Many steps go into fulfilling customer orders for goods or services, from sourcing raw materials to manufacturing, inventory and delivery. To meet demand, businesses must be able to plan for each of these interdependent processes. And inherent to planning is mastery of the concept of lead time — how long it takes, from start to finish, to complete a given process in the production or delivery of a company's goods and services. To maximize efficiency of operations, businesses must account for lead time in their schedules and have on hand just the right amount of inventory to fulfill customer orders.

Not surprisingly, baking lead time into schedules is growing in importance as more businesses sell online, because delivering a positive customer experience drives repeat sales. Accurate lead time forecasting also helps businesses better manage their manufacturing, inventory and supply chain operations.

What Is Lead Time?

Lead time measures the length of time — days, weeks, months — that elapses from the beginning to the end of a business process, such as the production of a car. Each process includes a number of smaller, distinct processes that must all be taken into account when calculating lead time. When dealing with suppliers, these might include the time required for processing an order, sourcing raw materials and delivering completed goods.

By continuously measuring, tracking and benchmarking lead times for various processes, companies can streamline, improve productivity and strike a realistic balance between their capabilities and output. For example, with an accurate forecast of lead time for the silicon used in its semiconductors, a computer chip company can set realistic expectations for the technology companies that rely on its products farther down the supply chain. The company can also set benchmarks and find ways to scale lead times in line with market demand.

In most cases, businesses want to reduce lead times, as this generally leads to faster output and drives more sales. However, with so many interdependent processes connecting their supply chain, manufacturing, inventory and fulfilment operations, it is equally important they strike a balance that eliminates bottlenecks and loss from having too much inventory on hand.

Lead Time vs. Cycle Time:

Cycle time is the time that passes to complete a specific task from start to finish. It is a component of lead time, which measures the total time for a business process to be completed from start to finish.

Consider the example of a car manufacturer under pressure to deliver 200,000 completed vehicles to its dealer network in the next three months. Cycle time calculations might include how many door panels it can paint in an hour and how many engines it can assemble in a day. The lead time measures the total time required to assemble and deliver a car from start to finish.

Lead Time vs. Delivery Time:

Delivery time is another component of lead time. It measures the time required for goods to be delivered from a business to its customers, whereas the total lead time for those goods includes the time needed to prepare, manufacture and deliver them to the customers.

Delivery time is a major consideration for consumers deciding who to buy from. This is especially true in the ecommerce sector, where competitive offerings are just a mouse click away. Retailers have been investing heavily in software and logistics solutions to shorten their delivery times and better compete with large marketplaces.

Key Takeaways

- Lead time is the total time it takes to complete a business operation.

- Accurate lead time forecasts are crucial to a business's operations, driving efficiencies and cost savings from supplier management to inventory to fulfillment.

- Software-based planning solutions can help shorten lead times.

Lead Time Explained

Lead time refers to the latency, or time interval, between the start and completion of a business process. It is often used by suppliers and manufacturers that must understand the time involved in sourcing, producing and delivering their goods. Project managers also use lead time to understand how long specific tasks will take, such as the time required for the review and signing of contractual documents with third parties.

Companies use numerous measures of lead time to inform their operations, manage business relationships and set customer expectations. Three of the most common lead time indicators are:

- Production lead time: The elapsed time from when a company places an order with a manufacturer to when the order is received. This is also known as manufacturing lead time.

- Materials lead time: The time between an initial order of raw materials and their delivery, before they can be used to produce final goods or services.

- Total lead time: The entire time required to receive goods or services, from the initial order to assembly to delivery, and all processes in between.

Why Is Lead Time Important to Inventory Management?

Inventory management is essential across many industries, from grocery stores seeking to drive sales while minimizing food waste to device manufacturers that want to make sure they have enough product in stock to meet customer demand for, say, the latest smartphone. Lead time has numerous implications for inventory management. For one, decisions about inventory, such as how far in advance to replenish, are made as a function of production times. Inaccurate forecasts can lead to stockouts, wasted space in warehouses and unfulfilled orders. These outcomes, in turn, can result in financial loss and damage customer relationships.

Suffice it to say, well-informed lead-time projections — everything from supplier lead time to production lead time to delivery lead times — are crucial to effective inventory management.

5 Reasons Why Lead Times Matter:

Lead time matters at every stage of the product life cycle. Major discrepancies in lead-time forecasts can significantly impact business workflows and a company's ability to meet customer expectations. Here are five reasons why lead time is an integral factor in a business's success.

-

Smoother workflows:

Accurate lead times ensure that the connections between individual business processes are timed properly, rather than creating gaps, bottlenecks and overall inefficiencies. For example, knowing that a windshield manufacturer is able to ship its product only once per month, a car company can adjust its manufacturing to make sure vehicles are manufactured at a steady pace and are ready for the windshields to be installed upon their delivery.

-

Reduced storage costs:

Insight into inventory lead times allows businesses to optimize their warehouse operations. For example, rather than investing in too much square footage to accommodate maximum inventory at all times, they can refine their inventory projections based on accurate lead time forecasts, thus lowering costs.

-

Better customer relationships:

Delivery lead times play a vital role in shaping customer relationships. Customers generally favor short lead times and have little tolerance for late deliveries or orders that are delivered when they are not around to receive them. Setting and meeting expectations underpins business success.

-

Business resilience:

Businesses live and die by their ability to change course quickly and adapt to new realities. Lead time should build in a reasonable amount of time for unforeseen circumstances, be it a delay in the supply chain or an unexpected spike in customer demand for a particular product. These forecasts position the company to take change in stride, rather than falling behind.

-

Greater confidence in output:

Accurate lead times give businesses greater confidence in their ability to meet operational and sales targets. This means they can operate in a more lean way. For instance, a fashion brand that knows it can source, manufacture and deliver 10,000 T-shirts each month under current supply chain conditions can reduce its safety stock.

Lead Time and Supply Chain Management (SCM)

An efficient supply chain depends on accurate lead time projections at every step of the chain and with regard to all sources of materials. This is especially true in the case of goods that require parts from various suppliers, such as a smartphone or flat-screen television.

By analyzing and basing their schedules on accurate supply chain lead times, companies can ensure that all the components required to assemble their finished products arrive at the same time, or in the right order, so as not to delay the manufacturing process. This can improve workflows, optimize shipping and receiving costs, and make it easier to predict lead times farther down the chain, such as delivery time for customers.

Lead Time and Manufacturing

Accurate lead time is central to the success of nearly all manufacturers. By precisely measuring the time required to source materials, produce goods and deliver them to their customers, manufacturers can shape their processes in the most efficient way possible.

Manufacturing lead time is based on a variety of factors that depend on the goods a company produces. For instance, when it comes to shipping times for raw materials, some companies will simply measure the time from their initial order to delivery from a supplier. Others must build in the time needed to process raw materials for the next step of the manufacturing process. Consider the case of a jewelry company that must process and clean precious materials before integrating them into its products.

Companies that practice just-in-time (JIT) manufacturing — meaning stock arrives at the time it is needed for production — must keep an especially close eye on lead times. JIT aims to reduce variability in the completion of manufacturing processes, which requires incredibly accurate lead time calculations across the supply and production chains.

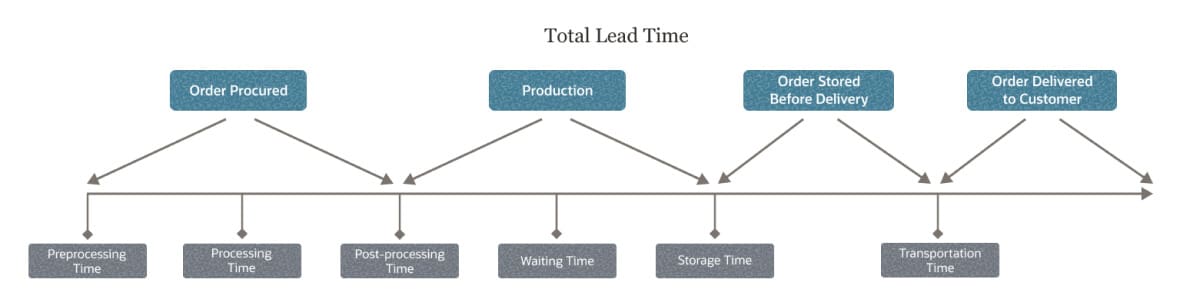

Components of Lead Time

Lead time measures the cumulative time it takes for a supplier to complete a given set of processes from the moment an order is made until delivery. Total time is the sum of a half-dozen smaller components, each with its own lead time. It is important for companies to factor in the components that apply to their processes in order to calculate accurate lead time forecasts across their operations.

Below are some of the most important components of lead time for businesses to consider.

-

Preprocessing time:

Also known as planning time, preprocessing time captures the time it takes to receive a purchase request for an item, understand the request and create a purchase order. In the case of a smartphone company, for example, preprocessing time would include the time required to set up a manufacturing task, or activity, in order to deliver a new order of phones in time for Black Friday.

-

Processing time:

Once preprocessing is complete, processing time is the time needed to procure or manufacture an item. For our smartphone manufacturer, processing time includes the time required to source raw materials from various suppliers and manufacture the phones.

-

Post-processing time:

Post-processing time refers to the span between when a purchased item is received until it becomes available in inventory. Depending on the item, post-processing might include inspection and safety checks, such as whether the smartphones do indeed turn on, or that the casing is, as promised, waterproof.

-

Waiting time:

Waiting time represents the time that elapses between procurement of raw materials until incorporating them into production or manufacturing processes. If our smartphone company uses an external supplier for its screens, it will need to calculate the time it takes to procure them until they're read to be integrated into the production process.

-

Storage time:

Storage time refers to how long the smartphones sit in a warehouse until they're ready for delivery. For companies that don't have warehouses, these items might sit directly in their factories.

-

Transportation time:

As its name implies, transportation time is the time it takes to transport an item from the warehouse or factory to the point where it reaches a customer. For example, retail outlets may have to wait one week after a new order of smartphones is manufactured before receiving them in-store.

Forecasting Lead Time

Forecasting lead time is a complex process. It involves calculating individual supply chain and delivery times, production and manufacturing times, inventory and inspection times, transportation times and other factors specific to an individual organization. Errors can lead to a range of issues, from operating inefficiencies and wasted inventory to lost sales and customer dissatisfaction, if projections are off by a significant degree.

Seasonality is an important consideration for accurate lead time forecasting. For example, supply chain pressures are higher during peak shopping periods, like at the end of the year, so some retailers will add a buffer to their lead time calculations. Meanwhile, car manufacturers know their sales spike comes in the spring, so they, too, are wise to adjust their forecasts accordingly.

Businesses operating globally must also be conscious of local particularities that can affect their supply chain or manufacturing lead times. For example, a high-end toy company that relies on parts from Germany must account for major German holidays when factories might be closed.

On the flip side, forecasting lead time based on the worst-case scenario — in other words, building in too much time to account for the unexpected — is not advisable. Doing so may cause companies to invest in additional safety stock, for example. It can also slow down processes, create potential bottlenecks and raise inventory costs. Worst of all, it may lead to disappointed customers in an era where faster is better.

Many businesses have turned to sophisticated software to improve their lead time forecasting. Machine-learning algorithms, in particular, help them account for the immense number of variables and their interplay in a global operation.

How to Calculate Lead Time

Lead time calculations vary depending on the process being measured. For instance, manufacturing lead time is the sum of preprocessing, processing and post-processing time for a given order. Meanwhile, inventory lead time includes the time it takes for suppliers to deliver items and any reordering delays.

Lead Time Formula:

Lead time calculations vary by industry and company. That said, the basic principle is the same: Break down the entire process into its individual tasks and assign a realistic lead time to each of those tasks. For example:

Total lead time for a manufacturer = procurement time + manufacturing time + shipping time

Whatever the variables, it is crucial that every element of the lead time puzzle be included in calculations and that projections and expected delays are based on robust historical data. Companies often rely on software-assisted lead time calculations to handle the heavy lifting.

Examples of Lead Time

Consider a local chain of office supply stores in the U.S. that must order 5,000 mechanical pencils in time for the new school year shopping rush, with 1,000 pencils going to each of its five franchises. Once the pencil manufacturer, in China, receives the order, it takes one day to process the request, another day to prepare and package the order, a week to deliver it to the office supply store's central location, and another day to deliver 1,000 pencils to each of the store's other locations. The total lead time is 10 days (1+1+7+1=10).

Or consider a mobile phone provider that must fulfill an order for 1,000 of the latest Android phones to be delivered on the day the product launches. The provider sends a purchase order to the phone manufacturer, where it takes two days to process the order before it's forwarded to the manufacturing facility. That facility is served by three suppliers — one for the phone's standard components, one for the phone camera and another for silicon chips. The longest lead time among these suppliers is two weeks due to a chip shortage, so the phone manufacturer must allow for a minimum of two weeks lead time before receiving the materials, at which point it needs two more weeks to assemble the phones, prepare the order and deliver it. The lead time in this example is four weeks and two days (2+14+14).

How to Improve (or Shorten) Lead Time

There are multiple ways businesses can reduce the time between an order being placed until its delivery. Among them:

-

Choose local suppliers.

While businesses might source specific materials and products from abroad to minimize their costs, using local materials and labor can speed up transportation and manufacturing processes, which in turn drives down costs in the long term.

-

Cut unnecessary tasks.

Lead time calculations can reveal process inefficiencies. Every business has room to optimize and, by benchmarking themselves frequently, they can position themselves for continuous improvement.

-

Change shipping methods.

As with its choice of suppliers, the shipping methods a company chooses for fulfillment require careful analysis. Less-expensive shipping methods might seem attractive at first glance, but more flexible shipping partners might allow for more frequent shipments, which drives down lead times and might pay off in the medium to long term.

-

Bring processes in-house.

While certain processes are highly localized, like the sourcing of alpaca wool in South America, many processes can be sped up by being brought in-house. Rather than waiting on external suppliers for materials and manufacturing operations, companies can look to own as much of the process as possible, giving them control over lead times. This is also known as vertical integration.

-

Automate inventory management.

Human error is a major cause of delays, and human errors in inventory are among the biggest culprits for businesses. By automating inventory management, businesses can significantly reduce the risk of human error, making their inventory operations and lead times significantly more efficient.

Improve Lead Times With Software

Modern software solutions can help companies stay on top of lead times and, as a result, operate more effectively. For example, NetSuite Demand Planning helps businesses — manufacturers, in particular — align planning with supply and demand for their goods to prevent issues such as excess stock or production delays.

In parallel, inventory management software can remove the risk of human error that could lead to misinformed inventory management decisions. This, in turn, drives down lead times, in addition to ensuring fulfillment accuracy and customer satisfaction.

The ideal approach is to integrate supply chain, production process, inventory management and logistics on a single software platform. A unified platform, such as NetSuite ERP, provides companies with visibility across each of these business functions. That way they're operating from a single and accurate source of truth to optimize virtually any operation that affects lead time.

Conclusion

Optimizing lead time is a top priority across industries. A company's ability to track, benchmark and reduce the time it takes to complete a given process in the production or delivery of its goods and services helps it set realistic expectations for customers and is directly linked to its success. As supply chains and supplier relationships grow in complexity, software-based practices can help companies create accurate forecasts.

Lead Time FAQs

What is lead time and why is it important?

Lead time is the time required to complete a business process from start to finish. Proper calculation helps companies optimize management of suppliers, production and inventory. This, in turn, makes them function more effectively while setting realistic expectations for customers.

How is lead time calculated?

Lead time is the sum of all the steps involved in a given process. This includes time spent on planning and preprocessing orders, sourcing raw materials from suppliers, manufacturing, transportation and delivery. Companies increasingly rely on software to forecast and calculate lead time accurately.

What is the difference between lead time and delivery time?

Delivery time is a component of lead time. Delivery time describes the time it takes to complete the last step of an order, which is delivery of an order to the customer.