Shipping delays are becoming more frequent—and more expensive. Indeed, global events, infrastructure failures, and labor issues make it hard for suppliers, manufacturers, distributors, and retailers to keep deliveries on schedule. Yet their customers still expect to receive their orders when promised. Organizations that understand these challenges can take steps to mitigate delays, minimize their financial impact, and keep supply chains running smoothly.

Shipping Delay Trends in 2025

Geopolitical tensions, evolving customer demands, and industry disruption are some of the leading forces behind shipping delays in 2025. Uncertainty about tariffs has raised concerns about an international trade war, which could lead to rerouted deliveries and supply chain bottlenecks that force companies to absorb extra costs, on top of several years of high inflation. Global conflicts also continue to affect major trade routes—particularly in the Red Sea, which handled 12% to 15% of global trade before militant attacks began there in 2023.

Meanwhile, consumers continue to expect faster deliveries at lower prices—high shipping charges and other fees are the No. 1 reason why customers abandon their online shopping carts during checkout. Companies are exploring new strategies to meet these demands. Fulfillment centers, for example, are expanding into high-density population centers, and app-based gig workers are transforming last-mile parcel delivery. For freight shippers, new and shifting alliances among ocean carriers aim to make some routes more efficient and reduce capacity on others, which could exacerbate delays.

Key Takeaways

- Shipping delays can result in lost sales and revenue, higher expenses, and problems with inventory management.

- Delays also interrupt production schedules, damaging brand reputations and throwing supply chains into disarray.

- By building resilient inventory systems and supply chains and streamlining logistics with advanced technologies, businesses can minimize shipping delays while maintaining customer satisfaction.

- Transparent communication about delays, through real-time tracking and proactive outreach, can alleviate complaints and restore customer confidence.

What Causes Shipping Delays? 10 Common Causes

Many shipping delays are beyond shippers’ control, though they are often responsible for addressing and mitigating the fallout. The effects of supply chain disruptions, extreme weather, and infrastructure failures can create widespread setbacks. Regulatory issues, incorrect documentation, and last-mile challenges can lead to shipment holdups, misrouted packages, and failed delivery attempts. And high demand, mechanical failures, and labor shortages can push carriers beyond capacity. Businesses with a firm understanding of these causes can anticipate risks, minimize disruptions, and keep shipments on track.

- Supply chain disruptions: Unexpected events or conditions, such as natural disasters, economic uncertainty, cyberattacks, and labor and trade issues, can create raw materials shortages and production problems. These supply chain disruptions and their resultant shipping delays have the potential to cause significant harm to affected businesses’ finances, operations, and reputations. They also tend to become amplified as the effects of a disruption reverberate throughout logistics networks. For example, a factory that shuts down because of an earthquake could delay the production of critical components, which, in turn, would stall assembly lines and incur delivery bottlenecks.

- Weather conditions: Hurricanes, blizzards, and other extreme weather events increase transport times and, in serious cases, may even force carriers to pause service for days. When Category 5 Hurricane Ian struck the US Southeast in 2022, for example, FedEx suspended operations in more than 150 cities. And during Winter Storm Blair in 2025, more than 2,700 ZIP codes across the Midwest were without UPS pickups and deliveries. These delays increase costs for shippers in multiple ways, including additional fuel consumption for longer alternate routes, overtime pay to make up for lost time, and inventory holding expenses.

- Traffic and infrastructure problems: Even in good weather, road and port congestion are common causes of delays. Infrastructure failures and accidents, such as the 2024 container ship crash that destroyed the Francis Scott Key Bridge and closed the Port of Baltimore for 11 weeks, result in more significant disruptions. Busy or inaccessible shipping routes often mean increased fuel costs. They also delay stock replenishment shipments and make route planning difficult for logistics and freight companies.

- Customs and regulatory issues: Inaccurate or incomplete documentation, misclassified goods, and heightened security checks may cause shipments to be held at borders, delaying deliveries. Tariff code errors and missing certificates of origin are common examples that prolong inspection times and incur additional fees for shippers and carriers. Logistics managers and freight forwarders need an in-depth understanding of multiple international regulations to avoid these delays. These issues are more common among small retailers and ecommerce businesses, which often lack the resources to effectively handle this complexity.

- Incorrect address or documentation: Errors on shipping labels and other paperwork generate domestic delays, as well. For example, an incorrect ZIP code or missing apartment number is all it takes to prevent carriers and last-mile delivery services from delivering packages, which then get returned to their original transportation hubs or sent directly back to shippers. This adds to costs, increases the chances of lost shipments, and frustrates customers. Similarly, mislabeled freight may end up at the wrong warehouse, forcing distributors to perform additional sorting and shipping work to ensure that it reaches its intended destination.

- Peak season demand: Spikes in consumer purchases during holidays or sales promotions strain supply chains, logistics networks, and carrier resources, creating bottlenecks that hinder timely deliveries. For instance, manufacturers could face delays receiving raw materials from suppliers and shipping finished products to distributors, creating a ripple effect that disrupts retailers’ on-time order fulfillment. Carriers and last-mile delivery services often operate at or above capacity during peak periods, resulting in further delays, missed delivery windows, and increased costs.

- Mechanical failures: Whether it’s something as simple as an overheated engine or a more serious problem, such as an electrical system failure, transportation vehicle breakdowns are commonplace. The trucks, ships, and planes that power worldwide shipping are complex machines operating under rigorous schedules and in challenging conditions, making them prone to wear and tear. Even a seemingly minor issue, such as a flat tire, can delay deliveries for hours, while more complex breakdowns may require specialized repairs that take vehicles out of commission for days or weeks.

- Labor strikes or shortages: Logistics and shipping rely on many manual tasks, such as picking and packing orders, loading and unloading packages, and delivering materials and goods to their intended destinations. Labor shortages or disruptions—which are increasingly common—often delay this work; last year, understaffing disrupted transportation at 61% of supply chain and logistics companies, with 58% saying these issues negatively affected customer service. The threat of labor disputes, such as the two-day strike by International Longshoremen’s Association port workers in 2024, also looms large. Supply chain experts and economists predicted that, had the strike gone on longer, it would have led to significant shipping delays and higher prices, costing the US economy $2.1 billion after just one week.

- Carrier capacity constraints: Peak-season demand increases, mechanical failures, and labor issues can all overwhelm a carrier’s available resources, making it difficult to secure capacity. Finite shipping space, limited vehicle availability, and regulations, such as drivers’ hours-of-service rules, add further constraints. Carriers operating at or above capacity may need to increase their freight rates and queue shipments, which disrupts production timelines and delivery schedules and tacks on additional costs for shippers.

- Last-mile delivery issues: Problems with local distribution networks and delivery scheduling are a major cause of delayed shipments and customer dissatisfaction. Missed deliveries often result in rescheduled delivery attempts that delay package arrivals further, while the alternative—requiring customers to pick up packages from a local post office or service center—can be inconvenient. Last-mile delivery operations that don’t rely on advanced route planning and optimization technologies are inefficient and generally have longer transit times. Traffic and limited parking pose additional challenges, particularly in congested urban areas.

What Problems Are Caused by Shipping Delays?

Late shipments damage brand reputation, hurt repeat business, and disrupt production schedules, contributing to lost sales, higher expenses, and inventory mismanagement. They can also strain B2B relationships and result in contract breaches and legal penalties. Let’s examine the broad range of problems caused by delays throughout the supply chain.

- Customer dissatisfaction: Fair or not, a shipping delay reflects poorly on the shipper. Customers will complain and leave negative online reviews in response to bad delivery experiences—even if they’re satisfied with the product itself. These comments can quickly spread on social media and review sites, amplifying the aftereffects of a single incident.

- Brand reputation damage: Late shipments from retailers and ecommerce companies disappoint consumers. For suppliers, manufacturers, and distributors, delays are even more consequential, causing serious supply chain and inventory management problems. In any case, the end result is the same: weakened loyalty and brand trust.

- Reduced repeat business: Over time, reliability concerns may deter current customers and partners from buying from a company again or renewing a contract. Instead, they might turn to competitors that offer more dependable shipping.

- Lost sales and revenue: Companies lose money when customers stop buying from them because of poor delivery experiences or unsatisfactory shipping times. Reduced repeat purchases, abandoned carts, and canceled orders also contribute to lower customer lifetime value. This is a serious problem for business leaders, 58% of whom say they’re concerned about the short-term loss of sales caused by supply chain problems. Additionally, these financial losses may limit a company’s ability to invest in long-term growth.

- Increased costs: Efforts to address the problems caused by delays bring additional expenses. Expedited shipping, for example, helps ensure on-time deliveries, but it comes with higher costs that shippers must absorb. Although refunds and future discounts may help preserve customer loyalty after negative experiences, they eat into profit margins. And operational adjustments, such as rerouting shipments or changing transportation modes, also strain budgets, especially for small businesses.

- Inventory issues: Shipping delays complicate demand planning and inventory management, creating the potential for stockouts or overstocking. A delayed shipment of raw materials to a manufacturer can halt production, leaving retailers without enough finished goods to meet customer demand. Or, if that shipment arrives after demand has peaked, the manufacturer may end up with excess inventory and be forced to pay extra for its storage.

- Operational inefficiencies: Delays disrupt supply chain and order fulfillment processes by throwing off carefully planned production, inventory management, and delivery schedules. Late deliveries to distribution centers, for example, prevent retailers from restocking shelves and fulfilling customer orders on time. The employees and equipment left idle as they wait for shipments wastes retailers’ valuable resources. Attempted workarounds, such as expedited or rerouted freight shipments, also add unplanned costs to the process, further increasing inefficiencies.

- Chargebacks and disputes: When shipments arrive late or fail to arrive altogether, consumers may pursue chargebacks—payment reversals initiated through banks or credit card companies—against merchants. In B2B relationships, customers may make deductions from their bills or issue penalties in separate invoices for delayed deliveries. Either scenario spells lost revenue, plus additional fees and processing costs. In addition, companies that receive constant chargebacks risk enhanced scrutiny from payment processors that can affect their ability to send and receive timely payments.

- B2B contract breaches: Legal agreements that explicitly state “time is of the essence,” such as those in industries dealing with perishable goods, allow buyers to terminate contracts and seek damages when faced with delayed shipments. The consequences of these breaches include financial penalties, strained relationships, and potentially lengthy and costly legal disputes. They can also destabilize supply chains by forcing businesses to quickly find alternative partners, leading to further delays and expenses.

- Legal and compliance risks: Additional legal risks include violations of trade regulations, missed customs filing deadlines, and failure to meet import and export standards. For example, a delayed shipment that misses its customs inspection could lead to the revocation of required permits. Other potential penalties include the seizure of goods and fines upward of millions of dollars. Companies that regularly violate regulations could also find themselves under increased scrutiny from authorities, increasing the odds for further delays, thanks to prolonged inspections and approval processes.

How to Address and Mitigate Shipping Delays

Inventory and supply chain resilience, coupled with streamlined logistics and order fulfillment operations, is the key to preventing and managing shipping delays. Real-time tracking and transparent communications help repair damaged customer and partner relationships when delays do occur. And advanced technologies, such as artificial intelligence and automation, help businesses efficiently implement these strategies.

- Optimize inventory management: Stocking products strategically helps minimize or prevent shortages caused by delayed shipments. By using vetted inventory management formulas and tracking key performance indicators, companies can optimize stock levels, identify potential stockouts before they happen, and take action to prevent them—before customers unwittingly order out-of-stock items. Multilocation inventory management enables monitoring of stock levels across all warehouses, retail stores, and sales channels, allowing more efficient fulfillment of customer orders. Inventory management systems automate much of this work, integrating with sales and shipping systems to provide a unified, real-time view of all stock.

- Use multiple carriers: Diversifying shipping partners reduces dependency on one provider, limiting the effects of delays while presenting an opportunity to negotiate more competitive rates. Evaluate carriers based on cost, delivery speed, and other factors that align with customers’ specific needs. Multicarrier shipping software helps businesses evaluate partners and manage their complex relationships.

- Have a contingency plan: Multiple carriers are just one component of a successful contingency plan. Using multiple warehouse locations and suppliers and maintaining buffer stock during peak seasons also help build resilience into shipping operations. In addition, companies should conduct risk assessments and scenario planning to identify and evaluate the likelihood of various disruptions, then define detailed procedures for responding to specific types of delays. Insurance coverage can also provide protection against delay-related risks, which 89% of senior decision-makers say is mission-critical for supply chains.

- Negotiate carrier contracts: Negotiations are an opportunity to not only secure lower rates but also improve terms that can reduce delays and mitigate their risks. For example, service-level agreements incentivize carriers by holding them accountable to performance metrics, such as specific on-time delivery rates and average transit times, and penalize them for missing these benchmarks. Shippers can also negotiate terms that give them priority over other companies, in exchange for more predictable shipping schedules, or include preplanned alternative routes in case of disruptions, further minimizing delays.

- Offer real-time tracking: Keeping customers apprised about shipment status helps alleviate some of the discontent associated with negative delivery experiences. Seeing estimated shipping and arrival dates, plus notifications about where a package is while in transit, reassures customers that they will still receive their orders, despite any delays. Most carriers, and even some ecommerce platforms, offer these capabilities. Real-time tracking also improves visibility and coordination within the supply chain, enabling identification and addressing of potential delays before they escalate.

- Communicate proactively: While real-time tracking allows customers to monitor shipment status on their own, proactive communication from the company takes it a step further by actively reaching out to provide updates that build trust during delays. For shipments to consumers, text and email alerts that provide detailed information and offer customer support go beyond simple notifications, turning potentially negative experiences into more positive ones. Elsewhere in the supply chain, transparent communications between suppliers, manufacturers, distributors, and retailers help prevent production delays and inventory shortages.

- Improve order processing: Order fulfillment is one of the most important tasks for any business that sells raw materials or finished goods. Efficiency and accuracy are keys to customer satisfaction and sales that drive growth. Automation that streamlines work, such as inventory management, order tracking, and packing, helps avoid delayed shipments and other problems that can throw a wrench into the process. For example, automated fulfillment robots in warehouses are able to select packing materials that provide the optimal dimensional weight for each order, which saves space on delivery trucks, lowers costs, and reduces shipping times.

- Use regional warehouses: Regional warehouses minimize the risk of delays because they store inventory closer to customers. They reduce transit times, improve delivery reliability, lower costs, and give companies more flexibility in responding to spikes in demand. Consider a sudden surge in demand for winter clothing before the season’s first snowstorm; regional warehouses allow for faster restocking of nearby retail locations and direct shipments to online shoppers.

- Set realistic delivery expectations: External factors make shipping difficult enough as it is. Companies make it even harder on themselves by overpromising and underdelivering (literally) on shipping times. Providing accurate, achievable delivery dates reduces the risk of complaints, negative reviews, and strained business relationships that happen when shipments arrive later than expected. Shippers need to have a thorough understanding of their operations, including order fulfillment and transit times, not to mention potential bottlenecks, to make and meet realistic delivery estimates.

- Invest in logistics technology: Systems powered by AI and analytics can predict and automatically prevent delays by examining shipping trends, improving demand forecasts, enhancing inventory tracking, and optimizing routing. Identifying potential choke points in advance allows businesses to address logistics issues before they cause delays, and access to simulations of storms, demand spikes, and other disruptions leads to more comprehensive contingency planning. These and other advanced technologies streamline logistics, reduce costs, and empower businesses to make smarter supply chain decisions.

- Offer free shipping or other compensation: Providing free shipping in exchange for accepting longer delivery times is an effective way to proactively avoid delays on some orders; 34% of customers say they would wait on deliveries for up to five days, given the right incentives. When existing shipments face delays, offering free shipping on future orders—or other compensation, such as discounts or gift cards—can restore customer trust and loyalty. However, these tactics require careful consideration to ensure that the benefits of maintaining customer satisfaction outweigh the extra costs.

Avoid Delays and Optimize Shipping With NetSuite

Shipping delays and inefficient logistics disrupt operations, damage customer relationships, and increase business costs. Unpredictable transit times, the risk of stockouts, and complex order fulfillment processes also make it difficult for businesses to meet customer expectations, control expenses, and maintain a competitive advantage.

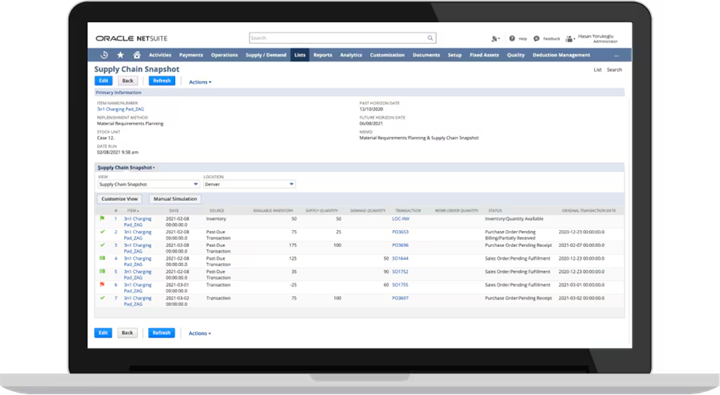

NetSuite’s pick, pack, and ship capabilities address these issues by automating and optimizing order fulfillment. Wave release policies and templates, multi-order picking features, and mobile packing and shipping capabilities streamline the process, reducing waste, increasing accuracy, and improving delivery reliability. From there, NetSuite Inventory Management provides real-time visibility across the supply chain to prevent stockouts and overstocking. With such features as demand-based replenishment and smart cycle counting, businesses can maintain accurate stock levels while decreasing the cost of goods sold. Companies throughout global logistics networks, ranging from retailers and small business owners to manufacturers and freight forwarders, rely on NetSuite to minimize delays, enhance customer satisfaction, and create a more efficient supply chain.

NetSuite Inventory Management

Shipping delays aren’t going away, but businesses can minimize their risks by studying the root causes and building more resilient supply chains. Diversifying suppliers and carriers, improving inventory management, and using real-time data for better decision-making helps keep goods moving through global logistics networks. Companies that incorporate emerging technologies into these strategies will be best positioned to provide consistent service if and when disruptions occur.

Shipping Delays FAQs

Is there still a shipping crisis?

Yes, there is still a shipping crisis, particularly in the Red Sea, where militant attacks that began in 2023 have led to rerouted transit paths, increased costs, and delayed deliveries. About one-eighth of global trade typically passes through the Red Sea, but many shipping companies have stopped using that route in light of the crisis. Commercial shipping in the Suez Canal, which connects the Mediterranean and Red seas, dropped by nearly half after the attacks began.

What causes carrier delays?

Supply chain disruptions, weather conditions, customs and regulatory issues, capacity constraints, traffic, and infrastructure problems are some of the most common causes of carrier delays. Other causes include incorrect addresses on labels and documentation, mechanical failures, labor strikes, workforce shortages, peak season demand, and last-mile delivery issues.