Better visibility into complex supply chains translates to fewer disruptions, increased customer satisfaction and lower costs. A supply chain visibility (SCV) project empowers product teams to spot and fix weaknesses in the supply chain, such as inventory shortfalls or order fulfillment issues, before they become major problems.

Sounds great, right? But many companies have found gaining meaningful end-to-end insights a bigger challenge than they banked on. Let’s look at why that is and how to overcome common roadblocks.

What Is Supply Chain Visibility (SCV)?

Supply chain visibility (SCV) is the ability to track individual components, sub-assemblies and final products as they travel from supplier to manufacturer to consumer. The scope — for example, are raw materials included, and will the item be tracked with forwards and backwards tracing — depends on the product.

SCV is enabled by supply chain management technology, which provides real-time data about logistics and other aspects of your supply chain. This data helps companies maneuver around inventory shortages, avoid bottlenecks, meet compliance directives and track products through to delivery.

SCV may refer to visibility both inside a company’s own operational borders and across a partner network. The former is clearly less of a challenge — though still not trivial — because the company controls access to relevant data sources. To track the movement of a widget from a factory in China to a U.S. assembly plant to a wholesale distributor and on to the customer or retailer is a multifaceted operation requiring the integration of diverse partner systems.

The technologies, such as procurement and inventory and order management software, to achieve this visibility are typically part of a company’s broader enterprise resource planning (ERP) system.

Key Takeaways

- Supply chain visibility applies to not only internal business operations, but those of external partners. It tracks raw materials through production and assembly, into finished products, all the way through to the customer’s doorstep.

- Modern supply chains are more complex than ever before, as they rely on diverse supplier networks all over the world.

- Transparency throughout this oft-expansive network can improve customer and supplier relationships, boost supply chain efficiency and increase profit margins.

- Improving your supply chain visibility involves automating supply chain processes for maximum efficiency, investing in supply chain management software and using insights from the software to drive decision-making.

Supply Chain Visibility Explained

Throughout the years, as companies have outsourced more pieces of their supply chains, they have found it more and more difficult to maintain control over their operations. This is where greater transparency throughout the process, or supply chain visibility (SCV), comes into play.

SCV relies on a business’s ability to adequately and consistently manage and keep records of all raw materials and components from suppliers and manufacturers as they progress through the supply chain. Companies need to track the movement of all products into, within and out of their facilities.

Oftentimes, companies will invest in supply chain management technology that automates many error-prone processes, reduces operational and overhead costs and makes information visible across the numerous departments responsible for managing the supply chain. In using this technology that improves SCV, companies can see the status of raw materials and the shipping and expected delivery dates of orders from both customers and suppliers.

Increased visibility into this network is also useful in enhancing internal business processes as it can alert employees of inefficiencies and highlight adjustments they should make. Without this data, businesses would be at major risk of losing out on sales and disappointing their customers with inaccurate product availability and inconsistent or nonexistent order tracking information.

Goals of Supply Chain Visibility

The broad goal of SCV is to collect better information about supply chain operations, improve efficiency, reduce risk, boost customer satisfaction and increase profits. Companies achieve these results via the improved planning, insights and supply chain execution delivered by supply chain management software.

Success depends on access to real-time, shared data across every node in a supply chain network. Often, that means configuring a centralized control tower, or hub, where SCV software analyzes supply chain data, such as product demand, sales forecasts, material availability and more. This control tower becomes a comprehensive source for decision-makers to review and manage all of a company’s supply chain activities.

Types of Supply Chain Visibility

Supply chain visibility is a broad concept, and which areas of the supply chain require increased transparency will vary by industry and company. When deciding how and where to gain greater insights into the supply chain, companies should consider cargo location, rates, auditing records and supply chain activities.

-

Cargo Location. Real-time visibility into the location and shipment status of cargo is one of the most important and foundational forms of SCV. Having access to the exact whereabouts of an order helps a business determine when to schedule the repurchase and delivery of products, stay on top of payments and keep internal and external stakeholders informed on the status of materials and goods. All of these improvements can improve operational efficiency. Given that customers increasingly expect to be able to track their purchases from the time it leaves the warehouse to the time it reaches their doorstep, visibility into cargo location also builds trust among customers.

-

Rates. Rates are defined as the costs related to the transportation of cargo. Therefore, visibility into them helps companies understand how much they are spending moving, shipping and delivering freight. This process used to be considerably simpler, yet as businesses expand their order volume and more closely monitor the number of shipments, available carriers and potential fulfillment locations, things start getting more complex. Full visibility into the various rates is necessary for supply chain leaders to conduct cost-benefit analyses and track company spending.

-

Auditing Records. Visibility into the supply chain yields accurate and detailed information on past transactions, documentation of freight activities and more. This information is invaluable within the auditing process as it allows businesses to fully inspect, review and validate past completed orders. Greater transparency within the auditing process also makes complying with regulations much easier, which is especially important for companies that operate across multiple countries.

-

Supply Chain Activities. Transparency within supply chain activities means tracking quotes, order receipts, bills of lading, proof of delivery and more, then sharing and managing all of that documentation. This allows organizations to trace each and every supply chain activity in order to better detect, pinpoint the source of and react to any problems that may arise.

4 Key Reasons Why Supply Chain Visibility Is Important

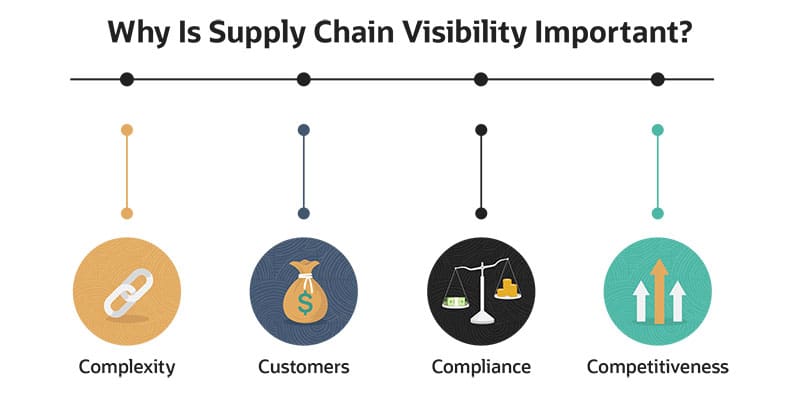

So, why is supply chain visibility important? Insights into the inner workings of a supply chain can inform operations, customer satisfaction, compliance and company growth. Other benefits boil down to four C’s:

-

Complexity: Modern supply chains are global. Extending insights across a diverse supplier network requires not just the right software and KPIs but a level of trust and transparency. It’s also the only way to head off logistical snafus that can damage customer relationships and erode profit margins.

-

Customers: Having the right products available at the right locations at the right time is fundamental to customer satisfaction, retention and acquisition. Moreover, customers have been conditioned to expect fast delivery and to be able to track their orders from loading dock to doorstep.

-

Compliance: International supply chains face steep regulatory requirements, including changing trade agreements, procurement rules and governmental tariffs. Then there’s your brand reputation: Are you sure that all the partners in your supply chain are behaving ethically? SCV helps companies monitor and manage variables including volatile monetary exchange rates, extreme weather and political or social unrest that could delay shipments.

-

Competitiveness: The supply chain encompasses a significant portion of many companies’ operating budgets, so inefficiency directly impacts the bottom line. SCV allows companies to spot and fix inefficiencies throughout the chain and thus reduce costs.

Award Winning

Cloud Inventory

What Does a Highly Visible Supply Chain Look Like?

Transparency within the supply chain has the potential to revolutionize a company’s operations by improving interactions and relationships with external suppliers and customers.

Regardless of whether a business needs to monitor supplies and products within the supply chain at a batch or individual item level, keeping track of safety, legal and material certifications, order and supplier information, the location and status of various suppliers, and the manufacturing date are integral to a highly visible supply chain.

A high-quality supply chain pulls data from across not only its internal operations, but from suppliers’ systems, allowing businesses to keep detailed tabs on each component it uses or sells. This transparency into upstream partners means companies are immediately notified of any issues, so that they have enough time to either address the problem or find an alternate solution.

A manufacturer with this level of visibility would first be able to track the movement of raw materials from the source to a sub-supplier or supplier. From there, the company could follow the movement of those materials or components as they eventually reached its manufacturing plant, where they are transformed into finished products. Not only would there be documentation for the use of each raw material and component within the production process — for future reference and to maintain accurate inventory records — but upon completion, the business could see the exact location of the finished goods. As goods left the plant, companies that purchased these goods would be able to track the movement of goods on ships, airplanes or trucks through customs or any other checkpoints. Once an end customer bought these products, they would be able to see the location and shipping status of their purchase, right up until it’s delivered.

If a customer initiated a return, reverse supply chain visibility would enable a company to track the returned item, receive it and document that when as it reached the fulfillment center. Ultimately, in the best and most efficient supply chain, there is an abundance of communication and information that is constantly being exchanged between all supply chain players to ensure that everybody has access to the most up-to-date data.

3 Steps to Increase Supply Chain Visibility

To increase SCV, you must gather and disseminate timely, relevant supply chain data across the organization — and then make sure it’s analyzed and acted on. This is a three-step process.

-

Select and implement SCV technology: Full-featured supply chain management software automates production from raw materials to delivery of finished goods to the consumer. First, diagram your supply chains so you know which modules you need. If your manufacturing is fully on-shore, for example, you can get by without insight into exchange rates.

SCV software ranges from simple point products to suites with dozens of modules that natively integrate supply chain and logistics capabilities with core back-end systems like ERP and CRM.

Look for capabilities across four areas: customer demand, inventory control and warehouse and fleet management. Popular modules include supplier relationship management and the ability to process client orders and closely track shipping and delivery.

-

Focus on process improvements: If your processes need serious work, you may want to shift this step ahead of software selection.

Once you’ve selected SCV technology, work with your software provider or integrator to make sure your team gets the full benefits. Eliminate manual or spreadsheet-driven processes — they are usually limited, inefficient and lack scalability. Make sure all decision-makers receive relevant reports related to supply chain activities — and that they have the ability to act on that information.

-

Drive efficiency: This is where you get returns on your software and process improvement investments. As your team gains deeper insights into the supply chain, from material sourcing to manufacturing to end customer, they’ll inevitably identify areas ripe for improvement.

2 Examples of Supply Chain Visibility

LovelySkin

Dr. Joel Schlessinger founded LovelySkin, an ecommerce site for skincare products and dermatology information, in 1997 to make skincare solutions and assistance more accessible. As the ecommerce business blossomed and the organization partnered with more brands and expanded its product offerings, it started to run into some logistical difficulties. Not only was there more inventory, orders, and vendors to manage, but the information related to each was spread across many different systems. This made keeping track of all supply chain data a daunting task filled with confusion and the potential for errors.

After replacing QuickBooks, Excel and other homegrown systems with NetSuite’s supply management systems, LovelySkin was able to better account for their inventory and plan for future business needs. Adopting a platform that updated information in real time and had demand planning capabilities helped LovelySkin become more profitable. The health and beauty brand was able to track all components from assembly to delivery, immediately place replenishment orders based on sales trends, avoid overstocks and hold less inventory.

With the help of NetSuite, LovelySkin was able to handle a 300% increase in orders at the start of the pandemic as demand for certain products surged. It’s better prepared for any future demand fluctuations with a single system that can manage its entire operational network.

Enjoy Life

Enjoy Life is a Chicago-based company that provides a line of allergy-free and gluten-free snacks and ingredients. After its founding in 2002 with 12 baked goods, the company quickly expanded and achieved its yearly growth milestones. By 2015, with business still booming, global snack company Mondelez International acquired Enjoy Life.

Yet, success was not without struggle. As Enjoy Life reached $40 million in revenue and had almost 100 SKUs, it realized that QuickBooks financials and Fishbowl inventory management could no longer keep up with the growing complexity and sheer volume of orders. Lacking access to real-time inventory data that would enable Enjoy Life to track product expiration dates and analyze product-related information was not conducive to optimizing business operations.

Turning to NetSuite’s supply chain management systems, Enjoy Life was able to exchange more data and improve communication with its many distributors, launching a key partnership with grocery chain Whole Foods. The business also started selling through a direct-to-consumer ecommerce site. Without having to worry about whether their software can keep up, Enjoy Life has tripled their sales and helped more customers enjoy tasty snacks.

7 Supply Chain Trends in 2023

Supply chains are increasingly digital, cloud-based and agile. Here are six trends to consider as you update your supply chain strategy.

-

Digitization: If we learned anything from an almost overnight shift to remote work it’s that manual processes and paper records are no way to manage a modern supply chain. Spreadsheets aren’t much better. By digitizing the supply chain, you’ll significantly improve the ability of business leaders to make timely decisions using demand forecasts and better manage inventory, suppliers, transportation and storage.

-

A move to the cloud: Along the same lines, the limitations of legacy on-premises systems and storage have become clear. Supply chain software delivered in an as-a-service model is accessible to decision-makers wherever they may be and is often easier to integrate with partner systems.

-

Focus on resilience: Modern supply chains enable adjustments in near-real-time to cope with disruptive events. Key here are end-to-end visibility and supplier relationship management capabilities paired with contingency planning and crisis management processes and incident response plans.

-

Nearshoring and reshoring: Companies are also increasingly looking to reshore parts of their supply chains to their home country or nearshore them, which is bringing the supply chain closer to, but not within, their home country. More than just a response to consumer demand, both processes can lower transit and shipping costs, allow for flexibility, decrease lead times and increase ability to detect risks and potential product defects.

-

Reverse and circular logistics: Today “end-to-end” doesn’t necessarily mean a linear progression from steel to sheet metal to carmaker to dealership. The concept of a circular supply chain is gaining popularity as companies look to make their manufacturing more sustainable by reusing and recycling stock. Similarly, reverse logistics is all about capturing value from, or properly disposing of, excess goods. As we discuss, in 2019, U.S. shoppers returned merchandise worth more than $300 billion, with a significant chunk of those items ending up back in the hands of distributors. Managing the reverse logistics process is critical to profitability.

-

Automation and robotics: Advanced automation and robotics — both on manufacturing lines and in software via robotic process automation (RPA) — enhance operational efficiency and reduce errors from repetitive manual tasks and data entry.

-

AI and machine learning: Artificial Intelligence (AI) and machine learning likewise increase supply chain efficiencies through trend-spotting and self-learning capabilities. These technologies will eventually be incorporated into top supply chain and logistics software to improve decision-making, planning, forecasting, advanced calculations and more.

Trends are always evolving, so check out our 14 supply chain trends to watch in 2023.

Increase Supply Chain Visibility With Supply Chain Management Software

The degree of visibility that an organization has into its supply chain has the potential to spell success or failure for the business. Having insights into the location and status of raw materials, finished products, delivered orders and returned items is crucial for the efficiency and lasting financial success of a business. NetSuite can make it easier to manage this complex and critical network with its supply chain execution software. This technology keeps track of the location and status of their current, in-transit and work-in-progress inventory and automates manual processes such as managing purchase and work orders, receipts and vendors.

NetSuite also helps companies strike the right balance between supply and demand trends with a demand planning module that can review historical data and other factors to make better procurement decisions. The tool can use a number of different calculations to come up with forecasts. NetSuite provides a centralized database that makes communicating with key supply chain players and keeping a close watch on all the moving parts of the supply chain feasible.

Although gaining full supply chain visibility is no easy feat, it’s a necessary one for any business that relies on a supply chain to generate revenue and wants to continue to satisfy and retain customers. Taking steps to generate greater transparency, efficiency and accountability throughout the supply chain can set companies on the path toward improved customer and supplier relationships and increased financial success.