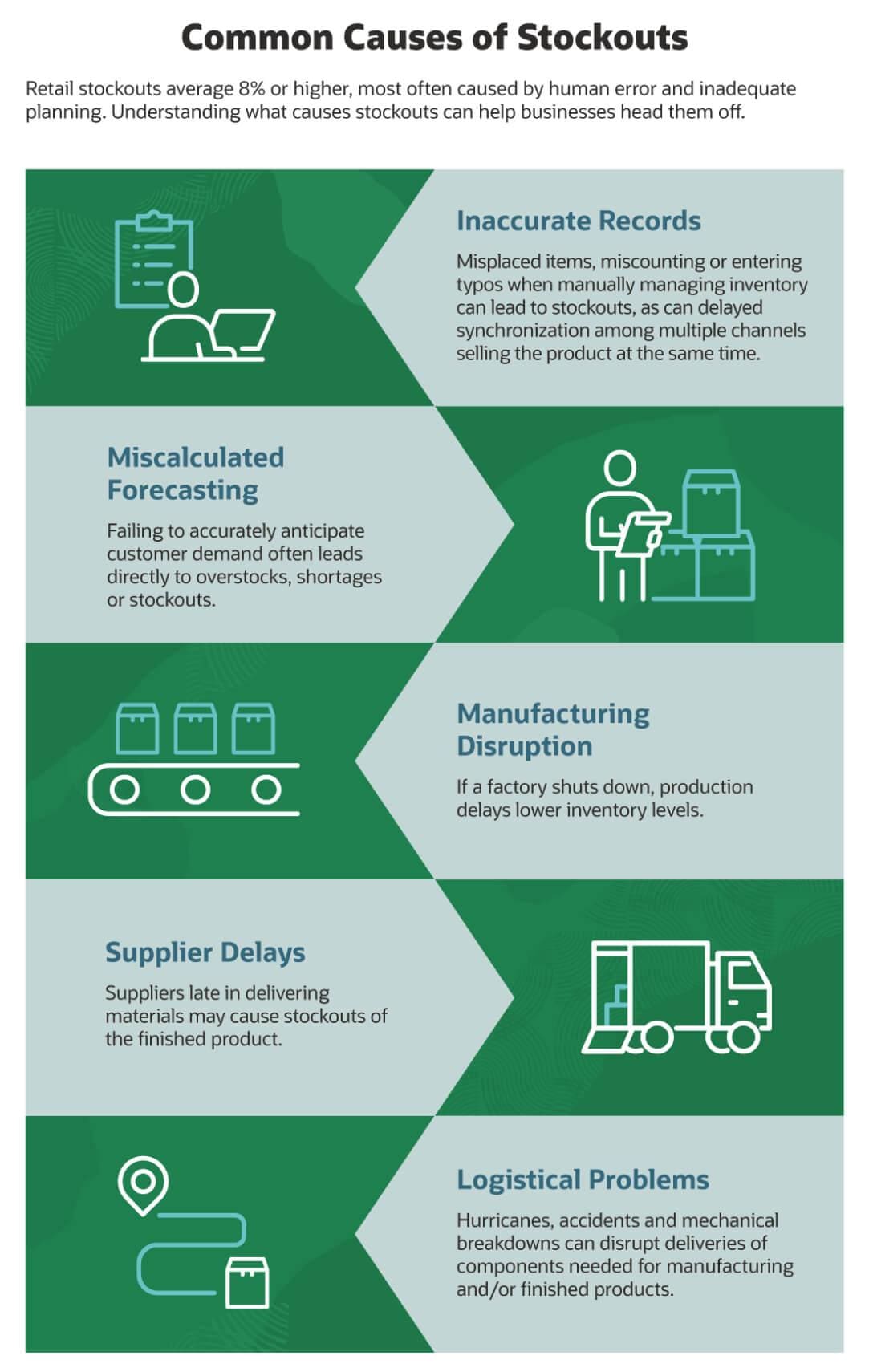

Human error and inadequate planning are among the major fundamental causes for a product to be out of stock. But there are others, and sometimes the cause may be out of a retailer's control. Here are some important stockout causes:

- Inaccurate records. Human error is usually the No. 1 reason for inaccurate item counts, which causes shrinkage, meaning loss of inventory. Miscounting or typing in the wrong number when manually managing inventory can eventually lead to stockouts. Although less frequent, technical problems might also affect the total tally of items available for sale — for example, delayed synchronization among multiple channels selling the product at the same time. And don't discount the possibility that items were simply misplaced when unloaded and added to the warehouse.

- Miscalculated forecasting. Good inventory forecasting is one of the most important elements of inventory management — and it's absolutely crucial to avoiding stockouts. Failing to accurately anticipate customer demand often leads directly to overstocks, shortages or stockouts. Yes, there will be times when a product trends overnight and the demand change is too fast to predict. But for all other cases, including seasonal products, a well-implemented forecasting system is essential to reducing the possibility of stockouts.

- Manufacturing disruption. If a factory shuts down for any reason, the production delay is likely to lower inventory levels.

- Supplier delays. Similarly, suppliers may be late in delivering materials necessary for manufacturing items, which may cause the finished product to be OOS.

- Logistical problems. Anything from an Atlantic hurricane to a roadway accident or a mechanical breakdown can interrupt the delivery of necessary components for a product, or the arrival of finished products to a warehouse, distribution center or retail site. These are largely outside your organization's control — though if your shipping company's trucks are constantly breaking down, that shipper can be replaced.

How Stockouts Impact Business

Stockouts can affect all types of businesses of all sizes. For large, established companies, stockouts might be only a nuisance because long-term loyal customers will opt to wait for a specific product from a favorite brand. For smaller or newer businesses, though, the consequences of OOS products can be more challenging.

- Negative reviews. More vocal customers might leave negative reviews about their experiences if they have to cancel their orders due to stockouts or if they're regularly unable to buy items due to unavailability.

- Refund costs. If inaccurate stock counts lead to a stockout after the customer has placed an order, a business may end up having to refund the customer's money. Refund costs add up when stockout mistakes become recurring.

- Loss of sale. Unless it's a limited-edition item or a product exclusive to a specific brand, chances are that customers are going to look for similar products elsewhere.

- Loss of customer. Product availability is one of the top factors that influence customer satisfaction. The odds of a customer returning after finding similar products of similar quality at a competitor after an OOS experience are slim. Therefore, stockout prevention is key to customer retention.

- Back-order costs. If the customer agrees to wait for availability, they can back order the product. This is better than losing the customer due to a stockout, but it comes with extra costs. For example, if the back-ordered item is part of a larger order, the retailer usually covers the second shipping fee. Additionally, it's common practice to expedite shipping for the back-ordered product to make amends with the customer for their substandard experience.

When Stockouts Are a Good Thing

Stockouts are seen as a problem that should be prevented or remedied, and that's true for most cases. However, having a product exhausted from inventory can be good in some situations — especially for products that have a finite life. For example:

- Ideally, there shouldn't be any — or at least very low levels of — fresh produce or other fresh foods left in a grocery store at the end of the day.

- Resellers of products that go through definite "generations" — like cars or electronics — aim to have the lowest level possible in stock before a new generation comes out.

- Fashion retailers usually liquidate their previous collections to make room for the new collection every season. In this case, they seek and achieve stockouts through discounts and sales.

- Some niche products run deliberately low stock, setting a production number that creates more demand for future products after scarcity inflates the demand.

Good inventory management practices, forecasting and monitoring the life span of a product are essential even when stockouts are good and/or necessary.

5 Ways to Reduce or Prevent Stockouts

While unforeseen circumstances outside a retailer's control can always occur, there are five inventory and supply chain management practices that can reduce or even prevent costly stockouts.

- Improve inventory accuracy. Conducting regular stock counts to monitor and update stock levels is key to avoiding discrepancies in inventory numbers that can lead to stockouts. Inventory management software helps automate stock level counts and can share the information with all sales channels, so their product availability information is always accurate and up to date.

- Improve inventory forecasting. Likewise, accurately anticipating customer demand for a product is an indispensable inventory management practice. Better inventory forecasting helps avoid stockouts or the reverse, surplus inventory, by keeping inventory levels close to ideal based on consumer trends and seasonality.

- Monitor your supply chain. Disruption in the early stages of manufacturing due to raw materials delays may cause a product to be OOS when a customer is ready to buy. Monitoring your supply chain and changing vendors when delays persist is a good strategy to avoid stockouts.

-

Calculate and keep safety stock. As the name implies, safety stock is extra product held in inventory as a safety measure in case of an emergency that causes stock levels to drop. When stockouts become recurring events, it's good to calculate and keep a percentage of safety stock. The formula to calculate safety stock requires the maximum and average daily usage — how many products are sold daily — and the maximum and average lead time — how long it takes for the product to be shipped from suppliers/manufacturers to the warehouse/fulfillment center.

Ideal safety stock volume =

(maximum daily usage x maximum lead time) - (average daily usage x average lead time) - Monitor inventory replenishment time. Customers might accept waiting for an OOS product if they see that it'll return to stock soon. Businesses that regularly monitor their inventory levels and reorder products when levels are low can reduce stockouts and, if stockouts happen, can more easily tell the customer when the item will be available.

Use NetSuite to Optimize Inventory

Good inventory management software can, among many other things, solve most of the causes of stockouts. NetSuite Inventory Management Systems Software provides visibility into stock levels across multiple points of sale and fulfillment centers. It automates monitoring and reporting of stock levels throughout, reducing the possibility of bad inventory numbers due to human error. When stockouts happen in one location, sales associates can potentially save sales by using other available warehouses or fulfillment centers. In addition, the data on NetSuite's reports is always up-to-date in real time, which is essential for accurate demand planning. The software lets you automatically schedule periodic counts of available inventory and generates tasks and alerts when low stock levels are ready for replenishment.

Conclusion

Recurring stockouts can reduce sales and damage customer relationships. But retailers and other businesses can take control of their inventory, supplier and customer relationships to avoid such costly consequences. Good inventory management software automates most of the workload associated with preventing or reducing out-of-stock problems, helping businesses to avoid stockouts while maintaining good customer relationships.

Stockout FAQs

What causes a stockout?

Stockouts can be caused by inaccurate inventory records due to human error, supplier delays or inadequate demand planning or forecasting. Unforeseen circumstances like theft, weather or other shipping logistics issues may also cause product unavailability.

What is the risk of a stockout?

When stockouts are recurring, businesses are at risk of damage to their reputations in the form of negative reviews. They also risk having customers look for similar products from competitors and/or losing the sale and the customer. Stockouts seriously damage customer retention.

What is the stockout rate?

Stockout rate is the percentage of items not available when needed for sale. It is calculated as items not in stock divided by total available items in inventory. The average stockout rate is about 8%, and it rises when products are on sale. A high stockout rate can lead to significant lost sales.