A well-structured and well-managed procurement process does more than simply fill a business need; it plays a significant role in bolstering a company’s overall financial health. In the short term, effective procurement saves time and money by streamlining the order process and making it easier to negotiate better pricing and other terms. Over the long term, the benefits expand to include improved productivity, greater financial control, increased visibility and transparency, and more cooperative relationships with suppliers. There isn’t a business executive alive who won’t welcome those kinds of results. But first they must have in place an effective procurement process with tools and techniques to optimize each step.

What Is the Procurement Process?

Procurement is the proactive and strategic process of buying goods and services to solve business problems. However, procurement encompasses much more than just purchasing. Although the terms are sometimes used synonymously — and there is some overlap between the two — procurement is a broader concept, comprising all of the elements of acquisition, while purchasing is a narrow subset that describes only the actual buying process.

More specifically, the procurement process includes ordering, obtaining and paying for goods and services, as well as identifying business needs, vetting vendors, negotiating contracts and measuring supplier performance. While the procurement function may take the lead on many of the steps and establish policies and practices, the process typically involves multiple stakeholders.

Procurement is crucial to an organization’s supply chain effectiveness, overall operational efficiency, financial stability and ability to meet customer demand. Thus, an effective procurement process must balance a variety of requirements. It should be designed not only to save money, but also ensure quality and timely delivery, minimize risks, comply with policies and regulations, and foster strong relationships with suppliers.

Key Takeaways

- Procurement is the process for acquiring the goods and services necessary for business operations and production.

- The best procurement approach is a proactive one that aligns with a company’s overall business strategy.

- Procurement is a multistep process that starts with identifying a business need and includes ongoing assessments of supplier performance.

- Technology that automates key aspects of procurement leads to a more efficient process that saves time and money.

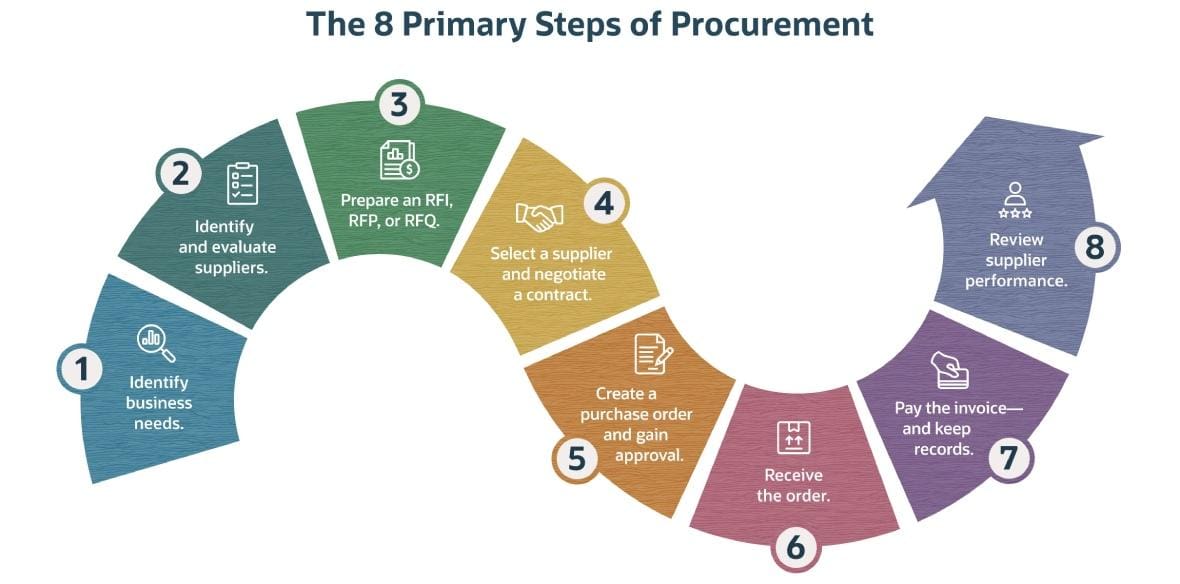

What Are the 8 Steps of the Procurement Process?

A full 95% of B2B decision-makers acknowledge there’s room to optimize procurement, according to Amazon Business’s global “2024 State of Procurement Data Report.” Indeed, procurement is a complex process that must be aligned with overall business strategy. Multiple players need to come together in a very specific way, and at different points, in the procurement process, to deliver the desired outcome. Just as great symphonies follow certain structural rules, procurement works best when it follows an orderly eight-step process.

1. Business Needs Identification

It’s always important to define a problem before deciding on a solution. That’s especially true when it comes to procurement, where those solutions can come with hefty price tags.

This stage of the procurement process is often entirely internal. For example, an advertising agency may be struggling to meet its commitments to clients. In exploring the reasons for these issues, fingers point to outdated design software. The staff complains that the current system is slow, isn’t fully compatible with the file formats used by some clients and lacks the artificial intelligence (AI) tools that competing agencies are using. In this situation, it seems the agency needs a more up-to-date and robust software solution.

But what features are needed? This is why including all agency stakeholders is vital, because they are likely to have different priorities. The graphic designers naturally want a package that has all the bells and whistles, which may be more expensive than the finance team believes the agency can reasonably afford. Consensus and compromise will be necessary.

To get there, the stakeholders must come together to share their expectations and expertise. Although the people involved will vary depending on the size of the business and the nature of the potential purchase, they typically include the owner and/or senior executives, procurement officer or manager, finance executive or accountant, IT professionals (including security experts), legal and representative end users (in the agency example, this would be the design team). Sometimes outside experts, such as a vendor or consultant, can be valuable, too. If the agency wants to use AI tools, for example, an expert in the evolving technology could educate stakeholders on the pros and cons.

2. Supplier Identification and Evaluation

Next, it’s time to seek out potential vendors. When evaluating the list of potential suppliers, investigating how much they charge for their solutions is certainly important, but other factors may be equally or more relevant to the business, as well, such as product or service quality, delivery time, supplier reputation, after-purchase support (such as warranties and upgrades), sustainability and ethics. Stakeholders must align on the priority of evaluation criteria before delving into market research and industry analysis. There may be direct vendor inquiries to gather detailed information. Other good sources of data to better understand the supplier landscape include online vendor databases, third-party vendor reports and evaluations, trade shows and customer referrals. A thorough supplier assessment may also include vendor audits or site visits.

3. Submission of a Request for Information (RFI), Proposal (RFP) or Quotation (RFQ)

After winnowing the list of potential vendors, the next step is to dig deeper into the specifics in order to make an informed choice. These approaches are sometimes referred to collectively as RFX, with the “X” representing one of three specific types of request:

- RFI: This is the broadest option and, therefore, often the first approach used. Instead of asking for a specific solution, an RFI is intended to help stakeholders become familiar with the market and the supplier. Because an RFI doesn’t mean a company is ready to buy, it’s typically kept short and simple so they’re easy for vendors to complete. RFIs can be especially helpful in the early stages of procurement, when stakeholders don’t know the best solution to a problem and want to explore different options or when narrowing down a large pool of vendors before seeking more detailed information from the finalists. For example, a company may send out an RFI to several marketing automation providers asking about the types of services they offer, general pricing structures, experience with similar customers and case studies.

- RFP: This request is more specific than an RFI, seeking detailed information that enables stakeholders to get quotes for the type of solution they’ve chosen. An RFP includes rigid guidelines for timeliness, content and vendor responses. A company uses the information in these proposals to find a vendor that meets the requirements, such as deliverables and schedules, defined by the stakeholders. RFPs are most helpful when the business need has been defined and stakeholders are ready to evaluate specific solutions from multiple vendors across a number of variables.

- RFQ: In contrast, an RFQ is focused primarily on price. Such a request is designed to get a detailed — and firm — quote for a specific product or service. RFQs can be most efficient when the potential solutions are comparable, customization isn’t required and stakeholders are seeking the best deal.

Depending on the culture — and the priorities of investors and shareholders — companies may also ask for other standardized information, intended to ensure that the supplier’s business practices are in sync to the company’s espoused values. Ways to collect this information include security questionnaires, vendor risk assessments, sustainability reports or supplier diversity information.

4. Supplier Selection and Contract Negotiation

A good RFX process often yields a clear winner or solid compromise choice. That said, companies should ask questions about anything that seems unclear, press the vendor on what may be left out of the document and ask for references. If the stakeholders prefer one product’s features but balk at the price, they should find out whether the vendor is willing to negotiate before passing on their preferred option. Once any loose ends are tied up, stakeholders can make a decision.

Next comes arguably the most important step in the procurement process: negotiating the contract. Not only is the contract a legally binding document, it defines the day-to-day reality of living — and working — with the selected solution and supplier. Therefore, it’s vital to negotiate a strong, effective contract. Of course, the contract must guarantee the agreed-upon price. It must also thoroughly and clearly stipulate the terms of the agreement, including the following elements:

- Statement of work and project scope, if the company is contracting for a service.

- Itemized costs, such as for raw materials, shipping, training and maintenance.

- Payment terms, including timelines, milestones and early-payment discounts, if applicable.

- Delivery terms and milestones, such as when implementation should be completed.

- Data security.

- Service-level agreements (SLAs), including key performance indicators (KPIs), to ensure the supplier meets the company’s performance expectations.

- Support commitments, such as an assigned a dedicated customer success rep or a 24/7 support line.

- Warranties and limitations on the supplier’s liability.

- Contract length.

- Dispute-resolution procedures.

- Contract-renewal terms.

- Termination clauses, including transition procedures.

5. Purchase Order Creation and Approval

Once contract terms are set, the supplier becomes an approved vendor in the company’s procurement system and the company is ready to place an order, a purchase order (PO) is created. Like contracts, POs are legally binding documents. A typical PO starts with the basics: the date, a PO number, a description of the goods or services to be bought, quantity, price and contact information for the business and vendor. Depending on the details of the transaction and the information required by the finance team, the purchase order might also include order and delivery dates, payment method and due date, shipping method, name and title of the person authorizing the purchase, and other terms and conditions.

In a mature procurement function, POs are reviewed and approved before they are submitted to the vendor. The company’s procurement policy should stipulate at the outset who has the authority to approve a PO. In many organizations, there may be more than one person approving the purchase — say, the relevant department head and a finance representative. An approved PO also typically triggers the finance team to provide relevant information, such as the finance department’s internal reference number, to the supplier.

6. Order Fulfillment and Receipt

The company submits the PO, the supplier ships the product and the company receives it. End of the order-fulfillment story, right? Not quite.

The step of receiving is rarely as simple as just opening a box. The effort often begins with tracking the order before it’s received and, when it is, communicating receipt with the appropriate people. Tracking the delivery date and comparing it to the order date to ensure the supplier has met the delivery schedule is another best practice, as is checking that the quantity delivered is correct.

Receipt of physical products should also trigger rigorous quality-control measures. Shipments should be inspected upon receipt for damages or defects. Depending on the product, quality control may include sampling, testing or certification.

Once these steps are complete, the company should record the receipt of the items in the procurement system so that inventory counts are adjusted appropriately, the value of the received goods are reflected in the accounting system and the appropriate stakeholders are notified about the delivery.

7. Invoice Payment and Record-Keeping

If the procurement process is working well, payment terms were delineated in the contract and PO. Companies should honor those terms; doing so goes a long way toward building trust and establishing a positive long-term relationship with the supplier.

When the invoice comes in from a supplier, a best practice is to match it to the PO and receiving documentation to ensure its accuracy, paying close attention to prices, quantities and payment terms. Once the invoice has been checked and approved, accounts payable can issue a payment based on the agreed-upon terms.

Keeping careful and accurate records of all invoices and payments is a business imperative. Doing so makes it easier to conduct cash-flow audits; it also empowers valuable spending, budgeting and financial analysis. For example, a company may want to compare expenditures to the budget to identify any areas of overspending. Another best practice: Companies should keep suppliers informed if they’re unable to make a payment on time, whether due to a temporary cash flow issue, error caused by a manual process, billing dispute or something else.

8. Supplier Performance Management

The procurement process doesn’t end once an invoice has been paid. The “last” step — though it should be ongoing — is for the company to measure and manage supplier performance using KPIs to ensure that the buyer is getting the full value of its purchases. The specific KPIs to analyze will vary among companies, depending on the nature of the product or service and the business requirements they meet, though some common metrics include the supplier’s delivery timeliness, product reliability and cost.

This is also a good time for the business to reflect inward. Frequent, internal feedback sessions in which business stakeholders share their experiences and observations, including candid assessments of the company’s internal processes and issues, can highlight areas in need of improvement. In addition, it’s valuable to assess whether the company’s needs have changed since the procurement process began and whether the problem is still as urgent as it once was.

The quantitative and qualitative data can be illuminated using dashboards or balanced scorecards. Of course, this review process is only fruitful if the company uses it to make improvements. Regular progress reports help companies spot challenges and deficiencies early so that they can work with suppliers to address them. Longer term, reviews can help companies make informed decisions regarding contract renewals, renegotiations or termination.

How to Optimize the Procurement Process

Anyone following a recipe can produce the desired dish. But experienced cooks know that by integrating their own expertise and preferences into the process, they can make that same dish faster, better or both. The same principle holds true for procurement. Consider the eight-step process described above as the basic recipe, which can be optimized over time with the following actions:

-

Assess the current process: Any company that has purchased something has some sort of procurement process. The real question is how well that process is serving the organization. Many companies yield to inertia and keep doing what they’ve always done. While there may be some value in that, there are likely missed opportunities. The best procurement processes clearly align with business strategies and scale as the business grows. So naturally, there’s a benefit to reassessing any existing procurement approaches on a regular basis to see what’s working and what’s not. Some best practices for evaluating the status quo include:

- Reviewing who is using the current procurement system and how they are using it.

- Assessing the effectiveness of procurement technology and tools and their usage.

- Conducting surveys and interviews to determine what stakeholders think about the current process.

-

Set clear objectives: Procurement is most effective if the process is framed by clear goals. Is it to save money? Improve productivity? Better support the company as it grows? Increase transparency and financial control? More likely than not, it’s some combination of these things. Defining and prioritizing these objectives will help clarify what process and technology changes need to be made.

-

Allocate resources: Savvy businesses understand that sometimes they have to spend money to save money — or, in this case, optimize procurement. Investing in centralized human and technology resources will pay off in relatively short order. Indeed, organizations that allocated more than 15% of their headcount to shared services and centers of excellence (COEs) outperformed their competitors in terms of cost savings and procurement ROI, according to the Procurement Leaders’ “Strategic Planning Guide 2024.” This approach streamlines processes and enhances performance.

-

Leverage technology: Due its complexity and breadth, the procurement process can be time-consuming, tedious and inefficient — particularly when companies rely on manual or siloed processes. Fortunately, there are purpose-built tools that can help to streamline and automate the process. They include:

- Supplier relationship management (SRM) systems, which offer a single platform to manage supplier relationships, contracts, performance metrics and collaboration. Doing all that in one place helps companies track supplier performance, negotiate better terms and spot opportunities for process improvement.

- Communication and collaboration tools, so that stakeholders can monitor the status of the procurement process and offer feedback as needed.

- Financial tools, which automate PO creation and approval, process invoices and payments, and more. Not only do these tools improve efficiency, they also improve accuracy.

- Analytics and reporting tools, which consolidate and analyze data so that companies can track KPIs, savings and other elements in real time.

- RFP management software, which automates the entire RFP process, saving time when issuing RFPs and comparing responses.

- Source-to-settle procurement solutions, which manage the entire procurement process, from identifying suppliers (sourcing) to making final payments for goods and services (payment settlement) in one seamless workflow.

When exploring any technology solution, companies should consider price, scalability, integration capabilities and ease of use. Many companies find that investing in an enterprise resourcing planning (ERP) system with procurement and other modules is the most helpful way to manage procurement and other overlapping processes in a single solution. Leading ERP providers also integrate artificial intelligence (AI) capabilities that can help further automate and optimize each step of the procurement process.

-

Manage suppliers: Like any good relationship, relationships with suppliers require clear communication, trust, mutual respect and aligned goals to function well. It’s also essential for companies to establish clear expectations with defined KPIs and SLAs, both of which must be actively managed. Best practices include ongoing performance monitoring, regular feedback sessions and effective conflict resolution skills to facilitate continuous improvement.

-

Centralize data: Effective procurement generates a lot of data (and documentation) throughout the process. In many organizations, this data may reside in different systems and with various functions. In the absence of data centralization, stakeholders can waste a lot of time trying to find what they need. Security is another important consideration because while this data should be easily accessible to stakeholders, no one else should be able to get their hands on it without the proper access privileges.

-

Streamline approvals: Sign-offs are necessary, but they can also slow the procurement process. The more people who must approve a PO, the greater the potential delay. One way to make this step more efficient is to set budgetary thresholds per department, permitting department heads to purchase anything below a certain level — $5,000, for example — without approval. Another option is to clarify who is in the approval loop and what role they play. Doing so mitigates delays caused by people waiting for approvals that they actually don’t need. It also helps avoid the realization late in the process that someone who should have been consulted was not. Finally, investing in a procurement management system that automates the approval process, prompting necessary approvers to review potential purchases in a timely manner, further streamlines this aspect of procurement management.

-

Negotiate better terms: No company wants to pay more than necessary for any solution. But companies also don’t want to negotiate so hard that they sour the partnership from the start. The goal should be a contractual agreement that both parties feel good about. There are several ways to get there. For example, if a product has everything the company wants but the price tag is too high, the company may seek a lower overall price. Many vendors are willing to be flexible on the price if it means getting the deal. If the vendor can’t lower the price enough, the company may be able to negotiate favorable payment terms to keep monthly or quarterly costs within budget.

-

Provide training and development: A new procurement process will likely represent a significant change in the status quo. Therefore, it’s important to invest in initial and ongoing training and development to ensure that any new processes and tools are readily adopted and used most effectively. This training and development is necessary not only for the procurement department, but also for senior leaders, finance and supplier management teams, and those making purchases within the business. Companies should establish a training program that addresses the needs of each group and offers a mix of training approaches (e.g., in-person training, self-service learning, etc.). Ongoing education is also important, as is a support system to answer questions and resolve issues.

-

Monitor and review: Some of the investment made in creating an effective PO and negotiating the contract can be lost if companies don’t circle back on an ongoing basis to make sure the agreed-upon terms were met. Some core metrics worth monitoring are the supplier’s delivery schedule, product reliability and whether the product is fixing the business problem as promised.

Just as — and likely even more — important is monitoring the performance of the procurement process, itself, to determine how well it’s meeting its stated objectives. Making course corrections and improvements based upon these reviews ensures that the procurement process will be in a state of continuous improvement.

Improve the Procurement Process With NetSuite

Procurement is not an isolated process. It intersects, at various points, with accounting, supply chain management, inventory management and other functions. Although each of these elements can be managed separately, procurement is more transparent and efficient when they are all integrated. NetSuite ERP makes that possible.

NetSuite includes a dedicated procurement module that automates key parts of the procurement process. For example, during the PO stage of the process, businesses can use the procurement module to automate quote requests, track and analyze submitted quotes, and maintain lists of approved vendors and suppliers. After signing a contract, businesses can use NetSuite to track related purchase orders, sales orders, invoices, shipments and payments.

Additional ERP modules integrate with the procurement module to optimize the process. For example, the finance module can automatically match POs to invoices and fulfillment tracking to automate payments based on a company’s specific rules and policies. Other procurement-related NetSuite modules include inventory management, order management and supply chain management, each of which can further streamline the overall procurement process.

A well-designed and managed procurement process is key to a company’s financial health. Done right, procurement enables product and service acquisition in a way that boosts productivity, improves efficiency, fosters long-term relationships with suppliers and saves money. Eight clear steps, as detailed above, form the core of effective procurement; companies can personalize and optimize each of those steps based on their particular strategies and goals to make the process even more impactful.

Procurement Process FAQs

What are the 5 Ps of procurement?

The 5 Ps of procurement are key elements that collectively contribute to the success and value of a procurement strategy:

- Planning: Ensures that the procurement process addresses a clearly defined business problem and supports the company’s overall strategy.

- People: The stakeholders involved in identifying the business problem, selecting the solution and implementing that solution. Everyone involved must work together and be accountable for their portion of the process.

- Pricing: How much to spend. Companies must see the value of their investment, but also believe that the deal they strike is fair.

- Proposal: The linchpin document that captures all the terms and details of the purchase. It’s vital that the proposal be accurate and thorough.

- Project management: Ensures that once the proposal is approved and the contract signed, the company receives the product as scheduled and implements it effectively.

When does procurement start?

Contrary to what many might think, procurement does not begin with a purchase. Rather, it starts with identifying the business problem that needs to be solved or a need that must be met. The rest of the process involves finding the appropriate goods or services, evaluating vendors or suppliers, negotiating contracts, purchasing, paying invoices and managing supplier performance.

How does contract negotiation impact the procurement cycle?

By securing favorable pricing and terms and setting clear expectations, contract negotiation builds a strong foundation for the entire procurement process. The benefits of an effective negotiation process can include cost savings, improved supplier relationships and better alignment with organizational goals.