Supply chain traceability is in fashion today — literally and figuratively. Literally, because so many shoppers are choosing to buy clothing that’s organic, fair trade, carbon-neutral, water-saving, wrapped in eco-friendly packaging and otherwise sustainably and ethically made. And figuratively, because companies across industries are employing traceability more every day — to satisfy not only consumers but also business customers, trading partners, regulators and investors. The business benefits can mount well beyond sustainability, too, to include improved product safety, quality and regulatory compliance.

This article looks at the state of supply chain traceability, its benefits and how to achieve it.

What Is Supply Chain Traceability?

Supply chain traceability involves tracking products from the source of their raw materials through production and into customers’ hands. Additionally, the practice includes documenting, and often disclosing, details about the various steps along a product’s journey. Supply chain traceability and supply chain visibility work hand in glove. Here’s how:

- Visibility at the operational level: Companies have long pursued the goal of supply chain visibility to boost operational efficiency. They use cloud-based applications and Internet of Things (IoT) devices to monitor the status of their supply chain operations, fix bottlenecks and take other necessary action. Achieving supply chain visibility remains a work in progress.

- Traceability at the product level: Companies have also begun leveling up to supply chain traceability to address rising customer and regulatory concerns. They track product-level details with more granularity and then document and often disclose this information to business partners, regulators and the public. Traceability, too, is a work in progress.

Key Takeaways

- Customers, regulators, business partners and investors are pushing companies to make their supply chains more sustainable.

- Supply chain traceability helps achieve this goal, as well as greater quality control, fraud prevention and other business objectives.

- Traceability works by digitally and wirelessly tracking products as they move through the supply chain — each tagged with a data-filled, unique identifier.

Supply Chain Traceability Explained

Traceability tools and procedures can, for example, capture data about a T-shirt all the way from the farming of the cotton to its cleaning, spinning, dyeing, weaving, cutting and sewing — and, ultimately, through packaging, warehousing and shipping. But traceability is complicated by the fact that these processes may involve not only a company’s primary, “tier 1” suppliers but also their suppliers’ partners in tier 2 or beyond. The World Economic Forum underscored the challenge, saying that a product made of cotton or another commodity may pass through 10 or more companies across different countries before hitting the retail shelves. Transformations along the way from origin to end product make it difficult to track a product’s journey.

Companies deploy various technologies and business controls to surmount these challenges. And they must do so in significant detail. According to the Association for Supply Chain Management (ASCM), they should break out components, products, the suppliers of each, customer deliveries, transaction dates, batch and serial numbers, quality records per component and more. Delving deeper, the information associated with a product and its journey might include methods of production (including social aspects, such as labor practices), standards certifications, life span, reusability and recyclability.

Technologically, traceability depends on barcodes, QR codes, radio frequency identification (RFID) tags and other unique identifiers, often in combination with wireless communications or GPS capabilities. Some companies have begun using distributed ledger systems in the cloud, also known as blockchains, which create an audit trail by transparently recording every transactional detail, such as origin, quality checks and ownership transfers. More widespread options currently include enterprise resource planning (ERP) systems that are integrated with inventory management and traceability software.

As for the business controls involved, one is certification. For instance, a company that promises its customers sustainable fashion might apply for a certificate of compliance with the Global Organic Textile Standard(opens in new tab) (GOTS), in a process that can include inspections. The company might also find like-minded, certified suppliers on the GOTS website to involve in its sourcing strategy.

Why Is Traceability Important in Supply Chains?

Sustainability is one of the highest-profile drivers of traceability, but it also improves operational efficiency and risk management. Others include quality control, managing recalls, fighting counterfeiters, regulatory compliance and overall supply chain management. Here’s a deeper dive on each area.

- Sustainability: Over two-thirds of consumers surveyed by the Visa credit card company said they factor sustainability practices into their choice of merchants. However, about the same percentage are skeptical of companies’ sustainability claims, another survey found. For businesses, the solution may lie in yet a third survey: Eight in 10 consumers said they are more likely to trust companies that back up sustainability claims with publicly shared data. Traceability enables such disclosures.

- Quality control: Traceability can help ensure quality throughout a supply chain, according to the ASCM. If an issue arises because one supplier instituted cost-cutting measures or slacked off on quality assurance, traceability tools can identify the culprit, allowing companies to take immediate action.

- Recalls: Having traceability tools and protocols in place can speed a company’s response in the event of a recall, easing customers’ concerns while also reducing waste by targeting and discarding only the affected batches of products.

- Anti-counterfeiting: With counterfeiting slamming so many industries from footwear to auto parts, companies have developed unique identifiers that work all the way down to the materials level. These might include chemical tracers in fabrics, IoT devices like RFID tags, and the means for tracking and tracing them all. The documented histories that result permit authorities and consumers alike to verify product authenticity.

- Regulatory compliance: Compliance tops executives’ traceability agendas, according to the Bain & Co.(opens in new tab) management consultancy. Companies in the food or pharmaceuticals industry, for example, must prove adherence to safety standards. Regulators’ focus on sustainability has also heightened.

- Supply chain management: Traceability can help with inventory management and operational planning. An example is the ability to know when a product is nearing expiration.

In contexts such as these, according to ASCM, “the inability to show evidence of origin or use can quickly escalate into a more pressing business issue. As such, having the ability to track components both forward and backward across the supply chain can eliminate unforeseen issues and save time and money.”

Evolution of Supply Chain Traceability

Companies began using traceability in earnest in the 1980s, when barcodes “began to appear like a rash on anything that benefited from instant identification,” according to Smithsonian Magazine. Barcode evolution has continued ever since, featuring newer capabilities, such as RFID tags and real-time tracking in the cloud. Changing business imperatives and societal goals have also driven traceability to its current state — for instance, from linear to circular and from centralized to decentralized, as described below.

-

Linear to Circular

Companies have historically engaged in the linear tracking of products from source to production to customer — with the assumption that the next stop is the landfill. But as Bain & Co. recently proclaimed: “Linear supply chains of the past are not fit for the future.” Today’s sustainability mandate is driving companies to “close the loop” with circular supply chains that reuse, recycle and otherwise aim to reduce waste.

In a circular supply chain, companies need to know what happens to their products beyond the point of sale in order to reduce their environmental footprint and derive other benefits, such as cost reduction. In many cases, this change involves rethinking old processes, and tracking and documenting new processes, throughout their supply chains. For instance, used products or their parts may be returned, enabling companies to make more products from repurposed materials and components instead of sourcing new materials. The impact throughout the supply chain becomes evident, as companies also redesign their products to make them easier to disassemble after their end of life so as to recycle plastics, metals and even rare-earth minerals.

Companies in the design, manufacture and distribution of batteries for electric vehicles provide a prime example. Their work to develop circular supply chains not only aims for responsible sourcing, but also tackles the recycling, remanufacturing or reuse of batteries, raw materials and components. In other industries, consumers often play a key role in circular supply chains by participating in trade-in programs for some products, such as used smartphones, and in “take-back” programs that encourage customers to return used Nikes for refurbishing and resale, for example. Research in the Journal of Marketing shows that consumers like having more control over product disposal in these and other ways.

Traceability of items and their related information empowers circular supply chains. For instance, a major consumer brand has been piloting digital watermarks that include packaging type, material and usage to improve waste-sorting and achieve more efficient recycling of plastic containers. A “sorting detection unit” at the recycling center then channels plastic back into the packaging value chain.

-

Centralized or Decentralized?

Companies take centralized, decentralized or hybrid approaches to traceability data. ERPs have already advanced traceability by providing centralized platforms into which a company’s suppliers and logistics providers can input such information as the status of orders. But supply chains continue to grow in complexity, involving more tiers of suppliers and circular product flows. At the same time, governments and consumers are pressing for the collection of additional, verifiable data related to sustainability.

A more decentralized approach is emerging in this context, based on the blockchain technology for distributed ledger entries. As described in the Harvard Business Review, multiple supply chain partners with unique “signatures” can record every step a product takes — transparently to all involved. They record product flows using unique identifiers assigned to units of inventory, orders, shipping documents and other data assets on ledgers that can also be programmed to trigger next steps automatically. Or, if something goes wrong with a product, a company and its supply chain partners can pinpoint the problem and fix it.

Blockchains are intended to feed into a company’s ERP system, creating a hybrid system of the distributed ledger and the ERP’s central data repository. In other words, the blockchains act as external complements to the ERP system, with its internal range of data storage, transaction processing, accounting, analytics and management functions.

While the blockchain’s use in supply chains is only beginning, large buyers are involving suppliers of all sizes in various pilots and development projects. The MOBI smart-mobility alliance, which includes dozens of companies and organizations engaged in vehicle manufacturing and transportation, is demonstrating a blockchain use case for the traceability of electric vehicle batteries in the supply chain. The Aura Blockchain Consortium of luxury brands touts a “digital product passport” that it says enables transparency of raw material origins and traceability of the full product life cycle.

-

Shared Responsibilities

Supply chains have always required collaboration between buyers and suppliers. But now changes are occurring in terms of the degree of interaction, the number of suppliers and the expansion of shared responsibilities to new parts of the supply chain. More specifically, sustainability regulations are requiring more information about suppliers and their goods; post-pandemic supply chain resilience strategies have expanded the number of suppliers and alternate suppliers in many networks; and the move toward more circular supply chains has driven the need for information beyond the point of sale to embrace reuse and recycling.

“Improved collaboration in the future can improve risk mitigation and environmental sustainability in even the most challenging and unprecedented circumstances,” according to a report from MHI, an association of supply chain professionals. Beyond collaboration, however, companies need to nail down the detailed roles and shared responsibilities of suppliers through contract terms that are continually monitored and strongly enforced. Otherwise, third-party risks can emerge in such areas as regulatory compliance, cybersecurity and general operations.

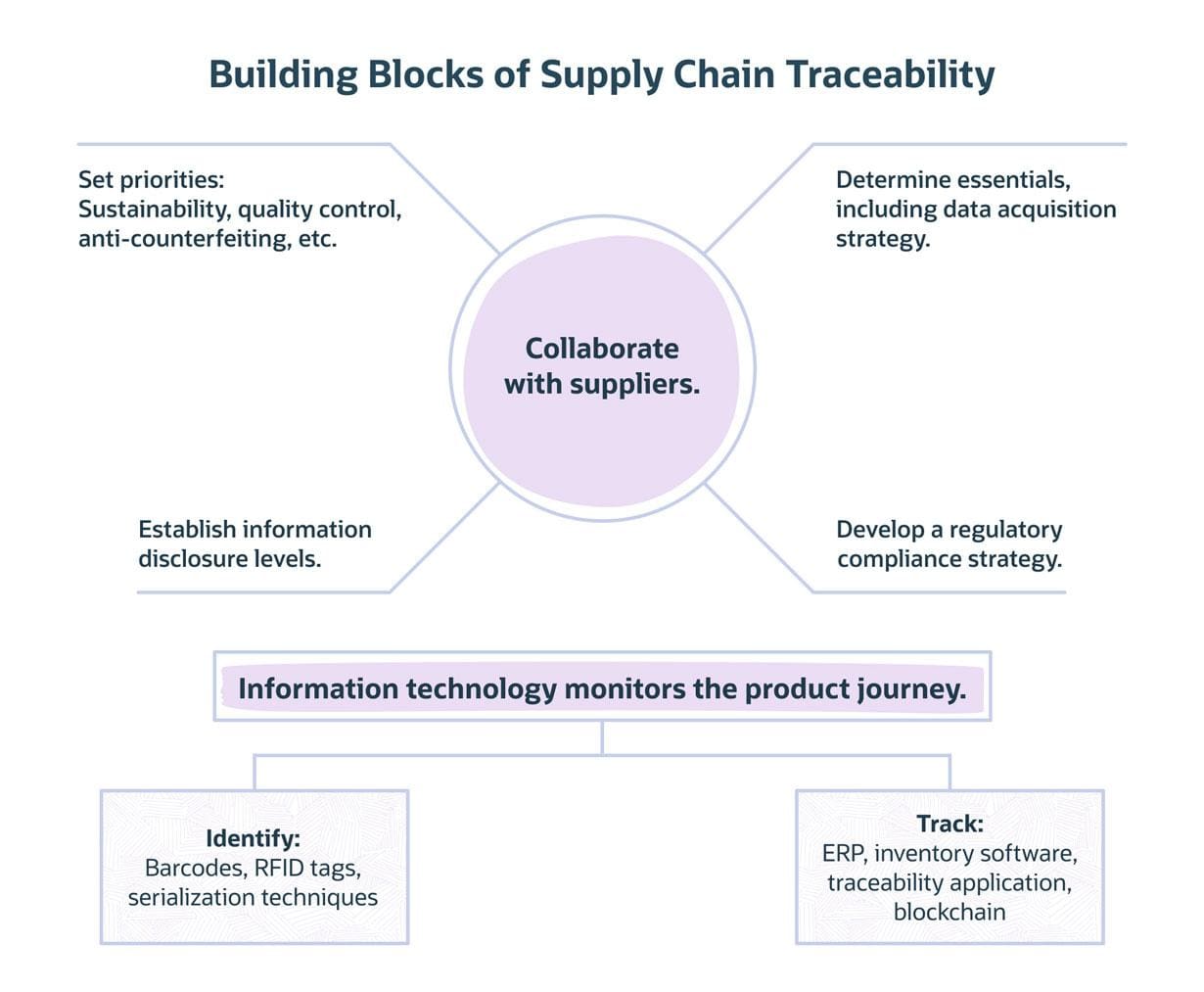

How to Implement Supply Chain Traceability

What is the greatest business value a company can derive from traceability? According to Bain & Co., this question should establish a company’s starting point for implementing supply chain traceability. Lacking such focus, a company risks overinvesting and/or overwhelming its supply chain with complexity. Here are eight key steps to follow.

-

Determine Tracking Data Essentials

To set the stage, company leadership needs to determine the results their traceability initiatives are intended to deliver. Their choices could be in one or more of the following areas: sustainability, regulatory compliance, quality control, brand reputation or operational efficiency. Another top-level essential is the internal operating model and data-acquisition strategy. In other words, which data does the company trace and how? Experts suggest beginning with a single initiative and then expanding as appropriate.

-

Adhere to Regulatory Standards

When setting traceability goals, companies tend to prioritize regulatory compliance. They face potential fines, reputational harm and other risks if they fail to meet rules, such as those set by the California Transparency in Supply Chains Act, which addresses forced labor; the U.S. Food and Drug Administration’s Food Safety Modernization Act, aimed at preventing foodborne illnesses; and the European Union’s forthcoming Deforestation Regulation (EUDR). Effective Dec. 31, 2024, the EUDR will require due diligence for all deforestation-linked commodities and related products sold in Europe, including wood, coffee, cattle and more. Noncompliance penalties can reach 4% of annual revenue.

-

Engage in Supplier Collaboration

Supplier relationship management should be baked into a company’s traceability strategy. Only by collaborating with first-tier suppliers — and beyond — can companies achieve the necessary supply chain visibility, technology integration and data sharing. Criteria for choosing and managing partners include strategic alignment, trust and shared targets. To advance a supplier relationship into a true collaboration, experts advise thinking beyond the transactional aspects, such as ordering and paying, and try to tap into suppliers’ experience with traceability and to learn from their knowledge of second- and third-tier suppliers in their networks.

-

Define Information Disclosure Levels

A company’s traceability goals will go a long way toward determining its appropriate information disclosure level. The profile of its various stakeholders will also feed into disclosure decisions, given today’s pressures for transparency from governments, consumers, advocacy groups and others — and so will the company’s ability to verify disclosures.

The level of disclosures can range from publishing a code of conduct to disclosing detailed traceability and impact information — and from full disclosure to selective disclosure to aggregated disclosure that protects competitive information. For example, the Patagonia outdoor clothing company publishes its code of conduct, plus details about how it prescreens and audits factories, mills and farms. The company has posted that in the spring of 2024, 98% of its styles used recycled materials, which helped avoid 8,500 metric tons of carbon dioxide. Yet even this market leader said it has only begun to map its supply chains to the farm level, an indication of the challenge traceability poses in complex supply chains.

In the high-priority area of sustainability, 98% of large companies reported some level of detail in 2022, according to a study(opens in new tab) that was reported in the Journal of Accountancy that analyzed filings of 1,300 of the world’s largest companies. In the study, 69% of the companies backed up their disclosures with assurances derived from supply chain data. Businesses large and small are expected to level up their disclosures following the Securities and Exchange Commission’s (SEC’s) 2024 ruling that public companies must make specific climate-related disclosures in their filings.

-

Foster Sustainable Practices

The new EU and SEC sustainability disclosure rules described above have raised the bar on supply chain sustainability. Since supply chains represent the vast majority of a company’s greenhouse gas emissions, companies reporting to regulators need to trace and tackle the root causes of environmental damage and pollution. The EY management consultancy emphasizes internal, interdepartmental collaboration to foster sustainable practices, citing the need for procurement officers, sustainability officers, supply chain professionals and technology teams to work more closely to develop digital solutions for supply chain traceability. “Without traceability, there is no accountability,” the group wrote. Beyond accountability, traceability should be based on new key performance indicators and metrics that drive operational improvements in areas such as carbon emissions, waste and water usage.

-

Monitor Product Journey

Experts make a distinction between tracking, which pinpoints a product’s current location and status, and tracing, which digs into the history and origin of a product or batch. Achieving both on an ongoing basis requires five enablers, according to Bain & Co.

In addition to the internal operating model and the partner ecosystem, described above, the other enablers include a data integration strategy, a robust technology architecture and alignment on standards and certifications. The data integration strategy might identify specific data points to achieve traceability goals, such as raw material sources, sustainability metrics and supplier details; it also should develop or adopt standards for sharing this data among supply chain partners. Cloud-based platforms, ranging from ERP and inventory management systems to the blockchain, can enable such data sharing and analysis. And standards and certifications, such as Global Food Safety Initiative norms, provide a common understanding of requirements for all industry participants and a benchmark for accountability in reporting.

The remaining two steps below provide some nuts-and-bolts examples of the tools and processes used in traceability initiatives.

-

Implement Barcodes, RFID Tags and Serialization Techniques

In the MHI trade association’s 2023 report, 87% of supply chain professionals surveyed said they were already using IoT devices and RFID tracking in their supply chains — or planned to soon.

RFID tags can be attached to individual items or to pallets of goods, and wireless scanners can capture data about each object, its origins, location, quality, expiration date and more. They complement barcodes, providing more versatility and easier readability across distances in comparison with the barcode’s benefits of lower cost and universal recognition. Because RFID tags on products and batches carry unique identifiers assigned in a technique known as serialization, they will play a growing role in blockchain-based traceability.

-

Establish Raw Material Procurement Tracking

Companies track raw materials where they can, but this area poses one of the biggest challenges in traceability. For instance, lithium extraction operations at a mine halfway around the world may expose a battery maker to criticism on environmental grounds. Yet the battery maker may have little visibility into those operations, which feed into its production through several tiers of supply chain partners. In another example, small-scale coffee producers overseas may conduct only manual recordkeeping, making it difficult to use electronic traceability systems.

While no immediate solution has emerged to tackle problems like these, companies can work in collaboration with supply chain partners closer to the source of raw materials. For instance, companies should provide their overseas manufacturing partner with clear specifications for the raw materials it uses and hire an offshore auditing company to inspect the factory — including the raw materials. Certifications can also provide some assurance; for example, a chain-of-custody certificate from the Forest Stewardship Council ensures that products have come from responsibly managed forests. Meanwhile, some big buyers have launched programs to help build the digital capacity of small-scale farmers and producers to participate directly in global supply chains.

Benefits of Supply Chain Traceability

In addition to the supply chain traceability benefits described throughout this article, such as sustainability, quality control and regulatory compliance, it’s worthwhile to explore more details about the following four:

- Enhanced supply chain integrity: Improving supply chain visibility and traceability is essential for identifying and responding to cybersecurity breaches. Moreover, having a clear picture of all the supply chain partners and the data flowing among them helps to avoid attacks before they happen by identifying potential vulnerabilities and then shoring up the defenses around them. Cyberattackers often target smaller partners in a supply chain in order to breach their bigger buyers. Enhancing supply chain integrity can fend off these attacks for everyone’s sake.

- Mitigation of mislabeling risks: Mislabeled risks come in many varieties, from fraudulent claims to adulterated products to outright counterfeits. The stakes are high, including food-safety dangers, harm to brand reputation and costly recalls. But the odds of these happening are lower with traceability.

- Comprehensive product management tracking: Product management begins with an idea and continues across many phases of product development, marketing and distribution before goods reach the market. Each of these key activities and their data points should be recorded to support business decision-making and ensure the product’s success — making traceability both an internal and supply chain exercise.

- Streamlined audit processes: Supply chain complexity and lack of visibility present significant challenges to completing routine supply chain audits. The audit process benefits greatly from traceability at the product level, presenting all the details about provenance and processing included on an RFID tag.

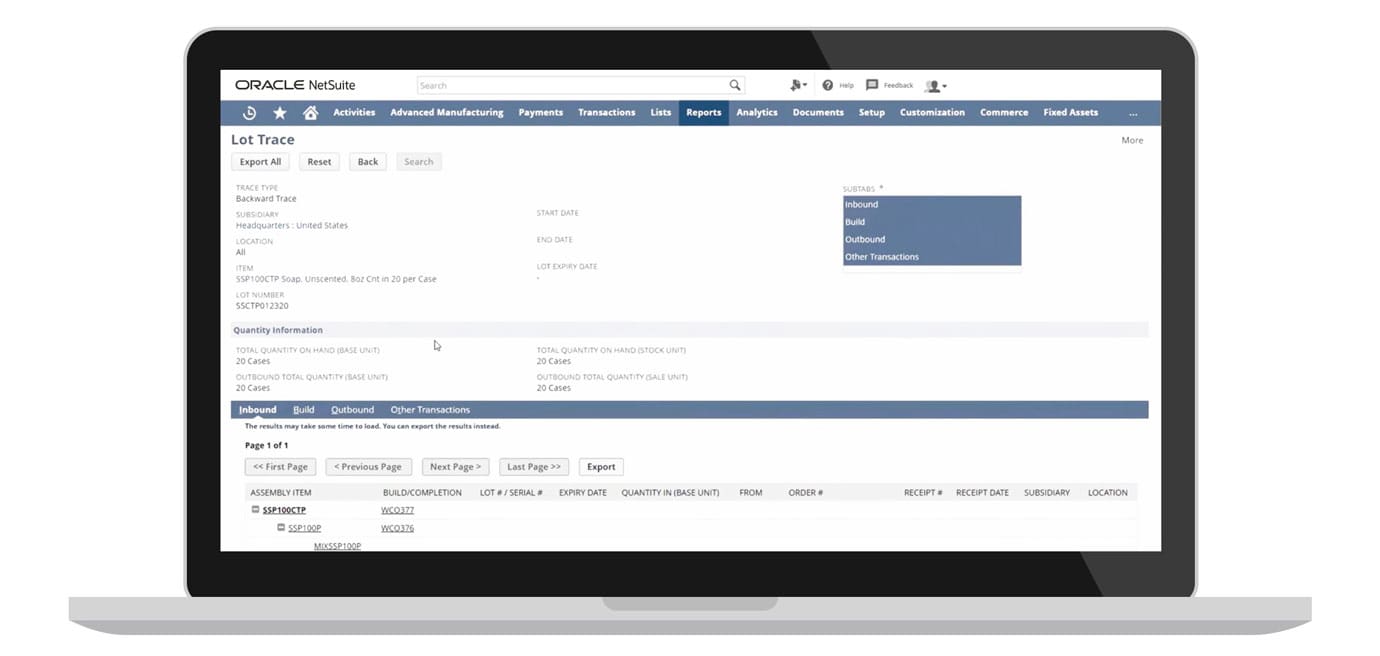

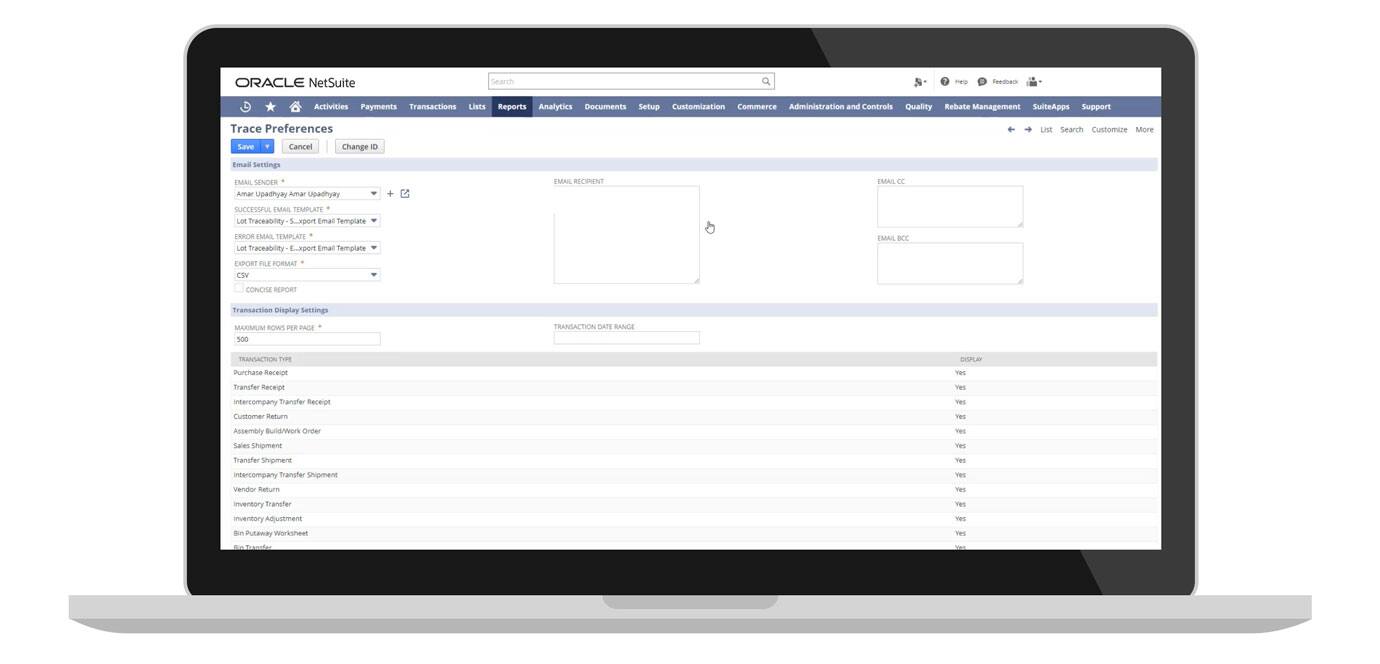

Track Your Whole Supply Chain in One Place With NetSuite

Supply chain traceability is a mere pipe dream in the absence of strong supply chain management technology that has rigorous processes around it. NetSuite’s supply chain management software streamlines communication with suppliers, fostering traceability of the flow of goods from their source through production and logistics and into customers’ hands. With NetSuite, data on critical product attributes can be refreshed in real-time, facilitating regular reviews by supply chain managers to ensure that their specifications are met, quality is maintained and progress is made toward goals, such as sustainability.

Sustainability — and, therefore, the supply chain traceability on which it depends — has become table stakes for large companies and is fast becoming so for businesses of all sizes. As traceability continues to evolve toward fulfilling its promise for sustainability, it is also helping companies tackle quality control, regulatory compliance and fraud prevention. By tracking and tracing product-level details across complex supply chains, traceability is becoming a means for doing business more profitably, as well as responsibly.

Supply Chain Traceability FAQs

What is the difference between supply chain visibility and traceability?

Supply chain visibility provides insights at the operational level of supply chains, while traceability delivers more granular details at the product level. The two work hand in glove. An example could be the way a traceable product detail, such as its expiration date, can also support inventory management.

What is tracking in supply chain management?

Tracking closely monitors the journey of a product in a supply chain, from the sourcing of its raw materials and components to its production and distribution to customers. Best practices in tracking deliver real-time, granular data on a product including raw material sources and processing locations, which can be important in pinpointing quality issues or reporting environmental sustainability.

What is the difference between supply chain and value chain traceability?

There’s little difference. A supply chain deals with sourcing materials, building the product and getting it to the customer, while a value chain works to enhance the product’s value as it moves along that supply chain. Traceability can capture product details that support both.

What is visibility and traceability in the supply chain?

Supply chain visibility and traceability work hand in hand. Supply chain visibility provides a view of the network’s operations, while traceability delivers granular, product-level details.

What is supply chain transparency and traceability?

Supply chain traceability provides the foundation for supply chain transparency. That is, by closely tracking a product’s journey through the supply chain, traceability tools can supply details on the item’s contents, expiration date and other attributes. This data can be important for reporting transparently to regulators and the public on sustainability efforts, safety provisions and other essential activities.

What is an example of traceability?

The maker of one luxury handbag has stitched radio-frequency identification tags discreetly into the bags, tracing their location and other details as part of the Aura Blockchain Consortium’s efforts to stamp out counterfeit luxury goods. For transparency, new owners can also view various attributes of the bag, such as the sustainable use of certified recycled material for its packaging, just by waving their smartphones across the bag.