You may not think of Napoleon Bonaparte as a logistician. But his axiom that “an army marches on its stomach”—that is, keeping forces well-provisioned is fundamental to success in war—launched logistics as a field of military concentration.

Today, the term “logistics” applies to the reliable movement of supplies and finished products. According to the Council of Supply Chain Management Professional’s Annual State of Logistics Report, US businesses spent $2.3 trillion on logistics in 2024, moving goods from origin to end-user through various supply chain network segments. And as these supply chains continue to grow more complex, businesses must also keep an eye on global trends—namely, the global logistics market is expected to grow by 4.7% annually until at least 2027, reaching $6.6 trillion that year, according to Benchmark International’s 2024 Global Transportation & Logistics Industry Report.

Without efficient logistics, a business cannot win the profitability war.

What Is Logistics?

Logistics is the systematic planning and coordination of the complex operations involved in the movement of goods, data, and resources from origin to destination. It encompasses the flow—both forward and reverse—and storage of all raw materials, in-process and finished inventory, and order information between the point of origin and delivery to customers.

While occasionally used interchangeably with the broader concept of supply chain management, logistics is just one aspect of the overall supply chain, focusing on transportation and warehousing. Transportation involves choosing shipping methods, carriers, and routes, as well as meeting any required regulations. Warehousing, meanwhile, includes receiving, storing, and organizing inventory to best use available space without sacrificing accessibility. Together, these two functions create the physical infrastructure that businesses use to deliver their products and guarantee that customers receive the right orders at the correct time and place.

Video: What Is Logistics?

Key Takeaways

- Logistics is the process of efficiently moving goods from Point A to Point B. Success demands minute attention to detail, from packaging to warehousing to transportation.

- At best, poor logistics will dent a company’s bottom line. At worst, it can be crippling because logistics is the physical manifestation of a transaction—without it, there’s no movement of cash from customer to seller.

- Logistical best practices vary depending on the nature of the business and its product decisions, but the process is always complex. Automation is key to efficiency.

Business and Management Logistics Explained

Business logistics refers to the entire set of processes involved in moving goods, whether from a supplier to a business or from a business to a customer. The key concept here is managing these processes as a unified system. For example, online retailers that successfully dropship products direct to customers from hundreds or thousands of small suppliers have advanced business logistics practices.

A logistics management system underpins that effort and includes inbound and outbound transportation management, warehouse management, fleet management, order processing, inventory control, supply and demand forecasting, and managing third-party logistics (3PL) service providers.

Importance of Logistics

Logistics extends far beyond simply moving goods—it impacts a company’s financial performance and competitive position through lower costs, better inventory control, organized warehouses, enhanced production capabilities, and more satisfied customers. Here are some of the primary ways businesses rely on logistics:

- Reduce costs: Businesses effectively managing logistics minimize their costs in two major areas—shipping and inventory. For example, a clothing distributor can plan bulk retail shipments for year-round items to optimize load sizes and reduce delivery frequency for each product line. Meanwhile, the business can also reduce carrying costs by maintaining just enough seasonal inventory to meet demand without tying up excessive capital in unsold stock. Companies often leverage logistics software with analytics capabilities to identify these granular and targeted cost-reduction strategies.

- Increase inventory control: Logistics metrics can give decision-makers real-time visibility into inventory quantities, locations, and movements. This transparency allows companies to respond quickly to demand fluctuations, reducing the risk of stockouts, overstocks, spoilage, and undetected theft. To strengthen this flexibility, many businesses integrate their logistics systems with sophisticated forecasting tools to better anticipate future inventory needs and plan accordingly.

- Optimize warehouse space: Strategic logistics planning elevates how businesses use storage facilities through more effective layout design, vertical space utilization, and inventory positioning. By organizing warehouses according to the business’s desired inventory strategy—such as first-in first-out, last-in first-out, or keeping fast-moving items up front—companies can reduce picking times and labor costs while increasing storage capabilities.

- Improve production rates: Coordinating logistics planning with procurement and production schedules helps make sure manufacturing staff can access raw materials and components when needed. This synchronization prevents production slowdowns due to missing inputs, which in turn reduces bottlenecks and stalled work-in-process inventory further down the production line. This steady flow of materials and goods allows manufacturers to maintain consistent output levels without creating excess supply.

- Boost customer satisfaction: According to Wunderman Thompson’s 2023 Future Shopper Report, the top three delivery requests from the 31,000+ respondents were faster (48%), cheaper (43%), and more exact delivery estimates (39%). Tight logistics control helps businesses speed up order fulfillment, reduce costs by optimizing packaging and shipping processes, and offer more accurate delivery expectations, all of which directly impact how customers perceive a business and its reliability. By consistently setting and meeting or exceeding expectations, companies build trust and encourage repeat business.

- Enhance customer experience: Advanced logistics capabilities go beyond basic services to enrich the customer experience with additional options, such as flexible delivery times, real-time order updates, easy returns processing, and personalized services if problems arise. For example, a plumbing supplies company with an effective logistics operation may offer same-day delivery and quick refunds for returned parts to stand out in a competitive market and keep customers coming back when they need urgent supplies.

The Role of Logistics

The very essence of a business is to exchange goods or services for money or trade. Logistics is the path those goods and services take to complete the transactions. Sometimes goods are moved in bulk, such as raw goods to a manufacturer. And sometimes goods are moved as individual disbursements, one customer at a time.

No matter the particulars, logistics is the physical fulfillment of a transaction and as such is the life of the business. Where there is no movement of goods or services, there are no transactions—and no profits.

There are seven pillars of effective logistics:

-

Material Sourcing

Material sourcing involves more than finding the lowest-cost supplier for a raw material used in manufacturing. Logistics includes calculating and managing contributing factors and costs, such as backorder delays, competitor priority rankings and lockouts, add-on services costs, extraneous fees, increased shipment costs due to distance or regulatory environments, and warehousing costs. Finding the right source for any given material requires a good understanding and management of all contributing factors. This process is called strategic sourcing, and logistics plays an important role in that planning.

-

Transportation

At the core of logistics is the act of physically transporting goods from Point A to Point B. First, a company needs to select the best mode of shipment—air or land, for example—and the best carrier based on cost, speed, and distance, including optimizing routes that require multiple carriers. In the case of global shipments, the shipper needs to be up to speed on customs, tariffs, compliance, and any relevant regulations. Transport managers need to document and track shipments, manage billing, and report on performance using dashboards and analytics.

-

Order Fulfillment

To complete a transaction, items must be “picked” from the warehouse per the customer order, properly packaged and labeled, and then shipped to the customer. Collectively, these processes comprise order fulfillment and are the heart of the logistics sequence in customer distribution.

To complete a transaction, items go through five stages: sourcing, storage, shipping, receiving, and processing. -

Warehousing

Both short- and long-term storage are common parts of logistic planning. But warehouse management systems also enable logistical planning. For example, logistics planners must consider warehouse space availability and special requirements, such as cold storage, docking facilities, and proximity to modes of transportation such as rail lines or shipyards.

Further, organization within the warehouses is part of logistic planning. Typically, goods that move frequently or are scheduled for transport soon are placed at the front of the warehouse. Lower-demand items are stored toward the rear. Perishable goods are often rotated so the oldest items are shipped out first. Items that are often bundled are usually stored beside one another, and so on.

-

Demand Forecasting

Logistics relies heavily on inventory demand forecasting to ensure that a business never runs short on core or high-demand products or materials—and never ties up capital unnecessarily in warehoused goods with sluggish sales, either.

-

Inventory Management

By using inventory management techniques to plan ahead for increased demand in seasonal or trending products, companies can keep profits higher and make inventory turns faster, meaning the ratio of how many times you sell and replace inventory in a set period. Conversely, by noting slowing inventory turns on other products, a company can better determine when to offer discount pricing or other incentives to free capital to reinvest in goods that are in higher demand.

Further, retail sales often differ store to store, region to region, and country to country. Good inventory management enables the business to decide to ship products that are performing poorly in one store or region to another rather than take a loss via discount pricing to get rid of the stock. Logistics is key to moving inventory where it is likely to get the best price.

-

Supply Chain Management

Logistics is an important link in the supply chain as it facilitates the movement of goods from suppliers to manufacturers, then sellers or distributors, and eventually buyers.

A supply chain is essentially a series of transactions. If logistics fails, the supply chain fails and transactions grind to a halt. A prime example: bare shelves in grocery store dairy aisles even as farmers dumped milk as supply chains broke during the pandemic.

Logistics Lingo

3PL (third-party logistics) partners are outsourcers that handle warehousing, fulfillment, and returns of certain goods for a fee.

Inbound logistics refers to purchasing and arranging the transportation of products, parts, materials, and finished inventory from suppliers to a company’s warehouse or manufacturing plant.

Outbound logistics refers to the flow of items through a company’s production line, warehouse, and ultimately to the customer.

Logistics vs. Supply Chain Management

Logistics deals with the movement of goods from a single company’s perspective, meaning the movement of materials and goods one company receives and manages internally as well as when it moves those goods to a customer. A supply chain is a network of businesses involved sequentially in the production or distribution of goods or services. In short, logistics is generally a one company issue while the supply chain is a multicompany issue.

While logistics may be coordinated throughout part of or even the entirety of the supply chain, each segment is the responsibility of one entity until it hands off the material or product to another entity in the supply chain. In its most basic form, logistic components are:

- Intake from suppliers and materials handling

- Labeling, packaging into smaller units, organization, and warehousing

- Inventory management for production or distribution

- Demand planning

- Order fulfillment

- Transport

Typically, a logistics management system includes inbound and outbound transportation management, warehouse management, fleet management, order processing, inventory control, supply and demand forecasting, and management of third-party logistics service providers.

Types of Logistics

Many businesses simultaneously deploy a combination of various logistics approaches, each specialized to address different aspects of their complex supply chains. For example, an electronics manufacturer might use demand planning logistics for timing component purchases, warehouse logistics for storing them, third-party logistics for distributing their final goods, and reverse logistics for managing warranty returns—all coordinated through a centralized ERP system. By using a combination of the logistics types below, businesses can overcome specific operational obstacles and build a cohesive logistics strategy.

Order Fulfillment

Order fulfillment logistics encompasses every step a business takes between receiving a customer’s order and delivering the product to its final destination, including picking, packing, and shipping. By connecting logistics systems with sales and customer service platforms, businesses can eliminate the manual data entry and miscommunications that slow down orders, as well as track key performance indicators over time, such as perfect order rates and delivery times, to spot further improvement opportunities. Automated order fulfillment techniques, including robotic picking systems and shipping label generation, can also minimize these errors and delays.

Third-Party Logistics (3PL)

3PL providers manage outsourced warehousing, distribution, fulfillment, and transportation functions for companies that lack the internal resources to efficiently handle them in-house. Businesses rely on these specialized logistics partners for expertise, established infrastructure, and economies of scale to access broader geographic coverage and manage seasonal demand fluctuations. This outsourcing allows companies to convert fixed logistics costs—warehouse rent and delivery vehicles, for example—into variable expenses tied directly to sales volume.

Fourth-Party Logistics (4PL)

4PL providers oversee complex aspects of the supply chain to manage resources, technology, and 3PL provider relationships on behalf of client companies. Unlike 3PLs that focus on specific operational functions, 4PLs take broader responsibility for designing, building, and managing comprehensive supply chain solutions across multiple providers and systems. For instance, a global fashion retailer might engage a 4PL provider to manage its entire distribution network, overseeing multiple regional warehouses, transportation carriers, and technology systems. In this way, 4PLs serve as a single strategic point of contact for supply chain performance issues while the client company focuses on its core business activities.

Warehouse Logistics

Warehouse logistics includes all aspects of storage facility management, from warehouse layout design and inventory organization to labor scheduling and equipment use. This approach focuses on maximizing space utilization, throughput capacity, inventory accuracy, and labor productivity through data-driven strategies. These strategies typically incorporate modern technology, such as automation tools for repetitive picking tasks, inventory management systems for real-time visibility, mobile and cloud-based applications for keeping staff informed of item locations and order changes, and analytic tools for optimizing loading/unloading schedules and docking bay layouts.

Ecommerce Logistics

Ecommerce logistics focuses on managing online retail operations, including multichannel inventory management and digital customer communications. This approach addresses the unique challenges of fulfilling individual orders directly to consumers rather than bulk shipments to retail locations or distributors. For example, an ecommerce clothing store may create a distributed fulfillment network that positions inventory closer to end customers, allowing the business to guarantee quick delivery times and reduce last-mile delivery costs. To compete in a crowded ecommerce market, companies often combine ecommerce logistics with order fulfillment to offer flexible shipping options, real-time tracking capabilities, and multiple sales channels, including online marketplaces and mobile apps, so customers can shop how they prefer.

Freight Logistics

Freight logistics controls the movement of large quantities of goods across significant distances, often involving multiple transportation modes, such as trucks, trains, ships, and aircraft. Controlling freight costs typically requires expertise in freight consolidation, route optimization, carrier selection, and international shipping regulations, especially during times of changing trade laws and tariffs. Logistics strategies that can reduce these costs include relying on intermodal transportation that leverages different shipping methods, implementing Internet of Things (IoT) devices to monitor shipping conditions while in transit, and conducting regular freight audits to identify consolidation, offshoring, or reshoring opportunities.

Demand-Planning Logistics

Demand-planning logistics links inventory management and distribution decisions to demand forecasts to help businesses align their resource allocation strategies with expected customer needs. Decision-makers use this forward-looking approach to combine historical data, market trends, and statistical modeling to predict future requirements and set inventory levels accordingly. To improve the speed, depth, and accuracy of their forecasts, some businesses use advanced demand-planning systems that incorporate AI into their models. Inventory and procurement teams can then use these detailed forecasts to more precisely adjust stock levels and reorder thresholds to better meet demand.

Reverse Logistics

Reverse logistics manages the backward flow of products from customers to suppliers or manufacturers, including returns, repairs, refurbishments, and recycling. This logistics function helps businesses recover maximum value from returned goods while reducing their environmental footprint. Reverse logistics systems enhance the return authorization process by efficiently sorting returned materials to determine which items should be restocked, repaired, recycled, or disposed of, thereby minimizing waste and replacement costs. Furthermore, these systems’ analytics capabilities can identify return patterns to address potential product quality issues or unclear marketing descriptions that lead to customer dissatisfaction, further reducing waste.

Inbound Logistics vs. Outbound Logistics

Inbound logistics manages how businesses receive materials from suppliers, encompassing procurement, transportation, receiving, quality control, and warehousing for raw materials, components, and purchased finished goods. Companies with strong inbound logistics typically prioritize strong supplier relationships to maintain production continuity and precise, reliable scheduling. In contrast, outbound logistics handles the movement of finished products to customers, including warehouse management, order processing, picking, packing, shipping, and delivery coordination.

While these aspects of logistics have different priorities, they typically share some resources and challenges in overlapping responsibilities, such as warehouse space, ports and loading bays, transportation assets and workers, and inventory management systems. This interconnection requires comprehensive planning and integrated data systems to maintain visibility across the entire operation. For example, if a warehouse schedules simultaneous supply deliveries and outgoing shipments at the same loading dock, there can be confusion, delays, and potential damage to goods.

Examples of Logistics

Logistics best practices vary depending on the nature of the business and its product decisions. Consider the variances in the following examples.

A manufacturer bases its business model on a just-in-time inventory management system that aligns receipt of raw materials with production schedules so there is little need to pay for storage, ensuring that the company’s capital is continuously freed for reinvestment. Its logistics priorities include demand planning, selecting suppliers that consistently deliver on time and on budget, fast intake of materials upon arrival, and efficient materials handling. Once final goods are manufactured, priorities shift to packaging the finished products and transporting them to distributors, wholesalers, retailers, or other customers. The manufacturer needs to manage true end-to-end logistics, including procurement, receipt of goods, manufacturing, packaging, storage, and transportation to buyers.

If the manufacturer has a direct-to-consumer model, it may use a supply chain as a service provider to get its products to the end customer.

In another example, a boutique clothing store orders stock from designers and manufacturers. Finished goods arrive at the retailer’s main distribution warehouse for intake. The items are first unitized—broken down from bulk commercial packaging to individual consumer packages. Barcodes are added, then items are sorted, packaged, and shipped to the store or a nearby warehouse. Logistics for the retailer begins with the intake of goods and continues through the movement of those goods to their final destinations, which in this case is a brick-and-mortar store, not the final customer.

In a second retail scenario, some or all of the goods are sent to an order-fulfillment center, where they are processed and shipped to end customers, who likely made the purchase online. In this example, logistics entails the retailer receiving the goods it ordered from suppliers, unitizing them, and storing them in the fulfillment center’s storage onsite to be sorted per customer order and then shipped by a third-party logistics supply company, such as UPS, FedEx, or the US Postal Service.

In yet another scenario, the retailer redistributes its in-store inventory to other stores where demand for the product is higher to avoid discounting and taking a hit to profits. Or, the retailer may know from its analysis that demand is sluggish everywhere for certain products. In that case, the more quickly it marks down the stock or sells to a retail discounter at a reduced bulk price the more likely it is to recoup much of its investment. Logistics in this case entails inventory control, demand planning, pulling, packing and shipping products between stores, moving some items to sales racks, and shipping a bulk distribution in a transaction with a third-party seller.

If the retailer declares some remaining product as too costly to sell because demand is too low at any price, then logistics would also include transport of these items to a charity for a tax write-off. If some of that product is also damaged, the retailer’s logistics manager would transport it to a disposal site.

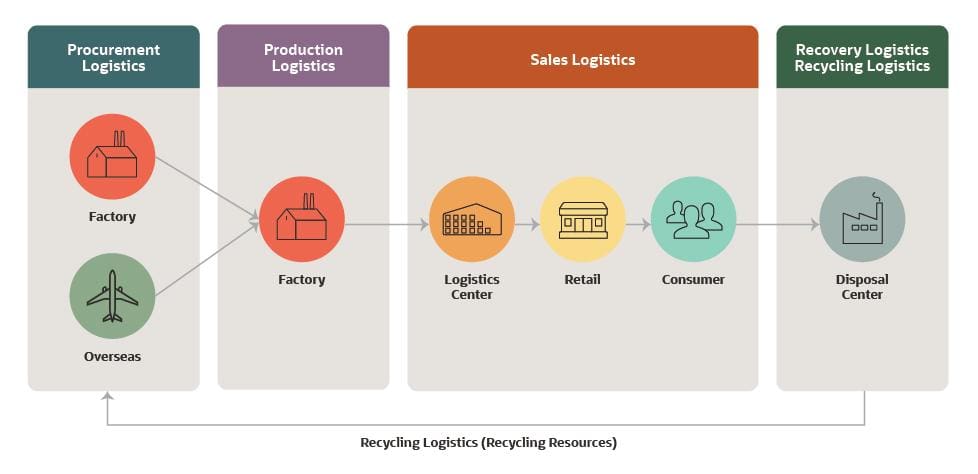

The Steps of Recycling Logistics

6 Benefits of Logistics Management

Given that the movement of goods is what drives cash flow, it stands to reason that managing that movement—logistics management—is a core business concern. Indeed, logistics management impacts a company’s bottom line for better or worse. It’s best not to leave that impact to chance.

The following are six major benefits of effective logistics management.

-

Visibility

Logistics management affords greater visibility into the supply chain. This enables businesses to better control costs, tease out efficiencies, spot supply chain problems, conduct demand planning, and gain insights into opportunities.

-

Reduced Overhead

Logistics management enables companies to reduce overhead in areas from cutting shipping costs to shrinking how much warehouse space they need by proactively controlling inventory levels.

-

Improved Customer Experience

An excellent customer experience (CX) is the driving factor behind repeat sales. By delivering orders accurately and quickly, companies improve the customer experience, which in turn increases brand loyalty and future sales.

-

Loss Prevention

Logistics management helps prevent loss in several ways. One is by a true inventory accounting, so a company knows exactly how much stock it has on hand at any given time. Companies can also track movement and current location so stock won’t be misplaced or diverted without notice. In addition, by ensuring optimal storage and transport conditions, such as temperature and moisture management, solid logistics prevents spoilage and damage.

-

Expansion Support

Demand forecasting supports expansion by realistically calculating inventory needs as well as ordering, transporting, and stocking accordingly. Further, logistics management best practices help companies scale to fulfill more customer orders on time.

-

Competitive Edge

Delivering orders correctly and on time is a foundational element in the customer experience—and good CX is key to repeat orders as well as solid brand reputation and net promoter scores, which in turn help a company acquire new buyers. Logistics management helps a company consistently deliver, or overdeliver, on promises and sharpen its competitive edge.

7 Rs of Logistics

The Chartered Institute of Logistics and Transport, an international organization for supply chain, logistics, and transport professionals, defines the seven Rs of logistics as “getting the right product, in the right quantity, in the right condition, to the right place, at the right time, to the right customer, at the right price.”

And in truth, that is the goal of logistics management.

-

Right Product

Job number one is delivering the product that was ordered according to specifications: color, size, and brand. But also consider an automated maintenance plan where manufacturers use IoT data to send a “just-in-time” replacement part, or something else that the customer may have not specified but needs. The point is to get buyers the products that are right for them or their situations.

-

Right Quantity

Say an item can be purchased as either a single unit or in packs of 12, which are also considered a unit. On a larger scale, a manufacturer may sell parts in a box containing a few products or as a pallet of multiple boxes. Getting quantity right demands clarity in how inventory is listed as well as proper picking and packing.

-

Right Condition

Customers expect a product to function properly and otherwise be usable—whether new, used, or refurbished. Products should therefore be inspected for flaws and damage prior to shipping. And return shipping processes should be simple and convenient for customers.

-

Right Place

Tracking to ensure receipt and that shipped items were delivered to the right address is essential to logistics management. A package that is never received and must be replaced costs a company twice—and damages the customer relationship.

-

Right Time

Often, from the customer’s perspective, timing is everything. Whether it’s a consumer ordering a birthday or holiday gift or a manufacturer that needs a raw material to meet its production schedules, late arrivals may cost the customer or be returned as no longer needed.

-

Right Customer

Order mix-ups, address errors, and other mishaps communicate a lack of respect for the customer and inattention to detail. An ERP system that automates outbound logistics can minimize errors and maximize a company’s supply chain execution.

-

Right Price

It’s important that a business’s pricing be competitive for the geographic area and the industry to turn inventory regularly and at a good margin. It is also imperative to adjust pricing—up or down—according to demand. To succeed here, companies need continuous insights into profitability ratios and unit margins.

4 Areas to Get Started With Business Logistics

Successful logistics is equal parts strategy and planning. Your strategy should encompass tactics to make the movement of goods work in your favor. Your plan should outline all the steps your company will need to take to bring your strategy to life. Get started in the following four key areas.

-

Spatial Management

Logistics requires sufficient space for goods, warehouse and materials-handling equipment, and people to receive, store, pick, package, label, and ship goods. Your warehouse management strategy should focus on making wise use of space so that goods are handled efficiently while keeping square footage and maintenance costs as low as possible.

-

Management and Staffing

One of the greatest expenses in any warehouse is staffing, so reducing picking time is a money saver. Inventory management software can show staff exactly where items are shelved and the best routes to take when pulling more than one item. Is your business seasonal? Plan for the necessary upsizing and downsizing in staffing to meet demand. You’ll need policies to guard against theft without making your people feel over-policed. Then there are benefits packages, workers’ comp insurance, and other HR-related functions that are crucial to a well-managed logistics team.

-

Equipment

Logistics requires specialized equipment, such as a truck fleet, conveyor belts, robotics, and forklifts—or some combination, depending on the type of materials or goods your company handles and how much of the work you outsource. Besides the capital expense, managing equipment and related issues, including maintenance, insurance, and depreciation, requires careful planning and tracking.

-

IT infrastructure

Your IT infrastructure must be optimized to accommodate functions from online ordering and purchasing to warehouse automation, IoT, and other technologies key to your logistics strategy.

What Is Logistics Management?

Logistics is the collection of processes involved in moving goods internally or from buyer to seller. Logistics managers oversee and control the many complexities involved in that process; in fact, there are a number of certifications for these professionals. Success depends on attention to many details: Routes need to be determined based on expediency, regulatory environments, and avoiding obstacles ranging from road repairs to wars and adverse weather conditions. Shipping provider and packaging options must be carefully considered, with costs weighed against factors from weight to recyclability. Fully loaded costs may include factors outside of transportation, such as those that ensure customer satisfaction and the availability of suitable warehousing. If a shipment of dairy products arrives spoiled because refrigeration failed, that’s on the logistics team.

Fortunately, logistics management software helps businesses make the very best routing and shipping decisions, contain costs, protect investments, and track the movement of goods. Such software can often also automate processes, such as choosing shippers according to rate fluctuations or contracts, printing shipping labels, automatically entering transactions in ledgers and on the balance sheet, ordering shipper pickups, recording receipts and receipt signatures, and helping with inventory control.

How ERP Benefits Logistics

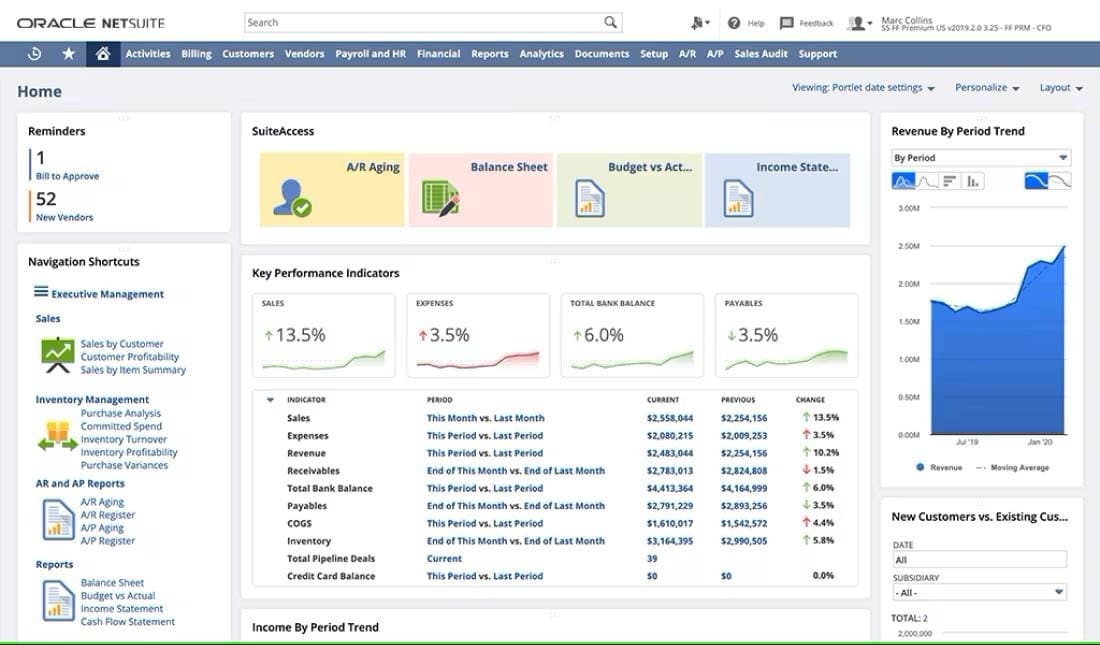

ERP software integrates a variety of applications that together constitute the flow of information within the company. NetSuite Transportation and Logistics is a powerful logistics tool as it enables effective order fulfillment.

Three top areas where ERP benefits logistics are inventory control, staff management, and product distribution. For example, fleet operators can manage asset distribution and maintenance based on information, such as work orders and parts inventory, pulled from ERP systems and feed that data back into the information flow as tasks are completed. Similarly, inventory control and supply chain insights can be automatically routed to reports, such as ledgers, the balance sheet, purchasing reports, automated ordering, and fleet and employee scheduling.

NetSuite’s ERP Dashboard

Transportation and logistics are central to a company’s success as they are the physical manifestation of transactions and without transactions there is no business. Managing logistics is also critical to the company’s financial health in that it can add or subtract money from the bottom line. Using software such as RPA, ERP, warehouse management, supply chain management, and others, a company can add efficiencies, cut costs, and gain control over this important business aspect.

Logistics FAQs

What do you mean by logistics?

Logistics entails the organization and coordination involved in moving goods from one place to another. It covers everything from where the goods start to where they end up, including transportation, storage, and careful handling to ensure that they are transported smoothly, securely, and promptly. The goal is to oversee the movement of items to satisfy customer needs while keeping efficiency high.

What does a logistics person do?

A logistics professional, typically known as a logistics manager, supervises the operations involved in the transportation and storage of goods. Their role involves planning, executing, and overseeing procedures to ensure the effective movement and storage of goods, along with services and relevant information, from where they originate to where they’re consumed. Their responsibilities may include choosing transportation methods, coordinating shipments, managing inventory levels, negotiating with suppliers and transport providers, optimizing routes for efficiency, and ensuring compliance—all within the laws and regulations of their industry and country. Additionally, they utilize logistics management software to enhance effectiveness by monitoring shipments and controlling costs.

What is the work in logistics?

Work in logistics encompasses managing the supply chain, from sourcing raw materials to delivering products to the end user, alongside managing information flows. This involves choosing efficient shipping methods and routes, ensuring timely deliveries, and overseeing warehousing to keep inventory secure and well-managed. Additionally, it includes tracking inventory levels, forecasting demand to meet customer needs, and handling order fulfillment—processing, picking, packing, and shipping orders. Effective logistics also requires coordinating with suppliers and customers to ensure operations run smoothly and maintaining high levels of satisfaction, underlining the importance of clear communication and collaboration throughout the supply chain.