In traditional inventory practices, a retailer pays a supplier for goods up front before reselling them to customers. This makes the retailer liable for any products it is unable to sell. A different supply chain model, however, shifts the inventory carrying costs from the retailer to the supplier. With consignment inventory, the manufacturer, wholesaler or supplier retains ownership of the goods until the retailer sells them to customers. The retailer then pays the supplier for the goods it sells and returns any items that go unsold.

This supply chain model is common among retailers that may not have the cash flow to purchase large amounts of products, especially expensive ones that take a long time to sell. The strategy also protects retailers from the risk of investing in products with questionable customer demand, since they won’t lose money on items that don’t sell — and it gives suppliers more control over how and where items are sold and at what price to align with brand identity.

What Is Consignment Inventory?

Consignment inventory is a supply chain model in which a retailer offers a product for sale, but the supplier retains ownership of the product until a customer purchases it. Because the retailer does not actually buy the inventory until it sells the products, it can return items that customers don’t purchase. Popular products sold through the consignment model include seasonal products, such as holiday decorations, and perishable items, such as produce.

For example, a supplier of outdoor Christmas lights might strike a deal with a big-box retail store to sell its products between October and December. The store wouldn’t pay up front for the lights; it would pay only for the lights that customers purchased during that period. In January, the retailer would return any unsold lights to the supplier.

Key Takeaways

- Consignment inventory is a supply chain model in which a retailer agrees to sell a product, but the supplier retains ownership of the product until it has been sold to a customer.

- Consignment inventory provides many advantages for both suppliers and retailers, including greater product visibility for suppliers and less financial risk for retailers.

- Certain best practices, including creating a strong contract and maintaining open communication, can ensure that suppliers and retailers both benefit from a consignment inventory agreement.

- Inventory management systems designed specifically to handle consignment inventory are critical to the success of the strategy.

Consignment Inventory Explained

Purchasing inventory comes with a certain level of risk. If a retailer purchases too much merchandise, for example, it may have to reduce the price of the products to sell them or find another way to unload them, which may lead the retailer to take a loss on the merchandise.

A different model — called consignment inventory — reduces the retailer’s risk.

Consignment inventory is an agreement between the consignor and the consignee. The consignor, which may be a wholesaler, manufacturer or supplier, provides goods to the consignee, the retailer. In this agreement, the consignor owns the products, and the consignee will pay for them once customers purchase them.

For example, a supplier of garden supplies may provide grass seed and flowers to a home improvement store to sell between spring and fall. When winter approaches, the store will pay only for the goods it sold and will return unsold items to the supplier.

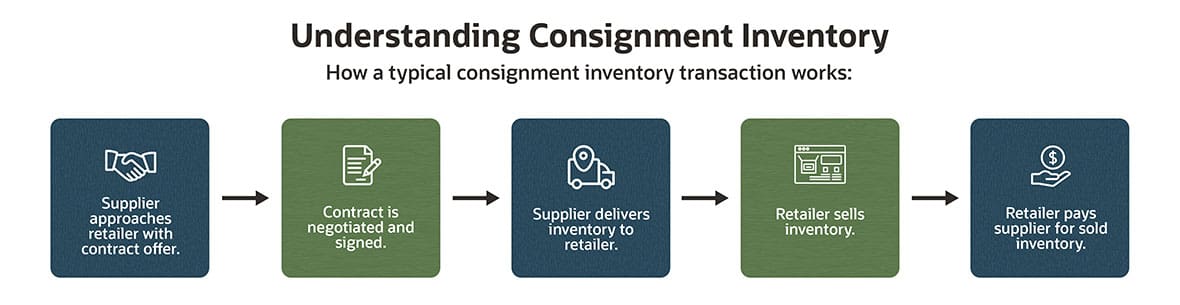

How Consignment Inventory Works

With consignment inventory, typically the consigner — who is the supplier of the goods — approaches a retailer, or the consignee, and both negotiate the terms of the contract. This contract will stipulate the cost of the goods, determine shipping fees and outline information on handling returns. The contract may also include information about how the inventory will be managed, denote requirements for deposits or commissions, and indicate which party is responsible for lost or damaged products.

Once both sides agree to the terms of the deal, the supplier will deliver the inventory to the retailer. The supplier will earn money only when the retailer makes a sale. The profit the retailer earns depends on the price it sets for an item. If the retailer doesn’t sell all the inventory, it can return the remaining products to the supplier without penalty.

How to Manage Consignment Inventory

Properly managing consignment inventory is critical for both the supplier and the retailer in order to keep close tabs on products. For organizations that sell a combination of consigned and non-consigned goods, managing inventory can be a complex task. Some organizations are still relying on spreadsheet-based or even paper-based systems, and these methods of tracking inventory are often slow and unreliable, and make collaboration between the vendor and retailer difficult.

A number of inventory management systems are available, but not all systems are designed to handle consignment inventory. Today, many organizations rely on robust inventory management systems that are designed to increase control of a variety of inventory-related tasks. Ideally, these solutions should track the inventory that the supplier sends to the retailer; identify when inventory needs to be replenished at the retailer to avoid stockouts; and track the inventory that the supplier needs to replenish its stock. These features help suppliers identify the products to purchase, reduce the amount suppliers need to stock at a retail site and make it possible to save money on shipping costs.

Advantages of Consignment Inventory

Consignment inventory has many advantages for both suppliers and retailers and, when executed well, can benefit both parties.

Advantages for suppliers:

- Visibility. Consignment inventory gives suppliers an opportunity to reach new audiences by selling their products through retail stores. This enables suppliers to generate revenue without renting or owning their own retail space or hiring employees to run a store.

- Testing. Consignment inventory enables suppliers to test new products in new markets, which can help them evaluate the product’s performance, based on the number of sales generated.

- Reduced inventory costs. If large amounts of the goods are stored in warehouses, consigning inventory can help reduce some of those carrying costs by placing the goods with retail partners until they sell.

Advantages for retailers:

- Low financial risk. Because retailers don’t pay for products until they’re sold, purchasing surplus stock and losing capital on inventory costs isn’t a concern. Consignment inventory allows retailers with tight margins to take on new products and to avoid assuming financial risk for products that don’t sell.

- Higher potential for sales. Consigned goods can help diversify retail inventory, which can increase sales and profits.

- Fewer storage needs. New stock can be brought in whenever there is customer demand for products. Retailers don’t need to make special storage arrangements for excess stock and can return any products that don’t sell.

Disadvantages of Consignment inventory

Consignment inventory may not always be an ideal arrangement for suppliers or retailers. Here’s a look at some of the downsides of this supply chain strategy.

Disadvantages for suppliers include:

- Higher costs. Suppliers must consider a variety of potential expenses, including shipping costs, the expense of storing the goods — whether in a warehouse or on dedicated floor space at a store — and any costs associated with damaged items.

- Uncertain effort to sell. Because suppliers must depend on retailers to make a strong effort to showcase and sell their products — and because retailers assume little financial risk — it can be difficult to know whether the retailer is making every effort to sell the goods.

- Unpredictable cash flow. Suppliers may need to wait to receive payment for their goods or receive less money than anticipated during a particular accounting period, since they are dependent on the retailer to make sales.

Disadvantages for retailers include:

- Greater risk of damaged inventory. The longer a retailer holds on to consigned goods, the more likely it may be that goods could become damaged. Often, retailers must pay for damaged inventory, even if it doesn’t sell.

- Management complexity. Sometimes the way consigned goods are tracked creates confusion between the two parties, as well as errors in the inventory process. To get a good handle on consignment inventory, businesses may want to consider purchasing an inventory management solution.

- Additional costs. Depending on the arrangement, retailers may need to cover certain costs for items until they sell, such as expenses related to ensuring the security of products.

Consignment Inventory Best Practices

Managing consignment inventory can be a complicated process if a business doesn’t have the right measures in place. Suppliers and retailers should work together to develop a mutually agreeable contract and forge a strong relationship; employ the right technology for their inventory needs; diversify their sales channels; and prioritize close communication. Here are some consignment inventory best practices.

- Develop a solid contract. The contract is the cornerstone of a successful consignment inventory arrangement. Both the supplier and the retailer should understand the terms of the agreement, including shipping and returns responsibilities, when payments will be made and who is responsible for damaged or lost products. For example, a retail inventory management contract should include details describing how the inventory will be counted and managed, listing deposits or commission requirements and outlining good faith efforts to sell the goods in a timely fashion.

- Forge a strong relationship with your partner. Forming a symbiotic relationship with your business partner is critical. Suppliers should work to ensure that the product is as successful as possible, while retailers should make a strong effort to sell the supplier’s product. The better both parties work to get the right product in front of the right customers, the stronger the relationship and the greater the sales.

- Use the right technology. Traditional inventory software may not be enough. Consignment inventory requires specialized systems to track goods and invoices. Organizations should seek solutions that provide data analytics and strong visibility into the inventory for both the supplier and retailer, which will reduce data discrepancies between the two parties.

- Seek multiple sales channels. Not all relationships work out, which is why it’s important to seek out more than one consignment inventory partner. This helps minimize risk on both ends by giving suppliers and retailers alike other options for business.

- Communicate. Communication between the supplier and the retailer is key throughout the relationship. When issues arise, the parties should look for a mutually agreeable solution, underscoring their commitment to the contract and their business relationship.

Consignment Inventory Accounting

In consignment inventory accounting, both the supplier and the retailer account for consignment sales, but consigned goods are included in the inventory of the supplier only. Although the goods are sold by the retailer, the retailer doesn’t take ownership of the goods; the only time products are accounted for by the retailer is at the point of sale, which is reflected on the balance sheet. The revenue from the sale of the goods and the payment to the supplier are then added.

NetSuite Provides Visibility Into Your Inventory Process

Finding the right technology to manage consignment inventory is critical to the success of these partnerships. Because traditional inventory management tools tend to fall short in effectively managing consignment inventory, organizations are in better hands with a specialized solution, such as NetSuite Inventory Management, which provides a single, real-time view of inventory across all locations and sales channels. This enables businesses to reduce inventory on hand to free up cash while avoiding stockouts. The NetSuite Inventory Management solution also provides automated inventory tracking, enables businesses to predefine fulfillment rules to eliminate multiple shipments for a single order, and uses historical and seasonal data to dynamically manage item-reorder points and maintain preferred stock levels.

To automate and streamline business processes that waste time and resources, NetSuite’s Enterprise Resource Planning (ERP) System working with inventory management also help organizations drive innovation and remain competitive, while balancing supply and demand.

Consignment inventory has a number of benefits for suppliers and retailers that choose to enter into this agreement. Critical to the success of this model is open communication between the supplier and retailer, a strong contract and the right technology to track goods and manage the consignment inventory process. When done correctly, consignment inventory is an arrangement that can benefit both the supplier and retailer, resulting in greater product exposure, tighter business relationships and improved sales.

Consignment Inventory FAQs

What is a consignment warehouse?

A consignment warehouse is a storage facility that the supplier manages to house its goods to ensure fast deliveries to retailers.

How do you record consignment goods?

Consigned goods should be recorded in inventory management systems that specifically support consignment inventory.

What is a consignment item?

A consignment item is any product that has been transferred from a supplier to a retailer with the intent of being sold to a customer.

What is a consignment stock contract?

In a consignment stock agreement, the supplier agrees to send a stock of goods to a retailer while retaining ownership until the retailer sells the goods.

Do you include consignment in inventory?

Goods held on consignment are included in the inventory of the supplier, not the retailer.

How do you handle consignment inventory?

To handle consignment inventory, a supplier (the consignor) and a retailer (the consignee) agree on a contract that stipulates that the supplier retains ownership of the goods until the retailer makes a sale. A retailer can also return any unsold goods to the supplier.

What are the benefits of consignment inventory?

Consignment inventory has several advantages for both suppliers and retailers. For suppliers, it helps suppliers acquire new customers, test new products and reduce their own inventory costs. For retailers, consignment inventory represents little financial risk because they only pay for what they sell. It also allows them to offer a broader range of products, while not taking up precious storage space unless demand calls for it.