Companies that can’t see the quantity or location of their inventory run into the same problems over and over: too much money tied up in stock, production slowdowns, missed orders, and decisions made on stale data. Those gaps can ripple outward, straining supplier relationships, squeezing margins, and leaving customers frustrated.

Improving inventory visibility gives supply chain teams the clarity they need to forecast more accurately, balance resources, and keep operations running even when disruptions hit. This article explores the core components of inventory visibility, how to improve it, common roadblocks for doing so, and some of the technologies that can help.

What Is Inventory Visibility?

Inventory visibility is the ability to track and monitor the location, quantity, status, and movement of the inventory it has on-hand. This helps companies track finished goods, works-in-progress, and raw materials at multiple stages between procurement and delivery.

Inventory visibility goes beyond basic stock counting. It encompasses real-time or near real-time tracking of inventory updates within and between locations and across sales channels and distributors, providing current availability information for decision-makers.

What Is Order Visibility?

Order visibility is a subset of inventory management focused on tracking customer orders from initial purchase to final delivery. Software can enhance order visibility by sending notifications at each order stage, updating delivery timelines, and adjusting inventory counts. These tools allow businesses to proactively manage delays, fulfill orders from cost-effective locations, and set accurate delivery expectations. Order visibility also helps businesses offer flexible fulfillment options—like in-store pickup or ship-from-store—without necessarily increasing carrying or shipping costs.

Key Takeaways

- Inventory visibility helps businesses prevent stockouts, reduce carrying costs, and assign orders to optimal locations.

- Poor inventory visibility leads to wasted labor, excess stock, and lost sales when actual stock levels don’t match records.

- Scalable inventory management systems allow businesses to increase order accuracy, accelerate fulfillment, and meet delivery expectations without proportionally increasing costs.

Inventory Visibility Explained

Inventory visibility is a pillar of effective supply chain management. When businesses know current stock levels and locations, they can allocate resources more effectively, avoid production delays, and reduce the risk of tying up cash in excess materials. Visibility also makes it easier to spot slow-moving or obsolete stock before it creates unnecessary carrying costs.

Modern tools support these needs by combining automation with barcode scanning, RFID, demand forecasting, and cloud-based systems. With accurate, continuously updated records, teams can reduce overstocks and safety stock, coordinate cross-location transfers, and confidently answer availability questions. This unified approach helps procurement, allocation, fulfillment, and planning groups work from the same data, close information gaps, and resolve bottlenecks before they affect margins or service levels.

How Does Inventory Visibility Work?

Inventory visibility relies on connected systems that capture, process, and share companywide inventory data. Platforms such as warehouse management systems, ERPs, and point-of-sale software link hardware—such as sensors, barcode scanners, and RFID tags—can track products as they move through receiving, production, storage, picking, shipping, returns, and other stages of the supply chain. This continuous flow of information makes it possible to automate reordering, optimize pick paths, and quickly reallocate inventory to keep operations running smoothly.

On a day-to-day level, teams strengthen visibility in the following ways:

- Capturing accurate details upon receipt to maintain reliable data.

- Using inventory management software with enterprise-wide visibility.

- Using mobile scanners in warehouses and fulfillment areas to track movement in real time.

- Choosing inventory management methods (such as FIFO, LIFO, or ABC analysis) that fits your business model.

- Regularly auditing inventory through routine cycle counts.

Why Is Inventory Visibility Important?

Inventory visibility is central to business performance because it affects everything from customer satisfaction to cost control. It lets companies know what’s in stock, where it’s located, and how much is available. For retailers, this insight is critical to meeting omnichannel promises. For distributors and wholesalers, it supports better cost management and demand planning. And for manufacturers, it helps maintain steady access to the raw materials needed for production. In service sectors like healthcare or hospitality, it helps make sure critical supplies are always on hand when they’re needed most.

Despite its importance, many small businesses still rely on manual tracking or don’t track inventory at all. Or they rely on fragmented systems that create data gaps. That lack of clarity can lead to late shipments, excess stock, and resources tied up in materials that aren’t moving. In many cases, inventory tracking software can address these challenges and help lower costs.

Aside from on-time shipping, stronger inventory visibility can achieve the following:

- Maintain accurate counts across locations, channels, or facilities, giving teams reliable information to plan and serve customers.

- Highlight point out issues that cause delays, so adjustments can be made before they affect operations.

- Provide insight into which products or materials are moving fastest, and which may be trending down.

- Identify opportunities to lower carrying costs and reduce excess stock.

- Provide real-time information on orders and shipments to support reliable production schedules, delivery timelines, and customer commitments.

- Improve service levels by making the full range of products, supplies, and fulfillment options visible.

Inventory Visibility Components

Inventory visibility relies on six core components that work together to provide oversight and operational data across all facilities. For new systems, businesses often deploy these steps incrementally to minimize downtime and improve user adoption.

- Inventory tracking: Real-time tracking systems use barcode scanners, RFID tags, and internet-of-things (IoT) sensors to monitor products throughout the supply chain. In addition to sending automated updates and eliminating manual counting errors, some systems also monitor special storage requirements, such as temperature or humidity.

- Multi-location synchronization: Centralized systems coordinate inventory data across warehouses, production facilities, retail locations, distribution centers, and even in-transit shipments. Cloud-based synchronization gives users up-to-date information on stock levels and order status, whether they’re on the factory floor, in a warehouse, at a storefront, or working remotely.

- Inventory reconciliation: Automated validation tools can identify and address discrepancies between physical counts and digital records. Early detection helps companies maintain data integrity, reduce shrinkage, and spot damage or spoilage before it escalates.

- Automated alerts: Notification systems flag issues for stakeholders when predetermined metrics exceed acceptable ranges, such as when stock drops below thresholds, fulfillment times rise, or raw material levels risk interrupting production. Proactive alerts allow teams to address these issues before they cascade through operations.

- Mobile device access: Warehouse staff, production teams, and managers use smartphones, tablets, handheld scanners, and other mobile devices to check availability, update inventory records, approve transfers from anywhere. Mobile access keeps all teams working from current data, minimizing miscommunication and speeding up decisions.

- Reporting and analytics: Dashboards organize inventory data into accessible reports using metrics such as turnover rates, carrying costs, order accuracy, and sales or usage patterns. Analytical tools also support scenario modeling, helping managers uncover trends that may not be apparent from raw data alone.

What Are the Impacts of Poor Inventory Visibility?

Without inventory visibility, companies can lose track of what they have and where it is. That means products listed as available online are actually out of stock, frustrating customers with backorders or cancellations. It can also mean items marked “sold out” are sitting untouched on warehouse shelves, or raw materials are misplaced, delaying production schedules.

Inside the warehouse, teams without accurate data may waste hours searching for items or performing manual counts to reconcile records—inefficiencies that only compound as order volumes or needs rise. The result is higher labor costs, slower fulfillment, and lack of service continuity.

Poor inventory visibility also reduces margins and ties up working capital in unnecessary stock reserves or procurement orders that later lead to markdowns or dead stock. In production environments, it increases the risk of line stoppages and idle labor. Across industries, these breakdowns weaken relationships with both customers and suppliers, creating openings for competitors to pull ahead.

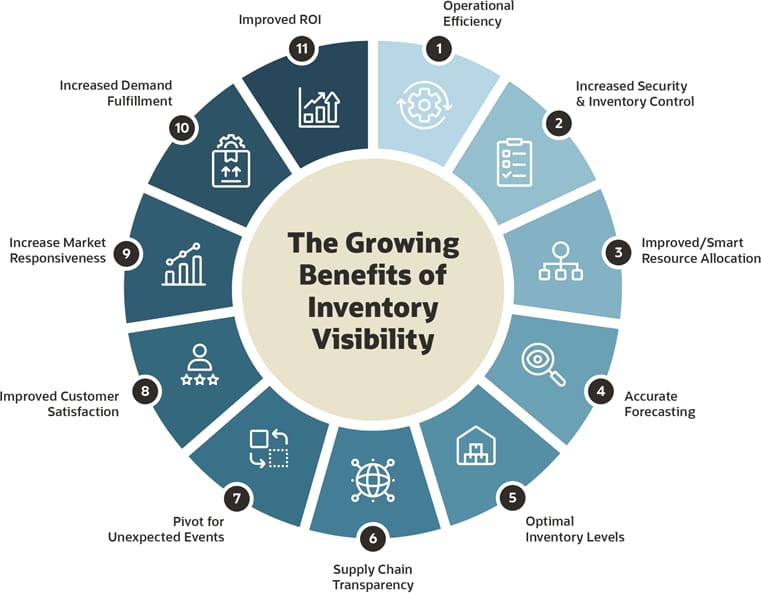

Benefits of Effective Inventory Visibility

Inventory visibility directly affects order fulfillment, production schedules, and financial performance. When a company knows how many stock keeping units (SKUs) it has and where they’re located—whether in a warehouse, production facility, distribution center, or with a third-party partner, it experiences a variety of benefits, such as the following:

- Operational efficiency: Time saved from otherwise spent searching for items, troubleshooting discrepancies, or responding to customer inquiries about delayed orders.

- Optimal inventory/stock levels: Accuracy prevents excess inventory that otherwise risks becoming obsolete inventory; instead, stockouts are promptly replenished.

- Increased security and inventory control: Inventory visibility and inventory control are crucial for highly regulated industries, such as chemicals, food, and pharmaceuticals, which require strict tracking of items and lots.

- Improved ability to meet demand: Good visibility means there are always enough popular items on hand to meet demand. Accurate information about fulfillment schedules improves the customer experience.

- Improved/smart resource allocation: Better visibility encourages inventory optimization by sending the right amount of stock to retail and ecommerce outlets.

- More accurate forecasting: Tracking inbound, outbound, and on-hand stock, as well as conducting regular stock audits, strengthens demand planning and purchasing decisions.

- Supply chain transparency: Customers want to know the status of their orders as they progress through the supply chain.

- Improved customer satisfaction: Better visibility on the back end identifies product and delivery problems before they reach the customer. Visibility also helps companies deliver more products to customers and meet fulfillment needs.

- Increased Market Responsiveness: Global, real-time data equips businesses with the knowledge needed to anticipate shifts in consumer demand.

- The Ability to Adapt to Unexpected Events: Businesses can more quickly adapt to trends and supply chain disruptions.

- Flexible Views: Some events require insights from historical and external data to prevent oversells and lost sales.

- Improved return on investment (ROI): Because inventory sitting in a warehouse represents tied up cash, visibility helps to hold the least amount of stock possible while still serving customer needs.

The Growing Benefits of Inventory Visibility

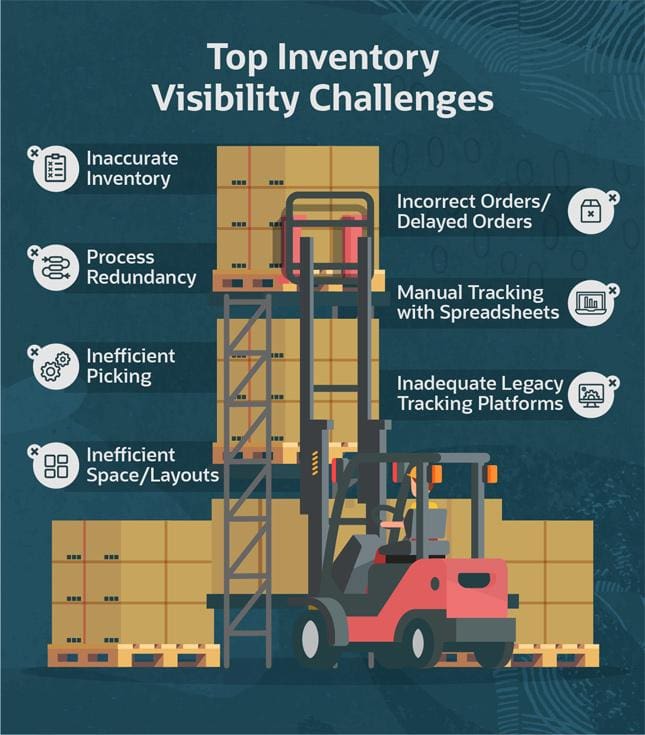

Top Inventory Visibility Challenges

Achieving inventory visibility requires overcoming technical and organizational barriers. Many businesses must work with legacy systems that struggle to provide real-time updates and manual processes that introduce errors and delays. Even companies investing in new technology face obstacles to integration, internal resistance to change, and scalability complications as order volume grows. These obstacles can delay returns on investment and prevent systems from delivering expected benefits.

Challenges to achieving accurate inventory visibility include the following:

- Unrecorded Changes: Undocumented inventory changes from theft or unreported breakage or spoilage hinder efficient planning and fulfillment.

- Manual Processes: Manual cycle counts and tracking in an age of barcodes and automated cycle counts is needlessly inefficient.

- Lack of Visibility: Inability to track and trace products across multiple ERP, SCM, and CRM applications internally and within the partner ecosystem can cause unnecessary delays and provide a poor customer experience.

- Reactive Management: When managers receive late notification of unplanned events, they can’t always use systems in place to respond.

- Uncertainty in Demand: Without visibility into inventory, businesses may deal with excess inventory and speculative ordering.

- Lack of Data: Managers who don’t have access to critical information when needed can result in lost sales, out-of-stocks, markdowns, and reductions.

- Deployment Issues: When managers lack quantity location and availability to deploy in the network across dimensions of time, geography, and demographics, they can make uninformed decisions.

- Out-of-Stock Items: Customers who can’t find what they want will likely substitute brands or make purchases from competitors.

- Loss in Productivity: When staff spend time tending to low-value data collection and manipulation efforts, they’re not focusing on their priorities and doing their work.

- Poor Planning: Lack of planning into stock levels, upstream and downstream, can lead to shortages, followed by overcompensation and excesses. These issues can result in an increased level of discounting and write-offs for slow moving and obsolete inventory.

- Inadequate Legacy Tracking Platforms: Older ecommerce platforms and enterprise resource planning (ERP) systems often don’t provide the real-time updates multichannel businesses need.

How to Improve Inventory Visibility

Tools and techniques that track goods throughout the supply chain can provide better inventory visibility. A company with capabilities for following its inventory from sourcing through delivery can help meet the rising customer demand for variety and fast, efficient service.

- Use RFID or Barcode Scanners: Scanning provides real-time updates as inventory moves from one location to another or within a building. These tools reduce labor costs for counting, increase inventory accuracy, and add quality control.

-

Advanced Tracking Systems: Using manual tools like spreadsheets and email to manage

multiple stock locations and sales channels and monitor a supply chain is all but impossible. Businesses need

digital tools to be successful.

- Add a Warehouse Management System (WMS): A WMS controls warehouse activities, from the overall layout and bin location to picking, packing, and cycle counting.

- Implement Inventory Management Software: This software manages activities in the supply chain that exist outside the warehouse. Managers also use the tool to help forecast future demand by gathering inventory data. However, implementing inventory management software that integrates with a WMS will provide more information about stock availability and its location. that integrates with a WMS will provide more information about stock availability and its location.

- Use an ERP platform: These robust platforms collect data and manage production, procurement, sales, accounting, inventory, and more. These tools help overcome supply chain disruptions and automatically adjust refill orders as stock levels change. ERP controls inventory across locations and channels, including cross-channel transfers. To become more proficient in ERP software, learn more about processes managed by ERP.

- Optimize Processes: Effective processes rely on complete data. Businesses use this information to maintain adequate inventory levels. Sticking to the plan, with only approved exceptions, allows for standards to gauge effectiveness.

- Automate Cycle Counts: Automating wall-to-wall and small-scale counts reduces labor costs and increases inventory and stock-level accuracy. Staff will have more time for money-making tasks like fulfilling orders. Automation also reduces secondary problems related to stock inaccuracies and indirect costs from data errors.

- Enhance Space Optimization: Improved warehouse layout reduces the time pickers spend searching for items and increases fulfillment accuracy.

- Implement a Distributed Order Management System (DOM/OMS): Order visibility for customers is essential, but so is visibility on the back end. DOMs provide a global view of all supply chain systems used to replenish orders. Order management systems (OMS) arrange orders in an efficient picking sequence.

5 Ways ERP Improves Inventory Visibility

To verify the inventory at all locations at any time, companies need reliable systems to track and manage it across the supply chain. ERP platforms offer this functionality and more.

The benefits of integrating ERP to increase inventory visibility include the following:

- Automates Processes: Automation reduces errors and increases efficiency, which means more revenue.

- Resolves Unforeseen Scenarios: ERP systems align inventory with production or consumer demand, no matter the circumstances. Consistency helps businesses stick to their inventory plan.

- Enhances Just in Time (JIT) Inventory: When companies order and receive products as needed, it reduces inventory carrying costs. Having the right amount of inventory, also known as just-in-time inventory, also helps minimize time wasted scrambling to handle shortages or excesses.

- Offer Actionable Insights: Managers can find global supply chain data and analytics on a single screen. Access to this information when they need it is crucial in making better business decisions.

- Supports Mobility: Cloud-based ERP means sales and customer service can work anywhere. Staff can continue to provide customers with up-to-date information about inventory and order details.

9 Questions to Ask to Help Make a Case for Inventory Visibility Software

According to a study from Gravity Supply Chain Solutions, only 15% of U.S. retailers have completed their supply chain digitization. These companies saw perceived costs and ROI concerns as primary hurdles.

Inventory visibility software provides transparency along the supply chain, improving customer service, forecasting, and overall operations. But how can managers make a case for investing in a digitized platform? The following nine questions can help:

- How many hours are spent each quarter taking inventory? How much could software limit that?

- How many hours might be saved with automated cycle counts?

- How many sales were lost due to lack of available inventory?

- Have online shoppers visited your brick-and-mortar store to find out an item was only available online?

- How much time does customer service spend answering questions about delayed orders or dealing with complaints about incorrect or damaged orders?

- What are the possible cost penalties of lacking traceability for recalled or defective products?

- Do stock arrivals require searching through files and emails for timely notifications?

- How much capital is tied up in stock with little demand?

- How would bottom lines improve with increased fulfillment accuracy?

The answers to these questions can create a solid case for investing in inventory visibility software.

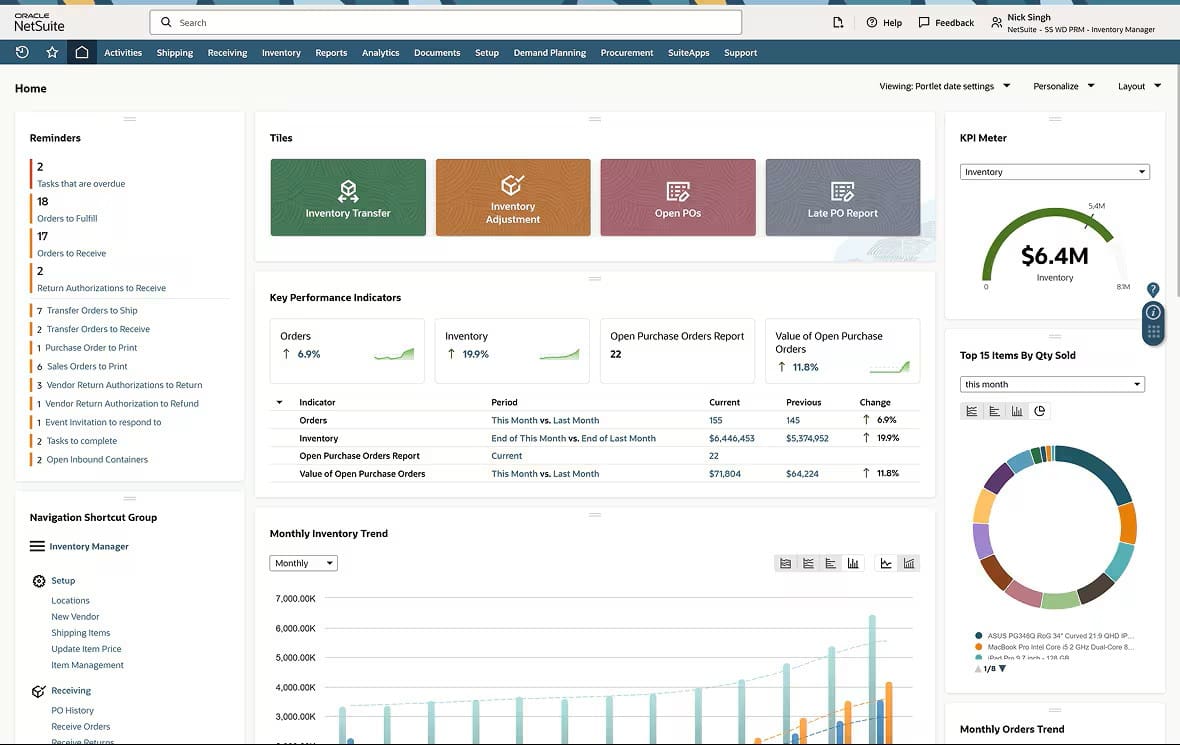

Enable Inventory Visibility With NetSuite

NetSuite Inventory Management provides real-time inventory visibility across locations, channels, and systems by centralizing company-wide inventory data from procurement through fulfillment. This unified ERP system combines warehouse management capabilities with order management, supply chain oversight, and financials to enhance transparency at every step. Mobile-optimized access allows warehouse staff to update inventory counts while sales teams process orders and managers assess performance metrics to improve operations—all from the same system’s role-based dashboards. With automated reorder points, built-in demand planning tools, and multi-location inventory controls, businesses can use NetSuite to reduce carrying costs and overhead without sacrificing service.

NetSuite’s Inventory Dashboard

Inventory visibility plays a core part in meeting demand and thriving in competitive markets. As businesses grow and introduce new sales channels and distribution models, traditional tools often lack the complexity to handle modern inventory data challenges. Inventory solutions combine automation, real-time tracking, system integration, and advanced analytics to help businesses manage rising material costs and meet increasingly stringent customer expectations. Whether they’re moving products or managing service-critical supplies, the right approach can minimize challenges like excess stock and operational inefficiencies to create competitive advantages that drive growth and profitability.

Inventory Visibility FAQs

What is a buffer inventory?

Buffer inventory, also called safety stock, is extra inventory businesses keep in reserve to protect against disruptions when demand spikes, supply is delayed, or forecasts miss the mark. By holding this cushion, companies reduce the risk of stockouts that can lead to lost sales, stalled production, or unmet service commitments.

How do you enable warehouse items in inventory visibility?

Businesses gain visibility into their warehouse items by cataloging goods, mapping floor layouts and bin placements, and integrating technology, such as barcodes or RFID tags. After coding items and assigning their locations, inventory management systems track their movement and status across facilities.

What is the 80/20 rule in inventory management?

The 80/20 rule, or Pareto principle, states that roughly 80% of outcomes come from 20% of inputs. In inventory terms, that means 80% of sales usually come from 20% of items. Businesses use this concept to focus their resources on high-value products—implementing tighter controls and frequent monitoring for best-sellers, while applying basic inventory management practices for lower-value inventory.

What are the four types of inventory?

The four main types of inventory are as follows:

- Raw materials: Production components procured from suppliers.

- Work-in-progress: Partially completed goods at various stages of production.

- Finished goods: Completed products ready for customers to purchase.

- Maintenance, repair, and operating (MRO) supplies: Items that support operations but aren’t sold like hard hats, repair parts, lubricants, etc.