Companies that adapt their business models for today’s demand-driven supply chains have a global competitive advantage. Learn how data analytics supports the demand forecasting and planning accuracy needed to grow revenue and profits in volatile times.

What Is Demand Management?

Demand management is a planning methodology that companies use to plan, forecast, and manage customer demand for their products and services. It involves coordinating various business functions, such as marketing, sales, and supply chain management, to ensure that a company can meet customer needs while optimizing resource allocation and minimizing waste. In other words, by aligning demand forecasts with production planning and resource allocation, businesses can ensure that they have the right products available at the right time to meet customer expectations.

A wide-ranging study conducted by the Global Journal of Management and Business concluded that demand management “provides an important bridge between the marketplace and a company’s internal operations.” The study also clarified the concept of demand management as “the creation of interactions between operations and marketing with the goal of understanding the market and developing actions in sync with company strategy, production capacity and end-customer needs.”

Those conclusions remain as valid today as they did when originally published in 2014. Modern demand management identifies and captures all potential demands, interprets them and communicates them to relevant departments within the organization. An example of external demand is an assessment based on customer inquiries or booked orders, while an internal demand assessment may calculate the raw materials needed to produce a new product and the promotional activities required to support the launch of that same product.

Key Takeaways:

- Demand is now driving supply. Demand management helps smooth out the volatility created by heightened consumer expectations and shorter fulfillment cycles.

- Organizations that are better at anticipating and planning demand gain a competitive advantage. The process eliminates waste and increases value in every area of the supply chain.

- Data and analytic capabilities supporting customer-centric demand management are what it takes to win in a fast-paced and intensely competitive global marketplace.

What Is the Purpose of Demand Management?

Demand management formulates an action plan to meet current and anticipated conditions in target markets. The process provides data and insights to marketing, demand planning, production, and sales forecasting teams to help them achieve company goals.

The role of demand management in the organization

Demand management covers multiple areas, including strengthening inventory levels and planning, trade and promotion planning, and customer service.

Demand management is a process that supports supply chain management (SCM). Supply chain management applies to managing all of an organization’s sourcing, developing, manufacturing, and delivery activities, including moving materials, services and goods from suppliers. The supply chain is a complex, interconnected system that enables companies to build products and bring them to market. A company may be a critical link in other businesses’ supply chains.

Who uses demand management?

Virtually all departments and divisions within companies use demand management directly or indirectly. Demand management determines upcoming needs, so every area of the business can work efficiently, without overtaxing systems.

Demand management users include marketing and sales, finance, research and development, production, quality control and logistics. The demand management data that flows from those departments impacts order fulfillment, customer service, customer relationship management, manufacturing flow management, procurement and product development and commercialization.

Objectives of Demand Management

Successful demand management teams today are customer-centric — it’s all about the ability to predict and fulfill demand with the right products and services. Specific areas of focus include improved customer service, more accurate forecasting and lower costs.

Specific objectives of customer-centric demand management include:

- Improved customer service: Understanding client needs and behaviors increases customer satisfaction and improves service.

- Forecasting with greater accuracy: Predictive analytics efforts optimize decisions by business leaders and improve supply chain management.

- Reduced costs: Improved forecasting optimizes inventory investments and can minimize safety stock levels.

- Enhancement of existing products and excellence at new product introductions: Create a line of customer-appropriate new products and refine them based on feedback.

- More efficient planning: Strike the right balance of supply to demand and minimize surpluses by using reliable data.

The end goals of demand management are to boost sales growth and deliver strong profit margins. Business leaders use the process as a central decision support tool, contributing to strategic initiatives and tactical execution.

Demand Management vs. Demand Planning

Demand management, like demand planning, aims to keep supplies and demand in balance. The difference is that demand management looks at consumer demand in the short term, while demand planning covers more extended time frames.

Demand management is like demand planning in that both help companies avoid producing more goods than they can sell at the price they want to charge. Demand planning analyzes consumer trend, historical sales, and seasonality data to enhance a company’s ability to meet customer demand in the most efficient way possible over the long term — up to 24 months for most businesses. Demand planning is crucial because it minimizes excess stock and the associated negative effect on cash flow while improving profits and flexibility as a business adapts to customer demands as they evolve.

Demand Management vs. Capacity Management

Demand management identifies potential demand variations. Capacity management is a response to demand. Capacity management aims to ensure resources are available, so business activities and production can thrive under any circumstances.

In general, demand fluctuates while near-term capacity remains constant. Demand management activities generate the information capacity management teams need to manage the company’s resources — including technology and equipment, manufacturing, labor and office and warehouse space — to best meet upcoming needs.

Subpar capacity management may create contracted revenues because of customer attrition, unfulfilled orders, and decreased market share — things every business wants to avoid.

Demand Management vs. Demand Generation

Demand management focuses on planning, forecasting and managing existing customer demand. For its part, demand generation seeks to create new demand for a company’s products or services. As such, demand generation is typically considered a marketing or sales function that is designed to attract, engage, and nurture potential customers and ultimately guide them through the sales funnel toward a purchase decision.

Despite their different roles, demand management and demand generation are interdependent. For example, a successful marketing campaign could convert a slew of prospects to paying customers, but without proper demand management, the company could fail to keep up with demand, leading to stockouts. Meanwhile, a company may excel at meeting existing customer demand — without overordering — but without bringing new customers into the fold, its sales could ultimately stagnate.

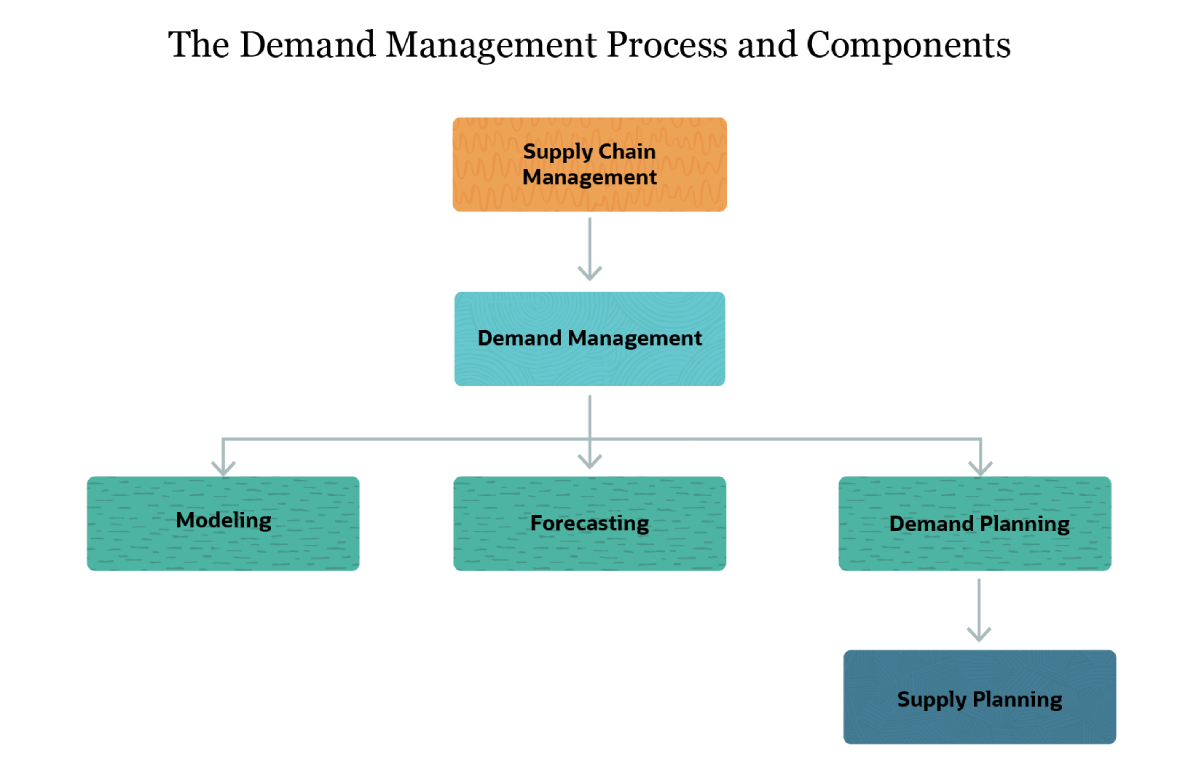

Demand Management Process and Components

The demand management process is intrinsic to supply chain management in that it balances supply with demand. The first three steps of modeling, forecasting, and demand planning inform the fourth, supply planning.

1. Modeling

This component requires the business’s demand planning team to acquire from other groups data linked to sales and demand drivers such as innovation, social media strategy, and market trends.

They can then enter these data sets into demand management and planning software or manually analyze them for various exercises including:

- Model review: Checks to validate the current demand model.

- Reality assessment, test and simplification: Checks to validate demand indicators for validity based on logic and statistics.

- Mathematical modeling: Uses equations based on historical data to check demand impact.

- Data collection and preparation: Data is used to devise a demand planning strategy.

2. Forecasting

Demand forecasting uses predictive analytics to forecast future demand for services or products. Demand forecasting supports reliable supply decisions based on estimated future sales and revenue. Areas of focus include:

- Objective setting: Make sure your objective satisfies your product marketing, financial planning, operations, and logistics teams — and be specific.

- Collection and data recording: Integrate data from sales channels for a cohesive picture of actual product demand and insight into sales forecasts. Check orders, dates, and sales channels to forecast growth and trend projections and see actual SKUs ordered. Evaluate products that have high return rates and make improvements based on the reasons for those returns.

- Measurement and data analysis: Whether you use automation and predictive analytics or complete the task manually, opt for a repeatable data analysis process to set yourself up for success with subsequent forecasts. As data sets and the company grow, start tracking additional information, such as frequency of stockouts, volume of obsolete stock, and other details, to find improvement opportunities.

- Budgeting: Based on a feedback loop, update the budget to allocate funds based on growth goals. Demand forecasting reduces inventory carrying costs and improves the accuracy of marketing spend, future headcount, inventory and production needs, and new product plans.

3. Demand planning

The demand planning process forecasts product or service demand to ensure you can satisfy customers. Demand planning aims to strike a balance — sufficient inventory levels to meet orders without a surplus.

Consider these best practices:

- Use past sales data: This information highlights past demand patterns, so a company can better understand its fluctuations from a historical perspective, which improves future forecasting.

- Confer with customers: Because historical data alone can’t predict future trends, it’s crucial to collaborate with manufacturers, distributors, and customers to form a complete picture of upcoming demand. That information factors into the planning process.

- Manage and combine forecasts: You must ensure forecasts reflect the most current data to inform decision-making. By implementing a system for updating and managing these forecasts, you make it easier to gauge progress and combine separate insights into a consensus-type forecast.

- Reexamine the data: Meet with key personnel to reanalyze your numbers. This step helps ensure that teams have the ability to reconcile demand with accessible supply.

4. Supply planning

Supply planning is the part of the demand management process handled by supply or inventory management. The goal is to identify and address the most critical problems, plan across multitier locations, and simulate potential responses to optimize inventory and customer service costs. Then, you can write and execute a plan based on the best data available, with customer needs in mind, based on all inputs.

Components in demand management

Each demand management process features specific components that allow businesses to identify and focus on customer needs. Based on the data derived from each element, managers arrive at the best plan to improve overall business performance and optimize the supply chain. Key components include forecasting, inventory management, supply chain coordination, capacity planning, demand sensing, and demand shaping.

- Forecasting involves predicting future customer demand based on historical data, market trends, and other relevant factors. For example, a clothing retailer might use sales data from the previous year, combined with insights on upcoming fashion trends, to forecast demand for the next season.

- Inventory management focuses on ensuring that the right products in the right quantities are available to meet customer demand. It involves monitoring stock levels, setting reorder points, and optimizing inventory turnover. For instance, the clothing retailer might use real-time inventory tracking to confirm that it can meet customer demand for the hottest new jeans on the market.

- Supply chain coordination involves collaborating with suppliers, distributors, and other partners so that products can be produced and delivered to customers. For example, the clothing retailer might share real-time sales data with its jeans supplier that shows which styles and sizes are selling quickly. The supplier, in turn, could adjust its production schedule to meet the retailer’s (and its customers) needs.

- Capacity planning is about having sufficient production capacity, workforce, and other resources to meet customer demand. For instance, the jeans manufacturer might plan to increase production capacity in the months leading up to the holiday season to ensure that it can meet the expected surge in demand from its retail customers.

- Demand sensing uses real-time data to identify short-term demand patterns and respond quickly to market changes. For example, if a photograph of a celebrity wearing new trendy jeans is making the rounds on social media, the clothing retailer might adjust its product mix and inventory levels to capitalize on the sudden spike in consumer interest.

- Demand shaping involves influencing customer demand through pricing, promotions, and other tactics. For example, the clothing retailer might offer a limited-time discount on the popular jeans to encourage sales.

Based on the data derived from each of these components, managers can develop a comprehensive plan to improve overall business performance and optimize the supply chain. By continuously monitoring and adjusting these components, companies can stay flexible and adapt to changing customer needs and market conditions.

One tip from experts is to stay flexible. A vital element of demand management is continuously finding ways to improve operational flexibility and reduce demand variability. When you have technology that supports planning you can react efficiently and quickly — then, disruptions don’t cause chaos, and it’s easy to pivot to a better position.

A 2002 study in the International Journal of Logistics Management on the demand management process describes synergies with business functions and departments and each component in detail. The research also stresses the need for collaboration in forecasting so that management remains in control and company goals and objectives are achieved.

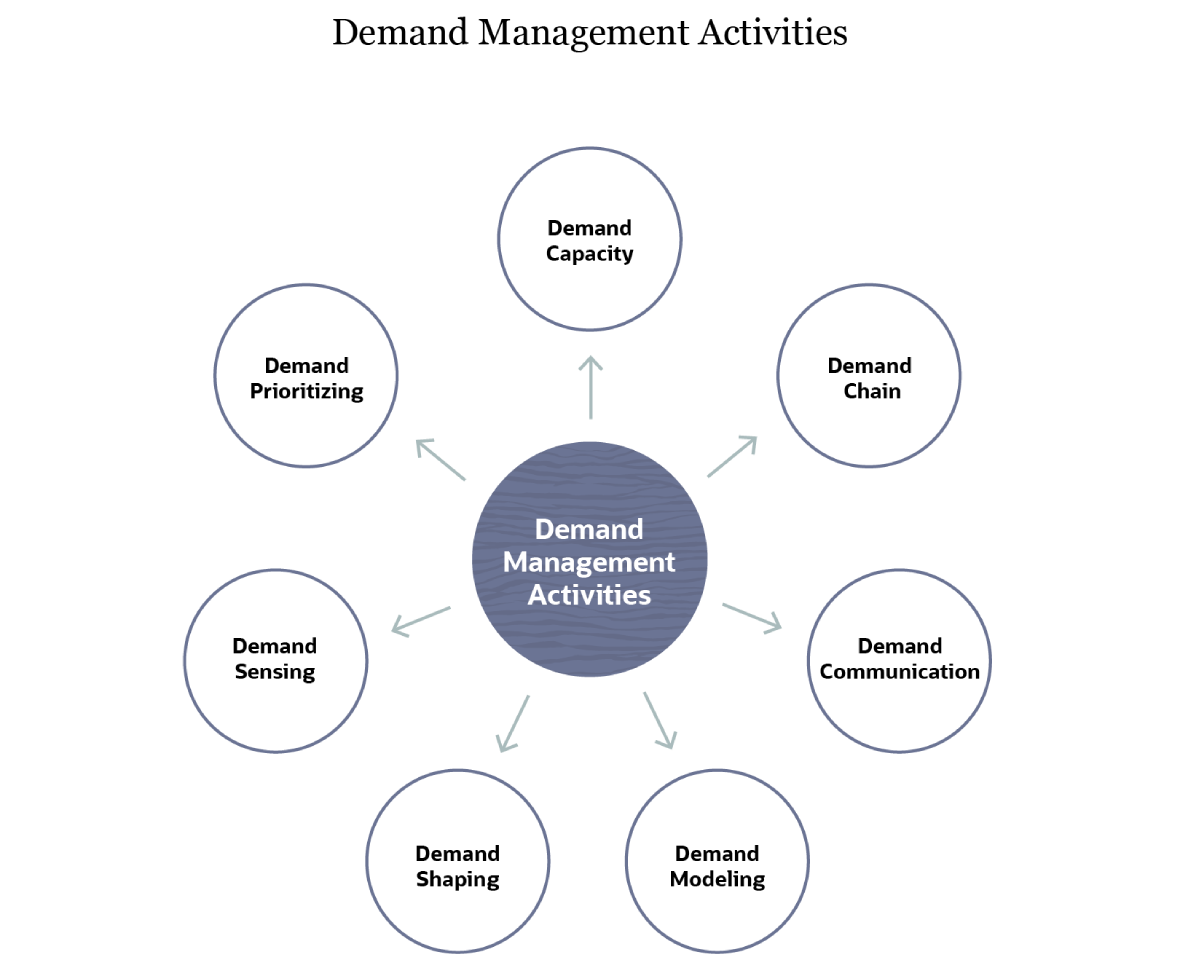

Activities in Demand Management

Demand management activities help teams dive deeper and develop plans to support a more efficient supply chain. Activities include demand capacity, chain, communication, modeling, shaping, sensing and prioritizing.

- Demand capacity: Demand management helps you coordinate capacity demands, such as production time, inventory, and resources. Capacity planning is critical because it directly impacts cost centers. Operating expenses are impacted when demand and capacity are out of sync, so coordination is essential to achieve alignment.

- Demand chain: The demand chain relates to the customer demanding products or services as and when required -- referred to as pull. In the internet economy, the demand-chain-based e-fulfillment model condenses time, is pull-driven by the customer, and is based on real-time event monitoring, inventory data, and information used for forecasting and planning — in other words, the end consumer is king.

- Demand communication: In the collaborative demand management model, you communicate forecast demand to all stakeholders, business areas, and teams affected by the forecast. This transparency allows everyone to work towards a common goal.

- Demand modeling: Demand modeling works from the bottom up. This activity breaks demand components into external and internal factors, and it examines how each factor influences purchases to ascertain future demand.

- Demand shaping: Demand shaping is an operational supply chain management strategy where a company uses price drops, incentives, and other tactics to induce customers to purchase specific items. Demand shaping helps the business match demand for a specific product to the planned supply.

- Demand sensing: This predictive tool is a game-changer in high-demand e-commerce scenarios. Demand sensing uses data collected in near-real-time. New mathematical techniques to sense demand make it possible to quickly understand what is selling, who is buying ,and how the product or service impacts market demand.

- Demand prioritizing: Identifying and prioritizing projects is the basis of demand management. By examining potential risk factors, organizational capacity, financial value, and implications, you can form policies based on priority items.

Activities in demand management require leaders and their departments to take a holistic view, work together, and make informed decisions based on data.

How Do You Manage Demand Management?

The demand management process functions best as a team effort, with the goal of better understanding supply issues. In larger firms, a demand manager oversees the process. Participants should include new product development, sales and marketing, and production schedulers.

The most effective way to handle demand management is to deploy integrated, analytics-driven processes. Successful companies use a combination of predictive analytics, market intelligence, and best-in-class technologies to achieve revenue growth goals and objectives.

Demand management extends beyond forecasting and incorporates the demand sensing and demand shaping techniques discussed earlier in this article. Demand managers can continuously shape demand based on analysis of key performance indicators (KPIs) and metrics.

Data sharing enables high supply chain visibility (SCV), another crucial demand management approach. Supply chain visibility alerts schedulers and planners when order fulfillment issues or low inventory levels threaten the ability to meet demand.

Demand Management Examples

Equilibrium of supply and demand is essential in every business. Demand management examples occur in both product and service companies. Industries that use demand management range from cosmetics to public utilities to theme parks.

Here are six example demand management use cases:

- Demand management in cosmetics: In 2023 the worldwide beauty and personal care market reached $627.3 billion, according to Statista. As good as that number looks, consumers are fickle, and what is hot today will likely not be in a few months. Cosmetics firms drive consumer behavior by, for example, seeding trends with celebrity product endorsements. Once cosmetic companies generate demand, they must ensure those products are available for purchase. Managing the supply chain plays a central role in helping trend-driven companies create a competitive advantage by sensing demand and responding fast.

- Demand management in automotive manufacturing: Like cosmetics firms, automotive businesses face challenges in predicting and responding to evolving customer demand. Leading automotive companies expend a lot of resources improving supply chain visibility and ensuring that suppliers have the financial and organizational capacity to meet demand changes. Several manufacturers are moving to a model that involves closer financial and operational collaboration and dropping standard contracts. Manufacturers using demand management trust the financial health of their suppliers and their response to demand variations.

- Demand management in hospitality: Hotel demand management (HDM) takes a holistic approach to marketing, finance, distribution and revenue in the hospitality business. Aggregating hotel data into usable information significantly reduces decision-making risk. Managing overall demand dynamically deepens existing customer relationships and helps teams predict revenue and strategically use various distribution channels to reach target customer segments.

- Demand management in theme parks: The Walt Disney Company is a leader in effective demand management and on-point customer service. Disney has carefully studied how long patrons will wait in a line before they require a distraction. The studies pinpointed when to engage guests with mirrors, Disney characters, videos or other methods. They also set the waiting queues in a serpentine pattern so guests cannot see the line length and feel that they are constantly progressing forward.

- Demand management in public utilities: Utilities employ demand-side management programs to comply with government regulations and help customers save money. Energy efficiency programs — the prime demand-side management effort — offer customers incentives to increase efficiency and decrease the overall demand for electricity in programs around the United States and abroad. Demand response programs lower customer demand during times of emergency, such as fires or very high system load during heat waves or sudden freezing weather conditions. The goals of these programs are to reduce pollution from electric generators, avoid new generator and transmission line builds, and lower customer utility bills.

- Demand management in air quality products: MAXAIR Systems provides ventilators and other solutions to meet personal respiratory and contact safety concerns. When the COVID-19 pandemic caused the company’s sales of air-purifying respirators to increase sixfold, it needed a way to manage its supply chain effectively so it could produce enough units to meet demand. Company management took the pandemic as a challenge to improve processes and help save lives. It quickly adopted demand management techniques and was able to keep up with orders while planning to meet future demand and supply chain challenges.

Demand Management Strategy

Superior demand management requires high-quality data that teams then analyze continuously — often daily, depending on the environment and type of business. The process includes updating forecasts based on that data to inform strategies.

In 2015, the Transportation Journal synthesized more than 100 demand management studies and found that “consensus in competitive orientation, operational strategies and the environment led to superior performance.”

Today’s demand management strategies still focus on cost reduction, revenue enhancement and streamlined operations.

Example of a demand management strategy

The pandemic underscored the effects of global events on product demand and supply chains. Even though COVID-19 was not something most companies planned for, those that already used demand management strategies to handle disruptions, particularly in retail, fared better than those with no strategy in place.

It is safe to say that companies have learned the lesson that disruptions are a present and future threat, and strategies are needed to fend them off.

Demand management strategies that have gained prominence post-pandemic include:

- More robust contingency plans: What-if exercises prepare companies for emergency situations and test the effects of changes, without production schedule disruption. Theoretical exercises preview potential impacts on issues such as inventory levels, whether KPIs are affected, and how adaptable the team is to changing conditions.

- Forecasting flexibility: Manufacturers should strive to accurately predict customer demand in any circumstance. One strategy is to look at previous demand and forecasts to determine forecasting accuracy and note whether the strategy needs to change — regardless of current variable conditions. One of the best ways to improve flexibility is to use multiple forecasting methods based on different situations in the market, selling profiles and lifecycle phases.

- Focus on resilient and flexible processes: Some companies are moving away from single supply sources to multi-sourcing to mitigate possible interruptions in supply chains. Analyzing the risk attached to each supplier, sub-supplier and step can ensure smoother delivery in any circumstance.

- Less focus on just-in-time models: Just-in-time production was the up-and-coming model pre-pandemic. Now, companies place less emphasis on lean inventory and more on ways to prevent shortages that affect delivery.

Demand Management Best Practices

Effective demand management practices are crucial for businesses to optimize their operations, improve customer satisfaction, and maintain a competitive edge. While the specific best practices may vary depending on the industry and the unique characteristics of each organization, several key principles can boost a company’s success in its demand management efforts.

Demand management best practices include:

- Fostering a demand management culture: When senior leaders embrace a demand management culture, the entire organization’s activities are synchronized toward product availability. The culture is now one with a single charge: Achieve greater efficiencies in the supply chain.

- Agreement and action on objectives: Most companies have strategic goals. Demand management programs based on an overarching strategy reduce inventory and increase service levels.

- Defining reasonable time horizons: Options for meeting surplus demand vary depending on the time frame of the predicted demand. Define these horizons in advance, so all stakeholders agree on appropriate actions in each situation. Short-range forecasts, around three months, tend to be more accurate than long-range forecasts because data is fresher. Medium- and long-range forecasts support management decisions regarding development and design and new processes, plants, and products.

- Maintaining a sound methodology: Imagine the consequences of making decisions based on a forecast demand shift, only to modify the predictions based on sweeping changes to the prediction model. It doesn’t work. Effective demand management relies on a dependably applied, company-standard methodology.

- Utilizing reliable statistical forecasting: Reliable planning consistently incorporates some form of statistical modeling. The prediction model should be proven valid, well-understood and repeatable, and it needs to evolve with the business.

- Respecting process owners: It is essential that process owners perform their appointed duties without meddling from company leadership. Even if their recommendations go against the grain of previous strategies or tactics or are inconvenient, organizations should abide by process owners’ input.

Benefits of Demand Management

Demand management delivers higher revenue, more control over product availability and the ability to respond to change without undue disruption.

Other benefits of demand management include:

- A solid foundation: Helps to create a foundation for merchandising, budgeting, and logistics processes.

- Improved forecast accuracy: The use of demand-sensing, point-of-sale (POS) data, and big data and data analytics enhances the precision of near-term forecasts and production forecasting. This helps companies optimize their supply chain scheduling, production, shipping, and warehouse operations based on reliable demand data.

- Supply chain support: Demand management processes boost operations with robust modeling, forecasting and demand and supply planning.

- Organizational agility: The ability to respond and adapt to change in the environment and within the company helps you better manage when pivoting in challenging times.

- Better labor management: Successfully predicting peaks in demand allows businesses to plan staffing levels more accurately.

- Easier product and service delivery: Builds confidence in the sales force about the company’s ability to deliver products and services; smoother product introductions.

- Stronger relationships: Reasonable pricing and targeted offers ensure that customer connections are built to last.

- Easy monitoring: It’s simple to review supplier transactions and see growth or decline, respectively; plus, it provides the ability to monitor all related expenditures.

- Enhanced competitive advantage: By successfully anticipating and planning demand and integrating business processes, companies gain an advantage by eliminating waste and increasing value in every area of the supply chain.

- Improved product forecasting: Well-executed demand management assists supply chain managers with more accurate production forecasting based on reliable data.

- More accurate supply chain scheduling and operations: More precise analysis and forecasting mean companies can optimize production, shipping and warehouse operations.

Disadvantages of Demand Management

Most barriers to demand management disadvantages arise when companies lack systems to easily handle the process and/or suffer from poor or insufficient data, are risk-averse, or have rigid management structures and siloed teams. Businesses need to remove a number of barriers or risk derailing the effort.

Barriers to demand management include:

- Poor or inadequate demand data: Gathering accurate, up-to-date, trustworthy, and relevant data can be difficult. Many organizations rely solely on historical data to predict demand, which is “old school” and problematic because market conditions shift continually. Taking advantage of technology that serves up the most current information removes the challenge of showing quantifiable demand changes.

- Lack of POS data: POS data is the closest many companies come to accurate, real-time demand information, so it makes sense to receive, store, and use this data in customer co-planning efforts. It can provide early warning signals of upcoming shifts in demand and help suppliers and their direct customers keep consumers happy.

- Fast pace of change: In an accelerating and complex business environment, companies that want to lead need to improve their forecast accuracy — and be ready to pivot to still manage demand when a forecast is incorrect.

- Risk-averse or rigid management: Demand management as a methodology sounds like a business superpower, and it can deliver big advantages. But it requires top-down buy-in, with executives dedicated to universal adoption and committed to creating scalable, agile processes supported by the right resources.

- A lack of proper expertise: Demand management is not easy to master. It involves many different components and requires people with the right skill sets. Success may require hiring managers with applicable experience and training as well as new technology to help simplify the process.

- Siloed teams: The company loses time and potential opportunities when it places great emphasis on demand forecasts and less on collaborative effort. For example, goal and expectation misalignment between demand-generation departments, such as marketing and sales, and supply chain departments, such as sourcing, logistics and operations, can result in duplication of efforts and losing sight of strategic objectives.

- Single-source supply: Manufacturers may still depend on only one supplier for components or materials. This approach has inherent risk because supplier failure is likely to mean failure to meet customer demand.

NetSuite’s Demand Planning Models Increase Turns and Reduce Lead Times

Companies can predict demand in various ways: current numbers, historical demand, open opportunities, imported sales forecasts – the key is always good data. The powerful functionality, ease of use, and multilocation inventory features in NetSuite Demand Planning mean solid plans are only a click away.

Companies can perform demand management weekly or monthly to generate forecasts using moving average, linear regression, or seasonal average calculations. And, you can review and edit all demand forecasts before proceeding with supply planning.

NetSuite Demand and Supply Planning Capabilities

Companies looking to strike the delicate balance between supply and demand can use a combination of strategies and techniques. Advanced inventory management and demand planning are simplified with decision-making support from Supply Chain Planning Solutions’ real-time visibility.

Demand Management FAQs

What is the role of a demand manager?

A demand manager plays a crucial role in overseeing the entire demand management process within a company. This includes forecasting future demand, planning production and inventory levels, and ensuring that the company can meet customer needs. The demand manager acts as a liaison between various departments, such as sales, marketing, inventory, and supply chain, to facilitate communication and align resources with market requirements.

What is an example of a demand management process?

Let’s consider the example of a clothing retailer. The retailer would start by analyzing historical sales data, studying current market trends, and gathering customer insights to develop an accurate demand forecast for the upcoming season. The retailer would then work closely with its suppliers, distributors, and internal teams to create a comprehensive production and inventory plan. This collaborative effort ensures that the right products are available in the right quantities at the right time, ultimately meeting customer expectations and maximizing sales.

What are two types of demand management?

Two types of demand management are strategic demand management and operational demand management. The former focuses on long-term planning, such as identifying new market opportunities. The latter deals with short-term, day-to-day activities, such as forecasting, inventory management, and order fulfillment. Other types of demand management are based on the source of demand (internal or external) and the nature of demand (independent or dependent).

What is the ultimate goal of demand management?

The ultimate goal of demand management is to strike a balance between customer demand for products or services and a company’s ability to supply them. By accurately forecasting demand, efficiently managing resources, and effectively collaborating with stakeholders across the supply chain, organizations can improve customer satisfaction, reduce costs and increase profitability.

What is demand management in logistics?

Demand management informs the work of logistics in the supply chain. Logistics is the part of the supply chain process that plans and controls the flow of objects between origin and consumption.