Facility maintenance contracts. Enterprise software licenses. Professional services. While these expenses don’t directly contribute to a company’s products or services, they are essential for keeping the business running smoothly. Yet, many have traditionally viewed these so-called indirect procurement costs as less strategically important than direct procurement spend. That’s a mistake. Without careful management and oversight—particularly because indirect procurement typically spans multiple departments and requires managing a diverse supplier base—these substantial costs can erode profit margins and hinder business performance.

This article explains the ins and outs of indirect procurement, its many business benefits, how to manage challenges, several best practices, and eight important key performance indicators (KPIs) to help businesses stay on the road to success.

What Is Indirect Procurement?

Indirect procurement refers to the purchase of goods, services, and resources that support a business’s daily operations but aren’t incorporated into its final products. This includes physical goods, such as office supplies and computer equipment; facility-related costs, like rent, utilities, and maintenance contracts; and external services, such as consulting, software subscriptions, and equipment repairs.

Indirect procurement is sometimes referred to as indirect purchasing, though an important distinction exists between the two terms. Purchasing relates specifically to the transactional aspects of acquiring goods and services, whereas procurement encompasses the entire life cycle, including supplier identification, selection, and performance management. Depending on the organization, these responsibilities may be consolidated under a single procurement team or separated into two departments.

Indirect vs. Direct Procurement

Much like the backstage crew to a Broadway show, indirect procurement is critical to an organization’s operational and financial success, even though it doesn’t directly contribute to the end products or services it sells to customers. Purchases for the latter are categorized as a second type of procurement: direct procurement. In the case of an LED television manufacturer, for example, direct procurement purchases would include LED screens, circuit boards, speakers, and electric wiring. For a grocery store, direct procurement purchases would include the prepackaged food and beverages it resells to its customers, as well as the ingredients needed by the bakery to make cakes and pastries.

Indirect vs. Direct Procurement: Key Differences

| Indirect Procurement | Direct Procurement |

|---|---|

| Goods and services that support business operations but don't appear in final products | Raw materials and goods needed for the production of products and services |

| Centralized purchasing process | Often decentralized across departments |

| Tied directly to revenue | Viewed as operational cost |

| More flexible supplier selection | Long-term supplier relationships |

| Predictable demand patterns | Variable demand patterns |

| Examples include office supplies, IT services, and facilities management | Examples include components, ingredients, and packaging materials |

Key Takeaways

- Indirect procurement encompasses the processes businesses use to obtain the diverse goods and services they need to run their daily operations.

- The decentralization of these purchases among business departments results in limited organizationwide visibility into total spending and fragmented supplier relationships.

- Benefits of effective indirect procurement include greater cost efficiency and supplier performance.

- By centralizing indirect procurement data and operations, businesses can save time, take advantage of volume discounts, and decrease their operational costs.

Indirect Procurement Explained

How much a company spends on indirect procurement is contingent on several factors, including its size, industry, and business model. For example, a manufacturing company might spend as little as 15% or 20% of its procurement budget on indirect materials and services because most of its budget goes to the direct materials needed for production, while a professional services firm could spend up to 90% on categories like office space, technology, and travel.

Effective procurement management can result in significant cost savings, greater visibility into spending, and improved operations. However, the decentralized nature of indirect purchasing can make it a challenge to control. Without proper coordination and oversight, organizations are at risk of overspending, duplicating efforts, and missing opportunities for volume discounts and supplier consolidation. But by adopting strategies from direct procurement, such as centralizing processes and streamlining the supplier base, businesses will be better able to optimize indirect procurement. Digital procurement tools and automation can also go far, increasing spend visibility and providing data-driven insights that lead to better purchasing decisions.

Indirect Procurement Categories

Organizations rely on a wide range of indirect procurement categories to maintain their daily operations and support business growth. These categories include:

- Office supplies and equipment: This broad category covers everything, including pens, pencils, paper, and paperclips; desks, chairs, and filing cabinets; and staplers, ink cartridges, and breakroom supplies.

- Software licenses and IT services: This category has become increasingly important as businesses become more digitally dependent. Many now manage extensive portfolios of software licenses and IT services, from customer relationship management and enterprise resource planning systems to cloud storage solutions and managed IT support.

- Telecommunications: These expenses cover mobile, landline, and internet services. They also account for related hardware, such as smartphones, tablets, and any other connected devices that are purchased for employees to use in the office or in the field.

- Facilities management: Cleaning and maintenance services, utilities such as electricity and water, and waste management are indirect procurement costs for any business that owns or leases space in a physical location. It may also include building management and security.

- Travel and expenses: Business travel expenses include transportation costs (airfare, train tickets, taxi fare, mileage reimbursement for personal vehicle use, etc.), food stipends, hotel costs, client meals, and conference-related fees.

- Marketing and advertising services: This category includes marketing software, fees for third-party agencies, self-employed content creators, SEO experts, and social media influencers. It also includes sponsorship deals, branded merchandise, and marketing collateral.

- Human resources and training: HR expenses include employee onboarding, training, and development programs; benefits and wellness initiatives; and external recruitment services.

- Professional and outsourced services: Professional services providers include external business consultants, legal counsel, and financial auditors. In some cases, companies will pay a third party to manage entire business functions, such as their call center operations.

- Fleet management: For companies not in the transportation industry, vehicle purchases, fuel, maintenance, and insurance are all indirect procurement costs.

- Uniforms and personal protective equipment (PPE): This category includes workplace attire and safety equipment required for employee protection and professional presentation, such as medical scrubs, protective masks, corporate uniforms, and other safety gear.

- Corporate services: This category covers internal support functions that serve the broader organization, such as the IT help desk and facilities management. While these services are delivered internally, they often require external procurement of tools, systems, and supplemental expertise to operate effectively.

7 Advantages of Effective Indirect Procurement

Organizations that manage their indirect procurement well can realize significant advantages that impact their bottom line, operational efficiency, and competitive position. Here are seven key benefits.

- Greater cost efficiency: The goal of any procurement team is to obtain the highest quality goods and services at the lowest possible prices. Effective indirect procurement secures cost savings through strategic sourcing, ongoing supplier collaboration and negotiation, and consolidated purchasing that reduces administrative overhead costs, eliminates duplicate purchases, and lowers the total cost of ownership across indirect categories. For example, by purchasing office supplies for several departments at one time, a business may qualify for a volume discount that decreases the total expense.

- Improved spend visibility: Without clear insight into indirect procurement spending—specifically, how much is being spent, on what, and by whom—businesses are at real risk of blowing their budgets and endangering their ability to turn a profit. Well-managed indirect procurement overcomes this lack of transparency, aided by spend analysis tools, dashboards, and AI integrations that track and analyze spending across every department and vendor. As a result, companies can identify where to cut costs, eliminate redundant purchases, and quash maverick spending, which is the purchase of goods and services that deviate from a business’s standard procurement procedures.

- Expanded supplier access: Unlike direct procurement, which often involves long-term contracts with specific vendors, indirect procurement typically enjoys greater freedom in supplier selection. This enables businesses to explore a wider range of potential suppliers, compare prices and terms, and negotiate competitive deals. An added benefit: Having access to multiple suppliers can help mitigate risks in the event of a supply chain disruption. For example, if a company’s main supplier of office equipment experiences a production delay due to a natural disaster, having relationships with alternative suppliers can help the company obtain what it needs elsewhere.

- Strengthened supplier relationships: Effective indirect procurement builds strong, mutually beneficial relationships with suppliers by creating clearer communication channels and performance expectations. Regular monitoring of supplier KPIs and a commitment to ongoing dialogue create collaborative environments that promote shared expertise and innovation, leading to improved levels of service, reduced costs, and development of creative solutions that benefit both parties. For example, by working closely with a supplier to understand its capabilities, a company might discover an opportunity to develop a new product that benefits both parties.

- Enhanced supplier performance: Supplier relationship management (SRM) —that is, the process of systematically tracking, evaluating, and optimizing supplier relationships—and continued monitoring and reporting are integral parts of a solid indirect procurement strategy. Ongoing analyses of supplier metrics, such as order accuracy, on-time delivery, purchase price variance, and defect rate, help companies identify their top-performing suppliers so they can nurture those relationships. These assessments also reveal underperforming suppliers that could benefit from additional support. For example, if a company notices a decline in on-time delivery rates from a critical supplier, it can proactively engage with the supplier to identify the root cause of the issue and collaborate on solutions (which feeds into advantage No. 4).

- Competitive advantage: By strategically managing their indirect expenditures and building strong relationships with key suppliers, businesses can gain access to innovative products, services, and technologies that may enhance their offerings, speed operations, and enable them to respond faster to new market opportunities than their competitors. For instance, through a preferred supplier relationship, a healthcare provider might gain early access to advanced medical equipment that enables it to offer innovative treatments before other facilities in its market have time to act.

- Sustainability and corporate responsibility: Indirect procurement can demonstrate a company’s commitment to sustainability by incorporating environmental, social, and governance (ESG) criteria into supplier selection and management processes. For example, a company may choose to work with suppliers that offer recycled or biodegradable products, thereby reducing its own environmental footprint. Or it might decide to contract services to a vendor that prioritizes diverse and inclusive hiring practices. Companies often include ethical and sustainability standards in their supplier contracts and then measure how well suppliers meet those standards.

Managing Challenges in Indirect Procurement

The rather loose and disjointed nature of indirect procurement often places its advantages out of reach for many organizations. It also threatens to unleash a host of inefficiencies that ultimately have bottom-line ramifications. Here are four main challenges that procurement teams face.

- Managing diverse categories: From office supplies and equipment to facilities and fleet management, to internal support services and more, indirect procurement covers a vast array of categories, a reality further complicated by the number of departments that procure these goods and services. Without a centralized system in place, organizations will likely struggle to maintain consistent data among categories, miss opportunities for vendor consolidation, and face difficulties ensuring procurement policy compliance.

- Visibility and control obstacles: The higher the number of departments making purchases independently of one another, each following their own processes and protocols, the easier it is for an organization to lose control. Without a centralized procurement system that provides real-time visibility throughout the business, different departments can easily purchase the same or similar products from different suppliers, losing out on the cost efficiencies consolidation can provide. Maverick spending can also raise a business’s procurement costs and could undermine already negotiated contracts.

- Spend management inefficiencies: Lack of visibility and control also give rise to significant spend management-related challenges. The nature of indirect procurement—characterized by frequent, low-volume purchases of diverse goods and services across various departments—makes it near-impossible to consolidate spending and qualify for volume-based discounts. This disconnected approach often results in different departments using multiple vendors for the same items, creating inconsistencies in procurement costs.

- Supplier relationship management issues: Plain and simple,SRM is more difficult when indirect suppliers lack oversight by a dedicated procurement team. When relationships are built and managed by multiple teams and stakeholders across the business—and without a centralized system—it becomes nearly impossible to effectively monitor them, much less proactively engage.

Indirect Procurement Best Practices

Indirect procurement is a function of every organization, no matter how small. These expenses, some of which cannot be linked directly to revenue-driving activity or customer success, can easily go rogue if not properly managed. The following five best practices not only can help businesses keep indirect procurement spending under control, but they can also refine processes, save money, and improve overall performance.

1. Monitor and Analyze Expenditures

Regularly monitoring and analyzing indirect procurement expenditures is a must for identifying where to reduce costs and improve efficiency. By leveraging spend analysis tools and techniques, such as data consolidation, categorization, and visualization, businesses can see just how much they’re spending on indirect purchases across myriad categories, suppliers, and business units. This visibility also allows them to identify trends, patterns, and anomalies, such as maverick spending, as well as to address inefficiencies. For example, a company might discover that different departments are purchasing similar office supplies from multiple vendors at different price points. By consolidating these purchases under a single, preferred supplier and negotiating better terms, the company can cut costs and improve its procurement process.

2. Implement Strategic Sourcing and Technology Solutions

Strategic sourcing is a component of the broader procurement process that focuses on identifying, vetting, and building long-term relationships with suppliers to deliver value beyond cost savings—in the form of improved quality, innovation, risk mitigation, or sustainability. By analyzing spending patterns, anticipating future procurement needs, tracking supplier performance, and conducting market research, companies can decide which suppliers to partner with and how to fine-tune their sourcing strategies.

Technology solutions support these efforts. Procurement management tools, such as e-sourcing platforms and contract management systems, streamline sourcing and improve supplier engagement, among other benefits. Advanced analytics tools and reporting dashboards help decision-makers easily see what is being bought and from whom, as well as spot occasions for supplier consolidation. Furthermore, tools powered by artificial intelligence (AI) can analyze vast amounts of data, identify patterns and anomalies, and provide intelligent recommendations. Indeed, companies in every industry see enormous potential in AI-powered software, with the global market for AI in supply chain management expected to exceed $83 billion by 2028.

3. Optimize and Streamline Procurement Processes

Process optimization is a cornerstone of cost reduction, especially for labor-intensive procurement processes, such as supplier onboarding, spend monitoring, and employee expense management. Standardized workflows, checklists, and approval processes that bring structure to the entire process are all ways that businesses can simplify their indirect procurement processes. Digital procurement technologies and automation tools also promise to play a growing role, providing businesses with greater visibility into their purchasing activities to improve data accuracy and strengthen collaboration among stakeholders. For example, automated invoice processing and expense management tools can streamline the accounts payable process, reducing the time and effort required to process invoices or reimburse employees for their expenses.

4. Foster Internal Collaboration and Communication

By encouraging cross-functional teamwork and open channels of communication, companies can align indirect procurement activities throughout their various business functions, reducing duplication of efforts, leveraging collective knowledge and expertise, and identifying opportunities for synergy and innovation. The implementation of a centralized procurement platform that houses all procurement-related information and activities is the key to enacting this best practice. Companies should also commit to informing team leaders whenever new procurement policies come into effect, and back up that commitment with the resources, tools, and training needed to integrate these new practices into their current activities.

Consider a company that has vowed to reduce office waste by 30% as part of a new ESG initiative. To achieve this, it decides to enact a new policy whereby office supplies must be purchased from suppliers that manufacture their products using recycled materials. To ensure adoption, the company should not only communicate the new policy to all relevant stakeholders but also provide a list of preapproved vendors, then train the stakeholders on how to evaluate suppliers based on sustainability criteria.

5. Encourage Responsible Spending Practices

Indirect procurement spending occurs in all departments—from marketing teams purchasing analytics software to sales representatives booking business travel. With purchasing decisions so widely distributed, organizations must establish and communicate clear expectations for responsible procurement that consider total cost of ownership and align with organizational goals and values.

Responsible spending starts with education and training, such as providing guidelines for evaluating suppliers and holding workshops on how to identify cost-saving areas. Employees must also understand the negative impact of rogue spending on their company’s bottom line. Centralizing indirect procurement activities on a common platform also promotes responsible spending and accountability. The company might even offer incentives to reinforce responsible spending behaviors, such as incorporating procurement efficiency metrics into bonus calculations.

6. Regularly Review and Negotiate Indirect Spend Contracts

Regular review of indirect procurement contracts helps organizations ensure that they’re receiving competitive pricing, maintaining appropriate service levels, and maximizing value from their supplier relationships. These reviews also open the door to renegotiating contract terms. Through systematic contract analysis, companies often uncover chances to consolidate vendors, take advantage of new service offerings, or restructure agreements to align better with changing needs. For example, a company might discover during its annual review that combining its separate contracts for office supplies, breakroom items, and cleaning materials under a single supplier could qualify it for higher-tier discounts.

8 KPIs for Indirect Procurement

KPIs are quantifiable business metrics that track and measure a business’s progress toward specific performance goals. Whether that means reducing maverick spending by 20% or improving supplier compliance rate by 5%, selecting the right KPIs—such as those listed below—helps companies improve their indirect procurement strategy.

1. Spend Under Management

Spend under management (SUM) measures the percentage of an organization’s total procurement spend that is actively monitored, controlled, and streamlined by a company’s procurement department. It is typically expressed as a percentage of total organizational spend. A higher SUM indicates greater visibility and control over purchasing activities, while a lower percentage suggests more maverick spending and less oversight.

The formula to calculate SUM is:

Spend under management = (Approved spend / Total spend) x 100

For example, if a company’s approved direct spend is $120,000 and its total procurement spend was $200,000, its SUM would be 60% [($120,000 / $200,000) x 100].

2. Cost per Invoice

Cost per invoice determines how much it costs to process a single invoice through a company’s accounts payable (AP) department. It can also flag ways to reduce costs, such as by automating manual processes or consolidating vendors to decrease the total number of invoices processed. AP costs include overhead, IT support, software subscriptions, technology infrastructure, employee salaries, and, if applicable, fees for late payments.

The formula to calculate cost per invoice is:

Cost per invoice = Total AP processing costs / Number of invoices processed

For example, if a company’s total AP processing costs for a month are $40,000 and it processed 4,000 invoices during that month, its cost per invoice would be $10 ($40,000 / 4,000).

3. Cycle Time

Procurement cycle time measures the amount of time that elapses between the initiation of a purchase request and the receipt of a good or service. This KPI helps procurement teams detect bottlenecks and inefficiencies in their procurement process. Note that cycle time can also be used to measure how long individual procurement activities take to complete. Two common individual cycle time KPIs are purchase order (PO) cycle time, which measures how long it takes for a purchase requisition to be approved, and sourcing cycle time, which quantifies how much time is spent on sourcing indirect suppliers.

The formula to calculate procurement cycle time is:

Procurement cycle time = Date goods or services received - Date purchase request initiated

Consider a retailer that placed an indirect procurement purchasing request on March 1 and received the order on March 21. The procurement cycle time would be 20 days.

4. Supplier Lead Time

Unlike procurement cycle time, which tracks the entire purchase process, supplier lead time looks at how long it takes a supplier to fulfill an order after it receives a purchase order. It is another valuable measure of efficiency that helps companies plan the timing of their purchases and evaluate supplier performance.

The formula to calculate supplier lead time is:

Supplier lead time = Date goods or services delivered - Date supplier confirms order

If it took the retailer in our previous example a week to get its order out, the supplier confirmed receipt on March 8, and, as mentioned, the order was delivered on March 21, the supplier lead time would be 13 days.

5. Compliance Rate

Compliance rate measures how consistently a supplier meets contractual requirements, such as delivery schedules, quality specifications, and pricing agreements, as well as industry compliance standards. This KPI helps organizations distinguish reliable vendors from those that may need additional oversight or replacement. Low compliance rates can expose companies to a number of risks, such as supply chain disruptions or regulatory violations.

The formula to calculate a supplier’s compliance rate is:

Compliance rate = (Number of compliant orders / Total number of orders) x 100

If a supplier correctly fulfilled 350 orders out of a total 500 orders placed over the past year, its compliance rate would be 90% [(350 / 500) x 100].

6. Cost Avoidance

Cost avoidance measures expected savings, based on actions taken to avert future expenses. Put another way, it calculates the hypothetical cost of a business’s inaction in the face of an adversarial situation, such as inflation. Even if it’s hypothetical, it should still be based on robust data and sound assumptions to ensure credibility. This metric also helps justify procurement decisions that may require up-front investment but would prevent larger expenses down the line. Because it deals with theoretical rather than actual savings, cost avoidance is often considered a “soft” KPI.

The formula to calculate cost avoidance is:

Cost avoidance = Estimated cost of inaction - Cost of proactive solution

Consider a logistics company that needs to buy 50 trucks. Based on historical data, it estimates that, without extended warranties, repair costs for these trucks over the next five years would be $500,000. The cost of purchasing extended warranties for all 50 trucks is $300,000. Its cost avoidance would be $200,000 ($500,000 – $300,000).

7. Procurement ROI

Return on investment (ROI) measures the profitability of an investment by comparing the gain or loss from an investment relative to its cost. Procurement ROI helps organizations evaluate the effectiveness of their procurement strategies and justify new investments. Unlike cost avoidance, which predicts theoretical savings, procurement ROI quantifies the value generated by procurement activities relative to their costs.

The formula to calculate procurement ROI is:

Procurement ROI = [(Total cost savings - Total cost of procurement) / Total cost of procurement] x 100

For example, one year after investing $100,000 in a training program to teach employees how to source indirect procurement purchases more sustainably, the company determined it had saved $450,000—resulting in a procurement ROI of 350% [($450,000 – $100,000 / $100,000) x 100].

8. Vendor Performance Metrics

Vendor performance metrics help organizations evaluate and perfect their supplier relationships. These KPIs identify top performers, flag underperforming vendors, and inform decisions about whether to invest in the improvement of struggling supplier relationships or end them. When selecting these KPIs, businesses should prioritize those that measure supplier quality, reliability, and potential to deliver competitive advantage through innovation and tailor them to the strategic importance of the particular supplier relationship.

Several metrics discussed earlier, including supplier lead time, compliance rate, and cost avoidance, play crucial roles in vendor performance evaluation. Additional KPIs include on-time delivery rate, which tracks how consistently suppliers meet delivery deadlines; order accuracy rate, which measures how often orders are filled correctly; response time, which evaluates how quickly suppliers address issues or inquiries; and defect rate, which calculates the percentage of products that arrive defective or broken.

Avoiding Common Pitfalls in Indirect Procurement

Successful indirect procurement requires discerning and managing several common pitfalls that can impact performance. One is neglecting to leverage technology and automation, which can manifest in inefficient manual processes, poor spend visibility, and missed savings. Organizations that rely on spreadsheets and paper-based systems often struggle to track spending patterns, consolidate purchases, or identify cost-saving opportunities.

Another pitfall is failing to establish and maintain clear procurement categories. When organizations don’t systematically group similar purchases—such as combining all software subscriptions under “IT services” or all cleaning contracts under “facilities management”—they can’t effectively analyze spending patterns or negotiate volume discounts. This lack of categorization frequently results in duplicated purchases, maverick spending, and missed chances to save money.

As in any business, lack of communication and engagement among internal stakeholders can also cause issues. Without buy-in from the top, organizations may struggle to enforce indirect procurement policies and compliance. Setting clear KPIs to gauge performance, plus providing training and support to employees involved in the procurement process, can help ensure that everyone follows procurement procedures.

Finally, as any contract expert (or experienced poker player) would say, organizations sometimes weaken their negotiating position by revealing budgets or making purchasing timelines public before finalizing contracts. Maintaining confidentiality during supplier negotiations and strategically timing purchases can help secure favorable terms and pricing.

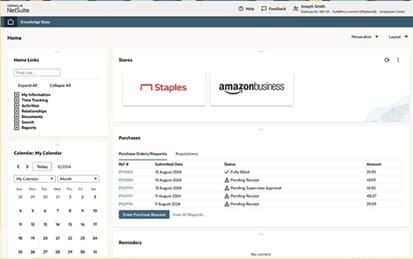

Optimize Your Procurement Performance With NetSuite

Organizations need robust technology solutions to stay on top of their procurement operations and supplier relationships. NetSuite Procurement, part of NetSuite’s cloud-based Supply Chain Management solution, provides businesses with a comprehensive, centralized platform they can use to enhance procurement performance. With user-friendly dashboards offering visibility into purchase information, transaction records, vendor performance, and expenditures, businesses can streamline operations, negotiate better pricing, strengthen vendor relationships, and reduce the high overhead costs associated with managing a large supplier network.

NetSuite SuiteProcurement, a key application within NetSuite Procurement, simplifies the entire purchasing process by automating purchase requests, approval workflows, and vendor communications. Predefined category mapping ensures accurate general ledger accounting, while standardized processes help reduce maverick spending. This automation improves efficiency and accuracy while minimizing the risk of costly human errors. The result is a more strategic procurement operation that fuels cost savings, improves supplier relationships, and supports sustainable business growth.

Traditionally viewed as less strategic than direct procurement, indirect procurement has emerged as a key priority for organizations seeking to control their spending and strengthen supplier relationships. The challenge lies in streamlining often disjointed and opaque indirect procurement processes, scattered across multiple departments, into a unified, consistent approach that increases value. By adopting best practices and leveraging advanced technologies, businesses will be well positioned to optimize their indirect procurement processes, reduce costs, and improve supplier collaboration.

Indirect Procurement FAQs

What is an example of an indirect procurement cost?

Indirect procurement costs are expenses incurred by a business for purchasing goods and services that support its daily operations but are not directly incorporated into the final products or services it delivers to customers. Common examples include office supplies, software and IT licenses, and professional services.