An essential step in manufacturing is completing a bill of materials, or BOM. Also referred to as an assembly component list, product structure, or product recipe, a BOM is fundamental to the effectiveness of multiple manufacturing and supply chain processes, including production, materials requirement planning, inventory planning, scheduling, and product costing.

What Is a Bill of Materials (BOM)?

A BOM is a structured, comprehensive list of the materials, components, and parts required to manufacture or repair a product, as well as the quantities in which the materials are needed and their names, descriptions, and costs.

A BOM also includes instructions for procuring and using these materials. Because of the breadth and depth of the data it captures, a BOM can act as a central record of the materials, components, and processes used to build a product.

Key Takeaways

- A bill of materials (BOM) is a structured list identifying all materials and components required to construct a product, as well as the instructions for procuring and using the materials.

- A BOM helps organizations plan purchases of materials, estimate costs, plan for and control inventory, and minimize production delays and waste.

- An accurate, complete BOM helps identify the cause of a product failure and enables quick replacement of faulty parts, materials, and components.

- BOMs come in a range of forms and types. They can be single- or multi-level. Some of the most common types are engineering, manufacturing, and sales BOMs.

Bill of Materials Explained

A BOM is essentially a blueprint for manufacturing a product. Bills of materials evolved from simple engineering drawings during World War I to become sophisticated planning tools essential to modern manufacturing. BOMs gained prominence in the 1960s, and as computing power increased through the 1970s and 1980s, they became integrated with broader systems—transforming from basic parts lists into central data hubs connecting engineering, procurement, inventory management, and production planning. Today’s digital BOMs are the backbone of manufacturing operations across various industries.

Most BOMs are structured in a hierarchy. At the top is the completed product, next are subassemblies and below those are the components and materials that go into making the product. This includes details like part names, numbers, descriptions, and the quantities needed.

While the concept of a BOM is straightforward, creating and managing bills of materials can become complicated, especially for products composed of hundreds or thousands of parts. For instance, if it becomes necessary to change one component because a supplier can’t meet its delivery deadlines, this change needs to be replicated throughout the BOM wherever that component is used. Some basic parts, like adhesives, may be used in multiple areas.

What Is the Purpose of a BOM?

The primary purpose of a bill of materials is to provide a comprehensive and structured list of all the raw materials required to manufacture a finished product. However, its role has grown far beyond simply listing parts; it’s now an integral part of managing manufacturing operations.

Historically, the need for precise materials management arose during periods of resource scarcity—such as World War I—when manufacturers had to maximize efficiency and minimize waste. Engineers used early BOMs to specify components within technical drawings so that every part necessary for assembly was accounted for.

As manufacturing became more complex with the rise of mass production in the mid-20th century, the role of the BOM evolved. The introduction of material requirements planning (MRP) systems in the 1960s, and, later, enterprise resource planning (ERP) systems, made the BOM essential for coordinating procurement, production scheduling, and inventory control. Companies quickly recognized that having an accurate and up-to-date BOM was essential for success.

Today, the BOM provides the necessary information for several important purposes:

- Centralized information: Ensures all departments—engineering, procurement, manufacturing, and finance—work from the same data. In automotive manufacturing, for example, centralized BOMs can immediately relay design changes across teams.

- Efficient resource planning: Helps forecast material needs accurately, reducing the risks of shortages and excess inventory.

- Cost control: Details every component and its quantity to support accurate cost estimation and budgeting.

- Quality assurance: Promotes product consistency by standardizing the materials and processes across production run.

Given these benefits, BOMs have been adopted across numerous industries. Beyond traditional manufacturing, they are essential to electronics assembly, where complex products often contain thousands of components; pharmaceutical production, where precise ingredient management is crucial for regulatory compliance; and even construction, where BOMs help coordinate materials for large-scale projects.

Why Use a BOM?

BOMs facilitate efficient and accurate manufacturing. By identifying and pricing all the materials and components needed to make a product—before production begins—an organization can determine whether it has everything it needs to move forward with minimal risk of delays. This reduces the likelihood of both shortages and overages of materials or components, helping manufacturers remain within budget and on schedule.

Companies that work with contract manufacturers and provide the manufacturer with a BOM can be more confident the final product will meet their specifications. Conversely, proceeding without a BOM increases the likelihood of costly and time-consuming mistakes.

Who Prepares a Bill of Materials?

Creating a bill of materials is a collaborative effort that typically involves input from multiple departments within a company. Key contributors often include design, engineering, purchasing, materials management, and manufacturing teams. Each group brings specialized knowledge to ensure the BOM is accurate, comprehensive, and aligned with the product’s requirements. Different departments might also be the primary users of specific types of BOMs.

Here’s how different teams might contribute:

- Design: Defines the finished product (e.g., "Office Desk") and creates CAD drawings or mockups that reflect the product’s form and functionality. They often initiate the BOM and manage revisions.

- Engineering: Assigns part numbers and breaks down the product into assemblies and sub-components (e.g., “Desktop,” “Steel Frame,” “Allen Screws”). Specifies materials, dimensions, and functional requirements for each part.

- Procurement: Adds supplier information, lead times, and unit costs for each item. Flags availability issues, recommends alternative materials based on sourcing constraints.

- Materials management: Verifies inventory levels for listed components, identifies reorder requirements, and confirms all listed parts are in stock or can be procured on schedule.

- Manufacturing: Reviews the BOM for assembly feasibility and adds process notes, tools required, or special instructions (e.g., "Pre-drill holes in desktop before assembly").

The Two BOM Structures

BOMs may be structured in one of the following two ways:

-

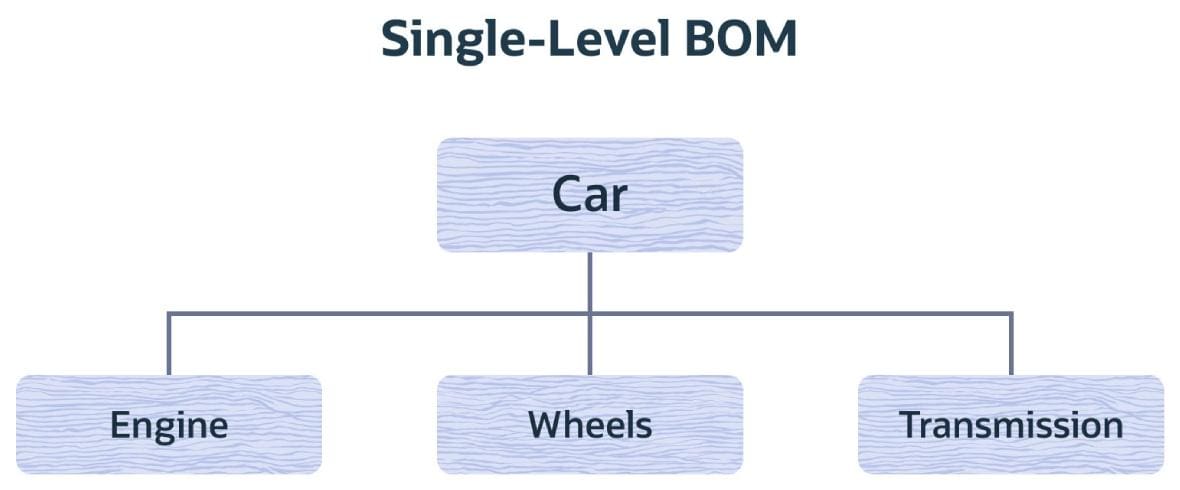

Single-level Bill of Materials

In a single-level BOM, each part that will make up the product or asset is shown once, along with the quantity needed. It’s similar to a shopping list.

While single-level BOMs are easy to create, they don’t show the relationships between the assemblies, subassemblies, and components used to construct a product. If a product fails, it can prove difficult to determine precisely which component needs to be repaired or replaced.

For instance, assume a BOM for a vehicle is constructed in a single-level format. It later becomes clear that the door handle on the vehicle is faulty. The single-level BOM won’t distinguish between the parts that went into the handle and those used in other vehicle parts. For this reason, single-level BOMs are typically used with simpler assemblies.

A single-level bill of materials (BOM) lists all components required to build the final product—in this case, a car—but does not show hierarchical relationships between those parts. Each item (e.g., engine, transmission, wheels) is listed once at the same level beneath the finished product. This format is straightforward and easy to create but doesn’t show how parts relate to one another. -

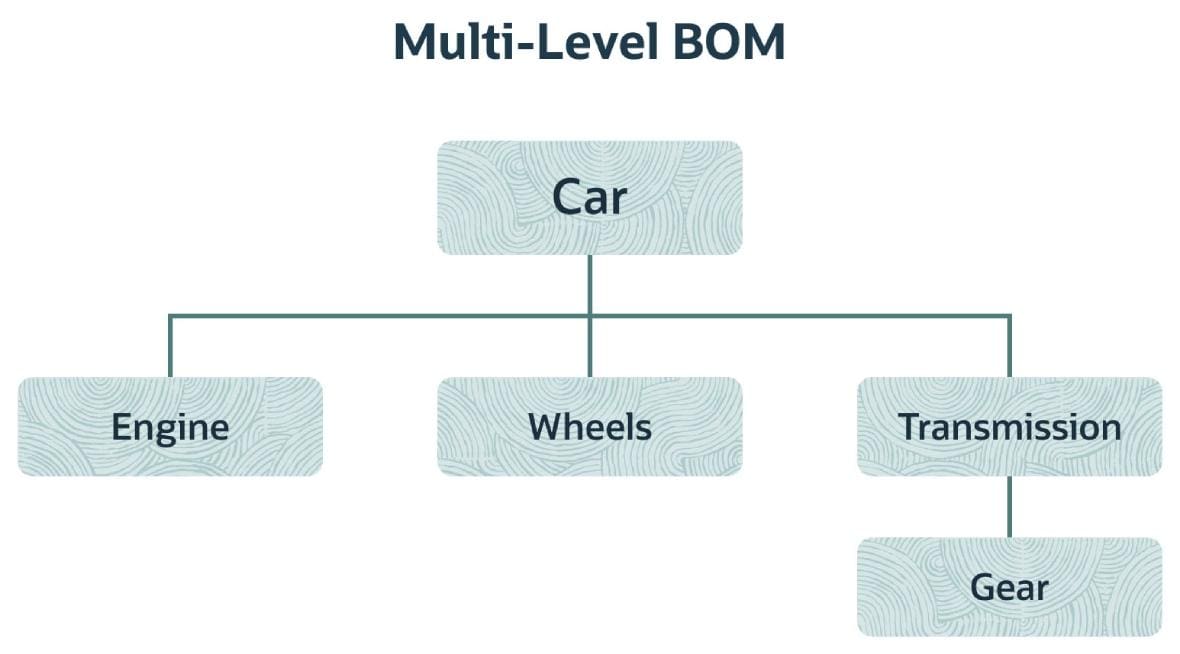

Multi-level Bill of Materials

In contrast to the single-level bill of materials, a multi-level BOM shows the relationship (sometimes called parent-child) between components, sub-assemblies, and assemblies. It often does this by indenting the materials and/or subassemblies that make up the higher-level part or assembly. For this reason, multi-level BOMs sometimes are referred to as indented BOMs.

A sub-assembly may, in turn, comprise multiple components. When changes are made to the assembly (or parent), they flow to the subassembly (or child). Because they show these relationships, most complex products use multi-level BOMs.

A multi-level bill of materials (BOM) shows the hierarchical relationship between product parts. The product is broken down into assemblies and subassemblies. In this example, the car is composed of main components: as the engine, transmission, and wheels. The transmission is further divided to show a sub-component, gear.

Components of a Bill of Materials (BOM)

Most BOMs include the following elements: BOM level; the part number, name, description, and quantity; cost; and the unit of measure. While the bill of materials includes components and parts, it doesn’t include labor.

-

BOM Level

This is a unique number showing where each part or assembly fits within the BOM hierarchy. Consider a BOM for a vehicle. Each major component, like the engine, doors, and drivetrain, would be a level. They’d be further broken into components and materials, like the pistons and crankshaft that are part of the engine. The pistons and crankshaft would themselves each be a level and then broken into their component parts. An example would be the piston rings that are part of the pistons.

-

Part Number

This unique number identifies a material or component, enabling anyone involved in the production process to identify it quickly. Part numbers can be intelligent—that is, they include some description of the part. For instance, an intelligent number for wire might be "WIRE-001."

Intelligent numbers can make it easier to identify each part. However, they require the person developing the numbering scheme to know each part in some detail before assigning numbers.

Non-intelligent part numbers include no descriptions. They’re generally easier to generate and likely to remain accurate for longer periods.

For most organizations, either numbering system can work. The key is to be consistent.

-

Part Name

The part name also is a unique identifier for each part or assembly. Like the part number, it helps users to identify the part quickly.

-

Phase

The phase indicates the lifecycle stage for each part. Examples include “in production” or “in design.”

-

Description

Also unique to each part or component, the description provides more detail than the part name or number. Descriptions are helpful when it’s necessary to distinguish between parts that appear similar. For instance, “screws” could include both 1/2- and 5/8-inch machine screws.

-

Quantity

The quantity indicates how many of each part will be used in an assembly or sub-assembly. An example would be two piston rings per piston cylinder.

-

Unit Measure

This designates in what unit of measure a part will be procured and/or used. Specifying the measure helps ensure the right quantities are ordered. For parts that are complete, like gaskets, the unit measure likely will be “each.”

For some parts or components, it makes more sense to use a unit of measure. For instance, wiring and lumber generally are purchased by the foot. Small, inexpensive parts that are difficult to count, like nails or screws, may be purchased by weight or by the box.

-

Procurement Type

This indicates how the part or component is obtained. Choices typically include purchasing the part, producing it internally or having it manufactured by subcontractors.

-

Reference Designator

The reference designator comes into play when products contain printed circuit-board assemblies. The reference designator identifies the location of each part within the circuit board assembly.

-

BOM Notes

The notes section offers a chance to include other information useful to anyone referring to the BOM. It might consist of a list of alternate suppliers or the specifications that a material, like an adhesive, must meet.

Bill of Materials (BOM) Displays

Bills of materials generally are presented in one of two ways: explosion displays and implosion displays.

Explosion Display

In an explosion display, the BOM starts with the highest level of the product—say, computer motherboard—at the top. It then breaks the product down into components and parts that become increasingly more granular.

Implosion Display

An implosion display is the inverse of an explosion display. It starts with individual parts and links them to form the major product or assembly.

Types of Bills of Materials

Both single- and multi-level BOMs may be created for use at various stages of the product development lifecycle. The primary types include engineering, sales and manufacturing BOMs.

Each focuses on different information.

Engineering Bill of Materials (EBOM)

An engineering BOM is developed while a product is being designed and defines a finished product’s original design. It includes the items, parts, components, and subassemblies as designated by engineering. It generally consists of a technical drawing of the product.

Engineering BOMs, as their name indicates, typically are developed by engineers. They often use computer-aided design (CAD) software or similar systems to create the BOM.

Sales Bill of Materials (SBOM)

A sales BOM lists the products and components required to develop a product as ordered by the customer. It’s developed from the sales order and includes both the finished product and components, as they appear in the sales record.

Manufacturing Bill of Materials (MBOM)

A manufacturing BOM is used during production. It identifies the parts and assemblies needed to produce a shippable product, including packaging, and accounts for waste and items consumed in the production process.

An MBOM identifies the groups of parts needed at each stage of the production process and provides information on the processing required by various parts before assembly. This helps determine when materials must be purchased and when various manufacturing processes need to begin to meet scheduled delivery dates.

For a new product, an MBOM may last for a set period, such as several weeks. Then, if it becomes clear the product requires changes, the MBOM can be updated or a new one may be generated.

Information in the MBOM typically is shared with several systems, including the ERP system and MRP systems.

Configurable Bill of Materials

This BOM is used for finished products that are configured and designed to meet specifications requested by a customer. It identifies the materials and components, including any labeling or packaging requirements, needed to manufacture the product to the customer’s requirements.

Production Bill of Materials

A production BOM acts as the foundation for a production order and includes the components and assemblies that make up a product. As production proceeds, the components are converted to finished products.

Assembly Bill of Materials

Like a sales BOM, an assembly BOM lists the parent item as a sales product rather than an inventory item. An assembly BOM also lists sub-assemblies (or children).

Template Bill of Materials

Template BOMs offer flexibility, as they can be used for either production or sales BOMs. These also include parent and child components.

Modular Bill of Materials

A modular BOM breaks down the product into distinct, self-contained units or subassemblies that can be independently assembled, replaced, or upgraded. This approach streamlines production, supports product customization, and can simplify maintenance. It’s common in industries such as automotive and electronics.

Advantages of a BOM

A BOM is more than just a list—it’s a foundational document that brings structure, accuracy, and efficiency to the manufacturing process. Here are some key advantages of implementing a well-structured BOM:

- Added structure: A BOM provides a standardized blueprint for production, acting as a central reference point for all product-related data. It outlines every component and assembly required to build a product, keeping production runs consistent and supporting product quality.

- Availability: With a BOM in place, purchasing and planning teams can verify that all required parts and materials are available in precise quantities before production begins. This minimizes inventory inaccuracies, reduces downtime, and helps maintain production schedules.

- Cost control: A detailed BOM allows companies to estimate production costs accurately by accounting for every component involved. It facilitates better budgeting, supports volume-based supplier negotiations, and helps identify opportunities for cost optimization through strategic part substitution.

- Reduced inaccuracies: By clearly listing every required item and its specifications, a BOM minimizes the risk of human error during procurement, assembly, and production. This improves product uniformity and helps avoid costly rework.

- Better traceability: In the event of a product issue or failure, a BOM makes it easier to trace problems back to specific materials or components. This capability is essential for warranty claims, quality audits, product recalls, and maintaining compliance with industry regulations.

- Improved lead times: When all departments—from design and procurement to production and logistics—work from the same document, processes become more synchronized. This alignment helps reduce delays, optimize inventory planning, and improve overall manufacturing efficiency and time-to-market.

How to Create BOMs in 7 Steps

Depending upon the industry, designers or engineers, as well as purchasing, scheduling, and planning workers, will want to review them to ensure accuracy—an accurate BOM serves as a roadmap for finished goods and frees up resources to spend on the actual production process. Several steps are involved in creating an accurate, useful bill of materials, among them:

-

Determine what data to include.

For instance, will the BOM include consumables, like glue or wire? While this may seem unnecessary, including these within the BOM from the beginning helps ensure these materials are available when needed.

-

Centralize control of the BOM.

In many organizations, different departments or functions use different information systems. For the BOM to remain accurate and up-to-date, it will need to assemble information from all these systems into a single record.

-

Determine who will be able to change the BOM.

To minimize the risk of mistakes, the number of editors should be limited.

-

Decide how to track revisions to the BOM.

Many BOMs are revised on a continuous basis. For the BOM to continue to provide value and remain accurate, all changes need to be tracked. Ensure all changes can be connected back to the authors.

-

Choose the BOM presentation.

Such as single- or multi-level, that makes sense for the product.

-

Begin listing.

The materials, components, and parts that will make up the product. This list will grow and change over time.

-

Continue to add to and refine the list.

Tracking all changes.

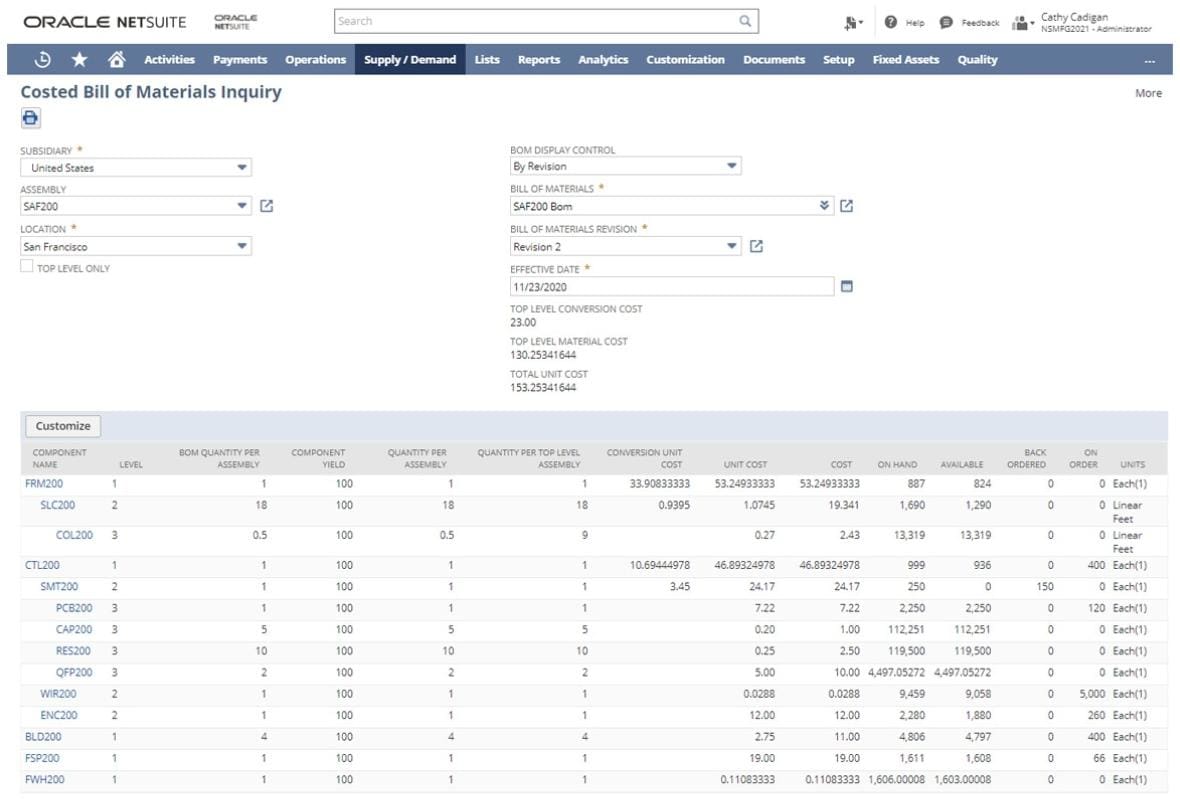

Make the Most of BOMs With an ERP System

Manually preparing and managing BOMs can quickly become unwieldy and error-prone. Software, such as a supply chain and inventory management solution, can help automate the development process. ERP systems also can automate the tracking of changes to BOMs and identify discrepancies that can occur when multiple areas, such as engineering and manufacturing, generate BOMs for the same product.

To help organizations manage inventory levels across their supply chains, look for an inventory management system that includes inventory control, tracking, and optimization.

An accurate, thorough, and updated bill of materials improves decision-making and facilitates efficient production processes. It can help organizations more quickly move designs into production, which may help them capture customers. By cutting waste, BOMs help organizations save money. Because of the depth and breadth of information they provide, BOMs can boost supply chain resiliency.

Conversely, neglecting to create a BOM or failing to update one can result in inaccurate product costs, products being made incorrectly, inventory overages or shortages and production delays, among other challenges.

Far more than a parts list, a bill of materials is the blueprint for accurate production. It also helps control costs while keeping different business departments aligned on product design, materials, and manufacturing requirements. Clear, complete, and up-to-date BOMs are essential to manufacturing anything from a basic chair to a complex automobile—with less waste and confusion, and greater efficiency and quality.

Bill of Materials FAQs

Does a bill of materials include labor?

Not typically. A standard bill of materials (BOM) lists physical parts, such as raw materials, components, and subassemblies, rather than labor hours or associated costs. However, some manufacturing systems use extended BOMs or routing documents to capture labor details for production scheduling and cost analysis.

What is the function of a BOM?

A bill of materials (BOM) lists all components needed to build a product. It helps organizations manage materials, control inventory, estimate costs, and keep production consistent. A well-maintained BOM also supports quality control, change management, and regulatory compliance by keeping departments on the same page.

What is the difference between a BOM and a BOQ?

A bill of materials (BOM) is used in manufacturing to list all parts and components needed to build a product. It typically includes part numbers, descriptions, and quantities and is often organized by assemblies and subassemblies.

A bill of quantities (BOQ) is primarily used in construction and project management to detail materials, parts, and labor required for a project, often grouped by work sections rather than product structure.