As a growing business, do you know how much production capacity you’ll need to fulfill anticipated future demand and keep customers happy? That’s the essential question capacity planning aims to answer. It helps organizations estimate the equipment, materials and people they’ll need to meet short-term and long-term demand — while minimizing the risk of overinvesting in capacity. This comprehensive guide delves into capacity planning types, strategies, benefits and best practices.

What Is Capacity Planning?

Capacity planning is a process for analyzing how much production capacity organizations need to meet customer demand. It’s widely used in manufacturing and services industries. Capacity planning helps companies determine whether they have enough raw materials, personnel and equipment to meet forecasted demand. If demand is expected to increase in the future, businesses can use capacity planning to estimate how much additional production capacity they’ll need. Companies can also use capacity planning to determine whether they have the ability to take on new customer projects.

Capacity planning vs. resource planning:

The terms capacity planning and resource planning are sometimes used interchangeably — but there are key differences between them.

-

Capacity planning is a strategic long-term approach that focuses on matching supply with demand. Do you have all the resources you need to make what customers want today, as well as what you’ll need in the future? Is a lack of specific resources restricting your overall capacity; did you turn away projects because you’re understaffed or are lacking necessary equipment, for example?

-

Resource planning is a shorter-term approach that looks at the resources you have on hand and how you can best deploy them to meet your current workload. For example, a consulting firm might consider how to assign its staff to the projects that best match their skills.

Key Takeaways

- Capacity planning helps organizations manage production capacity to meet customer demand.

- This process also helps businesses determine whether they have enough resources, such as supplies, personnel and equipment.

- Businesses may choose different capacity planning strategies depending on factors such as their overall business strategies, target markets and risk tolerances.

- Key capacity planning steps are forecasting demand, assessing current capacity and using that information to create a plan for the future.

Capacity Planning Explained

Capacity planning examines all the resources involved in production and estimates how much of each resource will be needed to meet demand. Resources include the people who perform the work, the raw materials and products used, equipment and facilities. The lack of a single resource can constrain the company’s production capacity. For example, the company may have enough equipment and skilled workers, but if there’s a shortage of raw materials, it won’t be able to meet production targets.

Capacity planning involves many parts of the business and can be a complex process, especially when customer demand changes frequently and unpredictably. Overestimating the capacity you’ll need may have expensive consequences. For example, a manufacturing business may buy expensive new manufacturing equipment that lies idle because the anticipated customer demand doesn’t materialize. But underestimating capacity can also be problematic, leading to lost revenue, stockouts and customer frustration.

How Does Capacity Planning Work?

Think of capacity as the maximum amount of work the business can complete in a given period. It may be calculated in various ways, depending on the company and the situation. Some companies may calculate capacity as the total number of employee work hours per week. For example, a consulting firm may have 25 employees who are each available for hire 40 hours per week, for a total capacity of 1,000 work hours per week.

Other companies, including manufacturing businesses, calculate capacity in terms of output. Let’s say a dishware company has 25 employees who can each produce 15 boxed sets of dishes per hour. If it’s operating 40 hours a week, without other constraints such as downtime, its capacity would be 15,000 boxed sets of dishes per week.

Capacity planning attempts to answer the question of how to match that capacity to anticipated demand. How will demand for the consulting firm’s services change over the next year, and how many consultants will it need to hire to meet that demand? Should the dishware firm invest in expanding production capacity to meet rising demand? Getting those answers right can result in increased revenue and profits. But a mismatch between supply and demand can lead to unused resources or an inability to fulfill orders.

History of Capacity Planning

The roots of capacity planning date back to the Industrial Revolution. With the transition from an agricultural to an industrialized society, product consumption increased and manufacturers started trying to anticipate demand.

During the 20th century, new manufacturing techniques enabled enormous increases in production capacity, helping to satisfy rapidly growing consumer demand. Henry Ford famously introduced assembly lines to cut production time for the Model T from 12-plus hours to 90 minutes, helping to propel the worldwide consumer adoption of automobiles.

Early attempts at capacity planning relied on manual methods that were extremely labor-intensive. More recently, capacity planning has been transformed by technology. Capacity planning software can consider multiple variables, including demand forecasts, to estimate the capacity required. Technology also makes it much easier to respond quickly to shifts in demand or supply constraints.

Types of Capacity Planning

Capacity planning typically focuses on three key resource categories: materials, workforce and equipment.

-

Products and materials capacity planning.

Do you have enough materials or other items to fulfill anticipated orders? For example, a plant nursery needs enough flowers, trees, shrubs, seeds and soil to meet the demands of its customers. A manufacturer needs enough raw materials to feed its production processes.

-

Workforce capacity planning.

This ensures businesses have enough people and work hours available to complete jobs in a timely manner. It also helps determine when you need to adjust the size of the workforce.

-

Equipment/tools capacity planning.

This aims to make sure that production capacity isn’t held back by a lack of equipment. It analyzes the quantity of tools and other equipment needed to meet projected demand. The equipment may include machinery, forklifts, assembly line components, computers and anything else needed to manufacture the company’s products.

Capacity Planning Strategies

Capacity planning isn’t a one-size-fits-all approach. Choosing a particular capacity planning strategy depends on factors such as the company’s growth targets, risk tolerance and the kind of products it makes.

-

Lead strategy.

This aggressive strategy calls for expanding capacity in anticipation of increased future demand. Manufacturers often use lead capacity planning when they’re aiming to win market share against competitors. If your lead strategy positions you as the only company with a large supply of a product in high demand, you may enjoy a boost in profit and market share. However, a lead capacity planning strategy can be risky if demand doesn’t grow as expected.

-

Lag strategy.

This is a more conservative capacity planning approach. Lag capacity planning focuses first on meeting current demand. Only when the company is already operating at its maximum capacity does it add more capacity if demand continues to grow. This strategy lessens the risk of overinvesting in production but also increases the chances of losing revenue and experiencing stockouts.

-

Match strategy.

This moderate strategy, also known as tracking strategy, mixes in elements of both lead and lag strategies. Match planning adjusts capacity by small amounts in response to market trends, as opposed to committing to a big capacity expansion in anticipation of demand growth (lead strategy) or waiting until you have already reached your maximum capacity (lag strategy).

-

Adjustment strategy.

This strategy relies on planning tools that analyze multiple variables, such as demand forecasts, real-time sales data and seasonal trends. The goal is to more accurately adjust capacity in advance of demand. For example, if demand has historically exceeded capacity during the summer, the company may plan to increase capacity during those months.

The Secrets to Mastering Inventory Management

Benefits of Capacity Planning

Capacity planning can deliver many benefits, including lower costs, higher customer satisfaction and a clearer view of future requirements. More specifically, this planning process can:

-

Reduce operational costs.

Capacity planning facilitates more accurate budgeting and helps minimize waste. It helps companies ensure they’re investing the appropriate amount in materials, equipment, facilities and staff. Capacity planning can also help companies identify potential bottlenecks and other resource problems, so they can adjust operations to increase efficiency.

-

Achieve on-time delivery.

Effective capacity planning means that adequate resources are available for each job, helping to ensure that production stays on schedule. You can fulfill orders on time and keep customers happy.

-

Avoid stockouts.

Good capacity planning means companies are better able to match supply to demand. It reduces the chance that you’ll run out of in-demand products, which can lead to customer frustration and lost business.

-

Inventory skill sets.

Part of capacity planning involves spelling out the skills needed to make your company’s products. A good plan forecasts skill requirements and incorporates any training needed for employees as well as expertise you’ll need to acquire from outside sources.

-

Provide a blueprint for growth.

Capacity planning provides a blueprint for the company’s future expansion. It determines the facilities, equipment and people you’ll need to meet demand as the company grows. That helps you plan your growth over time. For example, you can better identify potential new locations that offer the resources you need.

3 Steps to Capacity Planning

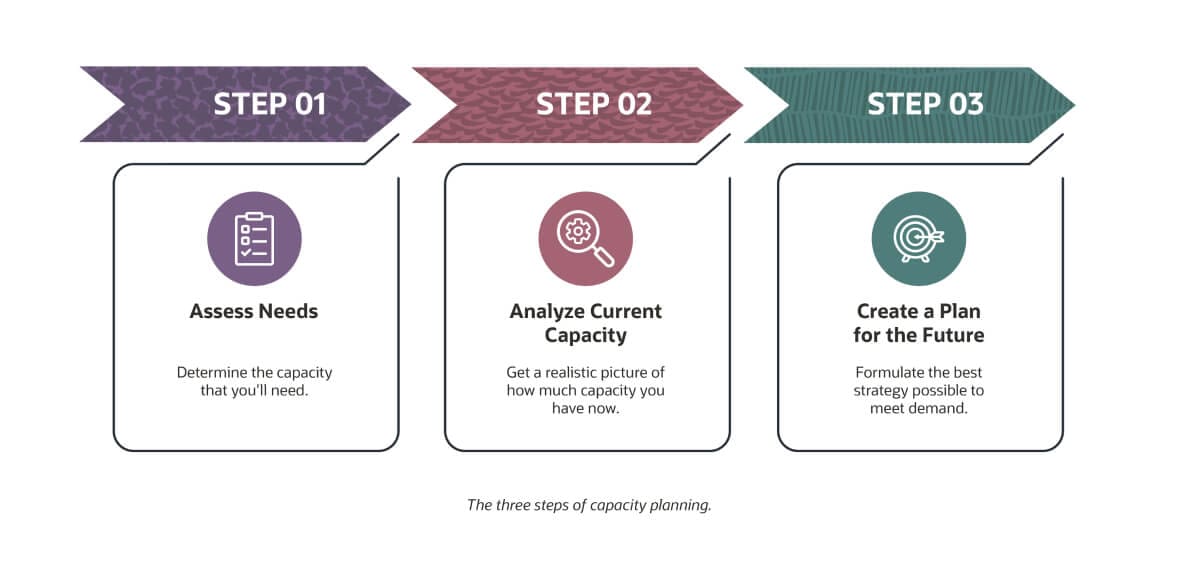

Capacity planning can be divided into three broad steps: What capacity do I need? What do I already have? And what changes are needed going forward?

-

Assess capacity requirements.

How much capacity will you need to meet your anticipated demand, and when will you need it? How many items will you need to make in a day? Consult your forecasts and production schedule to help determine how much production capacity you’ll need.

-

Understand current capacity.

Understanding current capacity provides a realistic expectation of what the company can produce. This requires an analysis of the company’s actual performance, not just its theoretical maximum capacity. How efficiently does the company use its capacity? Does it achieve a consistent level of use or is performance inconsistent? Analyze actual versus predicted process performance and calculate which parts of each process take the most time.

-

Create a plan for the future.

After analyzing your current capacity, it’s time to determine how you’ll move forward. Do you need additional capacity to meet demand? How much? Look at alternatives for adding capacity, such as adding equipment, streamlining workflows or expanding the workforce. Considering different scenarios based on demand forecasts and actual demand can help determine the production plan that’s most likely to meet demand with the lowest risk.

Capacity Planning Examples

A company makes pool toys and related products, including inflatable pools, rafts, beach balls, goggles and kickboards. Demand is seasonal, expanding in summer and shrinking in winter. So the company examines historical data and current market trends to estimate the capacity it will need. The historical data shows how many of each item the company produced and indicates whether that production resulted in excess products or a shortage.

Based on its research, the company sets a goal of producing 40,000 items in each product category. Its production process can make only one type of product at a time. Historical data indicates that the company can consistently achieve the following hourly production rates:

- Inflatable pools: 25 per hour

- Rafts: 50 per hour

- Beach balls: 100 per hour

- Goggles: 40 per hour

- Kickboards: 50 per hour

The company aims to keep its staffing and equipment resources the same as in the past: 50 employees who each work 30 hours a week, totaling 1,500 work hours per week.

Based on the project requirements that call for producing 40,000 of each item, here’s how much capacity the company needs:

- Inflatable pools: 40,000 / 25 = 1,600 work hours needed

- Rafts: 40,000 / 50 = 800 work hours needed

- Beach balls: 40,000 / 100 = 400 work hours needed

- Goggles: 40,000 / 40 = 1,000 work hours needed

- Kickboards: 40,000 / 50 = 800 work hours needed

That’s 4,600 total work hours needed. Since employees work a total of 1,500 hours per week, this project would take a little more than three weeks to complete.

That timeline doesn’t account for potential hiccups along the way, such as supply chain delays, unplanned resource changes, equipment breakdowns or employee absences. Plus, the company needs to factor in the amount of time it takes to change out the materials and reconfigure equipment for each product. So, the final plan may call for about four weeks or possibly even more to complete production.

8 Capacity Planning Best Practices and Tips

Capacity planners must determine the appropriate way to balance resources and demand. Here are some best practices to help with the balancing act.

-

Analyze current resources.

Get an accurate picture of your current capacity and the resources at your disposal. This provides a basis for determining how much capacity you’ll actually need to handle demand.

-

Aim for the right mix of skills.

Cross-functional teams that include a mix of planning, business and operational skills can bring the diverse perspectives needed to understand current capacity and how to meet future requirements.

-

Prioritize projects.

Focus on the most important projects first. Which orders are the most time-sensitive? What must be done right away to meet demand?

-

Track operational productivity.

Are tasks taking longer than planned? If so, why? Are delays due to unrealistic scheduling or are there other problems? Gathering this real-world data can help you better budget time for future jobs.

-

Pinpoint bottlenecks.

Is production held up by specific process steps or the lack of a single resource? Look for ways to restructure resources to eliminate any bottlenecks.

-

Focus on communication.

Staying in touch with all stakeholders helps to manage expectations and enable the company to make adjustments to accommodate any operational hitches.

-

Monitor risks.

Look for risks, such as potential supply-chain problems and rising costs. Identifying potential problems early allows the company to factor them into capacity plans.

-

Expect change.

It’s all too common to experience events that require a change in plan — an inaccurate estimate, a lack of a key raw material, a machine failure. A realistic approach to capacity planning recognizes that the company is not immune to these problems.

4 Common Capacity Planning Issues

Capacity planning is often a complex process that involves collaboration among multiple stakeholders and gathering information from across the company. Here are some potential problems to watch out for:

-

Data collection.

Capacity planning involves combining data from multiple sources, including internal groups such as sales, manufacturing and finance, as well as external information about market trends. Not all of this information may be easy to obtain. That can make it difficult to quickly build a consolidated, up-to-date view of current capacity use and determine how much capacity the company needs.

-

Data quality.

Data combined from multiple sources can be of inconsistent quality and in a variety of different formats. Some data may contain errors, especially if it’s been collected manually. Other information may be out of date.

-

Calculation accuracy.

Capacity planning can involve complex calculations that factor in materials, people, equipment, market demand forecasts and more. Accuracy is essential to ensure the company doesn’t underestimate or overestimate the capacity it needs to meet demand. But it’s easy to make errors, especially if data is drawn from many sources and the calculations are performed manually using spreadsheets.

-

Collaboration.

There are so many people involved in capacity planning, both internal and external, that it can be challenging to keep everyone in sync. Production teams may not be kept up to date with information about new projects and sales that affect the amount of capacity the company needs. Further adding to the challenge: Some information may need to be communicated externally to suppliers and customers.

Tackle Capacity Planning With NetSuite

NetSuite’s cloud-based Enterprise Resource Planning (ERP) solution helps businesses create effective capacity plans based on analysis of production capacity. NetSuite’s rough cut capacity planning (RCP) compares demand with resource availability to determine capacity use during a planning period. NetSuite generates reports necessary for both short- and long-term capacity planning, helping to predict future needs based on historical data. For manufacturers that need to plan capacity, NetSuite Advanced Manufacturing(opens in new tab) provides an integrated solution that ensures manufacturing processes are connected to financial reports, inventory management and outstanding orders in real time. Effective production plans determine the route for each item, estimate start and end dates and evaluate the available capacity for performing the work.

Capacity planning helps companies achieve the balance between supply and demand that’s often critical to business success. Through analysis of demand forecasts and current resources, capacity planning helps companies create a blueprint for handling future growth.

Capacity Planning FAQs

What are the three steps of capacity planning?

The three steps of capacity planning include determining how much capacity will be required, assessing your current capacity and planning how to expand current capacity to meet demand.

What is a capacity planning example?

You own and operate a bakery with four other employees and you all work five eight-hour days. That’s a total of 200 work hours per week. You know that the bakery generates 150 cookies and five cakes per hour using three ovens. That means your maximum capacity, based on continuous operation during working hours, would be 1,200 cookies and 40 cakes per day, and 6,000 cookies and 200 cakes per week. This provides the bakery owner with a basis for understanding how many supplies the shop should order to meet demand. The owner needs to consider factors that can impact production, such as staff absences and supply problems. Should the demand increase beyond the bakery’s current capacity, the owner could add another oven, increase its staff or pay overtime.

What are the four capacity planning strategies?

The four primary capacity planning approaches are the lead, lag, match and adjustment strategies. The lead strategy is an aggressive approach to expanding capacity in advance, based on anticipated demand. The more conservative lag strategy focuses on meeting actual demand; the company only expands its capacity when it’s already running at full capacity and sees an increase in demand. Match strategy is a moderate approach that combines elements of the lead and lag strategies, increasing capacity incrementally in response to market trends. Adjustment strategy applies demand and supply planning tools that consider multiple factors, including historical demand, seasonality and sales forecasts.

What is capacity planning in operations management (OM)?

Capacity planning in OM balances product demand with a company’s ability to meet that demand. The object is to optimize cost and operational effectiveness.