Whether shopping online or at a physical location, it's safe to say that most consumers have been met with the frustration of discovering their desired item is out of stock. Though inconvenient, a stockout can be a good sign for a business because it likely means the product is selling well. But stockouts are costly — beyond just losing a sale. They can lead to customer dissatisfaction and even defection, not to mention brand reputation damage. Preventing or mitigating the chance of stockouts should be at the top of the list for any business owner who wants to increase sales, customer satisfaction and customer retention.

What Is a Stockout?

A stockout, or out-of-stock (OOS) event, occurs when a business runs out of a specific product and therefore cannot fulfill customer orders. It's the opposite of overstock, or when there's too much inventory of an item with low demand in stock. Stockouts can happen at any point in the supply chain, for reasons including manufacturing delays caused by difficulties acquiring raw materials or retail shelf unavailability due to poor inventory management practices or unforecasted high sales.

When a stockout occurs, the item's availability status should immediately be changed across all sales channels to prevent customers from inadvertently purchasing it. If a customer does purchase an out-of-stock item, the business should explain the situation and come up with a satisfactory solution, such as suggesting an alternative item, offering a refund or putting the customer on a waiting list. When disclosing a stockout notice, businesses may want to include the anticipated in-stock date. Customers will likely appreciate the information so they can determine whether they'd prefer to wait or look for an alternative.

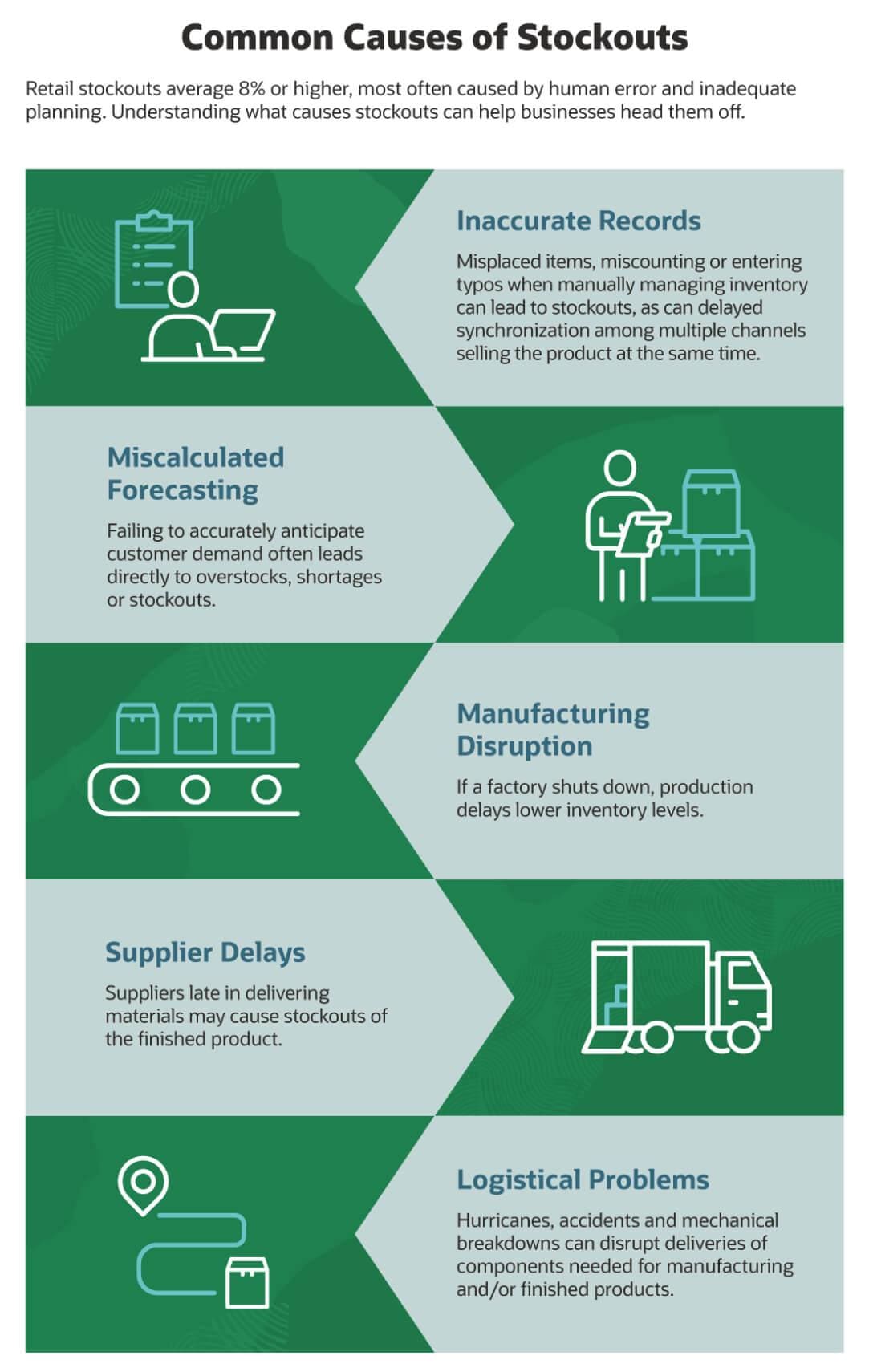

5 Causes of Stockouts

Inadequate planning and human error are some of the major causes of stockouts and indeed all inventory management challenges. But even the most prepared companies can face unforeseen circumstances that lead to unavailability, like supplier delays and manufacturing holdups. Here' a look at five of the most common causes of stockouts:

-

Erroneous forecasts.

Inaccurate forecasts are all but a surefire way to end up with stockouts (or overstock). Thus, accurate inventory forecasting is one of the most important elements to avoid or mitigate stockouts. Even in situations beyond a company's control — such as rapid, unpredictable swings in customer trends — a well-implemented forecasting system can keep stockouts, shortages and overstocks to a minimum.

-

Inaccurate records.

Inaccurate inventory counts are another leading cause of stockouts. These inaccuracies are usually caused by human error, often by miscounting, incorrectly typing the wrong number when manually managing inventory or misplacing items after they are unloaded in a warehouse. Technical problems might also affect product count, such as when a company has multiple sales channels with inventory counts that don't update in real time.

-

Supplier delays.

Stockouts can happen at any point in the supply chain, such as issues with acquiring raw materials or supplying parts to manufacturers. This, in turn, can lead to manufacturing delays and subsequent stockouts.

-

Manufacturing holdups.

Manufacturing delays are not only caused by supplier delays. They can also be caused by production issues, such as labor shortages, equipment malfunctions and poor planning. Any time manufacturing is held up, stockouts or shortages can occur.

-

Logistics issues.

Environmental phenomena like natural disasters can harm raw material supply or damage production facilities. Vehicle breakdowns or roadway accidents can prevent necessary materials or goods from being delivered on time. Mechanical problems can delay production schedules. While these logistical problems may be out of the retailer's control, repeat occurrences — such as machinery or trucks often breaking down — may warrant further investigation to prevent incidents from happening in the future.

How Can Businesses Prevent Stockouts?

From loss of sales and customers to negative reviews and damaged brand reputation, stockouts have costly consequences for business. Though stockouts can sometimes be out of a retailer's control — making them hard to eliminate completely — there are a variety of supply chain and inventory management best practices companies can enforce to reduce and prevent these costly occurrences.

18 Ways to Prevent Stockouts

Inaccurate inventory counts, forecasting errors, supplier and manufacturing delays, and logistical problems are some of the most common causes of stockouts. But there are many preemptive actions a business can take to get ahead of the problem, beyond implementing an inventory control system.

-

Increase inventory accuracy.

Inaccurate inventory counts can inadvertently lead to stockouts. To keep inventory accurate, it's important to reduce human error. Companies can avoid inventory discrepancies by regularly monitoring and updating stock levels, but doing so manually is likely to introduce the occasional error. It's more effective to use an inventory management solution that allows workers to scan items when they're received and picked to fulfill orders so inventory data can be updated and shared throughout a centralized system in real time.

-

Enforce a regular cycle counting practice.

Routinely shutting down shop to take a full inventory count is useful but not always practical. Cycle counting — the practice of counting and checking a small selection of SKUs according to a set schedule — can be much more effective. It allows inventory teams to audit inventory amounts and ensure actual counts match up with what's listed in a spreadsheet or inventory management software.

-

Set reorder points.

To prevent stockouts, good timing is essential. A reorder point tells inventory managers when to order more inventory to avoid running out of stock. Reorder points can also be understood as the minimum quantity of a specific product needed on hand at any time. Go any lower and there's no guarantee replenishment will occur in time to fulfill an order. Calculating ideal reorder points for each product — and setting automated reminders — can help companies better manage their inventory controls and ultimately minimize stockout events. Inventory management software can be used to automatically establish reorder points and create alerts. To calculate reorder point, use this basic formula:

Reorder point = (average daily usage × lead time in days)

-

Determine lead times.

Lead time, or the time it takes between placing and receiving an order, is necessary for determining the reorder point. It is also a key factor to consider when assessing prospective and current suppliers. Shorter lead times are usually preferred because they can lower inventory carrying costs. Shorter lead times are also useful in situations when goods are selling out faster than anticipated.

-

Improve forecasting capabilities.

The ability to accurately anticipate customer demand is an essential business practice. Of course, consumer demand can radically shift overnight, rendering forecasts unusable. But for most cases, demand forecasting can help keep inventory levels at an ideal level, thereby preventing stockouts, shortages and overstocks — and ultimately saving costs. To improve forecasting capabilities, take into account consumer trends and seasonality. Also, consider using an inventory management solution that automatically generates reports and insights to inform forecasts.

-

Utilize demand planning.

A demand forecast, which usually covers 18 months to 24 months and largely considers consumer trends, forms the foundation of the overall demand planning process. Demand planning takes forecasting to the next level by incorporating supply chain management and inventory management. In a nutshell, demand plans use forecasts to inform sales and operations strategies to better plan how much product to buy or manufacture and when to do so in order to successfully meet demand. Demand planning best practices include having accurate inventory data, factoring for the supply chain and working closely with marketing and sales teams to better grasp demand.

-

Keep safety stock.

Many businesses have favored just-in-time (JIT) inventory practices to maintain lower inventory levels and keep carrying costs down. But there's a caveat: Unless a business's suppliers' lead times match the speed of light, less stock equals a greater chance of stockouts. Keeping extra products in inventory as a safety measure, on the other hand, is an effective way to prevent stockouts. Of course, too much safety stock becomes costly overstock. To prevent unnecessarily high holding costs, carefully calculate ideal safety stock levels with this formula:

Ideal safety stock = (maximum daily usage × maximum lead time) - (average daily usage × average lead time)

-

Use automated inventory management software.

In the era of omnichannel sales, a modern inventory management solution (IMS) that automatically updates inventory levels in real time is necessary for any business that wants to reduce the chance of stockouts. These systems are capable of connecting to barcode scanners or radio frequency identification (RFID) technologies to instantly update inventory levels when items are received in a warehouse or distribution center. Inventory counts are once again updated in real time when sales are rung up, whether online or in a physical location. In addition to offering real-time benefits, an IMS should be able to handle inventory management tasks like calculating reorder points and setting reminders, and generating reports that can benefit forecasting and demand planning capabilities.

-

Integrate inventory platforms.

Synchronizing inventory numbers throughout multiple sales channels is essential to increasing inventory-level accuracy and thereby preventing stockouts. For example, if a retailer's physical store and ecommerce site rely on the same inventory, out-of-sync stock numbers might display a product as in stock in store after a customer purchased it online. This means a customer might go to the store to make a purchase only to find it's not in stock.

-

Consider using RFID technology.

RFID, a wireless technology that uses radio frequencies to transfer data, gives warehouse workers the ability to track inventory in real time. When shipments arrive, they're embedded with information, usually through an RFID tag that's attached to the item or items in the shipment. Each tag stores item information data that's automatically transmitted to a central database and updated as goods are put away, picked and shipped. This automated technology helps improve inventory counts and reduce human error, both of which are required to help minimize stockouts.

-

Identify stockout patterns.

Though consumer demand isn't always predictable, stockouts often form trends. It's a good idea to regularly audit and monitor stock to identify days and times stockouts tend to peak. If it's apparent that the same product gets exhausted every week on the same day or at the same time, retailers can adjust their replenishment schedules to avoid recurrent stockouts.

-

Pay attention to customer trends.

Past trends are essential when forecasting demand, but it's also important that a business study its market for any new and upcoming customer trends. For example, identifying new seasonal trends before ordering seasonal stock can help ensure companies have enough newly trending products on hand to meet with demand — while keeping outdated trends to a minimum to avoid overstock or excess carrying costs.

-

Monitor the supply chain.

Manufacturing disruptions due to a raw materials shortage can result in stockouts throughout the supply chain — creating a domino effect that becomes most costly when it reaches the retail level. Supplier shortages can be hard to prevent, but they can sometimes be predictable enough to mitigate stockout issues. Businesses should monitor how often supplier delays or shortages occur and consider changing vendors if issues persist. Additionally, developing regional or national sources when possible can help hedge against global supply chain disruption.

-

Develop strong relationships with suppliers.

Good supplier relationships can sometimes go a long way in helping to prevent stockouts. Businesses should keep them updated on their inventory needs, especially if a boost in orders is predicted. That way, suppliers — which know their industries at a deep level — can communicate their ability to meet those needs. What's more, proactive communication may be reciprocated; Advance warning from a supplier about upcoming shortages, for example, can give a business time to source alternatives instead of having to scramble at the last minute.

-

Use a vendor-managed inventory system.

Also known as VMI, vendor managed inventory systems share inventory management responsibility between retailer and supplier to ensure the latter maintains an agreed level of inventory of a specific product. In other words, the supplier manages lead times and reorder points, taking the burden off of the retailer's inventory management team. Generally speaking, VMI's should only be used with trustworthy vendors since the business is relinquishing some control over its inventory management process.

-

Implement consignment inventory.

For some businesses, especially those with unpredictable customer demand, consignment inventory can help mitigate stockouts. Unlike traditional inventory practices, suppliers hold the product in their stock until it's sold by the retailer. In ideal scenarios, this means the product is always available when purchased by a customer, circumventing stockouts. Consignment inventory can also be less financially risky for retailers because they only pay for the product after it's sold. This also decreases holding costs. Of course, communication between retailer and supplier must be precise and honest to avoid sale of items that are unavailable in the supplier's stock.

-

Liquidate surplus stock.

It may not seem obvious on the surface, but getting rid of overstock can help reduce stockouts because surplus stock takes up space that could be used to store high-demand products. One way to get rid of dead stock is by liquidating it — putting these items on sale or bundling them with high-performing products to get them off the shelves as quickly as possible. That space can then be filled with products that tend to sell out. Clearing out dead stock also decreases carrying costs.

-

Keep customers informed.

More and more companies are beginning to share expected shipping times for out of stock products in order to help set customer expectations. Although keeping customers informed doesn't directly prevent stockouts, it can be a successful way to mitigate lost sales, particularly for customers willing to accept waiting for an out of stock product if they see it'll be in stock soon. This level of transparency requires monitoring inventory levels and keeping close contact with suppliers.

Get a Handle on Stockouts With NetSuite

The right inventory management software can lower or solve most causes of stockouts and product shortages. For example, NetSuite Inventory Management Systems Software automatically updates stock counts across multiple sales channels, increasing accuracy and virtually eliminating the risk of human error. It's also possible to gain more control over several key inventory management tasks, like scheduling periodic counts, generating alerts for reorder points and automating product availability status changes when stock levels are below the desired threshold — all essential in the quest to eliminate stockouts. Furthermore, NetSuite can automatically generate reports that provide the insights required to more accurately forecast demand.

Conclusion

Though sometimes unavoidable due to unforeseen circumstances, the risk of stockouts can usually be prevented or at least mitigated by following proper supply chain and inventory management best practices. Additionally, implementing a good inventory management system can help retailers optimize their inventory levels by automating stock counts, generating alerts for reorder points and updating product availability status in real time.

Stock Out Prevention FAQs

What to do if you do go out of stock?

The first step when a product sells out is to change its availability status on all points of sale, before a customer places an order. If a stockout is noticed after a customer's order goes through, contact the customer to inform them of the shortage and determine the next steps, such as placing their order on hold, suggesting an alternative or providing a refund.

How do you manage stockouts?

Stockouts are manageable and often preventable by following good inventory management practices, such as accurate demand forecasting, setting reorder points, using buffers and safety stock, determining stockout patterns, and using inventory management software.

In situations in which stockouts are beyond a retailer's control, it's important to take measures to mitigate costs and prevent unhappy customers, such as suggesting or creating a product alternative or finding an alternative supplier.

What are the consequences of stockouts?

Stockouts can affect businesses of all sizes at different levels. Consequences are costly and can include:

- Incurring extra costs associated with managing refunds, back orders and split shipments.

- Negative reviews from impacted customers.

- Loss of sales, especially when customers go elsewhere to purchase the unavailable product or a similar replacement.

- Customer defection.

How do you solve out-of-stock problems?

A business can solve out-of-stock problems by implementing good supply chain and inventory management practices, such as prioritizing accurate demand forecasts and accurate inventory counts, keeping safety stock and incorporating inventory management software into its day-to-day operations.

What causes a stockout or shortage of inventory?

Stockouts and shortages can happen at any point in the supply chain. They may be caused by supplier delays, manufacturing issues, unforeseen logistics issues (like transportation failures or natural disasters), inaccurately recorded inventory levels and erroneous forecasts.

How do you ensure stock availability?

An optimized inventory strategy can help ensure stock availability. This can be achieved through a combination of good inventory management practices and using an inventory management software that fits the business's needs. Together, companies can create more accurate forecasts, automate common inventory management tasks and reduce the risk of human error.