Most consumers probably don’t give much thought to how their favorite products make their way to store shelves. Swimsuits somehow appear in the summer and winter coats arrive just in time for the snow. Behind the scenes, however, managing inventory is an intricate process. Manufacturers and retailers choreograph a delicate balance of supply and demand to avoid overstocking and shortages while ensuring timely production and product availability. It’s a critical process that carries considerable risk. Holding too much or too little inventory can have serious financial consequences when unsold products tie up capital or too little stock leads to lost sales and unhappy customers.

Finding the sweet spot between overstocking and understocking is essential to achieving the highest levels of profitability and customer satisfaction. This article takes a deep dive into the inventory optimization process, its advantages and challenges, and the latest techniques and best practices to promote success.

What Is Inventory Optimization?

Inventory optimization is the process of precisely balancing the amount of stock on hand with demand in order to minimize costs while ensuring product availability. The process uses analytics and forecasting tools to accurately predict demand. That demand data is then used to determine optimal stock levels and identify the most appropriate times for reordering.

Not only does inventory optimization maintain efficient production and distribution, but it also helps companies avoid two potentially costly scenarios. On one hand, maintaining too much inventory adds storage costs and takes up valuable warehouse space that could be used to stock more popular products. On the other hand, carrying too little inventory, a situation known as a stockout, can lead to lost sales opportunities and potentially unhappy customers. Research firm IHL estimates that the cost of overstocks and stockouts worldwide neared $1.8 trillion in 2023.

Key Takeaways

- Inventory optimization is the process of balancing inventory count and customer demand to maximize profits.

- Achieving optimal inventory allows businesses to reduce costs, improve customer satisfaction and supercharge sales.

- Companies use historical data, market trends and advanced analytics to determine the right locations, timing and volume of products to prepare for and store.

- Best practices for inventory optimization include adopting lean inventory practices, choosing the right suppliers and continuously improving optimization strategies.

Inventory Optimization Explained

Inventory optimization is one of six components that compose the broad process of inventory management. Demand forecasting is used to predict customer demand and maintain appropriate stock levels, while procurement and purchasing ensure timely acquisition of inventory. Warehouse management focuses on the efficient storing and handling of goods, while stock control monitors and manages stock levels. Order fulfillment involves processing, packing and shipping orders accurately.

Inventory optimization balances supply and demand to minimize costs and prevent stockouts throughout the inventory management process. It goes beyond managing stock levels. It’s about orchestrating the entire inventory ecosystem to streamline purchasing, align orders with demand fluctuations and secure the best deals from suppliers.

Goals of Inventory Optimization

If not handled efficiently, managing inventory can become a complex, tangled mess of excess products and stockouts that create potentially expensive consequences. Done correctly, however, inventory optimization can help companies achieve the following goals, thus transforming the challenge of maintaining inventory into a strategic advantage.

-

Balance Supply and Demand

Balancing supply with market demand is the ultimate goal of inventory optimization because it means there will be enough stock to meet customer needs without incurring excess costs due to overstocking. Inventory optimization leverages accurate demand forecasting, historical sales data, market trends and predictive analytics to anticipate future demand. The result is efficient inventory turnover that minimizes the time products spend in storage and reduces holding costs, which are the expenses associated with storing unsold goods.

-

Minimize Costs While Maximizing Service Levels

Efficient inventory optimization directly impacts a company’s profitability and customer satisfaction. For example, advanced technology tools facilitate accurate demand forecasts, reducing overstocks and associated holding costs while enabling companies to maintain sufficient stock to meet customer needs. These technologies, such as AI-driven analytics and cloud-based inventory management systems, can help streamline the supply chain process, keeping stock lean and reducing waste. Tight inventory control can also help with customer service by ensuring products are consistently available when customers need them. This leads to shorter wait times and higher satisfaction levels.

-

Reduce Waste and Obsolescence

The forecasting tools used in inventory optimization help identify products that have low sales frequency or sell in small quantities over extended periods. By recognizing these inventory trends early, businesses can make strategic decisions, such as marking down prices to liquidate inventory. This can free up the storage space and capital needed to bring in and house more profitable items. Inventory optimization also helps prepare for potential obsolescence or times when products risk becoming outdated before being sold. For example, many consumers find smartphones are relevant only for a few years before they should be replaced by updated models. By identifying these risks early, companies can proactively manage inventory levels and avoid the costly mistake of overstocking products that will soon be difficult to sell at full price.

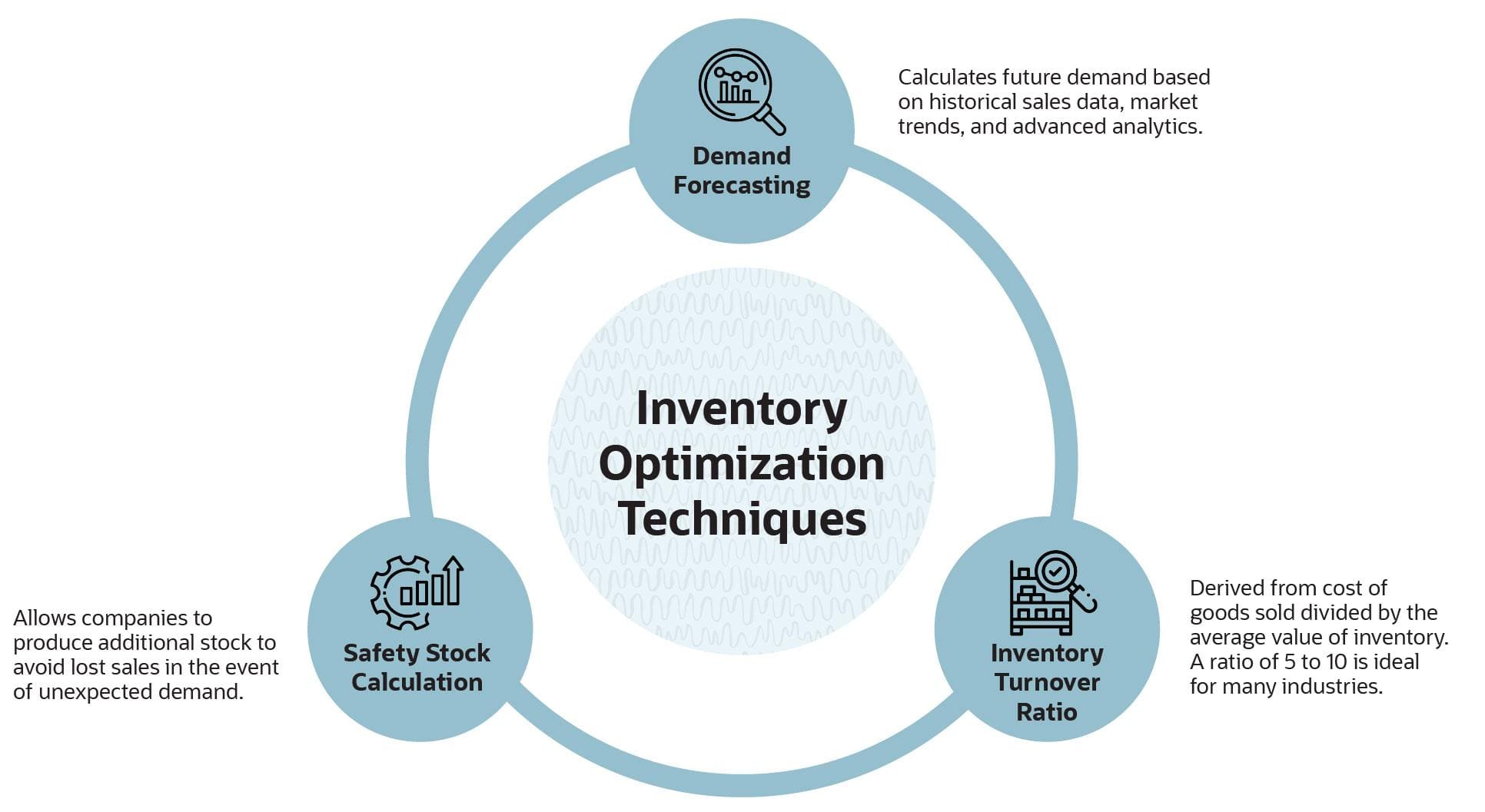

Inventory Optimization Techniques

Having the right amount of stock requires a strategic grasp of supply chain logistics, production, supplier schedules, historical trends and future needs. The following techniques can help companies master the process.

-

Demand Forecasting

Demand forecasting is the crystal ball of future market predictions. It estimates future demand for products based on factors such as historical sales data, market trends and advanced analytics. In turn, companies can make more informed predictions about what customers will want in the coming weeks, months and years. For example, an outdoor apparel manufacturer might consider multiple factors when deciding how many new jackets to produce, including how sales vary by season, weather conditions, fashion trends and promotions. Many inventory management systems automate the demand forecasting process.

Accurate forecasts enable businesses to make strategic decisions about inventory levels, production schedules and supply chain management. This allows companies to align their resources to efficiently meet customer needs, prevent overstocking or understocking and reduce the risks of missed sales opportunities or excess inventory costs.

-

Inventory Turnover Ratio

Inventory turnover ratio measures how many times inventory is sold and replenished within a specific period, typically a year. It’s calculated by dividing the cost of goods sold (COGS) by the average value of inventory. For example, an electronics store records $2 million in COGS and $400,000 in average inventory in 2023, meaning that it has an inventory turnover ratio of 5. For most industries, anything between 5 and 10 is ideal. Companies that deal with perishable goods, however, should aim for a higher ratio to prevent waste.

Low turnover ratios can indicate demand for certain items is decreasing, which might prompt companies to reduce pricing, run promotions or alter prospective product lines. High turnover ratios can signal inventory efficiency but can also indicate challenges, such as supply chain delays or surges in demand that could lead to stockouts. As a result, companies may decide to raise prices, increase orders or diversify suppliers to prevent future stockouts.

-

Safety Stock Calculation

Stockouts slam the brakes on sales and operations, leaving money on the table as customers turn to competitors. Safety stock is a risk management technique where companies produce and store an additional number of products beyond their forecast to serve as a buffer in the event of a stockout. This allows companies to meet unexpected demand and avoid lost sales, but it can also lead to increased carrying costs if the safety stock doesn’t sell.

A common method for calculating how much safety stock to hold involves determining the number of products sold per day and multiplying it by the number of days of safety stock needed. For example, if a company sells 200 items per day and wants seven days’ worth of safety stock, it will need 1,400 units. More complex formulas involve other factors, such as demand and lead time, to help pinpoint safety stock levels and prevent overstock.

Advantages of Inventory Optimization

The ultimate benefit of inventory optimization is to improve a business’s bottom line. The following advantages can go a long way toward helping companies reach that objective.

-

Reduced Holding Costs

Holding costs are the expenses associated with storing goods. They can quickly create financial headaches for companies when unsold items take up valuable real estate that would otherwise be used for more profitable products. Holding costs include the direct expenses of storing goods, like rent, utilities and security for the storage space, as well as broader financial implications, such as the opportunity cost of not carrying products with higher profitability. Insurance costs that protect against theft, damage or loss should also be factored in, as should financing expenses related to the capital invested in inventory (e.g., interest on loans taken to purchase inventory).

By accurately forecasting the right amount of stock a business needs, inventory optimization reduces the expenses associated with storage, insurance and financing. It also mitigates the risk of product obsolescence and depreciation when unused inventory loses value, such as with fashion products.

-

Improved Cash Flow

By carefully analyzing sales data and market trends as part of the inventory optimization process, companies can predict demand more accurately and reduce the costs associated with overstocking or stockouts. This frees up cash flow and allows companies to allocate resources more effectively. Efficient inventory optimization also improves cash flow by speeding up the supply chain and increasing turnover. This means capital is not tied up in unsold stock for extended periods.

Companies can further enhance cash flow by using lean inventory practices that aim to reduce waste by maintaining only the amount of inventory necessary to meet customer demands. Just-in-time (JIT) inventory practices, for instance, involve maintaining minimal stock and receiving items as they are needed in the production process. Companies can also leverage automated inventory tracking systems. These systems provide data that makes it easier to regularly review and adjust inventory strategies derived from current market conditions.

-

Enhanced Customer Satisfaction

Customers want the convenience of finding their favorite products wherever and whenever they want. Businesses that deliver this convenience are more likely to earn customers’ satisfaction and loyalty. With inventory optimization, businesses anticipate demand to reduce wait times and backorders, ultimately getting products into customers’ hands at the moment they want them (or as close to that as possible). Demand forecasting, for example, allows for a more accurate response to customer demand and a better selection of products that align with customer preferences. This approach not only meets customer demands but also builds a reputation for reliability and responsiveness. Efficient inventory management can also enhance the overall quality of service, which streamlines operations and can lead to faster delivery times.

-

Increased Productivity

Inventory optimization builds an understanding of trends and demand patterns that allows companies to better plan and allocate resources, leading to a more productive and agile operation. For example, a manufacturing firm can use inventory optimization to accurately predict raw material needs, ensuring they’re always available when required. This minimizes production delays caused by material shortages, which can significantly increase assembly line productivity and, in turn, on-time delivery rates. Inventory optimization also often involves automating processes, such as tracking stock levels and generating purchase orders. This reduces the likelihood of human error and frees staff from repetitive, time-consuming tasks like manual data entry.

-

Minimize Risks of Overstock or Stockouts

As discussed earlier, when companies use inventory optimization to regularly review sales patterns, market trends and seasonal variations to predict future needs, they can align inventory with demand to minimize the potential of excess stock and stockouts.

Inventory optimization also identifies items with lower or higher turnover rates so a store can adjust reorder quantities. In addition, advanced inventory optimization tools allow for automatic replenishment when a product drops to a certain threshold, which further maintains optimal stock levels.

-

Improved Supplier Relationships

Inventory optimization improves supplier relationships by supporting more accurate and consistent ordering patterns, which reduces the frequency of urgent or bulk orders that can strain supplier capacity. For example, accurate demand and inventory forecasts allow businesses to provide their suppliers with orders earlier and more accurately. This gives suppliers time to orchestrate their production processes and minimize the need for last-minute changes.

Similarly, reducing the likelihood of overstocks and stockouts makes a company’s production needs more predictable, allowing suppliers to better plan their own raw material orders or production. This collaborative approach also fosters trust and reliability, leading to potentially better terms and prioritization in times of limited supply.

Inventory Optimization Challenges

Businesses can enjoy a wealth of benefits from inventory optimization, but doing it well isn’t easy. Unforeseen challenges both within and outside of an organization’s control can have a big impact on inventory levels. Understanding the following challenges can make the process significantly more manageable.

-

Fluctuating Market Demands

Rapid changes in customer preferences, seasonal trends or unexpected economic shifts can create unpredictable demand patterns. For example, a global recession could cripple demand for new cars and luxury goods, prompting lower turnover and excess stock. This volatility requires businesses to maintain agile inventory management strategies. For example, JIT practices allow companies to adjust quickly to changing demands. Additionally, investing in advanced data analytics can help companies identify emerging trends and detect otherwise unnoticeable patterns in demand forecasts. Regularly reviewing and updating inventory strategies in response to real-time market data also enables companies to stay aligned with current market conditions.

-

Supply Chain Disruptions

Supply chain disruptions, such as natural disasters, geopolitical tensions or pandemics, pose a significant inventory management challenge by creating unpredictable delays and shortages. Order delays, whether due to stockouts or last-mile logistics issues, can drive customers to competitors or alternative products, making it even more difficult to forecast future demand accurately. To avoid these pitfalls, companies would be wise to diversify their supplier bases to avoid dependence on a single source and ensure alternative options in case of upheavals. Building safety stock or buffer inventory for critical items can also help manage short-term disruptions. Additionally, investing in robust supply chain management systems and maintaining flexible inventory strategies allow businesses to adapt more quickly and efficiently to unforeseen supply chain challenges.

-

Technological Challenges

Technological challenges, such as outdated inventory management systems, can make inventory optimization difficult. Companies using manual processes or outdated software, for example, may struggle with real-time data tracking, delaying responses to market changes. A lack of integration between inventory management software and other business systems can also hinder inventory optimization. For example, if a retail company’s inventory system isn’t integrated with its sales and forecasting platforms, inaccurate demand predictions and inefficient stock levels can result. Although integrating systems may require additional IT resources, advanced inventory management systems, particularly cloud-based systems, can make integration easier simply by using simple tools to connect various applications.

Inventory Optimization Best Practices

Successful businesses recognize the importance of maintaining and scaling inventory optimization efforts. This includes baking critical best practices into their processes. Here are several to consider.

-

Lean Inventory Management

Lean inventory management focuses on maintaining only the inventory levels necessary to meet customer demands. As a result, companies can lower storage costs, reduce waste and improve cash flow. For example, car manufacturers often use JIT inventory practices, which establishes minimal inventory by having parts delivered right before they’re needed on the production line. Lean inventory management involves continuously analyzing sales patterns, customer demand and production cycles to ensure that inventory levels are closely matched to actual needs, which, in turn, minimizes the costs associated with holding excess stock. It also emphasizes continued improvement and flexibility, allowing companies to adapt quickly to market changes.

-

Strategic Supplier Relationships

Building strong, collaborative relationships with the right suppliers is an important way to maintain optimal inventory and build long-term strategic business partners. Good relationships with suppliers mean better communication and collaboration, resulting in more accurate and timely information about product availability, lead times and potential disruptions. As a result, companies can plan more effectively and adjust inventory strategies to respond to supplier capabilities and constraints. For example, a strong supplier relationship might make it easier to negotiate faster delivery times or more flexible order quantities. Strong partnerships can also generate joint efforts in forecasting and planning to further align inventory levels with actual market demand.

-

Continuous Improvement and Adaptation

As business and consumer landscapes evolve, inventory optimization practices need to adapt, too. By continuously analyzing key performance indicators, such as sales trends, customer feedback and supply chain performance, companies can identify areas for improvement, whether it’s a need to adjust safety stock levels, enhance forecasting methods or streamline logistics. Improving these areas can then help companies limit overstocks, minimize holding costs and reallocate resources to other areas of the business.

Similarly, as new technologies emerge, such as advanced analytics or AI-powered forecasting tools, businesses can integrate these innovations to further enhance their inventory management capabilities. This cycle of evaluation, adaptation and improvement is crucial for a smooth inventory optimization journey.

Optimize Your Inventory With NetSuite

Successful inventory optimization relies on gathering considerable amounts of data from across an organization to build an accurate picture of consumer demand, production capability and timing. For many companies, however, that data resides in multiple, disparate systems, making it difficult to get the complete picture necessary for successful inventory optimization.

NetSuite ERP natively integrates companywide data across finance, sales and manufacturing into a single, real-time database to make it easier to forecast demand and optimize inventory. In particular, NetSuite Inventory Management provides a unified view of inventory across an entire company. Features, such as automated tracking of inventory levels, sales cycles and real-time inventory management KPIs, give businesses complete visibility on inventory levels across the enterprise. This software also uses sales forecasting and predictive analytics to help operations teams manage reorder points and maintain optimal stock levels.

In addition, NetSuite Inventory Management provides real-time visibility and traceability, making it possible to track inventory throughout the supply chain — be it incoming stock, returns, exchanges or warranties.

The benefits of inventory optimization are clear: higher customer satisfaction, reduced overhead costs and extra capital for other areas of the business. And while optimized inventory alone doesn’t guarantee profitability, having the right products at the right times and in the right locations is an essential part of successful operations.

Award Winning

Cloud Inventory

Inventory Optimization FAQs

What is inventory theory in optimization techniques?

Inventory theory involves determining the most efficient order quantities and reorder points, balancing the costs of holding inventory against the costs of ordering and stockouts. This theory aims to minimize total inventory costs while ensuring adequate supply to meet demand. It often involves several techniques. For example, linear programming uses mathematical models to determine the most efficient purchasing and stocking strategies, while stochastic modeling uses probability distributions to forecast various scenarios. Just-in-time (JIT) inventory management, a technique that involves maintaining minimal stock and receiving items only as they are needed in the production process, may also be used.

What are the two types of inventory optimization?

There are two main types of inventory optimization. Deterministic models assume that demand and other related factors are known and consistent over time; they focus on optimizing order quantities and timings under predictable conditions. Stochastic models account for uncertainty and variability in demand and supply, using probability distributions to forecast various scenarios. These models are more complex and suited for environments where demand is unpredictable.

What is an example of inventory optimization?

An example might be an online clothing store that analyzes historical sales data and weather patterns to predict winter coat demand. The retailer uses this forecast to determine which products to stock and how much of each it needs to prevent expensive overstocking in mild winters or stockouts during snowstorms.

What is meant by inventory optimization?

Inventory optimization involves balancing the right amount of inventory — not too much, to avoid incurring high holding costs, and not so little that stockouts arise. This process uses data analysis and forecasting to predict demand, streamline inventory levels and improve overall supply chain efficiency.

What are the 5 steps to effective inventory optimization?

Effective inventory optimization involves five key steps.

- Analyze historical sales data to understand demand patterns.

- Use this analysis to set optimal stock levels.

- Leverage automated inventory management systems for real-time tracking and replenishment.

- Continuously monitor and adjust inventory strategies based on market changes.

- Foster a coordinated approach in which all supply chain participants share data and insights to streamline end-to-end inventory processes.

What are 3 tools used to improve inventory management?

There are three main tools companies should consider to improve inventory management:

- Inventory management software, which offers real-time tracking of stock levels, orders and deliveries to streamline inventory control and forecasting.

- Business intelligence tools, which are used to rapidly analyze data and provide insights for better decision-making, enhanced inventory planning and greater efficiency.

- Demand forecasting tools, which leverage historical sales data and predictive analytics to accurately predict future inventory needs, ensuring optimal stock levels and minimizing excess.