Demand planning is a cross-functional process that helps businesses meet customer demand for products while minimizing excess inventory and avoiding supply chain disruptions. It can increase profitability, improve customer satisfaction, and lead to efficiency gains.

Demand planning should be a continuous process that’s ingrained in businesses. Fortunately, advances in technology have made accomplishing this possible as well as easier.

What Is Demand Planning?

Demand planning is a business process that predicts future product requirements based on anticipated customer demand. This forecasting also helps guide resource allocation as well as strategic and operational decisions about procurement, production, inventory management, logistics, and distribution.

Demand planning requires a comprehensive analysis of information best suited for specialized software and analytics tools. Internal sources include historical sales, marketing forecasts, promotional calendars, product lifecycle stages, and current inventory levels. External sources include macroeconomic conditions, consumer behaviors, competitive actions, and broader industry trends.

Key Takeaways

- Demand planning analyzes internal and external data to forecast future customer demand for a company’s products or services.

- This process helps companies optimize working capital by reducing excess inventory while avoiding stockouts.

- Demand planning requires input from sales, marketing, operations, finance, and supply chain teams.

- Advanced technologies, such as AI, can continuously update demand plans as conditions change.

Why Is Demand Planning Important?

Effective demand planning delivers both profit and customer satisfaction by helping businesses strike the right balance between sufficient inventory levels and customer demand. Achieving that balance can be difficult, especially since it requires coordination across an entire organization. But the business implications are significant, as excess inventory locks up working capital, adds inventory carrying costs, and increases the likelihood of remaining low-value or obsolete inventory. Alternatively, poor planning can result in avoidable supply chain disruptions and leave a company short on products, which can result in backorders, stockouts, or costly scrambles for raw materials. All of these issues can result in delays, which leads to dissatisfied customers.

Video: What Is Demand Planning?

Demand Planning vs. Demand Forecasting

Demand forecasting is part of the larger demand planning process tasked with analyzing internal and external data to accurately predict sales. Typically, forecasts cover the upcoming 18 to 24 months, but the forecast period can vary by product and industry. Companies may adjust those predictions frequently as they review the latest data and changes to market conditions. The demand forecast serves as the foundation for the overall demand planning process as the business determines how to fulfill expected sales.

Where Does Demand Planning Fit Within a Business?

The demand planning function requires input from and coordination between several departments, including sales and marketing, purchasing, supply chain, operations, production, and finance. Additionally, executives responsible for product portfolio management and overall business strategy play important roles by taking into account lead times for components and production times.

Since demand planning touches so many business functions, the location of responsible employees can vary: They may be part of an independent group or integrated into one of the departments listed above, as well as the procurement or operations departments. Some maintain that demand planning, especially the demand forecasting component, is most successful when closely linked to sales and marketing.

Key Components of Demand Planning

From data collection to scenario planning, demand planning is built on six main interconnected practices that collectively enhance processes for predicting demand and responding to sudden changes. Let’s examine each one.

-

Data collection:

Relevant information comes from all corners of the organization, with examples such as historical sales data and supply fluctuations, lead times for materials and production, current inventory levels, point-of-sale information, planned marketing campaigns, and market intelligence. Other examples include potential supply chain vulnerabilities, such as weather events or material shortages. All data should be standardized for consistent inputs and comparative analyses.

-

Data analysis:

Data analysis processes identify patterns, trends, and correlations within raw data sets. This step typically involves AI- and ML-powered mathematical analysis; it may also require additional cleaning and normalization steps to address inconsistencies leftover from the collection phase. Analysis should discard outliers and anomalies that could skew true demand drivers.

-

Forecasting:

Forecasting uses statistical models on analyzed data sets to predict future demand. The method chosen depends on product characteristics, market dynamics, and other factors. For example, forecasting a new fashion item with limited historical data might combine qualitative methods (like expert opinions) with advanced analytics (such as social media sentiment), whereas forecasting a staple product with years of stable sales data could employ simpler methods, like moving averages.

-

Inventory management:

Businesses are now ready to determine how much stock is needed across the supply chain, factoring for safety stock and other contingency plans. Effective inventory management relies on advanced systems that can monitor and update stock levels in real time and trigger reorders. These systems could also segment products based on demand patterns, financial impact, vendor reliability, and fulfillment times, applying different strategies to each category.

-

Demand sensing:

Demand sensing applies near-real-time data to spot sudden demand changes. While traditional forecasting methods primarily rely on backward-facing data, demand sensing incorporates up-to-date information from point-of-sale systems, Internet of Things (IoT) devices, distribution channels, internet traffic, and even weather forecasts to uncover new patterns that could significantly impact the company’s ability to align with demand accurately.

-

Scenario planning:

Scenario planning models potential outcomes in the event of a sudden market or behavioral change that could impact demand planning. By thinking through these hypothetical-yet-realistic scenarios ahead of time, businesses can develop contingency plans to mitigate risks or capitalize on opportunities. For example, a consumer electronics manufacturer might develop a scenario for a shortage of critical components, while a beverage company might prepare for an unexpected heat wave that increases demand for its cold drinks.

7 Key Steps for Successful Demand Planning

Demand planning is a multistep process that may involve further complications as the size and scope of the company or its forecasting efforts grow. Key steps include:

- Create a team: Assign clear roles and responsibilities to the members of the cross-functional demand planning team. For example, representatives from purchasing and supply chain groups may be responsible for acquiring enough inventory, at the right time, to meet the demand forecast. The finance team is often responsible for building the actual forecast.

- Define and aggregate relevant internal data: The various employees involved in demand planning should agree on what data used for development of accurate forecasts. The relevant data will vary by company but should include sales data by channel and location, out-of-stock rates, inventory turnover, lead times, production times, obsolete inventory, and other key inventory metrics. Check with sales and marketing teams about the timing of price changes, marketing campaigns, and promotions that could affect demand. Gather information from product teams about new launches, retirements, and competitive offerings, as all of those could impact forecast accuracy.

- Enhance the forecast with external data: External data is another crucial input for effective demand planning. This could be metrics around the recent performance and delivery timelines of suppliers and distributors or the latest purchasing habits of your key customers. Other external information includes overall economic conditions that may impact sales, specific product elements, or market shifts.

- Develop a statistical demand forecast: Collaboratively decide on the type of forecasting model (or models) that makes the most sense for the business, then start building it. This is best done with demand planning software, though some businesses still use Excel or other tools that require more time-consuming and error-prone manual work. Beyond companywide forecasts, consider building predictions by product or product line or for specific customers or regions.

- Challenge the demand forecast: Review, reanalyze, and refine the demand forecast with all key stakeholders. Add the most recent data to see if that has a substantial impact on predictions. Question any information that might be incorrect and remove unlikely outliers that could distort the overall forecast to understand the effects of doing so. It’s also a good time to double check that the demand forecast aligns with the company’s broader financial forecasts.

- Weigh forecasts against inventory: Determine how much inventory is needed to fulfill the predicted demand (cycle inventory), including a buffer of “safety stock.” Identify the necessary vendors to meet this demand and check in with them to make sure they can deliver the necessary products or services on your required timeline. Choose transportation vendors that can handle the volume and logistics needs for moving goods between locations.

- Measure results: Identify key performance indicators (KPIs) to measure the effectiveness of demand planning and set targets for each. A business may track sales forecast accuracy, inventory turns, fill rates, order fulfillment lead times, or cost of goods sold, for example. Continually review performance against these targets and make adjustments as necessary.

Skills for Demand Planners

Demand planners need excellent analytical skills, with competency in statistical data analysis and modeling. In addition to their numerical skills, the most successful demand planners are also great communicators given their interactions with many different departments.

They also tend to be innovators that champion progress through automation, since tools such as demand planning software and supply chain management software can help the company improve its demand planning, ultimately saving money. Demand planners should be familiar with ERP systems as a source of data, with the goal of eventually becoming power users for demand planning software.

Demand Planning Methods

At the broadest level, there are two philosophies that have been applied to demand planning: push and pull. The push method, which was popular for most of the 20th century, assumed that “if we build it, they will come.” Businesses took the approach that building innovative products would create demand for them, so they manufactured products, made them available to customers and waited for sales to roll in. In practice, the success of this strategy was hit or miss. Sometimes demand exceeded supply and shelves were bare, meaning a business missed sales opportunities. Other times, inventory lingered unsold on shelves or in warehouses, increasing costs and hurting cash flow. Companies rarely achieve the perfect balance, even with markdowns and sales.

Today, most demand planning processes use a “pull” philosophy. This starts with gauging customer demand and using that information to guide all other operational planning. The primary challenge of the pull approach is coming up with an accurate forecast of customer demand. Inaccurate forecasts result in the same problems as with the “push” method: missed revenue opportunities and higher costs.

Common models for creating a statistical forecast in the demand forecasting component of demand planning are:

- Moving average demand: This method assumes that future demand will be the rolling average of the last few sales periods.

- Linear regression: This method takes previous demand levels and puts them through a least-square regression statistical model to predict future sales. This model, sometimes called the “line of best fit,” plots a curve based on previous demand, and extends that curve to predict future demand.

- Seasonal trends: As its name implies, the seasonal trends method predicts future demand based on historical sales during particular months or seasons. This method is most appropriate for companies whose sales are highly seasonal.

- Sales forecast: This method estimates future demand based on sales opportunities and probabilities identified by the company for an upcoming period.

Businesses often use demand planning software in conjunction with these methods to automate certain aspects of modeling and forecasting. Advanced software can also make for more robust and accurate demand forecasts.

Challenges in Demand Planning

Even with sophisticated tools and well-designed processes at their disposal, demand planners could face some obstacles that undermine demand planning accuracy. The most common barriers include:

- Market disruptions: Inclement weather, natural disasters, health crises, geopolitical turmoil, and rapid economic shifts can significantly alter demand with little warning. These situations require quick responses that employ scenario-planning contingencies and real-time information to mitigate losses.

- Internal misalignment: When internal business departments operate in silos or have unchecked biases, they develop conflicting objectives that don’t account for each other’s priorities. This misalignment can lead to resource imbalances, creating surpluses in some areas while demand outpaces supply in others.

- Data gaps and data quality: According to a 2024 survey of finance practitioners, the top three demand forecasting and planning challenges are all related to data: lack of a single trusted data source, data complexity, and inconsistent data definitions. Indeed, fragmented systems, inconsistent data-collection practices, and limited market visibility can all compromise forecasts and impede inventory and production decisions.

- Market complexity: Evolving market conditions, such as the rise of ecommerce, have changed consumer preferences, shortened product lifecycles, increased competition, and expanded sales channels, all of which make for more volatile and hard-to-predict demand. This is especially challenging for businesses with many SKUs and product variations that require granular forecasting approaches.

Demand Planning Best Practices

Because the demand planning process is complex, best practices generally focus on increasing accuracy through collaboration. Some of these best practices include:

- Get buy-in and demand accountability from all stakeholders by relying on both statistical modeling and collaborative forecasts that pull in data from various departments.

- Have accurate inventory data. You can’t have successful demand planning without efficient, precise inventory management.

- Include information from the supply chain, weather events and natural disasters, market shifts, and consumer buying behavior in your forecasts, a process sometimes referred to as “demand sensing.”

- Actively shape demand with marketing, promotion, and pricing tools.

Another key best practice is to do your due diligence when choosing demand planning software. Software should automate tasks such as statistical analysis for forecasting, tracking KPIs, and calculating optimal stock levels, allowing your team to focus on interpreting the results, collaborating with other groups, and adjusting plans as necessary. Your software should be easy to use, intuitive, and integrate with your inventory management and ERP systems.

The Future of Demand Planning

Advances in demand planning software continue to enhance the accuracy of company forecasts. For example, software can connect to point-of-sale data and pull information from suppliers and distributors, enabling businesses to incorporate real-time data into their planning and analysis.

AI and machine learning are also becoming commonplace in demand planning strategies. These technologies go beyond simply forecasting demand to automatically adjust supply chain operations based on real-time data from diverse and often unorganized data sources, such as social media posts and IoT devices. Another advantage: AI and ML learn from this constant flow of information to continuously update forecasts.

Many demand planning models now incorporate “digital twin” technology to visualize and test supply chains under various potential scenarios, assessing how the effects will ripple across operations. Planners use these tools to run complex what-if analyses and stress tests before implementing real-world changes.

Additionally, cloud-based collaborative platforms that connect all stakeholders in a shared planning ecosystem are becoming more widely adopted by businesses of all sizes. These systems also customize and track critical metrics and feedback across the organization to help leaders balance financial performance with other priorities that their customers demand, such as environmental impact or supply chain traceability.

Ditch Manual Demand Planning With NetSuite

Manual processes waste time, introduce errors, and use outdated information, leading to demand plans focused more on yesterday’s customers than tomorrow’s. NetSuite’s ERP solution transforms demand planning by automating companywide data collection and analysis through integrated inventory, sales, and supply chain modules. The cloud-based platform’s built-in forecasting tools combine historical data with seasonality patterns, growth trends, and product-specific insights to predict demand more accurately than is possible with traditional spreadsheets or disconnected legacy systems.

Customizable, role-based dashboards provide every team member with access to the same real-time data, thereby eliminating information silos. When market conditions change and demand shifts, NetSuite automatically updates forecasts and alerts relevant stakeholders, which considerably shortens reaction time. Companies also have access to real-time inventory data that help ensure products are available when and where customers want them, even as the business scales and expands its offerings.

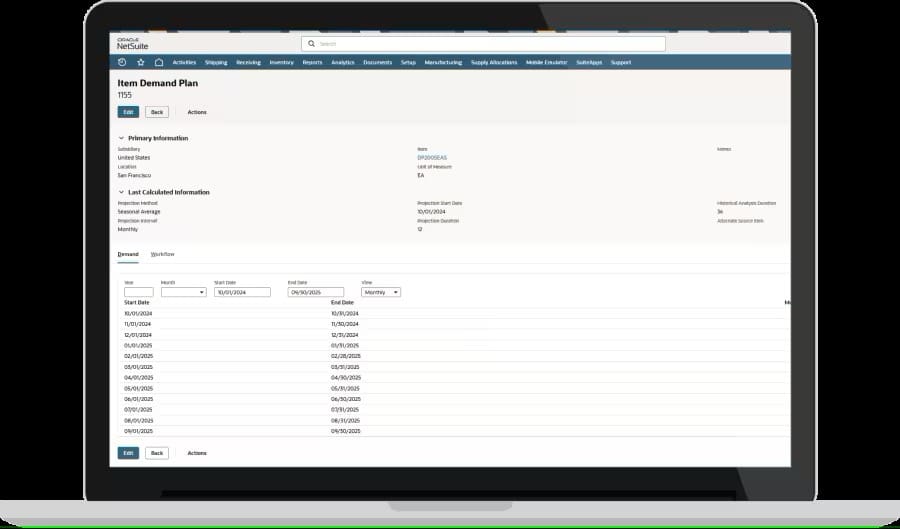

NetSuite’s Demand Planning Dashboard

Demand planning has evolved from running a simple forecast to conducting a detailed analysis of a business’s entire supply chain and customer base. By integrating demand planning across departments, businesses can continuously bring in new companywide data to refine their processes and balance inventory levels with expenses, ultimately reducing tied-up capital and carrying costs without sacrificing customer satisfaction. As markets and consumer expectations continue to shift, many companies leverage sophisticated demand planning platforms to gain greater responsiveness, seize new revenue opportunities, reduce waste, and better allocate resources. These tools, paired with accepted best practices, allow businesses of all sizes to pull ahead of the competition and build a more sustainable approach to predicting and exceeding customer expectations.

Demand Planning FAQs

What is the difference between demand planning and supply planning?

Demand planning focuses on predicting customer purchasing plans, then adjusting strategies, operations, and resource allocation to meet those predictions. Supply planning is a combination of a business’s production, procurement, and distribution strategies to make sure enough resources are available to fulfill those forecasted needs. Together, these processes form the basis of a company’s sales and operations planning process.

What are the 3 requirements for there to be demand?

For an offering to have real demand, customers must want the product or service, have the ability to pay for it, and have the authority or permission to make the purchase. Without all three elements, potential demand is purely theoretical and may not translate into real sales.

What is an example of demand planning?

Here’s a straightforward example of demand planning: A retailer analyzes two years’ worth of sales data to find that swimwear sales increased 300% during the three months leading up to the summer. To meet anticipated future demand, the company orders 30% more inventory than it did last year and hires additional sales staff to keep shelves stocked and customers satisfied.

How does demand planning work?

Demand planning predicts future demand by applying statistical models and trend analysis to historical sales data, market trends, and business intelligence. This process typically involves cross-departmental collaboration and advanced software that crunches the numbers and identifies new or emerging patterns.

What does demand planning impact?

Demand planning has a direct impact on inventory availability, production schedules, procurement decisions, warehouse space allocation, and transportation requirements throughout the supply chain. It also influences a business’s financial performance through improved working capital management, reduced carrying costs, and increased revenue and customer satisfaction from fewer stockouts and more reliable delivery.