Effectively managing raw materials inventory keeps production lines moving and costs under control. Otherwise, manufacturing, construction, and other businesses risk running out of critical resources or wasting money and storage space. Skillful raw materials management can also help procurement teams determine when to place orders and arm them with information to negotiate better terms with suppliers, free production planners from reworking schedules because materials aren’t available, optimize warehouse space, and even improve the business’s cash flow.

What Is Raw Materials Inventory Management?

Raw materials inventory management is the process of tracking and recording the flow of resources used to manufacture goods, in construction projects, and for energy production, for example. The goal is to have just enough raw materials on hand to keep production or project plans on schedule and meet demand—with little or no extra left over.

Effective management of raw materials can also curb the storage and other holding costs that result from overstocking, limiting the risk of inventory obsolescence and helping to avoid delays caused by raw materials shortages.

Key Takeaways

- Raw materials inventory management involves ordering, storing, monitoring, and inspecting resources throughout the production cycle.

- Effective raw materials management boosts operational efficiency, informs purchasing and planning decisions, cuts storage requirements, and reduces waste.

- Price volatility, supply chain disruptions, and financial constraints can stymie raw material management efforts.

- Implementing best practices and strategies like just-in-time inventory management, ABC analysis, and material requirements planning enhance visibility and long-term stability.

Raw Materials Inventory Management Explained

Raw materials—from basic commodities, such as metals and fabrics to chemical compounds and LED chips—are fundamental in manufacturing, construction, pharmaceuticals, and other industries. Managing this inventory involves ordering, receiving, storing, and using these materials, as well as tracking them throughout the supply chain and relocating them when necessary to balance stock levels.

Raw materials inventory management relies on closely coordinated procurement, inventory control, warehouse management, and quality assurance functions. By encouraging collaboration in this way, businesses can better control costs, curtail waste, and maintain consistent records. Proper inventory management also supports financial accuracy, as raw materials are typically listed as current assets on company balance sheets.

The two main types of raw materials that manufacturers need to manage are direct and indirect raw materials.

Direct Raw Materials

Direct raw materials, such as lumber, metals, or fabric, are physically incorporated into a finished product during manufacturing and become part of a company’s bill of materials (BOM). Companies monitor these materials to balance production goals and cost control. The tracking is relatively straightforward, because direct raw materials are quantified in standard physical units—pounds, yards, pieces—making their inventory measurement precise and closely tied to production output.

Indirect Raw Materials

Indirect raw materials are often needed for maintenance, repairs, and general production tasks. They contribute to the manufacturing process but do not become part of finished products and, therefore, are not included in the BOM. Common examples: lubricants, cleaning supplies, adhesives, and packaging materials. Intentional oversight of indirect raw materials helps prevent production delays and downtime, but they are harder to track because they are often used in small or variable quantities in multiple areas of production.

Raw Materials Inventory vs. Work-in-Process Inventory

Raw materials inventory refers to unprocessed materials purchased and stored for future use in production, while work-in-process (aka work-in-progress) inventory consists of partially completed goods. Both are classified as current assets for accounting purposes, but they are listed separately on the balance sheet to reflect their distinct positions in manufacturing. Once raw materials move from storage to the production floor for processing, their value shifts to the WIP account, which adds the costs of direct labor and production-related overhead.

Raw materials management helps derail inventory shortages that delay operations. WIP management helps manufacturers spot and address production bottlenecks. Monitoring each category separately equips businesses with the information they need to optimize production plans while controlling costs.

Why Does Raw Materials Inventory Management Matter?

Raw materials inventory management helps acquire the right materials at the right time and place, so as to support efficient, cost-effective production. It also provides accurate records—including material quantities, values, and locations—that support well-informed purchasing and production scheduling decisions. Effective management helps manufacturers avoid running out of materials (which halts production) or tying up capital in the guise of excess inventory. It also lowers storage requirements and cuts waste by identifying slow-moving and obsolete items before they pile up. When raw materials inventory is organized and aligned with demand, operational efficiency increases, order fulfillment quickens, and customers are happier.

Because less capital gets tied up in inventory, raw materials management frees up cash for other business priorities. This capital efficiency is evidenced in a business’s financial statements, because raw materials costs factor into inventory value and cost of goods sold calculations.

Raw Materials Inventory Management Core Functions

Raw materials inventory management brings several core functions together to keep production running smoothly and costs under control. Each of the following plays a distinct role in the process.

Procurement and Purchasing

Procurement and purchasing teams or individuals aim to establish steady material flows and block unnecessary stock buildup. Their success hinges on accurate demand forecasting for their ordering decisions and correct selection of dependable suppliers of high-quality materials. By negotiating well-thought-out contracts with their vendors, procurement teams can control raw material costs and set clear and enforceable delivery and quality expectations. Ongoing supplier relationship management, boosted by good communication and collaboration, helps companies identify and address causes of delayed deliveries, such as supplier production bottlenecks or logistics snags. The right technology, such as an ERP system, equips procurement teams to align purchasing decisions with real-time inventory data, helping them optimize stock levels and keep production running smoothly.

Inventory Control

Inventory control teams manage a company’s raw materials inventory. They can employ inventory management systems to track material quantities, issue alerts when stock needs to be replenished, set automated reorder points, and monitor stock movements in real time. Performing regular audits that include physical counts helps correct discrepancies that creep into estimates and that could lead to under-ordering or overstocking. Establishing clear reorder points, maintaining sufficient safety stock levels, and performing ABC analysis can reduce the risk of running out of essential materials. Strong inventory control also limits carrying costs and last-minute purchases, facilitating more stable and predictable production processes and financial outlays.

Inventory Handling and Storage

Warehouse teams are responsible for the handling and storage necessary to protect raw materials from damage. Temperature, humidity, and other environmental controls decrease the likelihood of spoilage, contamination, and deterioration for perishable goods and sensitive materials. Handling procedures often include protocols to limit waste and control inventory shrinkage. Clearly organized storage areas allow for faster material retrieval during production runs, reducing delays. Optimized layouts improve warehouse utilization and worker safety. Investing in automated warehouse systems for moving, storing, and managing raw materials helps minimize errors and manual labor. The use of scanning technologies like barcode or radio frequency identification readers, integrated with an inventory management system, furnishes real-time inventory updates.

Quality Assurance

Preventing defective raw materials from negatively affecting production and product quality is the job of the quality assurance (QA) team. QA starts by clearly defining raw material specifications and communicating them to suppliers in contracts before making purchases. Upon receipt, QA teams inspect and test materials to confirm that they meet the requirements. Entering quality data into inventory systems can flag nonconforming materials before they move into production. Continuous monitoring and auditing verifies ongoing adherence to quality and regulatory standards and helps identify recurring issues with specific suppliers. Businesses that take a proactive approach to QA can curb defect-related production delays, slash rework and scrap, and create more consistent finished products that satisfy customers and limit costly product recalls.

Raw Materials Inventory Management Methods and Strategies

Companies can manage raw materials inventory in different ways, depending on their size, industry, production needs, and business goals. Choosing the right strategy is crucial because it will improve visibility, reduce waste and costs, and support long-term operational stability.

There are a number of considerations when choosing the best inventory management methods and strategies, such as business model, product type, forecasting and technology capabilities, supply chain stability, and regulatory and financial concerns. For example, large, high-volume manufacturers may benefit from material requirements planning (MRP), while smaller, more agile companies might opt for just-in-time inventory management.

-

Just-in-Time (JIT) Inventory

With JIT inventory management, the goal is to order raw materials so that they arrive at the moment they are needed for production. This cuts the volume of supplies kept on hand, which lowers carrying costs along with the chances of overstocking materials that could expire or become obsolete. By tying up less working capital in inventory, JIT inventory management also supports lean operations, improves cash flow, and can give businesses more flexibility when responding to market changes.

JIT inventory management requires precise demand forecasting, close coordination with reliable suppliers, and real-time inventory tracking. Many companies implement JIT practices using ERP systems, because the software allows them to manage material flows, production timelines, and supplier relationships within a central platform.

-

ABC Analysis

ABC analysis categorizes raw materials into three groups, based on their value to the business. It helps focus attention on the materials that contribute the most to production continuity and profitability. To calculate ABC classifications, companies multiply the annual number of items used or sold times the cost per item, with the result being the “total annual usage value” of the raw material.

“A” items are high-value materials that significantly affect costs and production, so they require tight inventory control and frequent monitoring. “B” items are of moderate importance, needing less frequent oversight, and “C” items are low-cost or infrequently used materials that require minimal management. This structured approach focuses inventory control efforts where they will have the greatest operational and financial impact.

-

Economic Order Quantity (EOQ)

EOQ calculations help determine the best order size for raw materials. The aim of EOQ is to find the purchase quantity that minimizes the combined costs of ordering and holding inventory. Businesses use EOQ to reduce excess stock and storage costs, yet maintain enough raw materials to meet production demand.

This method counterbalances the opportunity for bulk purchase discounts against the financial risk of overstocking. It is particularly useful for managing high-volume or high-cost raw materials, where ordering errors can have a material effect on profitability. EOQ also supports better financial planning and lean inventory management practices, especially for companies with predictable demand patterns.

-

Material Requirements Planning (MRP)

MRP uses production schedules and sales forecasts to calculate how much raw material is needed and when. Inventory, purchase order, and production planning data inform these calculations, aligning material ordering with actual demand. MRP also enhances planning by distinguishing between independent demand, which is driven by customer orders, and dependent demand, which is driven by component needs within production. MRP systems can automate replenishment decisions to save time and cut down on human error.

This approach is especially helpful for businesses with complex product assemblies that require coordination of multiple raw materials, those with fluctuating demand, or those that face frequent stockouts or overstock situations. By integrating procurement and production planning, MRP helps companies rein in inventory costs, make sure the right materials are available at the right time, and better manage lead time—and, in these ways, increase their profitability.

-

Six Sigma

Six Sigma uses statistical analysis and structured problem-solving methods to improve raw materials inventory management processes. It aims to identify the root causes of inaccuracies and waste so businesses can cut costs related to overstocking, stockouts, and defects while improving supply chain reliability. By regularly analyzing inventory with Six Sigma tools, companies can spot and address issues before they have a chance to impact production. In addition, Six Sigma decreases variability in inventory data and usage patterns, improving demand forecasting. It can also help optimize warehouse layouts and workflows.

-

Safety Stock

Maintaining safety stock—that surplus raw material inventory that serves as a buffer—helps fortify companies against supply chain disruptions, unpredictable demand, and forecast inaccuracies. Safety stock is particularly valuable in industries where lead times are long, because delays in replenishment can significantly affect production. A well-calculated overabundance helps businesses prevent stockouts and production stoppages that might lead to lost sales, without tying up too much capital in excess inventory. It also keeps production schedules on track. Determining appropriate safety stock levels involves analyzing lead times, demand variability, and service level targets (specifically, the desired probability of meeting customer demand).

-

Reorder Point

The reorder point is the inventory level at which a business should replenish raw materials to prevent running out of stock. Accurate reorder point calculations consider average daily usage rates and supplier lead times to determine the right time and quantities to purchase. Automated systems can eliminate guesswork and manual interventions—as long as they are supplied with clean, accurate data—reducing the likelihood of costly last-minute orders. Businesses that reorder at the right time enjoy steady production flows without overstocking raw materials, striking a balance between holding costs and stockout risks.

Raw Materials Management Challenges

Managing raw materials comes with several challenges that can delay production and increase costs if not properly addressed. From market fluctuations to regulatory demands, businesses must navigate a range of factors that influence inventory decisions and operational efficiency. These issues can vary with business size, industry, and supply chain complexity. But what’s true for all businesses managing raw materials is that recognizing these challenges is critical to managing raw materials most efficiently:

- Price volatility: Swings in raw material prices can blow budgets and squeeze margins. Mitigation strategies include long-term contracts with suppliers, inventory buffering, and proactive planning.

- Supplier overreliance: Depending on a few suppliers (or, worse, a sole source) increases exposure to delays, cost fluctuations, and quality issues. Expanding the supplier base moderates these vulnerabilities and improves supply chain resilience.

- Supply chain disruptions: Disruptions can halt production and increase costs. Real-time tracking and maintaining safety stock mitigates these risks.

- Inventory waste: Excess inventory ties up capital and risks spoilage, obsolescence, and higher storage costs. Reliable demand forecasting and lean inventory practices minimize waste.

- Warehouse costs: High storage costs, especially for raw materials needing special handling or climate control, can erode profitability. Data-driven inventory management and efficient warehouse layouts lower expenses and improve efficiency.

- Financial constraints: When a company’s finances are limited, it’s less likely to make bulk purchases, which can inflate procurement costs. And whatever the company does spend on raw materials must be diverting working capital from other business priorities. Careful planning, tight inventory control, and JIT approaches can help businesses better manage stock without overextending finances.

- Regulatory barriers: Strict regulations pertaining to handling, storage, and traceability add cost and complexity to raw materials management. Clear processes, proper documentation, and cross-functional coordination help maintain compliance and avoid penalties.

How to Calculate Raw Materials Inventory Value

Calculating raw materials inventory value is central to managing production costs, and it supports the accurate accounting of raw materials on the balance sheet so is essential for financial reporting and business decision-making.

The basic formula for determining the value of raw materials at the end of an accounting period is:

Beginning inventory + Purchases – Raw materials used = Ending inventory

It’s important to note that both beginning inventory (the value of raw materials on hand at the start of the period) and raw materials used (the cost of raw materials consumed in production during the period) are influenced by a company’s chosen inventory valuation method. Businesses can choose from among three methods: first in, first out (FIFO), last in, first out (LIFO), or weighted average cost (WAC). FIFO assumes older inventory is used first, which can result in lower inventory values during periods of rising prices; LIFO assumes the most recently purchased items are used first, which tends to result in higher inventory values; and WAC calculates an average cost of all raw materials available, which can be beneficial if costs are volatile or individual material costs are difficult to track. WAC valuations tend to fall between FIFO and LIFO. Purchases are the total cost of raw materials acquired during the period. In every variable of the equation, it’s important to include all related costs—such as shipping and storage—that contribute to the total cost of buying and bringing materials to production.

Raw Materials Inventory Value Calculation Example

To better understand how raw materials inventory value calculations work, consider a fictional drywall manufacturer, We R Drywall Inc. (WRDI). WRDI started its most recent quarter with $25,000 in raw materials inventory, then purchased $15,000 in calcium and $5,000 in sulfur. Over the course of the quarter, the company used $22,000 worth of raw materials in production. Inserting those numbers into the formula, we get:

$25,000 + ($15,000 + $5,000) – $22,000 = $23,000

So WRDI’s inventory value at the end of the quarter is $23,000.

Raw Materials Inventory Management Best Practices

Despite the variations in raw materials inventory management methodologies and challenges, there are several practical strategies to improve efficiency, reduce costs, and strengthen supply chain resilience that can be applied almost universally. They include:

- Diversify your supplier network: Reduce risks of supply disruptions, price spikes, and raw material quality issues by sourcing from multiple suppliers located in different geographic regions.

- Utilize lean inventory methods: Under lean inventory management principles, businesses strive to continuously improve until they are able to maintain only the stock levels necessary to meet immediate production demand, thus minimizing storage costs and waste.

- Calibrate your demand forecasts: Analyze historical data and market trends for sharper purchasing decisions and smoother production planning.

- Standardize raw materials handling procedures: Curb material damage, contamination, and tracking errors with clear handling procedures. Standardized processes improve efficiency, support regulatory compliance, and help maintain quality.

- Cross-check records with cycle counts: Cycle counting is a continuous inventory auditing method in which a small subset of inventory is counted each day to avoid interrupting business operations—and to catch discrepancies early and avert costly stock errors.

- Repurpose materials to reduce waste: Finding ways to make use of leftover or excess raw materials shrinks waste, lowers waste-disposal costs, trims unnecessary procurement expenses, and supports an organization’s sustainability goals.

- Upgrade your technology: Investing in inventory management software can help businesses improve inventory accuracy and gain real-time stock visibility. Advanced software tools, especially ERP software capable of automating workflows and applying artificial intelligence algorithms to data analytics, can improve procurement processes and enhance demand forecasting.

Optimize Your Raw Inventory Levels With ERP Software

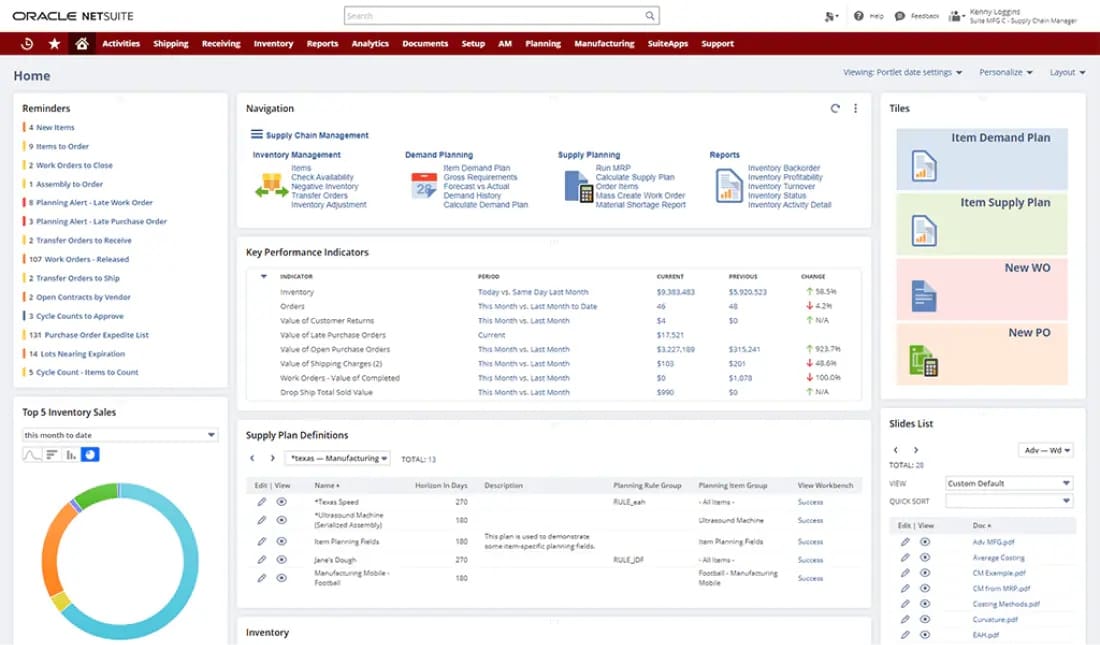

Volatile supply chains, rising costs, and limited visibility represent constant challenges for companies seeking to balance raw material stock levels against production demands. But disconnected systems and manual processes make it difficult to sustain accuracy, anticipate disruptions, and respond quickly when conditions change. NetSuite ERP for building materials manufacturers unifies the core functions involved in raw material management in a single cloud platform, providing up-to-date insights into procurement, inventory levels, and production plans. Built-in tools make easier work of labor-intensive tasks, from reordering and demand planning to warehouse and supplier management. Configurable dashboards give team members role-based views of the data they need for better decision-making. NetSuite’s end-to-end visibility helps companies optimize raw material inventory across locations.

End-to-End Inventory Visibility With NetSuite

Manufacturers and other businesses rely on raw materials inventory management to keep operations on schedule and avoid excess stock. Adopting the right methodologies, best practices, and appropriate technologies improves visibility, decreases delays, and supports smarter decision-making. Companies that manage raw materials effectively through better forecasting and optimized material flows are better equipped to meet demand and adapt to change.

Raw Materials Inventory Management FAQs

What are examples of raw materials?

Examples of raw materials include metals, crude oil, cotton, and other specialized components, such as chemical compounds and LED chips. These materials are either incorporated into finished goods or consumed during the production process.

What are the different types of raw materials?

The two main types of raw materials are direct and indirect raw materials. Direct raw materials physically become part of a finished product and are listed on the bill of materials. Indirect raw materials, such as lubricants and adhesives, are used in production processes but are not incorporated into the final product.

What does a raw materials planner do?

A raw materials planner is responsible for making sure the right raw materials are available in the right quantities at the right time and price to meet production plans. They monitor inventory levels, coordinate with suppliers, manage purchase orders, and collaborate with production, operations, and procurement departments to align their plans with manufacturing goals and schedules.

Which metrics track raw materials inventory?

Tracking raw materials inventory involves monitoring several key metrics, such as inventory turnover rates, average inventory levels, weeks/days on hand, demand forecast accuracy, safety stock levels, and inventory values. Regular audits help maintain accuracy.

How do you decrease raw materials waste?

Companies can decrease raw materials waste by utilizing lean inventory methods, calibrating demand forecasts, repurposing excess materials, and standardizing handling procedures. These steps minimize excess stock, reduce spoilage and obsolescence, and improve operational efficiency, profitability, and sustainability.