Procurement processes are integral to virtually every business. Whether for sourcing raw materials, machinery, technology consulting services or employee training, companies rely on goods and services from external suppliers to grow and meet their strategic objectives. An efficient procurement life cycle helps organizations obtain the right goods and services at the right time while minimizing unnecessary costs. This comprehensive breakdown of the procurement life cycle and its implications can pave the way for your company’s success, including the steps to take and best practices for managing procurement.

What Is the Procurement Life Cycle?

The procurement life cycle refers to all the steps involved in obtaining goods or services for your business. When designing the procurement life cycle, procurement management aims for efficiency — in terms of both speed and cost-effectiveness. An efficient procurement life cycle ensures that critical goods and services can be obtained with minimal delays, which in turn reduces costs.

Another major benefit for businesses that nail their procurement life cycle is improved customer relationships, because obtaining the right supplies at the right time helps companies reliably deliver their products to customers. For instance, major ecommerce marketplaces have built a reputation for quickly and reliably sourcing the products their customers need, which has helped them gain market share.

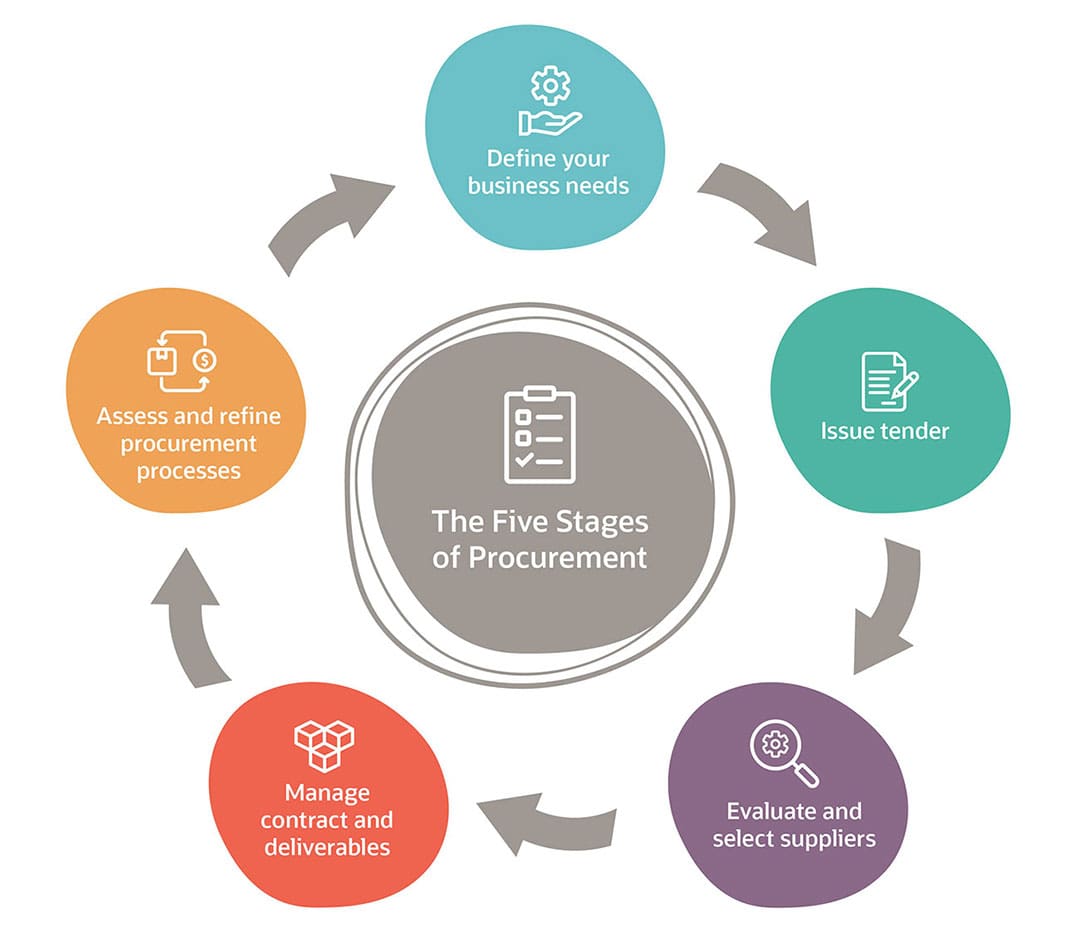

The procurement life cycle has many steps, but these steps can be grouped into five broad stages:

- Define and specify business needs.

- Invite suppliers to submit bids (a process known as “tendering”).

- Evaluate and select suppliers.

- Manage contract and deliverables.

- Assess and refine procurement processes.

Businesses may procure a wide range of goods and services, ranging from critical manufacturing machinery to day-to-day office supplies and consulting services. Procurement activities are typically grouped into the following categories:

Direct procurement refers to obtaining goods or materials that are used to make the company’s products and directly drive profit for your business. These include raw materials for manufacturing, such as the silicon wafers used by a semiconductor company. It also includes the purchase of products for resale, as well as the technologies or machinery a company uses to develop its goods or services, such as the factory robots used by a car manufacturer.

Indirect procurement is the purchase of goods or services that are critical to your company’s daily operations but do not directly contribute to its bottom line. In fact, many of these costs, like maintenance fees, office overhead and travel expenses, eat into the bottom line, which makes the efficiency of the indirect procurement life cycle even more important.

Services procurement refers to securing people-based services. These can range from third-party contact centers to on-site contingent labor or security services. Another example: hiring someone with the specific expertise needed for a major business challenge, such as an implementation partner hired to help with the challenges of implementing a new ERP platform. Services procurement can incorporate direct as well as indirect procurement.

Key Takeaways

- The procurement life cycle encompasses all the steps involved in procuring goods and services from external suppliers.

- An efficient life cycle is crucial to ensuring that the company obtains the goods and services it needs at the right time, while minimizing cost.

- Steps in the procurement life cycle range from defining business needs and selecting providers to managing contracts and supplier relationships.

- Supply chain and inventory management software can help companies trim time, costs and human error at multiple stages of the procurement life cycle.

Procurement Life Cycle Explained

The purpose of procurement is to source the goods and services your organization needs in order to operate efficiently and serve customers as well as possible. Effective procurement achieves these goals while minimizing unnecessary costs and delays. The balance of speed, efficiency and cost will vary from one company to the next. For instance, a luxury goods brand cannot afford to compromise on materials if it wants to maintain customers’ trust, whereas a discount retailer might focus on speed of product delivery to customers in lieu of quality when faced with time pressures.

The procurement life cycle encompasses all the steps involved in obtaining goods and services, from defining your business needs to soliciting bids, awarding contracts and managing supplier relationships. At many companies this is a dynamic, continuous cycle. Some steps overlap, and some depend on other departments — for example, purchasing decisions may be determined by budgeting priorities dictated by finance teams.

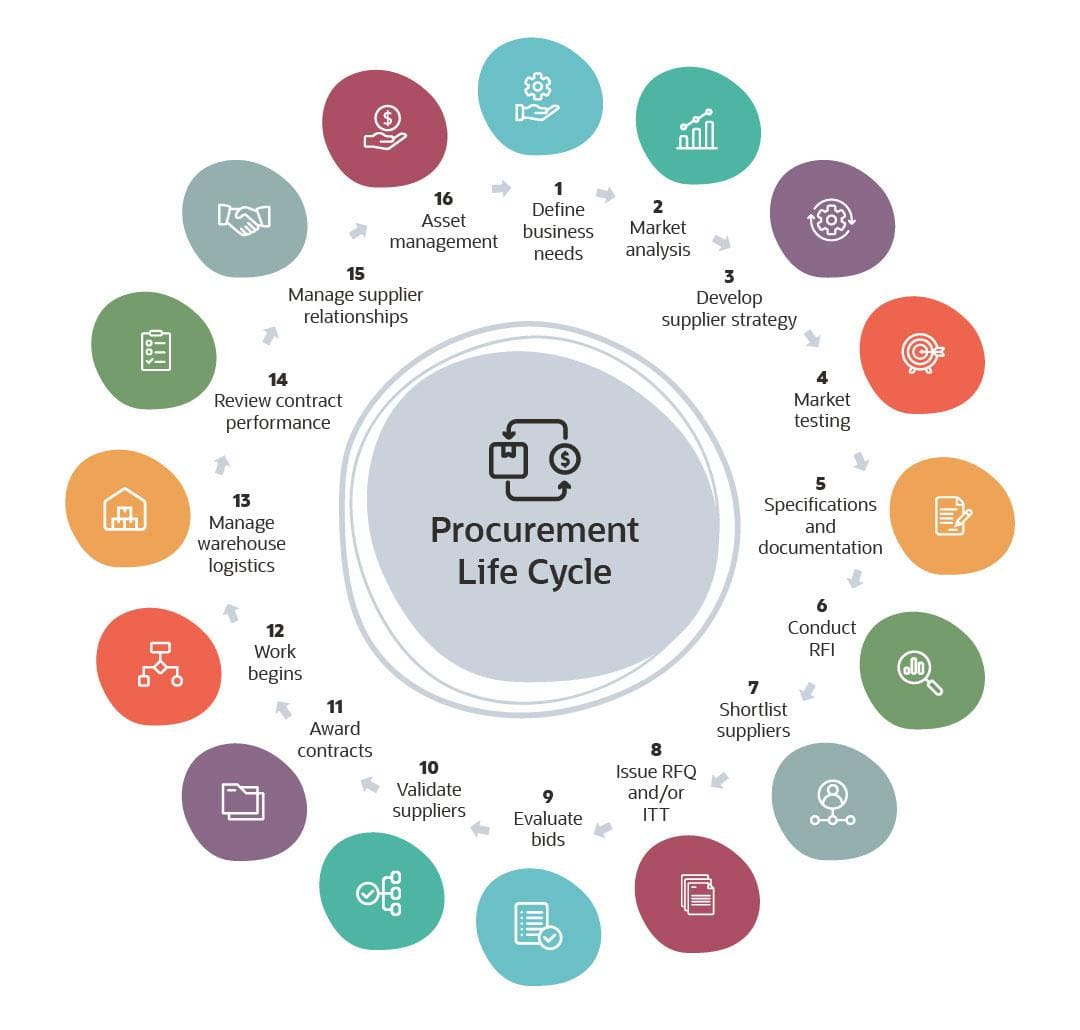

16 Steps in the Procurement Life Cycle

Though details of the procurement life cycle vary from company to company, many of the steps are common to different businesses and industries. Some companies are able to decrease the number of steps once they’ve built up a reliable network of trusted suppliers, allowing them to skip some tendering and supplier validation processes. Consider, for example, a high-end furniture company that orders its fabrics from the same short list of textile manufacturers every time, thus eliminating the need to validate its suppliers before procuring new raw materials. Here are 16 typical steps in the procurement life cycle.

-

Define your business needs.

Defining clear criteria will help you choose a solution that meets every one of your company’s needs. It is important to involve multiple stakeholders in this initial request of the procurement life cycle — from the employee to who initiates the request for the item — as this helps ensure their buy-in when the time comes to choose a supplier in their purchase request. New business initiatives often drive new procurement needs: A growing business may require a new technology provider to support increasingly complex requirements, or it might be launching a product line that requires procurement managers to source an entirely new range of raw materials and machinery.

-

Perform a market analysis.

Once your needs are clearly defined, conduct a market analysis to see what’s available and to get an idea of costs. This exercise serves as both a validation of your needs and a cost-benefit analysis. Some companies may even decide to develop the goods or services in-house if the costs are prohibitive.

-

Create a supplier strategy.

Develop an overall strategy for acquiring what you need, taking into account market availability and primary types of suppliers. Leverage is a powerful force in establishing supplier relationships. For instance, your company’s orders might represent a large proportion of a small supplier’s revenue, giving you leverage to negotiate more favorable rates.

-

Perform pre-procurement market testing.

It can be useful to test what the market really offers by initially acquiring small amounts of your needed supplies. This helps determine whether you should change anything in your procurement plans. Supply chain outages, geopolitical tensions and competitor activity can all have a significant effect on your ability to purchase what you need.

-

Develop specifications and documentation.

Dive deeper into the details of your business’s needs to create clear specifications for external suppliers. As with the first stage of the procurement life cycle, it is essential to involve relevant stakeholders to ensure that the specifications cover every aspect of the required quality, quantity and capabilities.

-

Conduct an RFI.

A request for information, or RFI, is a call for suppliers to share information about their business and solutions. Business details might include their history, financials and relevant case studies that demonstrate their ability to meet your needs. Solution details should include information such as product performance, capabilities and differentiators.

-

Shortlist suppliers to participate in tender.

After reviewing the RFI responses, you can create a shortlist of suppliers that meet your requirements. Some companies even complete a preliminary ranking of suppliers at this stage, based on their capabilities. Think about your future requirements, as well as your current needs, when creating a shortlist, as the suppliers you choose may eventually become long-term partners. To build a strong and mutually beneficial relationship, choose partners that are accountable, trustworthy and communicate well, in addition to meeting your technical requirements.

-

Issue tender documentation (RFQ or ITT).

The time has come to get specific proposals from relevant suppliers, using a request for quote (RFQ) or invitation to tender (ITT). An RFQ is a document sent to a shortlist of suppliers in order to solicit bids. Companies that have not previously defined a shortlist can instead put out an ITT, which is an open call for quotes from any supplier that can meet their needs.

-

Evaluate bids.

Thoroughly evaluate the bids received from suppliers. A typical goal is selecting the bid that delivers the greatest value and leads to a dependable supplier relationship. Reliable suppliers are more likely to submit quotes that are clear and structured, and reflect an honest assessment of their strengths.

-

Validate contenders.

It may be tempting to evaluate quotes based on cost alone, but it is just as important to evaluate suppliers to make sure they can credibly deliver what they promise. Look for feedback on their previous projects from other customers and ask for product samples, if relevant, to validate quality.

-

Award contracts.

Having chosen and validated your preferred supplier, draw up a contract laying out the terms. Be methodical and comprehensive when defining these terms, because the contract will become the foundation of the supplier relationship. The contract should include key performance metrics, timescales, provisions for a wide range of possible disruptions and the obligations of both parties.

-

Begin work.

Once the contract is signed, the supplier’s work begins. The supplier begins to manufacture and deliver the goods or services and continues to do so until the contract is completed.

-

Manage receipt and warehouse logistics.

When procuring physical goods, especially on a large scale, it makes sense to set clear terms for their delivery so you can effectively manage warehouse operations and inventory. These provisions can help the business accept deliveries efficiently, with minimal disruption to operations. In some cases, the terms may even cover the spacing and placement of delivered goods.

-

Review contract performance.

Supplier relationships are dynamic by nature and will evolve over time as both parties learn to work together, or when new conditions arise. To stay on top of any changes, conduct regular reviews of your contract terms and supplier relationships, identify any pain points and adjust tactics to maintain a high level of performance.

-

Establish continuous supplier relationship management.

No two suppliers are the same, so every supplier relationship may need to be managed differently. That’s why it’s important for companies to constantly analyze each relationship to be sure they are getting the most out of their vendors.

-

Conduct asset management.

Rigorous asset management helps the company track when it needs to replace or upgrade equipment or infrastructure, necessitating procurement of new items.

How to Manage the Procurement Life Cycle

The key to smooth operation of a complex procurement cycle is ensuring that you can effectively manage many moving parts. This is especially true for steps that require validation from multiple stakeholders, such as when defining business needs in the early stages of procurement. Failure to manage the procurement life cycle can lead to supply delays and added operating costs, potentially jeopardizing relationships with key suppliers and compromising your ability to serve customers. Here are five best practices for optimizing the procurement life cycle.

- Automate administrative tasks. The administrative burden of manually managing procurement amid shifting market conditions can be enormous. Automating elements of the procurement life cycle, such as reordering and invoice payment and automating the approval process, can save considerable time and cost while reducing the risk of human error.

- Structure your processes. Structure is the foundation of an efficient procurement life cycle. Laying out each step in detail, assigning ownership and defining best practices can help procurement operate smoothly.

- Champion visibility. Visibility and transparency are essential for effective procurement life cycle management when factors such as supply chain bottlenecks can force companies to reshape plans overnight. When every stakeholder has access to data and updates throughout the procurement process, they are well equipped to fulfill their role and manage last-minute adjustments when circumstances change.

- Give back to your supplier network. The best supplier relationships are mutually beneficial. Your company gets a trusted partner that reliably provides the goods and services you need, while your supplier gets a regular source of income and a case study to help them grow their own business. A healthy relationship also breeds healthy communication. For instance, by warning suppliers of potential future risks, you can make sure they are not caught off guard in the event of a crisis. In return, suppliers that are transparent about issues that may affect their delivery down the line can help you manage possible bottlenecks before they have knock-on effects for your customers.

- Optimize inventory management. Efficient inventory management is critical for companies seeking to procure the right quantities of new supplies at the right time. That is why many businesses rely on cloud-based inventory management systems to strike the right balance between inventory capacity and costs. Inventory management systems can provide real-time visibility into inventory levels, help companies predict demand and automatically alert purchasing staff when it’s time to replenish inventory.

Clarify Your Inventory Needs With Forecasting

Improve Your Procurement Life Cycle With Software

Managing complex procurement processes and supply chains requires complete control over your business data. NetSuite Procurement Management records and updates your production data, financial reports, inventory and outstanding orders in real time, so that critical supply chain management systems will be up to date and operating on the same information. This helps companies control costs associated with planning and executing supply chain processes. Supply-planning features analyze demand, determine replenishment needs and create orders as needed. NetSuite procurement capabilities automate communication with suppliers and ensure accuracy throughout the procurement life cycle.

A well-oiled procurement life cycle helps your company secure the critical goods and services it needs to maintain operations and serve customers, while minimizing costs. With the right software, businesses can better coordinate and automate procurement processes, forecast demand and reduce burdensome administration.

#1 Cloud

Accounting

Software

Procurement Life Cycle FAQs

Why should businesses follow all the procurement life cycle steps?

Effective procurement depends on managing the entire procurement life cycle, from start to finish. By clearly defining your business’s needs, taking a methodical approach to the selection and validation of suppliers and taking care to draft a comprehensive contract, you will not only secure the best supplier for your immediate needs but may also build a strong and mutually beneficial relationship that helps your company succeed in the long term.

What types of businesses use the procurement life cycle?

Virtually every business can benefit from a procurement life cycle. That’s especially true in today’s service-based economy, where companies in every industry rely on external consultants, cloud-based software and other services, in addition to the raw materials and machinery they need to manufacture goods.

What is a procurement life cycle?

The procurement life cycle refers to all the steps involved in securing goods and services for your company, from defining requirements and soliciting bids to vendor management.

What are the five stages in a procurement cycle?

The procurement cycle consists of many steps, which can be grouped into five broad stages: definition of business needs, supplier evaluation and selection, management of supplier relationships, delivery of goods and services, and assessment and refinement of procurement processes.

What is the first step in the procurement life cycle?

The first step in the procurement life cycle is to define your business’s needs. With a clear set of specific needs and buy-in from relevant stakeholders across the organization, procurement managers are better able to select the best suppliers to meet every requirement while keeping costs to a minimum.