Inventory management is one of the pillars of a successful retail operation. Retail inventory management techniques help stores and ecommerce sellers satisfy customers, reduce costs and increase profits.

What Is Retail Inventory Management?

Retail inventory management is the process of ensuring you carry merchandise that shoppers want, with neither too little nor too much on hand. By managing inventory, retailers meet customer demand without running out of stock or carrying excess supply.

In practice, effective retail inventory management results in lower costs and a better understanding of sales patterns. Retail inventory management tools and methods give retailers more information with which to run their businesses, including:

- Product locations

- Quantities of each product type

- Which stock sells well and which doesn’t, by location and sales channel.

- Profit margin by style, model, product line or item

- Ideal amount of inventory to have in back stock and storage

- How many products to reorder and how often

- When to discontinue a product

- How changing seasons affect sales

What Is the Importance of Inventory Management in Retail?

Inventory management is vital for retailers because the practice helps them increase profits. They are more likely to have enough inventory to capture every possible sale while avoiding overstock and minimizing expenses.

From a strategic point of view, retail inventory management increases efficiency. The practice:

-

Decreases Inventory Costs:

When you know how much stock you have and how much you need, you can pinpoint inventory levels more accurately, thereby reducing storage and carrying costs for excess merchandise. Other savings include shipping, logistics, depreciation and the opportunity cost that comes from not having an alternative product that might sell better. -

Minimizes Out-of-Stocks:

To avoid disappointing customers and missing sales, retailers want to avoid running out of inventory. Retailers can use inventory management tools to determine how much stock is “just right” to have on hand, neither too much nor too little. This amount will be larger for bestsellers than for unpopular products. Also, with real-time information on sales and stock, retailers can react quickly by reordering, transferring stock from another location or drop shipping to the customer. -

Improves Profit Margins:

With lower inventory costs and enough supply to fill every order, retailers improve profitability. -

Prevents Spoilage and Obsolescence:

Inventory management helps retailers address another costly inefficiency that happens when products expire or become obsolete. This phenomenon can apply to perishables that have a limited shelf life, such as milk and meat, or a non-perishable that becomes obsolete because consumer tastes and technology change. For example, season collections or holiday-specific packaging. Or when a piece of consumer technology adds a popular new feature, the old models may face plummeting demand: Consider how the rise of smart televisions sunk demand for models that weren’t capable of streaming content. -

Improves Multi-Channel and Omnichannel Performance and Order Fulfillment:

If you are selling via physical stores, your website and third-party merchants, it can be difficult to keep correct inventory counts across all channels. Having accurate inventory data across selling channels lets you use your inventory more efficiently, ultimately getting the product to consumers faster. -

Simplifies Processes and Facilitates Growth:

Strong inventory management also reduces friction in your systems as sales grow. Shipping, receiving and order fulfillment run more smoothly, and you minimize errors, customer complaints and staff stress. -

Reduces Shrinkage:

Shrinkage is inventory loss due to shoplifting, product damage, vendor mistakes or fraud, employee theft and administrative errors. According to a survey by the FMI food industry association, the average supermarket loses up to 3% of sales through shrinkage. A National Retail Federation survey puts average shrinkage for its members at 1.4% of sales in 2019. This data suggests that most losses stem from incorrectly recording inventory on intake, miscounting it or misplacing it. Stronger retail inventory management could reduce shrinkage by at least half. -

Eases Supply Chain Management:

Having a firm grip on inventory and sales trends helps you manage your supply chain better. You can use the replenishment system that works best for you, whether that’s just-in-time ordering or fewer, bigger orders. Retail inventory management helps you determine your economic order quantity (EOQ), which is the ideal order size to minimize inventory costs including holding, shortage and ordering expenses. The EOQ formula, which factors in demand in units, ordering costs such as shipping charges and holding costs, works best when these variables remain consistent over time. Learn more about the EOQ formula. -

Improves Customers Satisfaction:

When customers get the products they want faster with fewer mistakes or out-of-stocks, it increases customer loyalty. -

Improves Forecasting:

You can use data such as historical sales results and available inventory to project future sales, growth and capital needs. These forecasts are vital to your budgeting and guide spending for marketing, product development and staffing.

How Does Retail Inventory Management Work?

Retail inventory management works by creating systems to log products, receive them into inventory, track changes when sales occur, manage the flow of goods from purchasing to final sale and check stock counts.

The information from these systems helps you achieve the benefits of retail inventory management, such as lower costs and higher profit margins.

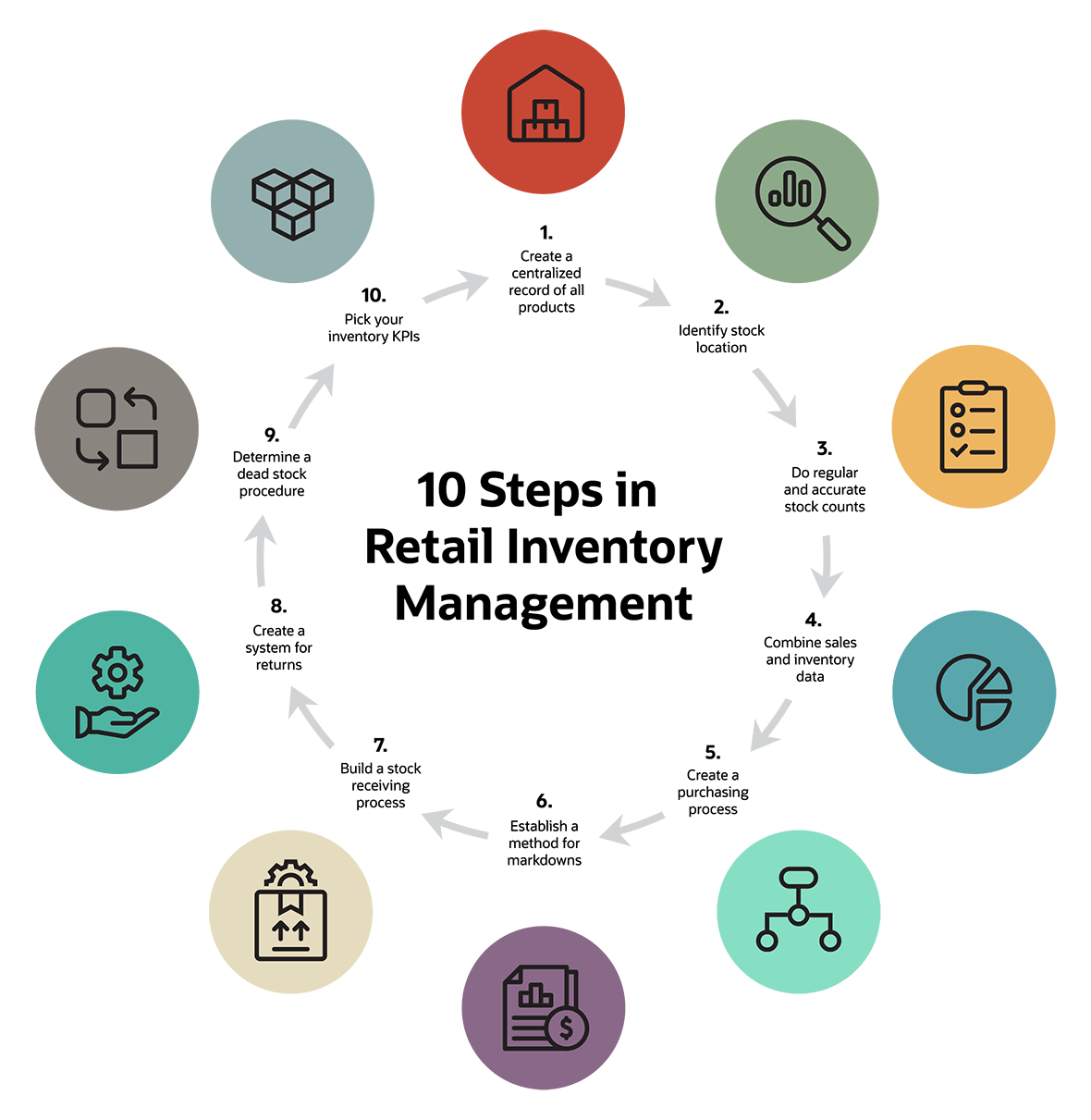

10 Basic Steps in Retail Inventory Management

The 10 basic steps in retail inventory management verify the goods you have, their quantity, location and other specifics such as expiration date. This stock data is useful for maximizing profits by understanding demand, costs and other variables.

You can integrate these procedures into a retail inventory management system, which can be as simple as a paper ledger or a spreadsheet but typically involves an electronic solution.

The following is a breakdown of the steps in retail inventory management.

-

Create a Centralized Record of All Products:

List all the products you carry in one place with these details:- Product name

- Stock-keeping unit (SKU)

- Brand

- Variables such as size, retail price, product category, lot number, location and expiration date.

- Vendor and vendor SKU

- Wholesale cost

- Minimum reorder amount

- Economic order quantity (EOQ)

- Case quantity amount

- Inventory on hand

- Reorder lead time

Add product images and descriptions to help staff identify products. This step is key if you sell by ecommerce. When you add new products, put them into your inventory record. Whenever information such as a vendor or wholesale cost changes, update it. Establish policies for entering inventory, including who is responsible and when to do it. Having rich data helps unlock the power of a retail inventory management system.

-

Identify Stock Location:

If you are a small business with just one store, recording your inventory’s location is straightforward. Items are probably either on display or in the stockroom. But retail chains with multiple sites and omnichannel sellers might have inventory in warehouses, distribution centers, transit, stockrooms and on store shelves. Within those destinations are more specific locations such as section, shelf and rack. Misplaced and overlooked products represent missed sales and lost revenue. Retail inventory management practices help prevent this. Use radio frequency identification (RFID) tags, bar codes and labels that contain category and department codes to fully or partially automate the mapping of your inventory. -

Do Regular and Accurate Stock Counts:

You need to count your inventory periodically to ensure it is accurate. Take into account shrinkage, damage, defects and returns to avoid errors. A retail inventory management system makes this process easier because you only need to double-check your data, rather than start from scratch. So, you can primarily focus on deviations. The frequency of counts depends to an extent on your business’s complexity, scale and the type of inventory management system you use. Nonetheless, experts recommend counting inventory once a quarter or once a year at absolute minimum. Some businesses count individual parts of their stock daily. Several counting techniques exist, including physical counting and cycle counting. -

Combine Sales Data With Inventory Data to Simplify Reporting:

A retail inventory management system can integrate sales and inventory data. This picture shows you which goods are turning over fastest (a metric called sales velocity) and which are lagging. Use the product data to decide when and how much to reorder and when to offer promotions or discounts. -

Create a Purchasing Process:

Schedule times to review data and place orders, so you don’t get caught behind seasonal trends or risk stock outages. With an electronic system, you can set stock levels for individual products that trigger alerts for reorder. These levels should include a buffer that allows sales to continue at normal levels. If you’re using a manual system, review which items are sold out or at reorder points, and add them to your purchase list. Prioritize purchases based on an item’s profitability, popularity and lead time. Then, create a purchase order. -

Establish a Process for Markdowns and Promotions:

Product sales can fail to live up to expectations for several reasons, such as a cooling trend, obsolescence or seasonal factors. If you offer markdowns, be disciplined about discounting and moving slow sellers, which can generate cash and make room for more profitable products. Additionally, create a strategy ahead of time for promotions to ensure that you have enough stock on hand to meet demand. -

Create a Stock Receiving Procedure:

During the receiving process, you’ll verify incoming orders and enter goods accurately into an inventory system. Without an established procedure, any supplier error or damage in transit can result in problems like unexpected stock outages, overpayment to vendors and dead stock. Check each delivery against the purchase order to verify the contents match the order. Count cartons and pallets, confirming product type and numbers and noting mistakes, damage or shortfalls. Follow up with vendors on any issues. Then, enter the new products into inventory counts and store the goods. Depending on your needs, you might add price tags or bar codes to the stock. Perpetual inventory management, the simplest way of managing inventory, involves counting goods as soon as they arrive. Read the article on perpetual inventory to learn more. -

Create a Procedure for Returns:

Without an inventory management process for handling customer returns, you face an increased risk of holding unsellable stock or missing an opportunity to put a sellable item back on display. When a customer makes a return, check to see if the item is damaged or defective, and route it for repair, write-off or return to the vendor as appropriate. If the product is sellable, add it to your inventory counts, and put it in its correct place (in a physical store, ecommerce inventory, etc.). -

Determine a Dead Stock Procedure:

Excess inventory ties up capital and weighs on profitability. Dead stock includes damaged items, incorrect deliveries and leftover seasonal products. First, record items that fall into this category and remove them from inventory. Designate a place to hold dead stock, and handle it regularly (weekly, monthly or in a timeframe that’s right for your business). Ship merchandise that you can return to vendors for credit, called pullbacks, promptly. Note any deadlines for the return shipment. Return damaged and defective goods to suppliers, or document and notify suppliers, according to their policy. Depending on your product line, you can deal with the remainder by selling to outlets, donating, recycling or disposing of it. -

Pick Your Inventory KPIs:

To gauge the success of your process, pick and track some key performance indicators (KPIs). Profitability, inventory value, sell-through rate and turnover rate are essential metrics for retailers. Learn how to calculate these, and see examples in the in-depth guide to KPIs for inventory management.

Inventory Management Methods for Retailers

Inventory management methods help retailers generate maximum profits by reducing costs, improving efficiency and understanding sales drivers. These methods optimize quantities purchased from suppliers, fine-tune fulfillment processes, strategically locate products, account for inventory and analyze demand and sales patterns.

The following are some of the key inventory management methods for retailers, organized by category. You can learn more about many of these in the “Essential Guide to Inventory Control.”

Inventory Ordering Techniques for Retailers

These methods will help you determine demand. Inventory management software can automate this planning.

-

Economic Order Quantity (EOQ):

Use this formula to calculate the ideal order amount. The equation takes into account demand, ordering costs and carrying costs. Where D is demand in units, S represents ordering costs per order such as shipping, and H represents holding costs such as storage expense, the formula is:EOQ = √ (2 × D × S / H)

-

Open to Buy (OTB):

This plan-ahead technique tells a retailer how much merchandise to buy in dollar terms for a fixed period. The goal is to ensure there’s adequate supply and to generate positive cash flow. The formula is:Planned sales + projected end-of-period inventory on hand, in transit and on order - planned beginning of period inventory = OTB at retail cost

-

Safety Stock and Par Level:

Safety stock is the amount of inventory you order to serve as a buffer to prevent running out of stock. You carry this additional quantity in case of incorrect sales forecasts or unexpected consumer demand.Par level = safety stock + the minimum inventory required to meet customer demand

If inventory falls below par level, it is time to reorder.

-

Reorder Point:

Using sales data and the lead time for new merchandise to arrive from vendors, retailers can calculate the reorder point, or the inventory threshold that should trigger reorder. The formula is:(Average daily unit sales x average lead time in days) + safety stock in units = reorder point in units

-

Just in Time (JIT):

With this method, retailers receive new inventory exactly when they need it, rather than in advance. Japanese automakers pioneered this approach, which minimizes tying up capital in inventory and storage costs. JIT is easiest to implement with high-cost, low-volume goods like cars and appliances. The savings on low-margin, high-volume products, when compared to the risk of stock-outs, may not be enough to merit the extra complexity.

Inventory Fulfillment Methods for Retailers:

These methods offer ways to reduce the cost of getting products to customers or holding inventory. They also increase handling efficiency.

-

Drop Shipping:

With this method, the retailer does not hold the products it sells. When a customer makes a purchase, the retailer buys it from the vendor, who ships it to the customer. This decreases the retailer’s costs for handling and storage as well as its investment in inventory. -

Consignment:

In this arrangement, the wholesaler or supplier still owns the merchandise, but the retailer stocks it in inventory. When the product sells to the end customer, the retailer pays the vendor, thereby reducing upfront expenses for the retailer. -

Cross Docking:

The goods in incoming deliveries are directly put onto outbound trucks without ever entering storage. The outbound goods may be going to customers or retail outlets and distribution centers. This technique reduces handling and warehouse space. -

Pick and Pack Process:

The way a retailer fills ecommerce orders from the warehouse will influence efficiency, volume, error rate and other factors that impact customer satisfaction and profitability. Methods include individual order picking (each order filled one at a time), batch picking (gathering multiples of the same item at one time for different orders), wave picking (filling groups of similar orders at the same time) and zone picking (workers pick only products in their assigned zone of the warehouse). -

3PL:

Some retailers benefit from outsourcing inventory handling and order fulfillment to third-party logistics services. They can save the retailer money and scale more easily.

Inventory Accounting Techniques for Retailers

Use one of these methods to determine the cost of your inventory and goods sold for accounting purposes. Both techniques impact profits, taxes and the usefulness of financial reports. They are strictly for the accounting of physical inventory. They do not require you to identify and track the age of each item sold.

-

First In, First Out (FIFO):

This method assumes you sell the oldest products in your inventory first. This option is the easiest to understand and use. This technique tracks the natural lifecycle of goods: Retailers usually prefer to sell older products first, before they spoil, become obsolete or lose value in another way. FIFO, the most popular choice for retailers, is thought to be a more accurate reflection of real business conditions than LIFO. -

Last In, First Out (LIFO):

This technique assumes you sell newer inventory first. These goods often have a higher cost than older stock, which reduces stated profits and taxes. LIFO carries a risk of allowing inventory to remain on the books indefinitely and become undervalued or overvalued relative to market costs. LIFO accounting is more susceptible to manipulation, so it is less trusted.

To learn more about inventory costs, read “The Key to Using Inventory Cost Accounting Methods in Your Business.”

Inventory Analysis and Forecasting Methods for Retailers

Retailers use techniques in this category to understand their performance. For example, they identify products that sell best so they can prioritize them. Stores also use these to determine their return on inventory investment and estimate the value of their stock.

-

ABC:

ABC analysis divides inventory into three groups:- A is for your most valuable products, typically the 20% of inventory that accounts for 80% of sales or profits.

- B represents the greater number of mid-range products that do not fit in either A or C.

- C is for the largest number of products that sell the least or contribute least

to profitability.

Retailers use this information to improve how they manage—how much they hold and their purchasing strategy—inventory in each group. ABC analysis data can also guide marketing efforts and other strategic activities.

-

FSN:

This method, which stands for fast, slow and non-moving analysis, is similar to ABC in that it categorizes inventory into three groups. Here, the division focuses on sales velocity (the speed at which you generate revenue). Fast-moving items might be able to support price increases. Similarly, a store owner might consider discontinuing non-moving items. An online retailer could also organize a warehouse, so F products are the easiest and fastest to pick because they are closest to packing stations and on the most accessible shelves. -

XYZ:

This technique also sorts products according to variability in demand and difficulty in forecasting sales. X products have steady demand, Y items have strong variability, and Z goods have erratic and hard-to-predict demand. Retailers can even combine the ABC and XYZ systems to segment their inventory for more precise ordering and stocking practices. For example, your reordering policies for an AX product, which is a strong contributor to your bottom line and has steady demand, would likely be quite different than for a CZ product, which contributes least to your business and faces unpredictable demand. -

Batch Tracking:

The objective of this segmentation technique is quality control. This method groups goods into sets of products that were manufactured or processed together using the same raw materials. Retailers monitor information about products, such as expiration dates, place and date of manufacturing, origin, recall status, defect rates and purchaser, by batch or lot. For example, a grocery store chain wants to keep an eye on all the milk expiration dates in its inventory. A paint retailer would make sure that all the cans in a customer’s purchase came from the same lot to avoid shade variation. Meanwhile, some goods such as medication need an audit trail. -

Gross Margin Return on Investment (GMROI):

This formula shows retailers how much gross profit they earn for each dollar invested in inventory. Many stores look at this value by department. The formula is:Gross margin return on investment = gross margin / average inventory cost

-

Inventory Turnover Rate:

This calculation tells a retailer how many times it sells its entire stock of inventory in a year, which is an indicator of financial health and liquidity. There are a few ways to figure this out. One is the cost of goods sold/average inventory value. Calculate average inventory by adding the beginning and ending inventory values and dividing by two. The second formula is the sales value/inventory value. Across all types of retail, inventory turnover rates average around eight. If your rate is higher or lower than your peers or makes a significant move, you may want to try inventory turnover rate optimization techniques. These include steps such as being more aggressive about putting items on sale and ordering more or less of a product. Knowing your turnover rate also helps you plan orders for long lead-time goods. -

Retail Inventory Method:

This technique is a fast way to estimate the ending inventory value. Since the result is an estimate, the number is not usable for financial statements, and you should confirm it against inventory counts. Follow these steps:- First, get the cost-to-retail percentage (inventory cost/retail price).

- Determine the cost of goods available for sale (cost of beginning inventory/cost of purchases).

- Figure out the cost of sales for the period (sales x cost-to-retail percentage).

- Calculate the ending inventory (cost of goods available for sale – cost of sales during the period).

-

Retail Demand Forecasting:

Use these techniques to predict how much your customers will want to buy. This one is tricky; there are many qualitative and quantitative methods. Among the common quantitative methods are moving average and time-series analysis—which take historical sales and seasonality into account. Predictive analytics software can perform this kind of forecasting by incorporating multiple methods. Having a good idea of demand can boost profitability by helping you determine staffing, purchasing needs and the optimal inventory to hold.

Inventory Audit Methods for Retailers

These techniques double-check inventory counts, helping retailers avoid stock outages and dead stock. Inventory errors, mistakes and miscounts are prevalent even when using RFID and barcode tagging. Inaccuracies cause inefficiencies, lost sales and budgeting and forecasting difficulties. A 2019 study for the ECR retailer-manufacturing working group found that about 60% of retailers’ inventory records were inaccurate(opens in new tab).

Inventory audit methods include:

-

Physical Inventory Audit:

This process matches financial records with counts of physical goods. In a formal audit, an accountant observes the physical count. Oftentimes, companies will pause operations so no items are moving during the audit. For large companies, physical inventories require a lot of resources, time and planning. On the positive side, a physical inventory is an excellent way to control for inventory shrinkage. -

Spot Checking:

This option involves doing a periodic check of a particular department or store location. Spot checking is a good method to identify issues in inventory procedures before they become larger problems. Managers should regularly perform inventory spot checks— especially after implementing a new plan or big change to the inventory management plan. -

Cycle Counting:

This technique calls for a retailer to count part of its stock daily. You don’t need to stop operations for this type of count, although retailers typically still do a full physical inventory periodically. Cycle counting is excellent for companies with a lot of inventory who cannot disrupt operations to perform full physical inventory checks. This method may be difficult for companies that are not able or willing to use inventory management software. To cycle count, companies need to keep an accurate record.

Best Practices and Expert Tips for Retail Inventory Management

Retailers that follow inventory management best practices lay the foundation for greater stock accuracy, lower costs, less shrinkage and higher profit margins. Strive to meet industry standards and follow the advice of inventory experts.

-

Flex Your Ordering Muscles:

Do everything you can to ensure you order the ideal amount of stock at the right time to satisfy demand and delight customers. This means setting data-backed levels for your safety and par stock, knowing reorder thresholds, optimizing order sizes with economic order quantity (EOQ) and using the open-to-buy technique to plan purchases. -

Be Proactive with Your Supply Chain:

Share sales and product forecasts with vendors, and ask for precise lead times. Track suppliers’ service levels, such as the percentage of complete orders and fulfillment times. Communicate with vendors that need to improve, and explain the concrete actions required to meet your needs. Do contingency planning to identify alternative suppliers of your most important items in case your primary supplier cannot deliver. -

Crunch Your Numbers:

Keep close tabs on your KPIs. Track which products are your best and worst performers using ABC, FSN or XYZ analysis. Understand indicators of customer demand and seasonal fluctuations, and know your turnover rate and GMROI. Actively try to improve the quality of your customer demand and sales forecasts. -

Maximize Efficiency:

Never stop trying to make every part of your inventory management more efficient. Arrange your warehouse strategically, and keep it organized. Here are other ways to improve efficiency.- Use the picking process that best matches your order volume and product types.

- Store items as close as possible to regions and communities where they are in the highest demand.

- Analyze whether using drop shipping or a third-party logistics provider would make your retail inventory management more efficient.

- Combat shrinkage with loss prevention programs, and monitor incoming goods.

- Use SKU management to analyze carrying costs.

- Make sure you are offering the right number of products and identifying your highest-velocity items.

- Document all your processes, such as receiving, to ensure standardization.

-

Prioritize Accuracy:

Perform regular inventory audits and counts. Train staff in inventory management, and set goals for performance. Build a culture that prizes the pursuit of accuracy. -

Use an Inventory Management System:

By leveraging technology, you can automate many tasks and instantly make progress on goals such as accuracy and efficiency. By choosing the right tool, you can integrate your point-of-sale (POS) system with inventory management, eliminating the need for manual data entry, which will reduce errors and generate richer data. An automated system can also send notifications for stock alerts and simplify your efforts to coordinate inventory in multiple locations.

Why You Should Invest in a Retail Inventory Management Solution

A retail business will quickly outgrow using pen and paper or spreadsheets to track stock. Retail inventory management solutions automate your administration and documentation, raise accuracy, improve the customer experience, reduce costs and reveal valuable trends.

The benefits include:

- Accurate receiving and shipping records

- Real-time, reliable inventory counts

- Merchandise traceability using bar codes or RFID

- Simplified returns

- Better forecasting

- Performance measurement with KPIs

- Insights into sales trends

- Easier implementation of promotions and discounts

- Support for dynamic and strategic pricing

- Custom notifications

- Easy report generation

If you operate an ecommerce, multichannel or omnichannel business, managing inventory is virtually impossible without an automated solution. See this article about the key features of inventory management systems to learn more about how this technology can transform your retail operations.

How POS Systems Can Help with Retail Inventory Management

Integrating a point-of-sale system with your inventory management process puts more information at your fingertips. You can use the data to improve many aspects of your retail business, such as purchasing, overhead costs and merchandise sell-through.

Here are some example benefits:

-

Less Guesswork:

With real-time and historical sales information to make your sales forecasts more accurate. This data gives you a strong basis for reorder decisions. You can also see which products and SKUs are selling well, so you can prevent stock-outs. Data on slow-moving products can trigger discounts and promotions, so you don’t end the season with dead stock. Additionally, real-time data helps keep inventory counts accurate. -

Lower Overhead:

With more accurate ordering, you can rationalize storage and reduce warehouse costs along with related expenses such as labor, taxes, insurance, dead stock and opportunity cost. -

Happier Customers, More Sales:

You can delight a store customer whose size or preferred color is out of stock at one location by using the POS system to check whether the item is available at another store or warehouse. The customer can pay for the item, and you can ship it to their home, saving a potentially lost sale. According to one survey on millennial purchasing habits, 39% of in-store shoppers leave without purchasing because of out-of-stock items.

Retail Inventory Management FAQs

Some retail inventory management topics crop up frequently:

What Are Retail Inventory Costs?

This retail inventory method, also known as cost-to-retail, estimates the ending inventory value by using the ratio of inventory cost to the retail price. This accounting technique shows how much the cost of the good represents of the merchandise’s retail price.

So, if you are selling dresses for $100 and your wholesale cost is $25, your cost to retail ratio is 25%.

From another perspective, retail inventory costs consist of more than the wholesale price of the merchandise. You have to factor in costs such as storage, insurance, transportation, shrinkage, handling and more.

How Are Inventory Levels Monitored in Retail Stores?

Keeping track of inventory in stores can be challenging, so most retailers use multiple techniques to monitor inventory levels. First, they integrate a POS system with an inventory management system, so the stock reflects every sale or return.

Retailers also put RFID tags and bar codes on merchandise to gather information on stock quickly, keep track of inventory location and update inventory records. They also make sure to record shrinkage. Store staff or managers update the POS system when products are damaged and stolen, which adjusts inventory counts. Implementing loss prevention measures, such as visible security guards, helps keep inventory counts accurate by deterring theft.

In addition, stores conduct physical inventory counts periodically and check these findings against inventory records. Any mismatch requires an adjustment. Finally, training staff on procedures such as exchanges and returns and stressing the importance of putting them into the system helps retailers maintain oversight of inventory levels.

What Is a Good Inventory Turnover Rate for Retail?

Inventory turnover rate measures how many times inventory sells in a year. Generally, a higher number is better. The average U.S. retail inventory turnover rate was about eight in 2019, according to CSIMarket, so a number above that qualifies as good.

For example, in 2019, Walmart’s inventory turnover ratio was 8.48 turns. This means that Walmart sold and restocked their inventory about 8.48 times in 2019, or every one to two months, to meet customer demand. This rate is most useful for comparing companies.

But turnover varies widely by store type, so retailers should compare their rate to their peers’.

For example, the Retail Owners Institute found RV dealers had an average inventory turnover of 2.4 in 2019, while bakeries averaged 52. Typically, CPG products will have higher turnover, while higher ticket items generally have a lower turnover rate. You can learn more about turnover by reading “Inventory Turnover Primer: Calculations, Rates and Analyses.”

Remember that the turnover rate does not tell the whole story. A store that has a much higher turnover rate than its counterparts may not be purchasing enough. The retailer may not be optimizing order size, incurring higher shipping costs or missing quantity discounts.

Moreover, turnover does not show how many sales a store missed because an item was out of stock. So, a seemingly positive turnover rate could mask underlying problems. Similarly, a store with a lower turnover number may be over-ordering or have too many slow-selling products and spending too much on inventory storage.

Low-margin, high-volume stores depend on rapid turnover to make a profit. Grocery stores had turnover rates around 17 in 2019, according to CSIMarket. Yet retailers that sell expensive products, especially those that take a long time to manufacture, can thrive on low turnover rates.

What Is Retail Inventory Control?

Retail inventory control is the process of managing retail goods from order to final sale. The goal is to ensure a retailer has the ideal amount of product available when customers want it while keeping costs at a minimum.

The retail inventory management methods described earlier, along with technology and other systems, work together to achieve retail inventory control. Learn more in the “Essential Guide to Inventory Control.”

Transform Your Retail Inventory Management With NetSuite

The right technology is crucial to achieving maximum efficiency in retail inventory management. You need to be able to see all products, across all channels, in a single view and apply intelligent order management to your purchasing to provide customers with an exceptional shopping experience. The right solution scales with your business and supports unlimited expansion.

NetSuite offers a suite of native tools for tracking inventory in multiple locations, determining reorder points and managing safety stock and cycle counts. Find the right balance between demand and supply across your entire organization with the demand planning and distribution requirements planning features. Learn more about how you can use NetSuite to help plan and manage retail inventory automatically, reduce handling costs and increase cash flow.