Ever notice how your cereal box or the tag on that new T-shirt contains a random sequence of numbers and letters, usually tucked below a series of vertical lines? Those digits are product identification codes known as SKUs, or stock-keeping units, and a unique one is assigned to each of the millions of products that hit retail sites and shelves every year. SKUs are how companies keep track of everything from apples to smartphones.

Here, we’ll discuss exactly what a SKU is, why a SKU system is important, and how you can put one to work for your business.

What Is a Stock Keeping Unit (SKU)?

While retailers often refer to their sellable products as SKUs, in reality, a SKU is a unique code companies use to track products internally. Because businesses create their own individual SKUs, they are unique to each product and each company.

Because SKUs are an internal tool, there are no official rules on how to develop or use them. However, you can learn from the best practices of industry leaders that have well-designed SKU systems that maximize efficiency and include all the key product data.

Key Takeaways

- A stock-keeping unit (SKU) is a unique code assigned to a product by a business.

- SKU systems are typically used internally and can vary from one business to another, even if both are selling the same product.

- SKUs play a key role in improving inventory tracking, financial analysis, and the efficiency of business operations.

- Nearly any business that holds and sells inventory could benefit from a SKU system.

Stock-Keeping Units Explained

SKUs are codes that businesses create out of letters and numbers that represents detailed information about a product, and they’re established by each business. The alphanumeric code could indicate an item’s color, style, size, brand, manufacturer, packaging, or even price. The company decides what information each SKU represents.

Businesses often tie their SKUs to universal product code (UPC) barcodes, which make products scannable for inventory and shipment tracking as well as faster checkout. When you go to the store and use self checkout, the UPC barcode you scan is most likely tied to the store’s SKU for that product.

What Are SKUs Used For?

SKUs are used for a variety of purposes. Here are some common ones:

- Analysis: Merchandise managers and business analysts may use SKUs to categorize products by profit margin. This data could be used to understand sales trends and forecast profitability, among other things.

- Inventory Management: Any business that holds inventory for sale or internal use can track items coming in and going out by scanning SKUs. This allows businesses to make smarter, more targeted purchasing decisions and avoid both excess stock and obsolete inventory.

- Customer Assistance: SKUs can help an employee figure out where to find an item for a customer on the shelf or direct a manager to the wholesaler or manufacturer of a defective item that needs to be returned.

- Advertising and Marketing: The marketing department may look at color, size, and other SKU data to understand what the company’s most popular products are and see any shifts in demand. If a product is sold in different locations in the same store, for example, on end caps or near a register, a unique SKU could tell you where a customer picked up a product in the store and where to restock items to maximize sales.

- Product Recommendations: Ecommerce sites can recommend products with similar SKUs or within a certain set of SKUs, encouraging purchases of higher-priced or complementary items. This can increase sales and help your business grow.

How a SKU Works

Brick-and-mortar retailers, online sellers, wholesale distributors, and manufacturers typically implement a SKU tracking system. The alphanumeric information in the code, which is usually eight to 12 digits, may intuitively represent certain item traits or may require a key to decode.

Each SKU should be unique to a specific product. If you sell widgets in five colors and three sizes, you should have 15 SKU codes for that one product. If you sell the same widget from three different brands, you could wind up with 45 SKUs for that one product. Each specific combination has its own SKU.

Why Is a SKU Important?

SKUs can be used for inventory tracking, facilitating faster sales, or routing products to the right locations. Managers or salesclerks may use SKUs to look up whether a product is in stock. In warehouses or large stores, overnight staff could use SKUs to sort boxes when unloading a truck and for restocking shelves. Again, every business is different, so your exact uses for SKUs could vary.

An example of one place where SKUs are important is retail clothing stores. When a cashier scans a SKU at a checkout counter, it pull ups the price in a point-of-sale (POS) system while recording that the item has been removed from available inventory.

If inventory gets too low on a specific good, it may trigger a notification to reorder or even automatically send a purchase order to a supplier. During regularly scheduled check-ins, employees can use SKUs to compare what's on the shelf to what's in the computer to identify any product shrinkage, a retail term that refers to lost, stolen, or damaged products that can’t be sold.

How Do You Assign SKUs?

While the steps below will get you started, there are some things to keep in mind. Be consistent, and remember you can use a hierarchical structure with categories and subcategories. Make sure everyone in the organization, and any retail partners, are up to speed on the effort. From there, follow these five steps to assign a SKU to a product:

- Define the format: Decide on the overall structure of your SKU, including the number of characters and any separators. Consider your company’s needs and future growth when determining the format, length, and complexity.

- Identify the attributes: Determine which product characteristics are most important for identification and tracking. This could include elements like product category, color, size, or location, depending on your specific inventory needs.

- Create the coding system: Develop a consistent method for representing each attribute with letters, numbers, or a combination of both. Ensure the coding system is logical and easy for your team to understand and remember.

- Combine the codes to form the SKUs: Assemble the individual attribute codes into the full SKU according to your defined format. Double check that each SKU is unique and follows your established conventions.

- Test for usability and scalability: Apply your new SKU system to a sample of products and evaluate its effectiveness. Ensure that the system can accommodate future product additions and variations without becoming overly complex or running out of unique identifiers.

SKUs can be very obvious or highly encoded. For example, let’s say you’re an online clothing store. For a blue men’s T-shirt in size medium that came from Vendor X, you could use a SKU like this:

|

VX-M-SHRT-T-BLU-MED |

In this example, VX stands for Vendor X, M stands for men’s, SHRT stands for shirt, T refers to T-shirt, BLU represents the blue color and MED stands for medium. But to be even more compact, the code could turn into something like this:

|

12MSTLU2 |

Here, instead of referring to the vendor by name, we used a vendor number (12). Blue becomes LU, and instead of letter spelling out size medium, this code used the number 2. The business can translate this code into a traditional UPC barcode or even a QR code that employees can scan using any computer, tablet, or smartphone.

If you work with another company that also uses UPC barcodes, it may be a good idea to coordinate so you don’t use overlapping systems or barcodes that could be easily mixed up.

Benefits of SKUs

While there are many benefits of using SKUs, here are six of the biggest:

-

Tracking Inventory

It doesn’t matter if a business is tracking cars, apples, hinges, sunglasses, paint cans, toilet paper, or anything else—SKUs make it much easier to obtain an accurate and real-time view of inventory levels. -

Easy Inventory Counts

By giving team members a physical or digital list of products by SKU, a business can quickly take stock of everything it has on hand for physical inventory counts. -

Identifying Shrinkage

According to Capital One, retail shrinkage is projected to result in $132 billion in losses globally in 2024, compared with $112 billion in 2022. Knowing which SKUs are disappearing can help you identify the problem and respond to it, whether that involves adjusting security plans or cutting back on orders of products with high shrinkage rates. -

Replenishing Inventory

When someone wants to buy a product from your business, it’s important to have that product on hand to sell. Monitoring SKUs will help you see when a certain item is running low so you can place a replenishment order before you run out. Similarly, if another SKU is selling slower than expected, you may delay or reduce the size of a purchase order. -

Identifying Profitable Items

Reviewing the sales volume for different products and knowing the gross margin on each SKU can help a business quickly calculate where the majority of its profits come from. It can then find new ways to push these key items and may consider offering a new version or color of these proven products. -

Preparing for Seasonal Shifts

SKUs play a crucial role in preparing for seasonal shifts by allowing businesses to track and analyze the performance of individual products over time. By monitoring SKU-level data, companies can identify which items experience seasonal demand fluctuations, helping them to adjust inventory levels, optimize storage locations, and plan marketing strategies accordingly for upcoming peak seasons.

Stock Keeping Units (SKUs) vs. Universal Product Codes (UPCs)

Stock keeping units are often confused with Universal Product Codes. While the two can be related, they are not the same thing.

SKUs can be unique within a business, as businesses create these codes themselves. They are usually alphanumeric strings that indicate product details, and the exact same item could have two different SKUs at two different businesses.

UPCs are used in conjunction with SKUs but are specific to the product and are the same regardless of the business, identifying the manufacturer and item. UPCs are assigned by GS1, an international standards organization, which sets the format. Companies do not create these codes on their own.

Are SKUs the Same as Model Numbers?

SKUs and model numbers aren’t the same, although they’re both used for product identification. SKUs are unique codes created by retailers or distributors to track and manage inventory internally, often incorporating details like brand, color, size, and style. They are customizable and specific to each seller.

Model numbers, on the other hand, are assigned by manufacturers to identify specific product models and remain consistent across retailers. While SKUs are primarily used for inventory management and sales tracking, model numbers are useful for customers seeking product information or support from manufacturers. Some businesses may incorporate model numbers into their SKU systems, but the two serve distinct purposes in product identification and management.

Is a Barcode a SKU?

While barcodes and SKUs are both used for product identification, they’re not the same. A barcode is a visual representation of data, typically in the form of parallel lines or patterns that can be scanned and read by machines. SKUs, meanwhile, are alphanumeric codes created by retailers or distributors for internal inventory management. While SKUs can be represented as barcodes for easy scanning, not all barcodes are SKUs. Barcodes can represent various types of information—including UPCs, which are standardized across retailers—whereas SKUs are unique to each seller.

SKU Examples

You can find SKU examples by walking into just about any retail store or opening your kitchen cabinet. The UPCs on products will usually translate to the retailer’s or distributor’s SKU system. But SKUs are not limited to physical products. They could also identify different software solutions or labor hours for a car mechanic, for example. Here's an example of how two large companies use SKU codes.

Intel uses manufacturing part numbers, a type of SKU, to track its processors.

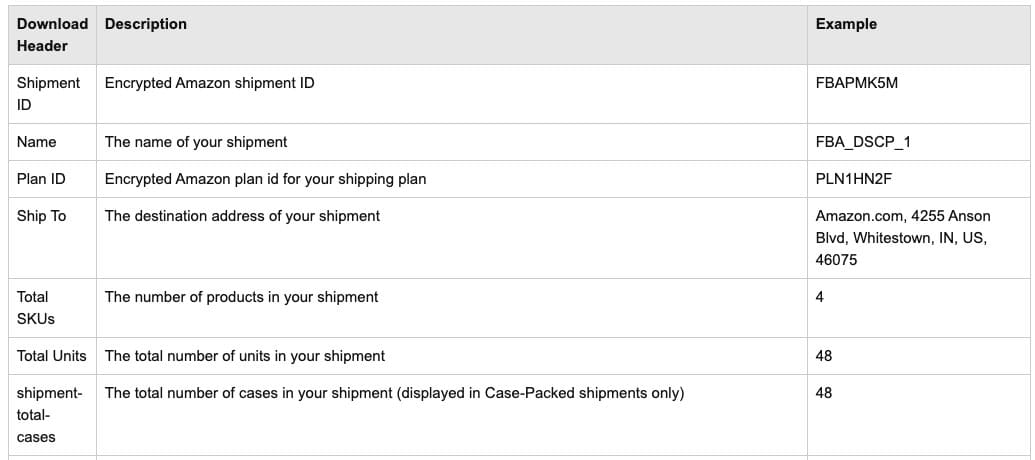

Amazon.com uses SKUs to manage the fulfillment of products from third-party sellers that use the online retailer’s Fulfillment by Amazon (FBA) program. Amazon publishes SKU guidelines for these sellers since it handles such a massive number of products.

5 Ways to Use SKUs to Boost Your Business

When planning out how to use SKUs for your business, consider the following benefits that can translate to bottom-line results.

- Inventory Tracking: A better understanding of your inventory can help you home in on the best-selling, highest-margin products. It also improves workforce efficiency, as staff don’t wasting time searching the warehouse for goods.

- Sales Forecasting: When you have more accurate sales data, you can better forecast sales. Knowing what you expect to sell can also lead to more accurate inventory planning and purchasing.

- Boosting Profit: Less spending on slow-turning products and an increased focus on what's moving quickly can help increase overall profits.

- Customer Loyalty and Satisfaction: The granular details provided by a SKU may help you determine what products to develop next based on current customer demand. This system will also reduce out-of-stock situations that can frustrate customers and lead them to buy from a competitor.

- Suggested Products (Related SKUs): Related SKUs are ideal for cross-promotions and personalized product suggestions, which could increase average order value (AOV) and repeat sales.

How to Generate Your Own SKUs

It’s best to generate your own SKUs following internal guidelines. Consider the following tips when creating your own SKUs.

- Use a SKU Generator. One of the easiest ways to get started is to use a POS system or ecommerce solution to generate SKUs. If you don’t have either, there are a number of free generators(opens in new tab) and templates available online.

- Create Your Own Code System. Make sure your coding system uses the same characters to indicate the details for each item feature you want to track, like product type, color and size.

- Make SKUs Unique. Your SKUs won't be very useful if several products share the same code. Make sure to use a unique SKU for every possible product permutation.

- Don’t Use Spaces. Spaces can complicate SKU systems and increase errors. Instead, consider dashes to break up SKU information.

- Choose a User-Friendly System. If you are the only one who understands your SKU system, it won't be so advantageous. Consider your staff and customer needs and preferences while trying to keep the code as simple as possible.

Free SKU Generator Template

Want to get a jump start using a simple spreadsheet? Try out this free template(opens in new tab) to help you develop a new SKU tracking system.

Tracking Inventory with SKUs and Inventory Management Software

Once you set up a SKU system, you’ll need software to fully capitalize on SKUs. Most inventory management systems include the ability to enter and track products by SKU. Once goods are tied to specific SKUs, you can track the amount of each product available and its location. This helps optimize stocking levels and cross-channel fulfillment, enabling you to fulfill an online order from a store, for example. The inventory management system provides a central repository of all key information related to one of your largest and most important assets.

Leading inventory management software can also provide reporting capabilities that make it easy to see key product-related metrics and leads to better decision-making. Ideally, your inventory management system is integrated with an enterprise resource planning (ERP) platform allows data to be shared between various systems.

Putting SKUs to Work for Your Business

Businesses that have to track inventory are most efficient and successful if they use an organized system to keep everything in order. For many industries, the best option is a SKU system. With a well-thought-out SKU system in place, key stakeholders can better manage inventory and quickly find what they need, when they need it. That can lead to cost savings, happier employees, better vendor relationships and a better chance of long-term business success.

SKU FAQs

What Does SKU Stand For?

SKU stands for stock keeping unit. It helps companies track and manage their stock internally.

Is SKU the Same as a Serial Number?

A SKU is not the same as a serial number. Serial numbers are typically unique to each unit produced, while a SKU is unique to each type of product. For example, two identical computers sold by the same retailer would have the same SKU but different serial numbers.

Can Two Items Have the Same SKU?

Two items on the shelf can share the same SKU if they are identical (same item, color, size, gender, price, etc.). But any difference between the products would require a second SKU.

Where do you find the SKU on a product?

The SKU can typically be found on product packaging, labels, or stickers, often located near the barcode, as well as in product descriptions on retail websites and manufacturer catalogs.