Learn everything you need to know about inventory management KPIs and metrics, including when to use them, formulas and the difference between sales, receiving, operational and employee KPIs. Experts offer advice and tips for your success.

What Is a KPI in Inventory Management?

Key performance indicators (KPIs) in inventory management are metrics that help you monitor and make decisions about your stock. In inventory management, KPIs matter because they offer information about turnover, sales, demand, costs, process success, relationships and more.

You can easily track KPIs using inventory management systems. KPIs in inventory management systems can show progress, where processes need work or where they find success.

How Do You Measure Inventory Management?

Businesses assess inventory management using different metrics for different business operations. Categorizing KPIs by operation type lets leaders focus on areas in need of change. By discovering problem areas, leaders can implement process adjustments and track their improvement. These types of metrics are:

Inventory Metrics: Sales KPIs

You can use sales metrics to better compete in the marketplace and help your sales team to win deals and collaborate. Set up these KPIs to mesh with organizational goals, and use them to optimize the sales teams’ performance.

1. Inventory Turnover Rate

Also known as inventory turnover ratio or inventory turn, inventory turnover rate is the number of times a company sells and replaces its stock in a period, usually one year.

You can use the inventory rate to determine if a business has too much inventory compared to how much of its stock is selling. Inventory rate measures how well a company makes sales from its inventory. Use this formula to calculate inventory turnover rate:

Inventory turnover rate = cost of goods sold / average inventory

2. Days on Hand

Days on hand (DOH), also known as the average days to sell inventory (DSI) or average age of inventory, is the rate of inventory turns by day. This daily interval is the most common timeframe after an annual range. Use this formula to calculate days on hand:

Days of inventory on hand = (average inventory for period / cost of sales for period) x 365

3. Weeks on Hand

Weeks on hand demonstrates the average amount of time inventory sells per week: a high weeks on hand measure shows inefficient movement, while a low weeks on hand rate shows efficient inventory movement. Use this formula:

Weeks on hand = (average inventory for period / cost of sales for period) x 52

4. Stock to Sales Ratio

Stock to sales ratio is the measure of the inventory amount in storage versus the number of sales. This broad calculation can be used to adjust the stock to maintain high margins. Use this formula:

Stock to sales ratio = $ inventory value / $ sales value

5. Sell-through Rate

Sell-through rate is a comparison of the inventory amount sold and the amount of inventory received from a manufacturer. This helps demonstrate the efficiency of a supply chain. Here is the formula to calculate sell-through rate:

Sell-through rate = (# units sold / # units received) x 100

6. Backorder Rate

Backorder rate is a measurement of the number of orders a company cannot fulfill when a customer places an order. It shows how well a company stocks in-demand products. Calculate the backorder rate with this formula:

Backorder Rate = (# delayed orders due to backorders / total # orders placed) x 100

7. Accuracy of Forecast Demand

Accuracy of forecast demand, also known as the demand forecast accuracy, is a percent of how close the actual on-hand quantity is to the forecast. It checks on what a company forecasted, ordered and sold in the prior period. Use this formula to calculate the accuracy of forecast demand:

Accuracy of Forecast Demand = [(actual – forecast) / actual] x 100

8. Rate of Return

Rate of return (ROR), also called the return on investment (ROI), is a percentage that shows the profit on an investment over a period. This percentage is a proportion of the original investment and usually expressed for a year. Calculate the rate of return with this formula:

Rate of return (ROR) = [(final value – initial value) / initial value] x 100

9. Product Sales

Product sales, also known as sales revenue, is the income from customer purchases minus any returns or canceled sales. This metric is normally reported for a standard period, such as a month or year. Use this formula to calculate product sales:

Product sales = gross sales revenue – sales returns – discounts – allowances

10. Revenue per Unit

Revenue per unit is how much one unit of product is worth. This metric is particularly helpful for subscription-based businesses. Calculate revenue per unit with this formula:

Revenue per unit = total revenue for period / average units sold for period

11. Cost per Unit

Cost per unit is how much a single unit of product costs a company to produce or buy. It is best used in companies that manufacture or sell large amounts of the same product. Use this formula to calculate cost per unit:

Cost per unit = (fixed costs + variable costs ) / # units produced

12. Gross Margin by Product

Gross margin by product is the amount of money a company keeps per dollar of sales. This metric removes any costs from producing the item. Calculate gross margin with this formula:

Gross margin = [(net sales – cost of goods sold) / net sales] x 100

13. Gross Margin Return on Investment

Gross margin return on investment (GMROI) shows how much a company made compared to how much it invested in stock purchases. This metric measures how efficiently a company buys and sells its products. Use this formula to calculate gross margin return on investment:

Gross margin return on investment = gross margin / average inventory cost

Inventory Metrics: Receiving KPIs

Receiving KPIs, also known as warehouse KPIs, may overlap with operational KPIs, especially in regard to storage. Receiving KPIs are specific to the process of bringing in, receiving and immediately dealing with inventory.

14. Time to Receive

Time to receive is the rate at which staff bring in and prepare to sell new stock. This KPI measures the efficiency of a company’s stock receiving process. Use this formula to calculate time to receive:

Time to receive = time for stock validation + time to add stock to records + time to prep stock for storage

15. Put Away Time

Put away time is the amount of time it takes for a company to stow inventory. Chronologically, the actions that determine put away time follow those that determine time to receive. With increased efficiencies in this metric, lead time decreases. Calculate put away time with this formula:

Put away time = total time to stow received stock

16. Supplier Quality Index

Supplier quality index (SQI) aggregates and weighs a vendor’s performance in important areas such as material quality, corrective actions, prompt reply, delivery quality, quality systems and commercial posture. This is the broadest metric companies can assign to their vendors.

Most companies prefer to report monthly weighted scores, then calculate SQI for an annual average. This is one example of a formula to calculate weighted supplier quality index:

Supplier quality index = (material quality x 45%) + (corrective action x 10%) + (prompt reply x 10%) + (delivery quality x 20%) + (quality systems x 5%) + (commercial posture x 10%)

Inventory Metrics: Operational KPIs

Operational KPIs show how well your business is running. Improved internal business processes and metrics lead to more satisfied customers.

17. Lost Sales Ratio

A lost sales ratio is the number of days a specific product is out of stock compared to the expected rate of sales for that product. It indicates when a company runs too lean on its stock. Use this formula to calculate the lost sales ratio:

Lost sales ratio = (# days product is out of stock / 365) x 100

18. Perfect Order Rate

Perfect order rate is a measurement of how many orders a company ships without any issues, such as damage, inaccuracies or delays. Every company aspires to 100%. This metric leads to excellent customer satisfaction and denotes an efficient company. Use this formula to calculate perfect order rate:

Perfect order rate = [(# orders delivered on time / # orders) x (# orders complete / # orders) x (# orders damage free / # orders) x (# orders with accurate documentation / # orders)] x 100

19. Inventory Shrinkage

Inventory shrinkage is the amount of inventory a company should have on-hand but cannot account for. The company lists these products for sale but either doesn’t have or cannot sell them. Shrinkage usually results from theft, damage, miscounts or fraud. Calculate inventory shrinkage with this formula:

Inventory shrinkage = ending inventory value – physically counted inventory value

20. Average Inventory

Average inventory is the amount of inventory a company has on-hand during a period. The goal is for companies to keep their average inventory consistent over the course of a year. Calculate average inventory with this formula:

Average inventory = (beginning inventory + ending inventory) / 2

21. Inventory Carrying Cost

Inventory carrying cost, also known as holding costs or the cost of carrying inventory, is the percentage of the total value a company pays to maintain inventory in storage. The costs include warehouse, insurance, rent, labor and any unsellable products.

The total cost depends on which products a company carries, the number of SKUs, the storage location, the inventory turnover rate and whether the company used a third-party fulfillment company.

Calculate inventory carrying costs with this formula:

Inventory carrying costs = [(inventory service costs + inventory risk costs + capital cost + storage cost) / total inventory value] x 100

22. Customer Satisfaction Score

Customer satisfaction score (CSAT) is a measure of the level of customer happiness with the product and the company. Customers rate the product and company on a scale with a short survey. Use this formula to calculate the customer satisfaction score:

Customer satisfaction score = (# positive responses / # total responses) x 100

23. Fill Rate

Fill rate, also called line fill rate, is a measure of all portions of the supply chain, including the order fill, line fill and unit fill. This important metric helps companies monitor order fills and line fills.

Use this formula to calculate fill rate:

Fill rate = [(# total items – # shipped items) / # total items] x 100

24. Gross Margin Percent

Gross margin percent is the portion of the selling price that is gross profit. This metric describes the level of profits. Calculate gross margin percent with this formula:

Gross margin percent = [(total revenue – cost of goods sold) / total revenue] x 100

25. Order Cycle Time

Order cycle time (OCT), also known as order timeliness, is the average time it takes for a company to fulfill a customer order. It demonstrates how well companies meet demand, including shipping readiness, shipping and delivery. Calculate order cycle time with this formula:

Order cycle time = (time customer received order – time customer placed order) / # total shipped orders

26. Stock-Outs

Stock-outs, also known as out-of-stock items, is the percentage of items not available in inventory when a customer places an order. This metric shows a company’s ability to meet customer demand. Companies hope to keep this percent low. Use this formula to calculate stock-out rates:

Stock-outs = (# items out of stock / # items shipped) x 100

27. Service Level

Service level in the context of inventory management is a metric that addresses the percentage of customers who do not experience stock-outs. Use this metric to balance excess inventory costs and stock-out costs resulting from having too much and not enough inventory to fulfill orders.

It also helps companies account for the challenges of the supply chain, customer demand and stock rotation. Use this formula to calculate service level:

Service level = (# orders delivered / # orders received) x 100

28. Lead Time

Lead time is the time it takes for a customer to receive a product after they order it. This KPI measures the efficiency of the entire supply chain or business. Use this formula to calculate lead time:

Lead time = order process time + production lead time + delivery lead time

29. Dead Stock/Spoilage

Dead stock is inventory no one wants to buy. When the company cannot sell the remaining inventory after a time, the stock is “dead.” Spoilage is the same concept, but for fresh items such as expired food.

This stock may be a write-off because of its diminished value. The percentage of stock that is dead stock is an important metric because it indicates the company’s viability. Companies with more than 25-30% dead stock are not competitive. Before calculating, determine the point at which you’ll consider stock dead or spoiled. For example, at the end of a season, some unsold inventory may be considered dead. Calculate dead or spoiled stock rates with this formula:

Dead/spoiled stock = (amount of unsellable stock in period / amount of available stock in period) x 100

30. Available Inventory Accuracy

Available inventory accuracy relates to the company’s stock status. This KPI shows the difference between the number of items the company claims in electronic records and what is on the shelf for sale. The physical inventory count confirms the electronic file totals. The difference can be due to theft, breakage, fraud and loss. Use this formula to calculate available inventory accuracy:

Available inventory accuracy = (# counted items that match record / # counted items) x 100

31. Internal Warehouse Management System (WMS) Efficiency

Internal warehouse management system (WMS) efficiency is the return on investment (ROI) for a company’s internal inventory management system. A good time to measure this is after the staff has become comfortable with the system.

ROI includes profit and loss resulting from the purchase of the software and any required hardware, unrecognized gains (e.g., saved data entry time), and new opportunities (e.g., customers the business could not have served before). Each of these categories can include many factors; the company should decide which data goes into its own ROI measurements. Use this formula to calculate internal WMS efficiency (ROI):

Internal WMS efficiency (ROI) = (gain on investment – cost of investment) / cost of investment

Inventory Metrics: Employee KPIs

Also called labor KPIs, employee KPIs measure staff performance. The better the outcomes for employee KPIs, the better your business performs overall. Greater employee productivity and effectiveness means you can pass savings on to customers.

32. Labor Cost per Item

Labor cost per item, also known as unit labor cost, is how much a company spends to produce one unit of product. This metric includes workers’ wages and any additional costs of moving a product through production to sell. Calculate labor cost per item with this formula:

Labor cost per item = # total units / total labor expense

33. Labor Cost per Hour

Labor cost per hour is how much an employee costs the company on an hourly basis. This KPI reminds employers to make better use of their employees’ time.

For example, based on employees’ salaries, you might calculate how much an hour-long, company-wide meeting costs and consider whether it is worth spending that money accordingly. Use this formula to calculate labor cost per hour:

Labor cost per hour = (employee annual gross salary / # weeks employee works in a year) / # hours an employee works in a week

How to Choose the Right Inventory Management KPIs

Choose the right inventory management KPIs—ones that are specific, measurable, achievable, relevant and timely (SMART) to your business. Only spend time on KPIs that move your business toward its strategic goals.

Other Factors to Consider for Inventory Management KPIs

When developing KPIs, it is essential to target them narrowly to the business unit. Sometimes, new measures can feel overwhelming to staff. Consider selecting a few KPIs per area to start. Work with department managers to understand:

- How job tasks will change.

- Whether the metric will increase effectiveness, not just efficiency.

- How can staff act upon the insights you learn from the metrics.

- How KPIs could affect staff competition or collaboration.

- Whether the KPIs align with the company’s mission, goals and objectives.

- Whether the metric measures what you want to know.

- Whether the metrics apply to areas that need real improvement.

- Whether the chosen KPIs are dynamic. Always look for ways to improve.

Inventory Metrics Best Practices

Inventory metrics best practices always start with measuring the right elements. The goals for each parameter should be within reach, not pie-in-the-sky projections. Stretch goals should not be part of KPIs. Each functional area should have no more than 5–7 metrics.

Additional Best Practices for KPIs

Once the KPIs have been established, it is important to set staff up for success. Make sure they understand what the goal is, where you want to be and give them the tools to get there successfully. Don’t set goals that aren’t attainable or that don’t have a clear path to success. Before rolling out new KPI metrics to functional teams you must:

- Define and document the metrics.

- Get employee buy-in on the measurement of metrics, their performance and possible outcomes.

- Train the team that will use the metrics.

- Ensure the team processes support the metrics.

- Create benchmarks to target. Adjust as necessary. Set up a review schedule for the outcomes.

- Develop a dashboard to show the metrics and their progress.

Benefits of Inventory KPI and Metrics

Inventory metrics and KPIs are beneficial because they set up a method to measure and achieve progress in a company. Without measurements, companies can’t set or meet goals. Appropriate KPIs direct behavior, productivity and decision-making.

Other benefits inventory metrics and KPIs can provide:

- Increase sales and revenues.

- Make the business financially competitive.

- Improve customer relations and satisfaction.

- Enhance the company’s reputation.

- Improve productivity for employees and operations.

- Reduce operating costs.

- Eliminate supply chain issues.

- Connect inventory management to company strategy and goals.

- Ensure marketing and merchandising are effective.

How to Track Inventory Management KPIs

Track inventory management KPIs in an orderly, efficient manner. Use dashboards that can automatically pull from data systems, not manual sorting, calculating and reporting. Inventory management software tracks and reports metrics for stock across the company.

Use NetSuite Inventory Management Software to Simplify KPIs and Metrics

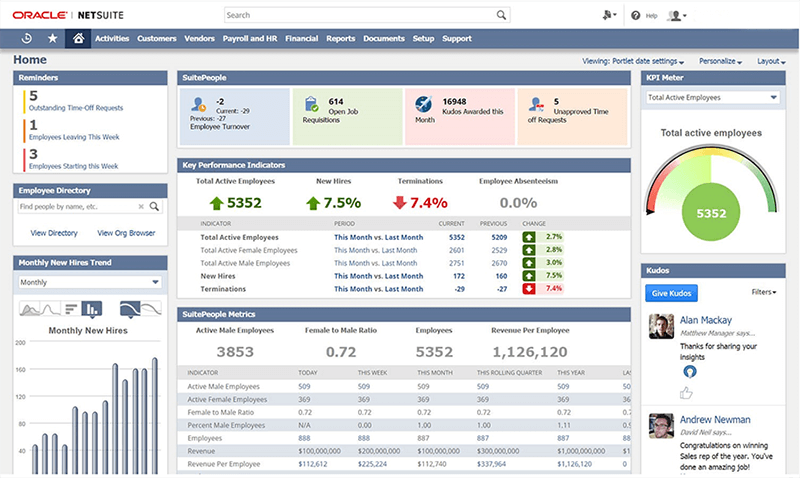

Monitoring inventory KPIs is essential for tracking the health of your business. That’s why it’s crucial to have an inventory management tool that can power a KPI product dashboard and show changes in real time.

A robust inventory management system will calculate costs like revenue per unit, cost per unit, gross margins by product and labor cost per item—to name a few. The software should also track stock issues problems and stocking and delivery times. NetSuite’s real-time dashboards provide you with business intelligence from a single system of record across all areas of your company—from accounting and sales to fulfillment and support.

Increase Sales & Revenue

with Inventory Management