When shipments arrive late, products are damaged, or inventory runs out, customers rarely distinguish between a logistics failure and a quality issue—they simply take their business elsewhere. These breakdowns often stem from systemic issues, such as siloed systems, manual workflows prone to errors, or reactive approaches that don’t address problems until after they’ve affected customers.

Too often, companies treat logistics as a basic function—just moving goods from point A to point B—rather than as a strategic lever. Yet effective logistics can drive operational efficiency, resilience, and customer loyalty, and savvy businesses would be wise to take heed.

What Is Logistics?

Logistics is the process by which businesses coordinate the movement, storage, and flow of raw materials, supplies, finished goods, and related information from their point of origin to the end customer. It encompasses several core functions, such as transportation, warehousing, inventory management, order fulfillment, and demand planning.

Effective logistics management makes sure the right resources reach the right place at the right time—in the most efficient, cost-effective way possible. It serves as the operational backbone of any supply chain by uniting procurement, production, and delivery with customer expectations.

Key Takeaways

- Logistics is the part of supply chain management responsible for coordinating how goods, materials, and information move from origin to destination.

- Strong logistics management can improve profitability by reducing operating costs and supporting higher revenue through faster, more reliable customer fulfillment.

- Effective logistics increases visibility across the supply chain, helping businesses predict and prevent disruptions before they impact customers and operations.

- Advanced logistics capabilities improve agility, enabling companies to respond to market shifts, navigate disruptions, and reduce financial risks when entering new markets.

The Role of Logistics in Business Explained

Logistics serves as the operational backbone that connects six key areas, each with a distinct role:

- Demand forecasting anticipates market needs so leaders can plan accordingly.

- Materials management allocates inputs where and when they’re needed.

- Transportation moves goods and materials across the supply chain.

- Warehousing manages storage to optimize space and access.

- Order fulfillment delivers the right products to the right customers on time.

- Inventory management balances stock levels to avoid over- and understocking.

Together, these elements form a comprehensive strategy that enables businesses to meet customer demand as efficiently as possible.

While logistics originated as a military term for the movement of supplies and troops, it now underpins resource allocation in nearly every industry. A manufacturer’s logistics strategy, for example, determines when and how materials arrive at production sites. In healthcare, logistics is used to distribute supplies to different facilities. In retail, it supports not only delivery but also the smooth handling of returns—all with the shared goal of balancing cost control with operational competitiveness.

The Importance of Effective Logistics: 9 Key Benefits

Businesses that adopt modern logistics software and platforms gain a clear advantage over competitors that still treat logistics as a basic transportation function. When logistics systems are integrated into a big-picture supply chain strategy, leaders can monitor real-time inventory metrics, identify bottlenecks before they escalate, and make data-driven improvements that benefit the entire organization. Here are nine key benefits:

-

Improves Cost Management

Modern logistics platforms give decision-makers extensive visibility into transportation, warehousing, and inventory expenses, revealing inefficiencies that might otherwise go unnoticed. With built-in reporting tools, automated cost accounting features, and customizable dashboards, businesses can pinpoint avoidable expenses, such as wasteful shipping practices, high inventory carrying costs, or performance issues with third-party vendors that lead to delays or penalties.

For example, a manufacturer facing rising shipping costs might discover that delays in the order picking process are causing daily partial shipments—with added fees for expedited delivery to meet deadlines. By using their logistics software to coordinate picking and shipping schedules, the company can shift to full truckload shipments twice a week—cutting costs without sacrificing service quality.

-

Increases Profitability

Effective logistics strategies benefit profitability in two key ways: by lowering operational costs and by enabling new revenue opportunities. Beyond the cost-cutting examples above, logistics technology can help increase margins through automation and smarter planning. For example, demand forecasting tools can better predict procurement needs, automatic reordering systems can prevent stockouts, and robotic picking machines and scanners can maintain real-time inventory accuracy and order tracking.

On the revenue side, on-time delivery and consistent product availability—enabled by well-orchestrated logistics systems—translate into better customer experiences. This reliability encourages loyalty and repeat business.

Across both cost and revenue factors, logistics management systems bring targeted data to the surface, such as order cycle times, stock turnover rates, and vendor performance metrics. This delivers key data that guides investment decisions, maximizes returns, and monitors the impact of each operational decision.

-

Optimizes Use of Resources

Logistics platforms help businesses deploy labor, equipment, facilities, and capital where they generate the most value. By analyzing historical and current performance data, these systems can forecast demand trends and workload fluctuations—enabling managers to adjust staffing, fleet usage, and storage capacity ahead of known or predicted peaks and slow periods.

For instance, logistics tools can identify underutilized assets (such as underused machinery, idle warehouse space, and partially loaded delivery vehicles) to reveal opportunities that support a leaner operation—perhaps via equipment reallocation, right-sizing facilities, or consolidating shipments.

As resource needs change, logistics systems support real-time scenario planning. Decision-makers can model the resource impact of entering new markets, responding to supply chain disruptions, or launching new product lines—facilitating smaller, informed pivots that maintain efficiency and support growth.

-

Leads to Better Customer Satisfaction

By prioritizing logistics, businesses can deliver consistently high-quality customer experiences. Systems that provide real-time order tracking, for instance, keep both internal staff and customers informed about updates, delays, or issues to reduce uncertainty and improve transparency throughout the fulfillment process.

Beyond tracking, logistics systems also collect data on delivery performance, helping businesses identify recurring delays or errors. These insights drive key factors in meeting modern customer expectations, such as shorter lead times, fewer bottlenecks, and improved on-time delivery rates.

In fact, according to a 2023 report on future shoppers by Wunderman Thompson, ecommerce shoppers now expect delivery within just 2.15 days, on average. When businesses consistently meet those expectations, they build trust, earn repeat business, and turn satisfied customers into brand advocates.

-

Improves Supply Chain Visibility

Modern logistics technology provides companies with full supply chain visibility by tracking materials, products, and inventory in real time, from initial procurement to final delivery and returns. This transparency helps companies detect potential disruptions early, respond to delays, and plan contingencies more effectively.

When logistics data is integrated into a centralized system—such as an ERP platform—businesses can monitor supplier performance, inventory levels, and transit timelines within a single view. These insights reveal potential issues, such as shortages, recurring delays, or unusual patterns that might indicate deeper problems.

For example, if an electronics manufacturer sees a spike in returns due to faulty motherboard components, logistics data can trace those parts through the supply chain to identify where the defect originated. If it’s an external supplier problem, the procurement team can use that data to either negotiate better terms or switch vendors, which ultimately will support a more resilient, responsive supply chain.

-

Enhances Competitive Advantage

Businesses that invest in integrated, data-driven logistics platforms can move faster and operate more efficiently than competitors that rely on outdated or disparate systems. With centralized visibility and timely insights, businesses can quickly respond to changing customer preferences, supply chain disruptions, or new market opportunities.

A retailer expanding into a new region, for example, can use its logistics software to analyze customer demand data, position inventory in nearby fulfillment centers, and coordinate same-day delivery options. This level of precision and responsiveness enables the company to meet rising customer expectations—such as quick delivery and easy returns—while earning a higher market share and building their brand reputation.

-

Supports Efficient Inventory Control

Integrating logistics with inventory management tools makes it possible to align stock levels with demand forecasts across all distribution points. More specifically, logistics software can synchronize inventory decisions with transportation, warehousing, and fulfillment operations, enabling end-to-end inventory control.

With built-in forecasting capabilities, logistics software analyzes historical sales data, seasonal trends, and current market conditions to determine the ideal stock levels or production needs for each product. This kind of data-driven approach helps companies prevent stockouts that might push customers to the competition while avoiding excess inventory that ties up capital and warehouse space.

-

Strengthens Risk Mitigation

Comprehensive logistics planning helps businesses manage supply chain risk more effectively than traditional, reactive strategies can accomplish. By continuously monitoring key performance indicators like supplier performance, transportation reliability, and regional risk factors, these systems can point to vulnerabilities before they turn into disruptions.

Armed with these insights, companies can build contingency plans into their logistics operations. These plans might recommend maintaining safety stock, sourcing from diverse suppliers and carriers, defining alternate transportation routes, or distributing inventory across multiple regions to create a buffer against localized disruptions.

Proactive approaches of this caliber are especially important in today’s volatile environment. According to WTW’s “Global Transportation and Logistics Risk Report 2024/2025,” 68% of the 400 global senior decision-makers surveyed cited trade disputes as one of the top risks to their supply chains. When disruptions do occur, businesses with logistics strategies in place—as well as flexible logistics systems—can quickly reroute shipments, tap into inventory reserves at strategic locations, or pivot to backup suppliers. This helps them maintain continuity while less-prepared competitors scramble to recover.

-

Increases Flexibility

To stay competitive in changing markets, companies need flexibility to be able to scale operations quickly—whether that means launching new products, entering new regions, or responding to demand spikes. Modern logistics systems support flexibility by offering modular features that can be activated as needed, making it possible to expand capabilities without immediately investing in new warehouses or major infrastructure.

For example, a business can use its logistics system to coordinate temporary storage with third-party providers, adjust routing strategies to serve new locations, or accelerate fulfillment workflows, all without overhauling core operations. This flexibility extends to customer-facing services, with offerings such as a variety of delivery speeds, pickup locations, or return options to accommodate customer preferences.

How Does Logistics Differ From Supply Chain Management?

Though some businesses use the terms “logistics” and “supply chain management” interchangeably, the two concepts serve distinct—yet interconnected—roles. Logistics focuses on the movement, storage, and flow of goods into, within, and out of a business. It manages day-to-day operations, such as transportation, warehousing, and delivery scheduling.

Supply chain management takes a broader view. It encompasses everything from procurement and production planning to supplier relationships, demand forecasting, risk mitigation, and sustainability. Logistics is just one component within this larger framework. A logistics manager might prioritize improving warehouse workflows or coordinating last-mile deliveries, while a supply chain manager could be responsible for expanding into new distribution models, implementing fulfillment technologies, or aligning sourcing strategies with business growth goals.

Businesses that recognize this distinction can better align their talent, processes, and technology investments. Treating logistics as a focused but essential aspect of a wider supply chain strategy allows companies to support both immediate operational needs and long-term competitiveness.

Accelerate Delivery With NetSuite ERP

NetSuite Transportation and Logistics helps businesses navigate logistics cost and visibility challenges by bringing financial, inventory, and supply chain data together on a unified and scalable cloud-based platform for a single, companywide information source that supports faster, more informed decision-making. With built-in tools for planning, procurement, and inventory, NetSuite facilitates greater control over core logistics functions. Real-time transportation and warehouse data helps analysts identify inefficiencies, optimize routing, and balance stock levels to better meet customer demand, all while reducing IT overhead and supporting growth without disruption.

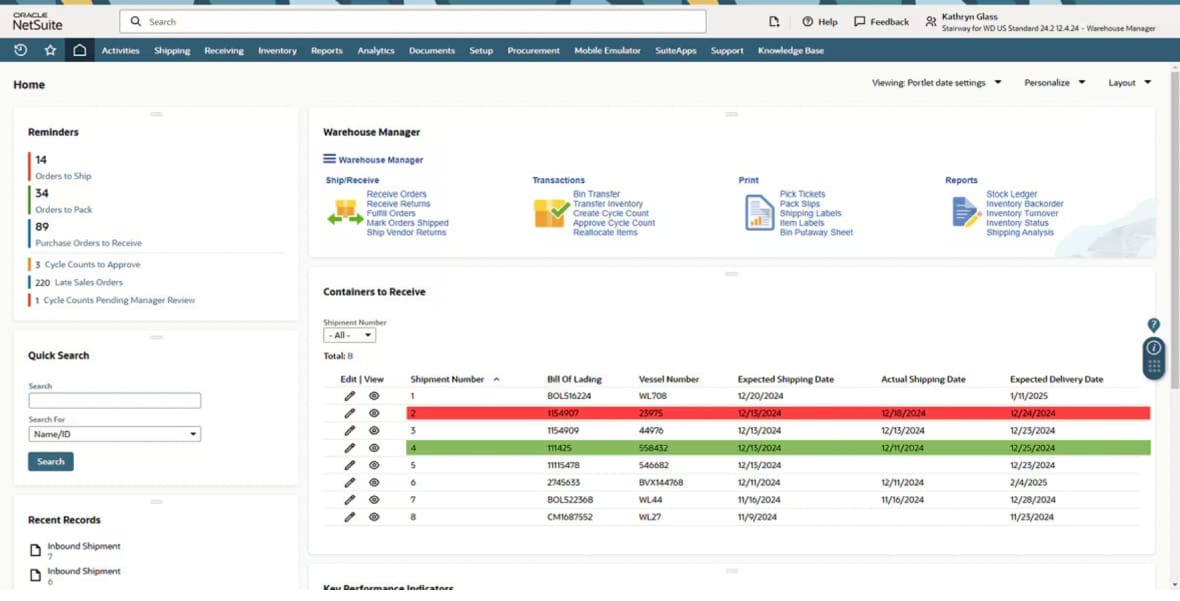

NetSuite Container Tracking

Logistics has evolved from a back-office function into a companywide strategy that drives customer satisfaction, operational efficiency, and profitability. Businesses that invest in comprehensive logistics solutions gain visibility into how goods and materials flow through the supply chain, as well as the inefficiencies that hinder performance. This visibility helps decision-makers act quickly, seize revenue opportunities, and build a more resilient, responsive operation. With the right tools in place, logistics can evolve from its historical status as a cost center into an important competitive advantage.

#1 Cloud ERP

Software

Importance of Logistics FAQs

What is the most important function of logistics?

The most important function of logistics is to efficiently move products, materials, and information from one location to another to meet customer demands. This involves coordinating key supply chain activities, including procurement, warehousing, order fulfillment, and transportation, to deliver the right products to the right places at the right time.

What are three basic functions of logistics?

The three basic functions of logistics are transportation management, inventory control, and warehousing operations. Transportation management involves selecting carriers, planning routes, and monitoring shipments to move goods. Inventory control uses forecasting, ordering, and tracking systems to balance stock levels, prevent stockouts, and reduce carrying costs. Warehousing operations focus on receiving, storing, and retrieving goods to meet production needs and order fulfillment requirements.

What are the benefits of good logistics?

Effective logistics reduces costs, improves delivery reliability, and strengthens inventory control—leading to higher customer satisfaction and better cash flow. It also increases supply chain visibility, reduces disruption risks, and helps companies adapt to changing market conditions. Together, these benefits drive profitability and create competitive advantages.