Faced with an out-of-stock notification, many consumers will simply click over to a competitor’s site. For some retailers, the answer is to use backorders, where a desired item that is still in production but currently out of stock is promised to ship in a set timeframe.

The customer gets the item, the retailer makes the sale. Win/win.

Backorders can be tricky, though. If you end up being unable to fulfill the order, the customer may be more irritated than if you had just marked the item as out of stock. And, managing backorders can be a headache for finance and logistics teams.

So are backorders right for your business? Maybe. Here are some items to consider.

What Is a Backorder?

A backorder is generated when an order can’t be fulfilled at the time of purchase because the item is not in the seller’s current inventory. However, the item is still in production or available from the distributor.

Also known as a backlog, a backorder indicates that demand for a given product exceeds what the seller produced or ordered. That could be a function of poor planning, supply chain issues, overly strict policies on safety stock, or an unforeseeable spike in demand for an item.

Key Takeaways

- Backorders occur when a company accepts orders for out-of-stock items that are expected to be available in a reasonable timeframe.

- Effective backorder management involves setting realistic customer expectations, efficiently processing orders, and proactively communicating status updates to maintain customer satisfaction.

- Companies can minimize backorders and their negative impacts by improving demand forecasting, diversifying suppliers, leveraging real-time inventory data, and developing contingency plans.

Why Do Companies Offer Backorders?

Backorders may benefit companies in a few ways. Retailers with limited warehouse capacity may not be able to hold a large amount of stock, but if they can confidently track availability of items from suppliers, they can avoid overcrowding and incurring excess storage costs while confidently accepting backorders.

Sometimes, companies see an unexpected surge in demand for a product. Again, depending on visibility into availability of additional stock, accepting backorders allows the retailer to make those sales and keep customers happy.

Small suppliers that drop-ship most or all of their items often take backorders as a matter of course and place an order with the supplier only once backorders reach a certain threshold. These companies avoid inventory carrying costs altogether.

Should Your Business Offer Backorders?

Avoid allowing backorders on inexpensive or commodity products that customers can readily purchase elsewhere. Where backorders are offered, make sure the profit margin makes the extra logistical effort worthwhile and that you can fill those requests promptly. The amount of time it takes to get a backordered item to the customer depends on several factors:

Factors Affecting Backorder Fulfillment

When estimating the length of a backorder, consider:

Your supply chain: The longer and more complex the supply chain for a backordered item, the longer it will take to acquire enough to meet demand, and the more likely it is that the item will go out of stock before backorders are filled.

Customer service capacity: Backorders add extra steps and exceptions. Companies with automated order management and exception handling, or that use 3PL providers, can more quickly and efficiently manage reorders and fulfillment.

Dropship capabilities: If feasible, cutting out steps and dropshipping backordered items direct from the maker or distributor speeds fulfillment.

Marketplace rules: Retailers selling on Amazon, Ebay or another marketplace may choose not to accept backorders because of selling terms, such as strict rules on fulfillment times; generally, the restock date must be within 30 days of the sale.

How Backorders Work

When a company takes orders — and potentially payments — for products that are not in stock, it is accepting backorders.

Once backorders are accepted, the inventory management system converts them to purchase orders and sends them to the appropriate internal department, vendor, or distributor. Customer service teams should provide buyers with an estimate of when they can expect their orders and how payment will be handled.

Retailers may choose to have the supplier drop-ship items directly to customers, or the retailer may take delivery of the items, translate the backorders to sales orders, and ship the items to customers after charging the customer’s account, if applicable.

For a limited number of SKUs at a manageable volume, this is not an overly complex process. Problems mount, however, when the number or quantity of backordered products multiply or when retailers have a lot of manual order processes and must match each purchase order with a current sales order when completing the fulfillment process.

Backorders vs. Out of Stock

An item is out of stock when the seller doesn’t have the item in inventory and has no sure date to restock, or the item is seasonal or a limited run. Backordered items are expected to be available in a reasonable timeframe.

What Causes Backorders?

Addressing the causes of backorders is the first step in preventing — or at least minimizing — them. Let’s take a look at some of the common reasons for backorders, which in a sense are all symptoms of inaccurate forecasting that can in turn be cured by improved inventory forecasting:

- Unusual demand or demand exceeds supply: Holiday seasons or unforeseen circumstances, like extreme weather, may lead to unusual purchasing patterns. For example, a sudden heat wave, or when a hurricane warning leads to an uptick in orders for generators, leading to backorders.

- Long lead times: Long lead times can cause backorders when suppliers can’t deliver products quickly enough to meet customer demand, resulting in a shortage of inventory and delayed fulfillment of orders.

- Inaccurate forecasting: Less accurate forecasts could lead to low safety stock and a higher chance of backorders.

- Supplier or manufacturing issue: Supply chain challenges, such as factory shutdowns or raw material shortages, can lead to items being unexpectedly out of stock.

- Delayed orders: Companies that order based on safety stock formulas and require manual review of purchase orders may run into restocking delays, only to experience a sudden surge of orders. Delays may also happen when the company’s upstream supplier hasn’t replenished its usual stock.

- Human errors: An employee may enter an order as a backorder even if the item is available. Or, worse, a retailer may accept a backorder even though the item is out of stock. This may happen because of error or because of lag time in inventory updates.

- Warehouse management discrepancies: Warehouse management refers to all the processes involved in daily warehouse operations — and it’s a lengthy list. A glitch in an inventory management system may provide inaccurate data, or a breakdown in data entry may lead to stock being miscounted or misplaced.

How Backorders Affect Supply Chains

Backorders affect supply chains because they place additional burdens on distributors and manufacturers. When fulfilling backorders, suppliers need to produce or procure additional backordered stock in addition to their normal inventory. If there isn’t enough product to fulfill these orders, the burden is shifted up the supply chain, or retailers are forced to cancel backorders.

These sudden demand fluctuations can end up causing what’s known as a “bullwhip effect,” an overcorrection of the supply chain. The farther an entity is removed from the source of the backorder demand, the more uncertainty is introduced. Overseas suppliers at a distance from retailers, for example, are unlikely to receive timely information on what caused the backorder situation. That may cause them to hedge by increasing production to ensure they can meet downstream demand — even if the backorders were the result of a fluke, like a heatwave in October leading to people buying up AC filters. Thus, total supply chain costs increase, and retailers may actually end up with excess inventory.

How to Account for Backorders

Even with the right inventory management systems in place, backorders typically require special accounting and customer service processes because the company has to inform buyers about the backorder, when they will be charged, and when to expect delivery.

A company’s backlog is usually conveyed as a subcategory of sales, as a dollar figure, or by the number of units sold or ordered. Rather than considering it as a completed sale, the backorder will be recorded as such on the company’s books. That’s so the company doesn’t have to go back and reconcile their accounting records if the customer cancels the order, or if the company can’t acquire the stock.

Once a backorder is recorded, the company places the order. When items are received, the company follows through, delivering the product based on the customer’s purchase order. Alternately, items could be drop- shipped directly. The sale will then be recorded and marked as complete.

It’s important for companies to calculate backorder rates, among other vital inventory KPIs and metrics, like forecast accuracy and time to receive.

The backorder rate measures what portion of customers’ total orders are for items that are backordered. It shows how well a company stocks in-demand products.

Calculate the backorder rate with this formula:

Backorder Rate = (# delayed orders due to backorders / total # orders placed) x 100

Advantages of Backorders

Positive reasons to offer backorders include increasing sales and adding some flexibility for small businesses.

Other advantages include:

- Offers market insights: Backorders act like customer surveys, indicating what kinds of products buyers want, and when they’re in the highest demand.

- Improved cash flow: Companies that avoid holding excess stock, with the associated costs, free up cash for other priorities. In some industries, less inventory also translates to reduced taxes.

- Minimizing storage: Minimize this and other inventory costs that come with holding extra stock.

Disadvantages of Backorders

Backorders do have some significant downsides that can cost your company. These include:

- Losing out on business: Customers may not want to wait, or trust the company to fulfill their orders, causing them to cancel and purchase elsewhere.

- Loss of market share: If customers frequently encounter backorders or must wait a long time for fulfillment, their loyalty to your brand may wane, and they could turn to other brands.

- Increased complexity: Backorders increase the chances of a company having to resolve customer service issues, such as trying to update expired payment information.

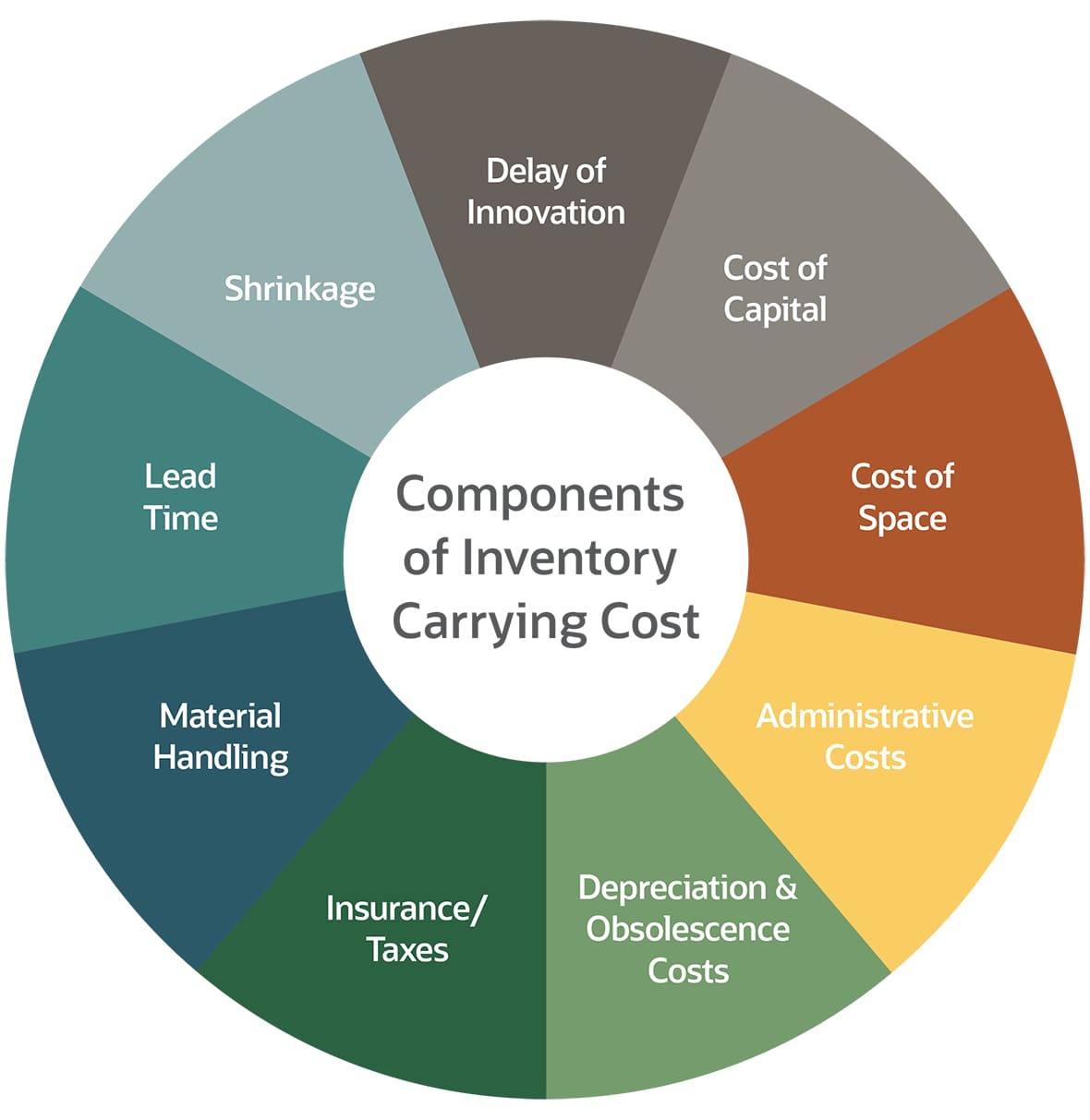

Finally, a major pros/cons pivot point for backorders is inventory carrying costs. A company that sells mainly inexpensive, small, non-trendy items may not worry as much about obsolescence, space, or tying up capital and thus can keep more stock versus, say, a company that sells large appliances.

Managing Fulfillment of Backorders

The best way to manage backorders is not to need to accept any. Realistically, however, most sellers will run into this situation. This is where an order management system can pay for itself by ensuring you don’t alienate customers, providing accurate and real-time data to help with decision-making, and compiling insights based on seasonal trends to forecast supplier performance and predict surges in demand.

Businesses that are able to manage inventory flows around supplier lead time and adapt purchase orders based on real-time data can avoid running out of products, especially when selling potential is highest.

When you must fulfill backorders, use a 5-step process:

- Make good — consider whether to thank affected customers for their patience with a shipping upgrade or by including a low-cost item at no charge.

- Notify the customer of the expected delivery date range. Check whether the customer has placed another order with which you could bundle the backordered item.

- Shift backorder to sales order and authorize shipment.

- Process payment or issue an invoice.

- Ship item and close sale.

But don’t stop there. If you see a significant number of backorders, consider recalculating your reorder points, setting a higher safety stock threshold, or rethinking your inventory forecasting process.

Best Practices for Backorders

Some backorders are unavoidable, but it’s a best practice to minimize them and thus limit the chances of a bullwhip effect negatively affecting your supply chain, as well as other challenges like disappointed customers, longer fulfillment intervals, and added back-end complexity.

Best-in-class retailers:

- Gather as many of a customer’s backordered items as possible before notification, shipping or billing.

- Set a time limit on how long backorders will be kept open and active. What that timespan is depends on the business, but 30 days is average.

- Make every attempt to acquire the backordered items within that time span, even if it means a higher cost of goods and/or manual processes.

- Notify the customer promptly if an item can’t be shipped within the time limit, and make an entry in your CRM to email if the item does become available in the future.

Other best practices you can implement:

- Communicate with your supply chain partners — open lines with both upstream and downstream partners means fewer assumptions and fewer chances of overestimating or underestimating demand.

- Educate employees on the downsides of backorders and the need to go the extra mile in terms of customer service.

Five Tips to Minimize Backorders

Minimizing backorders is doable if you use the right combination of business processes and technology. Steps you can take:

1. Know what your customers want — and need.

By prioritizing inventory items by importance to customers, you can be selective about increasing safety stock. For example, a restaurant owner will be less understanding about potatoes being backordered versus an exotic fruit. And since the cost of carrying plenty of spuds is low, there’s little reason to ever be out. On the other hand, if your largest customer’s most popular dish requires an expensive and hard-to-find ingredient, and too many backorders will cause it to seek another supplier, you’ll want to have a dependable supply chain.

2. Look for real-time data and reporting.

Ensuring that data is accurate and reported in near-real-time ensures two things: That your warehouse will be notified to restock items in a timely manner, lowering the chances of delays in purchasing that lead to backorders. And that customers can be notified promptly — ideally at time of purchase — that an item is backordered, so they can choose whether to keep it in their carts.

3. Set system triggers.

These can range from simple alerts when stock is low all the way to automated alerts to customers on the status of their orders or to let them know that a new shipment of a frequently purchased item has arrived.

4. Develop backup or contingency plans.

When an item is backordered, smart sellers do whatever it takes not to disappoint valued customers. This includes sourcing local suppliers or even purchasing the item elsewhere at retail.

5. Diversify suppliers.

Manufacturers or suppliers can also hit peak demand, planned or unplanned. Ordering from a wide variety of sources is just good supply chain management, which begins with timely purchase orders and cycles through performance tracking, including productivity, costs, fill rates, on-time delivery, and customer satisfaction.

Customer Service & Backorders

Keeping customers happy during backorder situations is key to keeping them coming back.

They’ll expect to receive timely updates and be kept in the loop about delays or changes. Being proactive with communications will maintain your company’s reputation. Specific action steps include sending out emails regularly, providing an estimated arrival time, and updating customers on any events that may accelerate or delay their shipment.

If you collected a deposit or full payment and the customer cancels, process the refund promptly.

Backorder Examples

Backorders can significantly disrupt supply chains and customer satisfaction, often resulting from unforeseen surges in demand or delays in supplier deliveries. Here are three examples of backorders and potential strategies for avoiding or resolving them:

- An electronics retailer experiences a backorder on a popular smartphone model during the holiday season because it underestimated the demand for the new model, which was heavily promoted by the manufacturer. The sudden surge in orders depleted the retailer’s inventory faster than anticipated. This could have been avoided by implementing better inventory management and demand forecasting tools, allowing the retailer to anticipate higher demand and adjust orders accordingly.

- A manufacturer faces a backorder on critical components due to a supplier issue. The backorder occurred because the primary supplier experienced an unexpected factory shutdown due to a natural disaster, halting production of the needed components. This situation could have been mitigated through stronger supplier relationship management and risk assessments to ensure that alternative suppliers are available to fulfill orders when primary suppliers face disruptions.

- A clothing retailer experiences backorders on winter coats because an unseasonably early cold snap hit multiple regions simultaneously, causing a sudden spike in demand before the retailer had fully stocked their seasonal inventory. The retailer could been better prepared for this scenario by employing more agile procurement practices, enabling it to quickly adjust orders and negotiate with suppliers.

Track Stock and Manage Backorders With NetSuite

ERP software can help your company automate much of the supply chain and inventory management process and manage backorders. More specifically, it can help with demand planning, using historical data to plan your inventory around meeting customer demand and special events like sales or promotions.

Using software can help you create a sustainable roadmap for your fulfillment process, from ordering products to receiving and shipping them. It can even help you automatically place purchase orders with your suppliers, decreasing backorder times.

Backorder FAQs

How long is a backorder?

The length of time for backorders will vary depending on factors such as whether they are in stock with your distributor or supplier, when you order the items, and the time it takes to ship the order to your warehouse. The critical thing to remember is that you need to clearly communicate to customers when they can expect to receive their purchases.

Why do backorders occur?

Backorders generally happen when demand exceeds supply, whether that’s due to a successful marketing campaign or seasonal trends. They could also occur when there is a disruption in the supply chain due to unforeseen circumstances such as extreme weather, challenges with transportation, political upheavals, a shortage of raw materials, or a supplier going out of business.

Are backorders bad for business?

Backorders can be both good and bad for business, depending on how they’re managed. While backorders can provide short-term benefits, like increased sales and market insights, poorly managed backorders can lead to customer dissatisfaction, lost business, and supply chain disruptions that ultimately harm a company’s reputation and bottom line.

What is a partial backorder?

A partial backorder occurs when a supplier can only fulfill part of an order, delivering some items while the remaining products are delayed due to insufficient stock or other supply chain issues.