Businesses rely on procurement to produce their goods or services and to keep operations running smoothly. Done right, procurement ensures that a business has what it needs, when it needs it, and in a cost-efficient manner. It is a multistep process that can keep a business humming along—or bring it to a grinding halt. This article explores the various types of procurement, how the process works, where it fits into a business’s overall operations, and how technology impacts the process.

What Is Procurement?

Procurement is the end-to-end business process of obtaining goods or services that a company needs for day-to-day operations. It includes identifying requirements, selecting suppliers, negotiating contracts, creating purchase requisitions (PRs) and purchase orders (POs), receiving and verifying goods, and approving supplier payments.

Procurement’s overarching objective is to supply the key inputs for the business at the best price, ensuring a steady supply and minimizing risk. The way this objective is achieved can vary depending on the type of business and how a company defines the procurement process. For manufacturers, it means making sure raw materials are ready to be placed into production; for professional services firms, procurement might focus on securing laptops and specialized software for all employees. Depending on the company, the procurement team may have a narrow focus or a broad remit. For most, procurement begins with recognizing a business need and ends with reviewing a supplier’s performance, with many steps in between.

Key Takeaways

- Procurement is a vital business function that, when well executed, can help increase a business’s profitability.

- It involves sourcing raw materials and services, negotiating terms, tracking when supplies are received, and maintaining records.

- It’s important to continuously monitor and assess the procurement process to improve any weak spots or inefficiencies.

- Technology makes procurement more effective and scalable, reduces costs, and minimizes the risk of business disruption.

Procurement Explained

In recent years, the term “supply chain” entered the popular lexicon, as many businesses faced challenges due to the pandemic, labor strikes, shortages, tariffs, natural disasters, and geopolitical instability. Procurement is a subset of the supply chain. Put into perspective, a supply chain refers to the broad process of moving goods from raw materials through production and on to the final customer; procurement is the piece of that process that focuses on sourcing and acquiring the necessary raw materials and services and overseeing supplier performance. Both supply chain management and procurement are strategic functions, but procurement stops short of the logistics involved in getting products or services to the end customer.

In turn, purchasing is a subset of procurement. Procurement includes identifying and selecting the best suppliers based on quality, price, and reliability, as well as negotiating, maintaining, and evaluating these long-term relationships. Purchasing is the transactional part, beginning when a PO is created and ending with an approved payment. It’s the tactical execution of ordering from suppliers that were vetted as part of the procurement process.

Whether at the supply chain, procurement, or purchasing level, each of these functions plays an essential role in supporting business operations and has a critical impact on profitability. Many CFOs focus on procurement as the core activity because of its direct impact on financial statements and risk management, especially in businesses where cost, risk, or quality control are under pressure.

How Procurement Works

The procurement lifecycle generally involves a number of steps that businesses must follow, including:

- Identifying the goods and/or services needed.

- Sourcing suppliers, requesting quotes, and filling out PRs.

- Negotiating terms and costs with suppliers.

- Receiving the relevant items and submitting payment.

- Evaluating supplier performance and maintaining records.

A small company may have just one person handling procurement of all goods and services. Larger companies may have a team of people specialized in dealing with diverse suppliers or supporting specific internal business groups. For some items, the team may need to gather input from several different business groups in order to determine the company’s overall requirements.

It’s important to remember that procurement doesn’t consist of a series of isolated acts—it’s an ongoing process. For example, businesses generally aim to establish relationships with key suppliers to help obtain the best service and lowest possible costs, which ultimately translate into higher profit margins. Companies may also need to conduct regular quality assurance checks and performance analysis to make sure suppliers consistently meet expectations.

Competitive Bidding

Competitive bidding is a procurement method that involves inviting multiple suppliers to submit proposals or bids to provide a good or service. Typically, a company’s purchasing organization issues a detailed request for proposal that outlines its requirements, timeline, and selection criteria. Interested suppliers then submit sealed bids, which are opened and evaluated simultaneously. The goal is to foster competition among vendors in order to secure the best possible price, but competitive bidding also allows buyers to assess factors like quality, delivery time, vendor reputation, and after-sales support. This approach is commonly used for high-value purchases, complex projects, or public-sector procurement to ensure transparency and fair competition. However, it can be time- and resource-intensive, so it’s important for companies to weigh the potential benefits against the administrative costs involved.

Why Is Procurement Important in Business?

Procurement is an important step in understanding supply chains, because it helps a company find reliable suppliers that can provide competitively priced goods and services that match the company’s needs. That’s the case whether the company is seeking raw materials for manufacturing, a marketing services provider, or new office supplies.

For example, if a company needs a new supplier to provide an ongoing service for an indefinite period of time—such as an email security solution—the procurement process helps the company choose the supplier that best meets all of the business’s requirements at a reasonable price. It enables the business to avoid wasting time, money, and valuable resources dealing with an inadequate supplier.

Minimizing cost is one important aspect of improving procurement processes. But it’s also vital to identify suppliers that provide the quality of goods and services that the company needs and have the capacity to deliver reliably and a track record of doing so.

Video: What Is Procurement Software?

Types of Procurement

Procurement can be categorized in several ways. It can be classified as direct or indirect, depending on how the company will use the items being procured; it can also be categorized as goods or services procurement depending on the items that are being procured:

- Direct procurement: Refers to obtaining anything that’s required to produce an end-product. For a manufacturing company, direct procurement includes raw materials and components. For a retailer, it includes merchandise purchased from a wholesaler for resale to customers.

- Indirect procurement: Typically involves purchases of items that are essential for day-to-day operations but don’t directly contribute to the company’s primary operations. This can include anything from office supplies and furniture to advertising campaigns, consulting services, and equipment maintenance.

- Goods procurement: Largely refers to the procurement of physical items, but it can also include items like software subscriptions. Effective goods procurement emphasizes quality and cost controls and avoids costly supply disruptions. It may include both direct and indirect procurement.

- Services procurement: Focuses on procuring people-based services. Depending on the company, this may include hiring individual contractors, contingent labor, or retaining professional services, such as legal or onsite security services. It may include both direct and indirect procurement.

Types of Procurement

| Direct Procurement | Indirect Procurement | Goods Procurement | Services Procurement | |

|---|---|---|---|---|

| What is it? | Any good or service required to produce an end product | All non-production-related goods or services | Physical items typically held as inventory, whether for direct or indirect procurement purposes | All people-based services procured, whether for direct or indirect procurement purposes |

| Examples | Raw materials, components and parts, machinery, items purchased for resale | Office supplies, marketing services, utilities | Raw materials, wholesale items, office supplies | Law firms, contractors, contingent labor, on-site security services |

Direct vs. Indirect Procurement

Direct and indirect procurement are two key categories of purchasing within a business. Direct procurement refers to obtaining the raw materials, components, or contracted labor that are directly incorporated into a company’s products or services. Direct procurement has a significant impact on the final product and tends to be more strategically managed due to its effect on a business’s primary revenue-generating activities. Direct procurement fuels production schedules and relies on sales forecasts. In contrast, indirect procurement involves purchasing goods and services that support the business but aren’t part of the final product, such as office supplies, software subscriptions, travel services, and equipment maintenance. Indirect procurement often presents more opportunities for cost savings through vendor consolidation, process efficiencies, and economies of scale.

Goods vs. Services Procurement

Goods and services procurement are equally important. Goods procurement involves acquiring tangible products, including raw materials, equipment, inventory, and supplies. These purchases are often recurring and require careful management of factors like order quantities, delivery schedules, and inventory levels. Services procurement, meanwhile, focuses on contracting labor and expertise, such as consulting, marketing services, facilities management, and IT support. Service contracts tend to be more complex, with considerations for scope of work, service-level agreements, and performance metrics. While goods procurement is critical for manufacturing and retail businesses, nearly all organizations rely heavily on procured services to operate effectively.

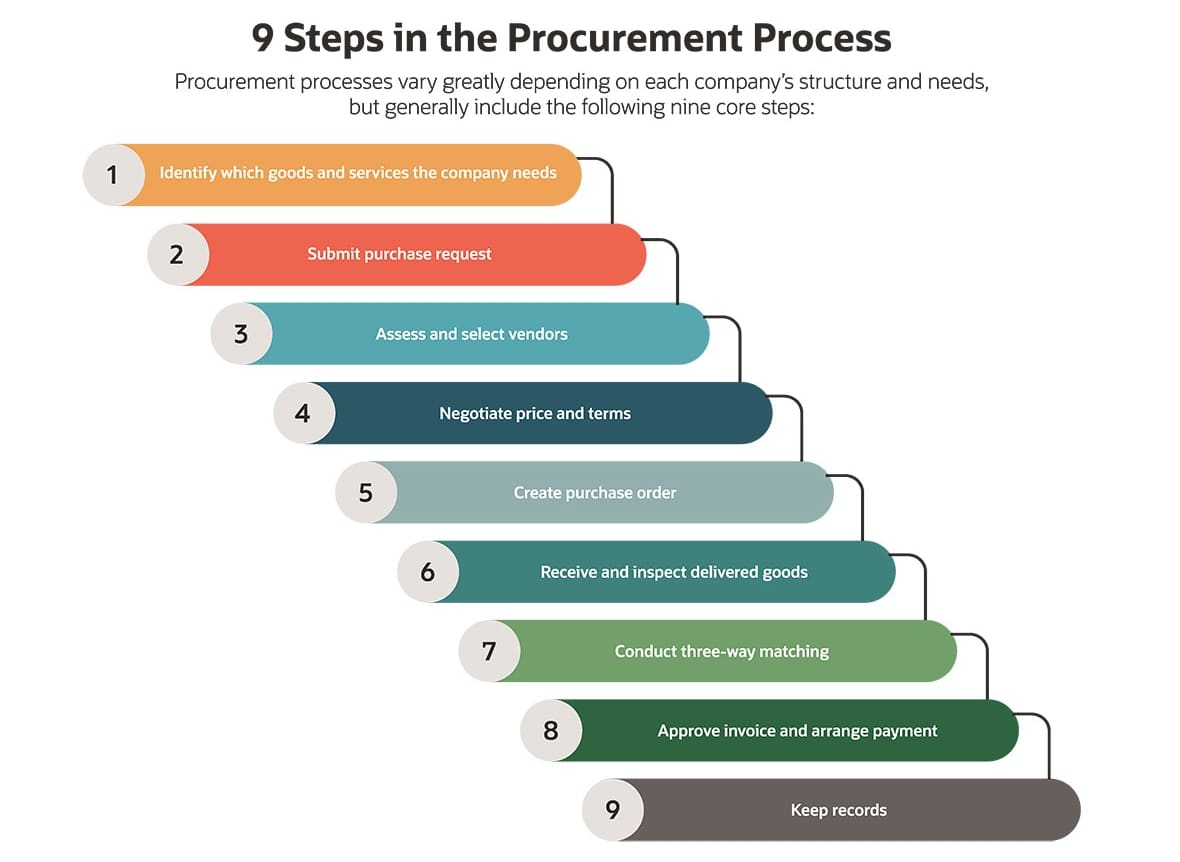

9 Steps in the Procurement Process

Procurement processes vary greatly depending on each company’s structure and needs, but generally include the following nine core steps.

-

Identify Which Goods and Services the Company Needs

First, a business must identify its requirements for a specific item or a service. This may be a new item that the company hasn’t previously purchased, a restock of existing goods, or a subscription renewal. This step typically involves delving into the nitty-gritty details of what the business needs, such as the precise technical specifications, materials, part numbers, or service characteristics. At this stage, it’s a good idea to consult all business departments affected by the purchasing decision to ensure the items procured accurately reflect the needs of each department.

-

Submit Purchase Request

When an employee or business group needs to procure a significant quantity of new supplies or services, they submit a formal PR. A PR notifies the company that a need exists, usually via department managers, purchasing staff, or the financial team, as well as specifications such as price, time frame needed, quantity, and other important details for the purchasing team to keep in mind. The department overseeing the purchase can then approve or deny the PR. If approved, the procurement team can proceed with selecting a vendor and making the purchase.

-

Assess and Select Vendors

With a clear list of requirements and an approved PR, now is the time to find the best vendor and submit a request for quote (RFQ)—this is what the purchasing team sends to potential suppliers in order to receive a quote. It’s important to be as detailed as possible to compare apples to apples. Vendor assessment should focus not only on cost but also on reputation, speed, quality, and reliability. Many companies consider ethics and social responsibility as well, since procurement is often intertwined with corporate identity. A retailer that prides itself on sustainability would stand to benefit from partnering with environmentally responsible suppliers, for instance.

-

Negotiate Price and Terms

A common best practice is to get at least three quotes from suppliers before making a decision. Examine each quote carefully and negotiate where possible. Ensure that you’re getting the best payment terms and contract length in addition to prices. Consider asking for value-added services or other flexibility. Sometimes walking away from an arduous deal is the best option, so long as there are concrete alternatives. Once you’ve agreed on final terms, be sure to get them in writing.

-

Create a Purchase Order

Fill out a PO and send it to the supplier. The PO should be sufficiently detailed to identify the exact services or goods needed and to enable the supplier to fill the order. Also ensure that the PO has the necessary approvals and proper accounting information for internal tracking.

-

Receive and Inspect the Delivered Goods

Carefully examine deliveries for any errors or damage. Make sure everything is delivered as specified in the PO and that the quality meets or exceeds expectations. Ensure that receiving documentation is accurate and that any returns or rejections are clearly documented.

-

Conduct Three-Way Matching

Accounts payable should conduct three-way matching by comparing the PO, order receipt or packing list, and invoice. The goal is to make certain the goods or services received match what was ordered and to prevent payment for unauthorized or inaccurate invoices. Highlight any discrepancies among the three documents and resolve issues before arranging payment.

-

Approve the Invoice and Arrange Payment

If the three-way match is accurate, approve and pay the invoice. Businesses should strive to have a consistent invoice payment process through accounts payable that checks that payments match the invoice amount and due date. A standardized process can help make sure invoices are always paid on time, which can prevent late fees and build good relationships with suppliers. It can also help capture available early-pay discounts.

-

Keep Records

It’s important to maintain records for the entire procurement process, from PRs to price negotiations, invoices, receipts, and everything in between. These records may be useful for multiple reasons. They help the company reorder goods at the right price in the future, as well as assist with auditing processes and calculating taxes. They’re also essential for tracking progress toward any contracted volume discounts or claiming penalties for late deliveries. Clear, accurate records can also help resolve any potential disputes.

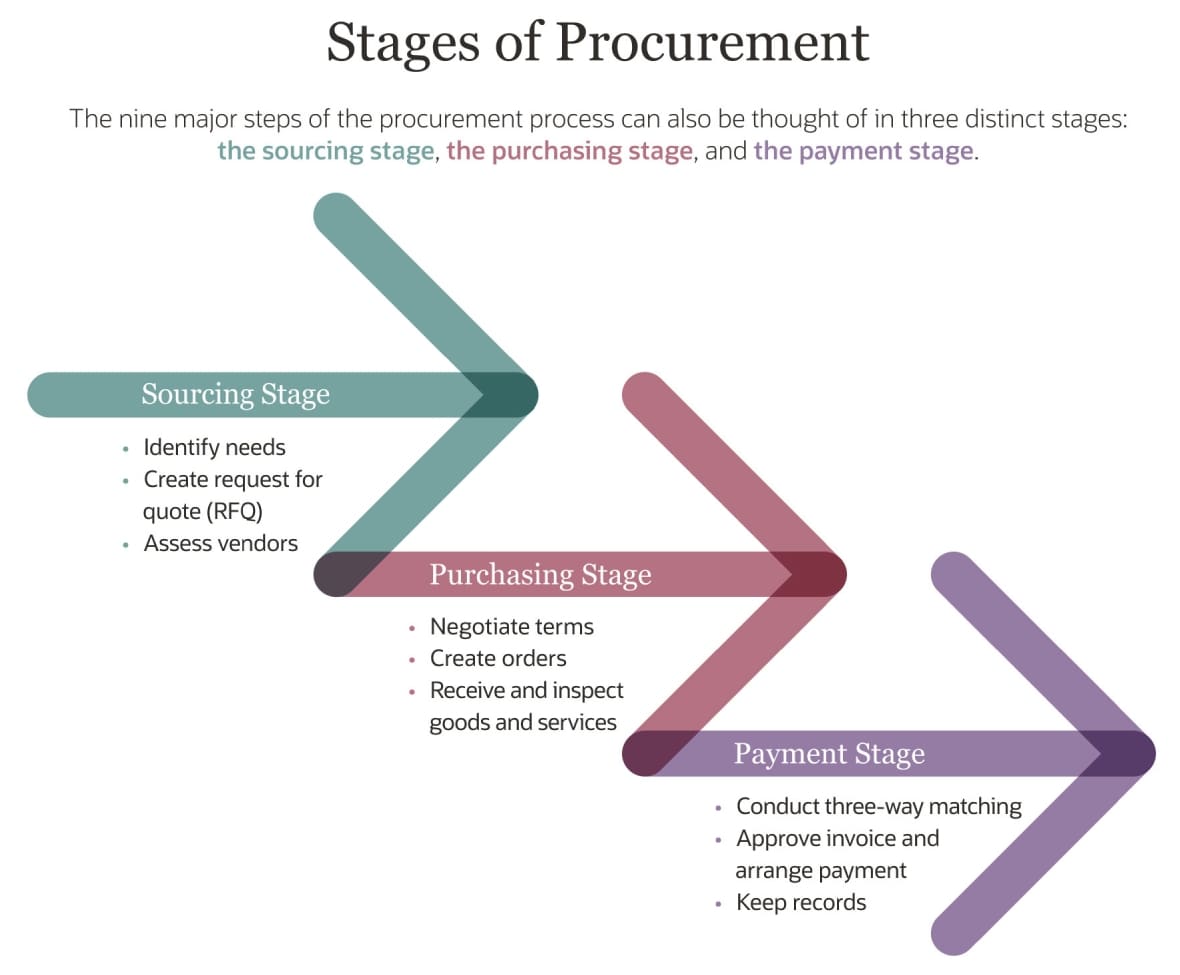

Stages of Procurement

The nine major steps of the procurement process can also be thought of in three distinct stages: the sourcing stage, the purchasing stage, and the receiving stage.

- Sourcing stage: This covers the initial steps in which the business identifies its needs, creates and distributes RFQs, and assesses vendors. After the initial sourcing steps are complete, it’s a good practice to build strong relationships with suppliers. They can establish grounds for suppliers to learn from partners, improve products, and processes and develop trust.

- Purchasing stage: This stage includes negotiating terms, creating orders, and receiving and inspecting goods and services.

- Payment stage: Accounts payable conducts three-way matching to ensure order and invoice accuracy. The invoice can then be approved, and the payment is arranged. Records of all invoices, orders, and payments should be kept and carefully maintained.

Procurement Lifecycle

Organizations commonly think of steps in the procurement process as a procurement lifecycle. This perspective provides a reminder that all the tasks and stages in the procurement process overlap and rely on each other and that the process is continuous. A carefully thought-out procurement lifecycle takes into account its integration with the business as a whole, aligning with existing company policies and procedures, especially with regard to budgeting. The process is not always linear, and sometimes adjustments need to be made to account for a dynamic digital supply chain with shifting suppliers, availabilities, and costs.

3 Components of Procurement

Three key components work together to make the procurement process happen: people, process, and paperwork:

- People: People generally are responsible for initiating or authorizing every step of the procurement process. In addition to procurement specialists, other stakeholders include accounts payable and the business groups that request the goods and services. The number of people involved often depends on the value of the goods and services; more stakeholders may be involved in specifying and approving high-value purchases.

- Process: An effective procurement process can help a company succeed by keeping costs down and ensuring that supplies arrive when the business needs them. A well-designed and methodical process promotes accuracy and timeliness and safeguards against potential risk management concerns. Proper training makes certain every person understands their role and is held accountable. In contrast, a disorganized procurement process results in inefficiencies and potentially costly errors. Overpayments, for example, can impact the bottom line, while late payments negatively affect relationships with suppliers.

- Paperwork: It’s important to maintain records for every stage of the procurement process and make sure they’re easily accessible. Many companies have shifted to e-procurement systems, digitizing the paperwork aspect. These records act as a store of organizational knowledge about payment terms and supplier performance, helping the business maintain an efficient procurement process—even if the procurement staff changes over time. In the case of an audit or a dispute, a business must easily be able to follow the paper or electronic trail through each stage of the procurement process.

Procurement, Purchasing, and Supply Chain: What’s the Difference?

The terms procurement, purchasing, sourcing and supply chain are often used interchangeably. However, there are important distinctions:

- Procurement vs. purchasing: Purchasing is transactional, focusing on managing specific orders to meet company needs. Procurement is broader and more complex, including establishing and maintaining supplier relationships. Another way to think about the difference between purchasing and procurement is that procurement takes a proactive approach that starts with analyzing the company’s needs, whereas purchasing is a reactive approach—simply focusing on obtaining what the company has already decided it needs.

- Procurement vs. sourcing: Sourcing, like purchasing, is only part of the overall procurement process. Sourcing is an early stage of the procurement cycle. It encompasses activities such as identifying, engaging, and assessing potential suppliers of goods or services, negotiating terms, and selecting the vendors that best meet the company’s needs.

- Procurement vs. supply chain: Procurement is a subset of supply chain management. Procurement includes sourcing, obtaining, and paying for goods and services. Supply chain management also covers the logistics involved in obtaining goods, such as shipping and warehouse management, as well as transforming the procured goods into products and distributing them to customers.

| Procurement | Purchasing | Sourcing | Supply Chain Management | |

|---|---|---|---|---|

| Definition | All activities related to carefully sourcing and obtaining goods and services needed to support business operations | Buying goods and services | Selecting and vetting vendors to provide goods and/or services | Managing the coordinated network of companies, facilities, and business activities involved in sourcing, developing, manufacturing, and delivering products |

| Scope | Includes sourcing, negotiation, purchasing, receiving, and recordkeeping | Part of the procurement process | Part of the procurement process | Includes the entire procurement process |

| Focus | Ensuring that the company gets the most value from goods or services to increase the business’s profitability | Usually focuses on ensuring adequate supply for day-to-day activities | Establishing good, long-term relationships with suppliers | Optimizing the flow of goods and services into the business through production and out to the customer, without sacrificing quality or accuracy |

7 Common Principles of Procurement

The following principles of procurement can be regarded as an ethical code of conduct. These principles are considered best practices for all procurement professionals, but especially necessary for those in public-sector organizations entrusted with public funds. Stricter regulations and formal processes are in place to hold public servants even more accountable for their purchases, aimed at reducing the incidence of corruption and protecting the public trust.

The principles vary somewhat depending on the organization. Here are seven of the most common procurement principles for public and private sector organizations:

- Value for money: The organization must manage funds efficiently and economically when procuring goods and services. This may include conducting cost-benefit analyses and risk assessments. It’s worth noting that low cost does not necessarily equate to greater value; characteristics such as quality and durability also factor into determining whether the purchase represents value for money.

- Fairness: Procurement should not give preferential treatment to individuals or suppliers. All potential suppliers should be given equal opportunity to compete for contracts and all bids should be assessed objectively, based on how well they meet the organization’s needs.

- Competition: Organizations should seek competitive bids from multiple suppliers, unless there are specific reasons not to do so, such as a sole-source provider where the good or service is only available from a single vendor.

- Efficiency: Procurement processes must be carried out efficiently to help maximize value and avoid waste or delays.

- Transparency: Organizations should make relevant procurement information available to everyone, including the public and suppliers. Information should be kept confidential only when there are legal or other valid reasons to do so.

- Integrity: Procurement professionals should always strive to be perceived as trustworthy, reliable, honest, and responsible. Funds must be used for their intended purpose and in the public or business’s interest.

- Accountability: People involved in the procurement process are accountable for their actions and decisions. They are required to report procurement activities accurately, including any errors.

Which Personnel Are Involved in Procurement?

Procurement involves a wide range of personnel across different levels and functions of a business. At the core is the procurement or purchasing department, which is responsible for overseeing the entire procurement process. This team typically includes procurement managers who develop overall strategy, negotiate major contracts, and manage vendor relationships. They often work closely with other line-of-business staff to understand their needs and ensure that procurement aligns with broader business goals.

Procurement agents, or buyers, handle day-to-day purchasing activities, such as issuing POs, expediting deliveries, and maintaining procurement records. For technical purchases, subject matter experts from relevant departments may be involved in defining requirements and evaluating proposals. Finance personnel also play a key role in budgeting, cost analysis, and invoice processing. In larger companies, there may be dedicated roles like contract administrators, supplier diversity managers, and procurement analysts. Ultimately, effective procurement requires collaboration and communication across multiple stakeholders to make sure the right goods and services are obtained at the best value for the business.

A number of additional job titles fall within the procurement function, including:

- Procurement assistant: Typically an entry level position, procurement assistants provide administrative support for the procurement team. Procurement assistants need to be detail-oriented and can be called upon to assist with any of the department’s tasks, from researching suppliers to managing POs.

- Procurement coordinator: This is primarily a liaison role. A procurement coordinator ensures that procurement processes are running smoothly and that policies and procedures are being followed. It requires strong communication skills in order to make sure the line of business managers’ needs are being met and to engage with new suppliers.

- Procurement specialist: This position has broad responsibility for all aspects of procurement, from sourcing suppliers to negotiating contracts and managing the acquisition of the goods and services. Sometimes called purchasing agents, they also are responsible for tracking key performance indicators (KPIs) and contract obligations. The role usually requires a bachelor’s degree and strong analytical, organizational, and negotiating skills.

- Sourcing specialist: This role focuses on setting sourcing strategy and finding and evaluating new suppliers. It involves doing market research and matching supplier capabilities with the business’s needs. Strong analytical and problem-solving skills are needed for making strategic recommendations and resolving any issues. Depending on the organization, sourcing specialists generally have a master’s degree, procurement certification, and several years of procurement related experience.

- Category managers: A category manager has deep expertise in a particular type of good or service. They are proficient in their category’s market dynamics and are intimate with their internal stakeholder’s needs. Category managers must think strategically as they are expected to help drive improvement and innovation for the business’s products or services. This role often necessitates a combination of procurement knowledge and familiarity with the business.

- Purchasing manager: The purchasing manager oversees the entire procurement function and team. They are responsible for developing and implementing all strategies and policies, as well as ensuring compliance with them. They are usually the final approver for major contracts and purchases and accountable to the company’s C-suite. Purchasing managers are experienced professionals with strong management skills.

How Procurement and Finance Work Together

In many companies, procurement and finance teams operate as separate departments. However, a strategic partnership between the two can benefit the business as a whole, since they share a common goal—driving operational efficiency and effective financial management.

There are several ways these teams can work together to achieve this goal. First, they should collaborate on budgeting and financial planning, with procurement providing input on expected costs and potential savings so that finance sets more realistic targets. Second, they should work together on cost control, with procurement identifying savings through strategic sourcing and finance tracking their financial impact. Third, two teams should function as two legs in the payment relay, with procurement initiating POs and invoice approvals, then handing the baton to accounts payable for payment processing and compliance checks. Beyond these core processes, procurement and finance can also partner on data sharing, risk management, contract oversight, compliance, strategic planning, and technology integration.

Integrated supply chain management software is an important tool for helping these teams work together to advance business objectives. It also helps track progress toward goals by providing KPIs in a simple-to-understand format for the procurement team.

Common Procurement KPIs

By monitoring procurement KPIs, businesses can boost the efficiency of their procurement process, track progress toward business objectives, and identify areas for improvement. In addition, tracking KPIs over time can uncover meaningful trends and insights. Here are some commonly measured procurement KPIs:

- Purchase order cycle time: The average number of hours or days it takes to process PRs and send POs to suppliers. This alerts for potential bottlenecks.

- Supplier lead time: The average number of days it takes for suppliers to send items after they receive a PO. Lengthening supplier lead times can cause production delays or inventory shortages.

- Number of suppliers: Having more suppliers gives the company more options but also increases administrative work. Many procurement groups monitor the number of vendors in their supplier networks and periodically remove little-used suppliers to increase efficiency.

- Supplier defect rate: An important measure of supplier quality usually measured as the number of defective parts divided by the total number of parts supplied. This rate often factors into procurement contract renegotiations.

- Supplier availability: A measure of a supplier’s ability to respond to last-minute or emergency demands. This is an especially critical KPI in industries with unpredictable demand patterns or short product lifecycles.

- Fulfillment accuracy: The percentage of orders that suppliers fill accurately and match the PO exactly. Higher rates are preferable, so as to avoid rework and unmet needs.

- Total ROI of procurement process: The value that an organization’s procurement strategy delivers to the organization. It’s the ratio of the annual savings generated by the procurement group to the total annual amount spent on procurement.

How Is AI Enhancing Procurement?

Procurement teams are actively leveraging AI to increase efficiency and elevate decision-making across the entire procurement lifecycle. With this advanced technology, procurement professionals can better scale their operations and move beyond tactical execution to focus on higher-value priorities.

AI can deliver meaningful productivity gains by streamlining many traditionally manual processes. For instance, it can quickly and accurately perform spend analysis, track contract activity, run supplier evaluations, and monitor compliance with company or regulatory policies. In invoice processing, AI automates the three-way matching of POs to receiving documents and invoices and highlights discrepancies, which reduces manual intervention and shortens processing times.

AI’s ability to recognize patterns in spending behaviors also improves efficacy by flagging anomalies that may indicate fraud and uncovering cost-saving opportunities that might otherwise be missed. AI can compare supplier pricing and total costs in real time, helping teams capture the best value on frequently purchased items. And if stockouts occur, it can recommend comparable alternatives and calculate the total cost of replacement, including shipping and fees.

Beyond operational efficiency, AI supports data-driven, forward-looking decision-making. For example, AI-powered spend analytics. helps reveal purchasing trends that can pinpoint overspending and forecasting inconsistencies. It also highlights areas where renegotiation or supplier consolidation could lower costs or strengthen supplier relationships. When combined with AI predictive demand forecasting, the procurement team is better prepared to meet future production needs and anticipate potential market shifts, reducing overstock and shortages.

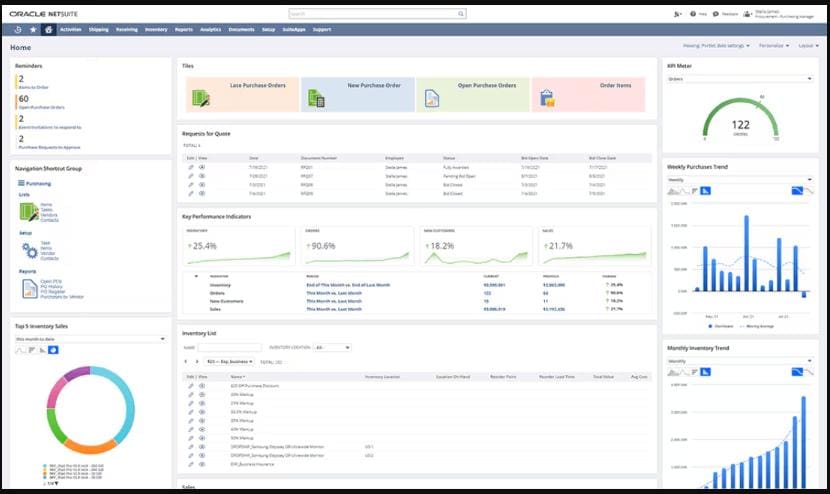

How Technology Can Help Manage Procurement

NetSuite Procurement streamlines and unifies the entire procurement process on a single, cloud-based platform. It reduces manual work, making teams more efficient and scalable. At the same time, it enhances visibility across the entire procurement operation—from vendor selection and PRs through invoice processing and payment. This end-to-end transparency makes it easier for the procurement team to access relevant information, which is particularly helpful when negotiating contracts and for capturing volume-based savings. The system’s configurable approval workflows support adherence with company policies and regulatory requirements to reduce the risk of non-compliance and prevent fraud.

At the same time, AI-powered automation for tasks like PO management and three-way matching boosts productivity while enforcing cost controls and flagging variances. Real-time collaboration through the included vendor portal makes communication smoother, which strengthens supplier relationships. NetSuite Procurement’s seamless integration with NetSuite’s financial management, inventory management, and supply chain management modules delivers real-time information businesses need to manage spending, evaluate supplier performance, lower costs, and drive both efficiency and profitability.

NetSuite Procurement Dashboard

Procurement is a strategic business process that directly impacts a company’s bottom line and overall success. A subset of supply chain management, procurement encompasses a wide range of activities, from identifying business needs and sourcing suppliers to negotiating contracts and managing vendor relationships. Its importance extends beyond simply transactional purchasing, influencing costs, product quality, operating efficiency, risk, and even corporate social responsibility. The integration of advanced technologies, particularly AI, is revolutionizing procurement processes.

Procurement FAQs

What is procurement in simple terms?

Procurement is the process of acquiring the goods and services a company needs to operate, such as raw materials, equipment, and business services. It involves identifying requirements, selecting vendors, negotiating contracts, and managing orders and payments to obtain the best value for the business.

What is an example of procurement?

An example of procurement is a manufacturer that sources and purchases raw materials necessary to produce its products, such as a car manufacturer procuring steel, rubber, and electronic components. This process involves identifying suppliers, negotiating contracts, placing orders, and managing the delivery of these materials to ensure a steady supply for the production line.

Is procurement the same as purchasing?

Procurement and purchasing are closely related but distinct concepts. Procurement refers to the overarching process of identifying needs, sourcing suppliers, negotiating terms, and managing relationships to acquire goods and services. Purchasing refers to the specific transactional activities of placing orders and making payments.

What does a procurement role do?

A procurement role is responsible for managing the end-to-end process of acquiring the goods and services a company needs to operate effectively. This includes identifying business requirements, sourcing and selecting suppliers, negotiating contracts, managing vendor relationships, and ensuring the timely delivery of purchases at the best possible value.