Anyone who has ever shopped for an item and found it out of stock has encountered the challenges of stock availability. For retailers, managing stock availability can be equally challenging. It's a delicate balance to maintain enough stock to meet customer demand without tying up too much capital in inventory — especially when facing supply chain problems and swings in demand. Inventory management systems that help retailers track and manage inventory in real time are critical to optimizing stock availability and keeping customers happy.

What Is Stock Availability?

Stock availability is a straightforward concept: It's the degree to which a business has enough inventory of each item to meet customer demand. Managing stock availability, however, is not so clear-cut. Retailers must balance the need to fulfill orders and keep customers happy with the cost of buying and storing inventory. What's more, they must do so amid often rapid and sometimes unforeseen changes in demand and supply.

Key Takeaways

- Stock availability represents the extent to which a company has enough inventory to fulfill customer orders.

- Stock availability is a key success factor for retailers — but also one of the biggest inventory management challenges.

- A key goal is to maintain enough stock to meet customer demand without incurring excess inventory and related costs.

- Inventory management systems can give retailers real-time visibility into stock levels, avoid stockouts, keep inventory carrying costs low and help meet customer expectations.

Stock Availability Explained

Stock availability is a key success factor for ecommerce companies and retailers. Optimizing stock availability can increase revenue, reduce costs and improve customer satisfaction by enabling retailers to meet customer demand while minimizing inventory costs. However, managing stock availability is also one of the most common inventory management challenges. To maintain the ideal level of inventory for each product, retailers need robust inventory management processes and tools to be sure they know how much stock they have, can accurately forecast demand, and can reorder in time to avoid running out of products.

Why Stock Availability Matters

Stock availability problems can have significant detrimental effects for retailers. Failure to foresee and address supply chain issues or volatility in demand can wreak havoc on stock availability, impacting revenue, profit and customer satisfaction. Stockouts — running out of products that customers want to buy — can hurt the company's sales and brand reputation, driving customers to its competitors. But maintaining high levels of every stock keeping unit (SKU) just to meet demand is not a good option either. Buying too much stock can tie up capital in carrying costs (the expenses associated with holding inventory at a warehouse, distribution center or store) and increase the risk of excess and obsolete inventory. There's a real danger that a company may spend money on inventory that would be better invested in other parts of the business.

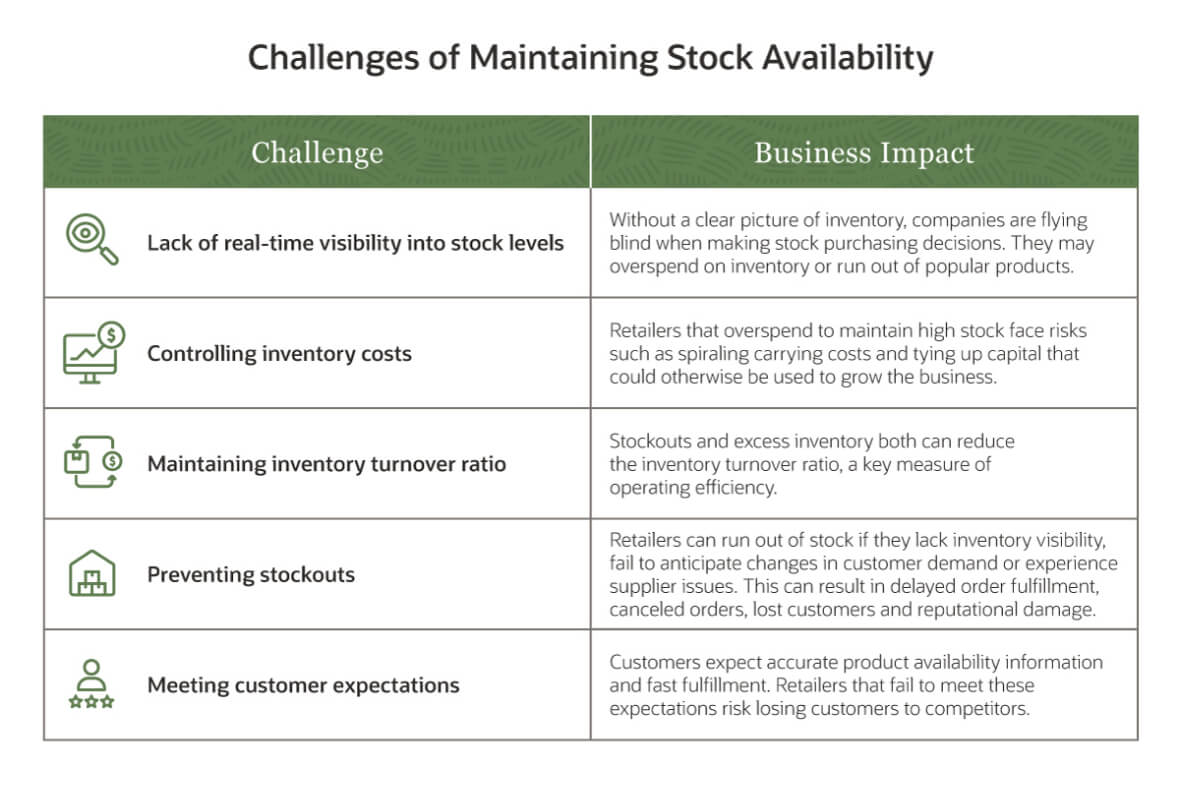

5 Challenges of Stock Availability

Achieving the right balance in stock availability — having enough of the right products in the right place at the right time without overspending on inventory — is tricky. The biggest challenges include:

-

Gaining real-time visibility into stock levels.

This is especially challenging for retailers with stock distributed among multiple locations or sell across multiple channels. However, real-time data is essential to ensure that the company always has an accurate picture of the stock that is available.

-

Controlling inventory carrying costs.

Carrying costs (which include expenses such as storage, labor, transportation, handling, insurance, taxes, item replacement, shrinkage and depreciation) often total 20% to 30% of total inventory value. Overstocking to avoid stockouts increases carrying costs. Worse, a retailer may eventually find itself paying to store, or rid themselves of, dead stock — damaged, expired or outdated products that it can no longer sell.

-

Maintaining inventory turnover ratio.

The inventory turnover ratio — the number of times the company sells and replenishes its inventory in a given period — is a key indicator of business performance. For most retailers, a high inventory turnover ratio is desirable, reflecting strong sales and efficient inventory management. However, poor management of stock availability — such as buying excess inventory because of inaccurate demand forecasts — can reduce the inventory turnover ratio and minimize excess or obsolete inventory.

-

Preventing stockouts.

Retailers can experience the dreaded stockout if they are unable to accurately predict customer demand, are blindsided by supplier issues or lack visibility into their inventory levels. Running out of the inventory needed to meet customer demand can lead to fulfillment delays, canceled orders, lost customers, bad reviews or worse.

-

Meeting customer expectations.

Stock availability issues can send customers straight to a competing retailer. Today's customers expect visibility into inventory so they can make informed buying decisions. They expect sellers to have products available, accurately represent their inventory and fulfill orders quickly — and if a product is backordered, they want to know.

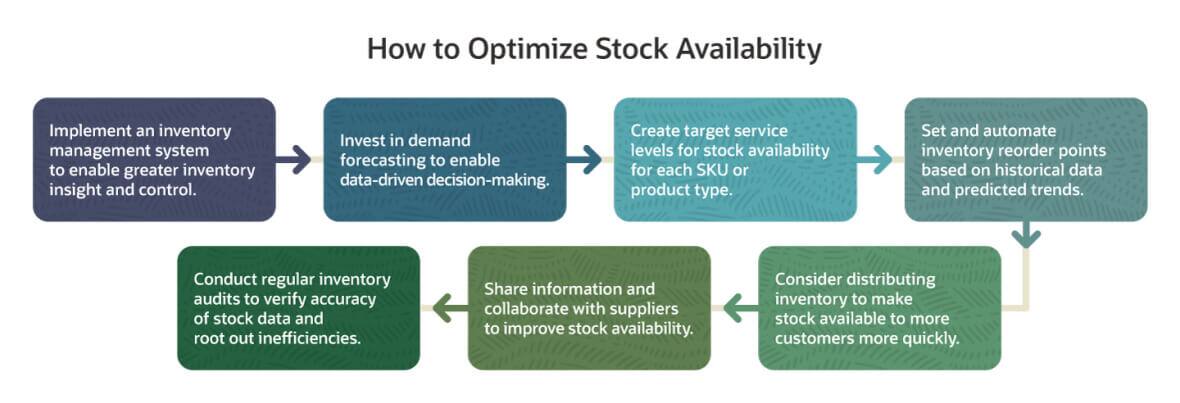

7 Tips to Improve Stock Availability (Without Carrying Excess Stock)

To manage stock availability, retailers must maintain visibility not only into current inventory but also into their supply chain and expected customer demand. Here are some of the top ways retailers can improve stock availability — and boost business performance as a result.

-

Implement an inventory management system.

An inventory management system can increase productivity and accuracy by automating inefficient, error-prone manual inventory tracking processes. A good inventory management system provides centralized, real-time information about stock levels and status, plus analytics, to help businesses determine the right amount of inventory based on past and predicted supply chain trends and purchasing behavior.

-

Use demand-based forecasting.

Demand forecasting software means retailers can predict how much inventory they need, based on historical demand, seasonality and sales forecasts. Forecasting tools help companies improve decision-making and reduce the likelihood of stockouts or overstocking. The software can help retailers decide when to reorder certain SKUs, where to store them to optimize fulfillment and when to put them on sale.

-

Create target service levels.

It's important to measure stock availability performance over time to manage and improve it. Monitoring the company's ability to achieve targeted service levels is one way to achieve that goal. With well-managed stock availability, "service level" refers to the probability that you'll be able to meet all customer demand within a given period — in other words, that you won't suffer a stockout. Retailers can use those service level goals to determine minimum order quantities or how much safety stock to maintain.

-

Set inventory reorder points.

Armed with an inventory management system that provides timely stock availability data as well as other information, such as demand forecasts and service level targets for each SKU, a retailer can reliably determine when to reorder products. Some inventory management systems automatically calculate reorder points based on historical trends and forecasts and notify staff when inventory levels get low.

-

Distribute inventory in multiple locations.

Distributing inventory across multiple warehouses can position products closer to customers, so the company can deliver them more quickly. However, distributing inventory also complicates tracking stock availability. To achieve this effectively, retailers need real-time inventory data and demand forecasts to determine which SKUs to store at each location and track availability across the company.

-

Deepen supplier relationships.

Fostering closer relationships with suppliers and collaborating with them on order volumes, timing and terms can improve stock availability and trim costs. Ideally, a retailer will share information with key suppliers about its future demands and challenges, and the suppliers will provide insights into their capabilities and anticipated risks. Working with clear demand projections, the companies can work together to improve stock availability.

-

Conduct regular audits.

It's important to ensure that the data that exists in inventory management systems (or spreadsheets) reflects the reality in warehouses, distribution centers and stores. Performing audits, including physical inventory counts, can help identify inconsistencies and allow retailers to correct inefficiencies that increase storage, shrinkage and depreciation costs.

Stock Availability and Inventory Optimization

Inventory optimization is the process of holding the right amount of inventory to meet demand while keeping logistics and storage costs as low as possible. The goal is to avoid common stock availability problems like stockouts, overstocking or backorder delays. In today's hyper-competitive and fast-changing retail environment, inventory optimization becomes imperative in controlling costs, increasing profitability and satisfying customers.

Inventory optimization begins with creating accurate demand forecasts. That intelligence then drives the optimization of stock levels to ensure that just enough product is available to meet demand without overstocking and thereby tying up precious capital that could be invested in expanding other areas of the business. To optimize inventory, companies need to consider factors such as their storage capacity and costs, supplier lead times and seasonal buying trends.

Optimize Stock Availability With NetSuite

For retailers, tracking inventory using spreadsheets and manual processes is inefficient and quickly becomes unmanageable. NetSuite Inventory Management enables retailers to automate inventory management processes and make data-driven decisions to improve stock availability, keep inventory costs low and improve customer satisfaction. A cohesive, real-time view of inventory metrics across all locations and sales channels helps businesses optimize inventory levels.

An inventory management system that supports inventory optimization gives retailers greater visibility, insight and control over their inventory and product availability. NetSuite Inventory Management dynamically manages reorder points to optimize stock availability, using demand-based planning based on historical demand, sales forecasts and seasonality. Companywide inventory visibility enables companies to monitor stock levels proactively, transfer inventory between locations as necessary and minimize carrying obsolete stock. Support for periodic, selected cycle counts helps ensure that inventory information is accurate and requires less effort to maintain.

Conclusion

When it comes to stock availability, retailers are looking for a Goldilocks-like middle ground — not too much stock, not too little, but rather just the right amount to meet demand. That can be a tall order, particularly when there are sudden swings in supply and demand. Real-time data and analysis of historical sales trends and predicted shifts are key to improving stock availability in a way that controls inventory costs and meets customer expectations.

Stock Availability FAQs

How do you ensure stock availability?

Real-time data and analytics are critical to ensuring stock availability and meeting customer demand. Inventory tracking systems allow retailers to accurately assess current inventory levels, analyze historical sales trends to forecast the right level of stock needed to meet customer demand and determine reorder points to guarantee stock availability.

How do you maintain stock?

The key for retailers is not simply to maintain stock but to maintain optimal levels of stock. To do so, businesses must closely monitor current stock levels, anticipate demand, manage replenishment cycles, work closely with suppliers, perform regular inventory audits and maintain a level of safety stock. Inventory management tools can provide real-time visibility into stock levels and optimize inventory levels.

What does product availability mean?

Product availability is a retailer's ability to meet customer demand at a given item. Retailers may provide detailed information about product availability to help customers plan and make decisions. For example, products may be categorized as currently in stock, backordered, stocked on-demand or unavailable. Effectively managing stock availability requires retailers to balance the need to meet customer expectations with the cost of maintaining inventory in a dynamic marketplace.

What is inventory availability?

Inventory availability refers to whether a specific item is available for customer orders. Additional information provided by retailers may include the quantity available. If the item is not in stock, the retailer may indicate its status — whether it is backordered or in transit from suppliers, for example. Inventory management systems help retailers monitor inventory availability and accurately communicate detailed information to customers.

What does "subject to stock availability" mean?

When a customer is purchasing an item, a retailer may indicate that the sale is "subject to stock availability." This indicates that the order will be fulfilled only if the retailer has the item in stock or can provide it to customers directly from its suppliers or partners. If the retailer or its suppliers do not have the product in stock, the order will be canceled or delayed.