Supply chains have become more complex and vulnerable due to globalization, and businesses of any size must take proactive steps to protect their operations from possible disruptions. Even small slowdowns can ripple throughout the supply chain, creating major bottlenecks that can reduce output, raise costs and push dissatisfied customers away. But businesses must balance two strategies that can often seem at odds — creating a supply chain that is flexible and resilient while also maintaining efficiency and keeping costs in check. This article will explore how to develop a resilient supply chain that can help businesses achieve long-term success and even avoid future risks — a must in today’s dynamic and unpredictable business landscape.

What Is Supply Chain Resilience?

Companies with resilient supply chains prioritize identifying vulnerabilities, then implement strategies and technologies to help minimize — and even avoid — their potential impacts. This is often accomplished by integrating siloed operations for increased visibility and investing in technology, such as automated data collection and companywide business platforms. By strengthening supply chain operations, businesses can better serve their customers and gain a competitive edge, even in the face of volatile demand and increasing global pressures.

Key Takeaways

- Resilient supply chains are better at withstanding threats, including natural disasters, material scarcity and other disruptions, that, if not planned for, can raise costs and harm the customer experience.

- Businesses can increase their supply chain’s resilience by focusing on contingency planning, agile operations, increasing visibility and working with partners, among other best practices.

- Maintaining a resilient supply chain is a continuous process that requires monitoring and regular improvements as strategies and technology evolve.

Supply Chain Resilience Explained

Supply chain resilience is a measure of how well a supply chain can withstand and recover from disruptions and breakdowns, regardless of whether the challenges are predictable or unexpected. Resilient supply chains maintain continuity of their essential functions, such as manufacturing and delivering goods to customers. On the other hand, weaker supply chains are less likely to be able to effectively respond and adapt to challenges like natural disasters, material shortages or global market shifts. Resilient supply chains often employ techniques like process mapping and predictive risk analysis to plan for contingencies and proactively mitigate potential threats before they become major disruptions, often through sophisticated technology and robust data collection and analysis. Disruptions in the supply chain can have significant negative effects on businesses, including increased costs, delays, revenue loss, reputational damage and customer dissatisfaction. By focusing on resilience, businesses can minimize these impacts and quickly recover when supply chain breakdowns occur.

Supply chains have been put under the spotlight in recent years, due in large part to shutdowns caused by the COVID-19 pandemic, changes in international trade policy and global conflict. Experts suspect that these widespread disruptions may become more common in the future. Research conducted by the global management consulting firm McKinsey & Co. estimates that supply chain disruptions lasting a month or longer will occur every 3.7 years. As a result, McKinsey says, companies should expect supply chain disruptions to “erase half a year’s worth of profits or more” over the next decade, averaged across industries. Different industries have different processes and risks, but most businesses rely on some form of a supply chain to procure raw materials, manufacture goods and deliver them to customers.

Importance of Supply Chain Resilience

Modern businesses are exposed to new vulnerabilities as globalization continues and supply chains rely on far-reaching and compartmentalized processes. As stated in the 2022 Economic Report of the President, “As supply chains have increased in complexity, firms’ need for risk management has also grown.” If businesses are unable to effectively manage supply chain risks, their bottom line will likely suffer because “when unable to produce due to lack of inputs, firms lose revenue,” the report states. Furthermore, companies will likely not be able to meet other obligations, such as effectively fulfilling orders or maintaining quality standards.

However, businesses must focus on attainable and realistic goals. According to the report, it is “not cost-effective for firms to invest in completely avoiding all disasters”; instead, they should focus on prioritizing risks and making smart investments. These investments include general fixes that increase efficiency and productivity to minimize waste and raise output. Businesses can also reduce risk exposure through external changes, such as reducing overreliance on a single supplier or transportation route.

A primary goal of supply chain resilience is to create contingencies that balance the additional costs of building resistant operations with the revenue that would be lost if an unforeseen disruption were to occur. Decision-makers should also consider nonfinancial risks, such as reputational damage and customer loss, when running cost-benefit analyses, as qualitative losses can also contribute long-term harm to business performance. By investing in a more resilient supply chain, businesses can take proactive steps to ensure that they are prepared for future challenges and maintain high standards of goods and reliable deliveries for their customers, while reducing costs and optimizing operations.

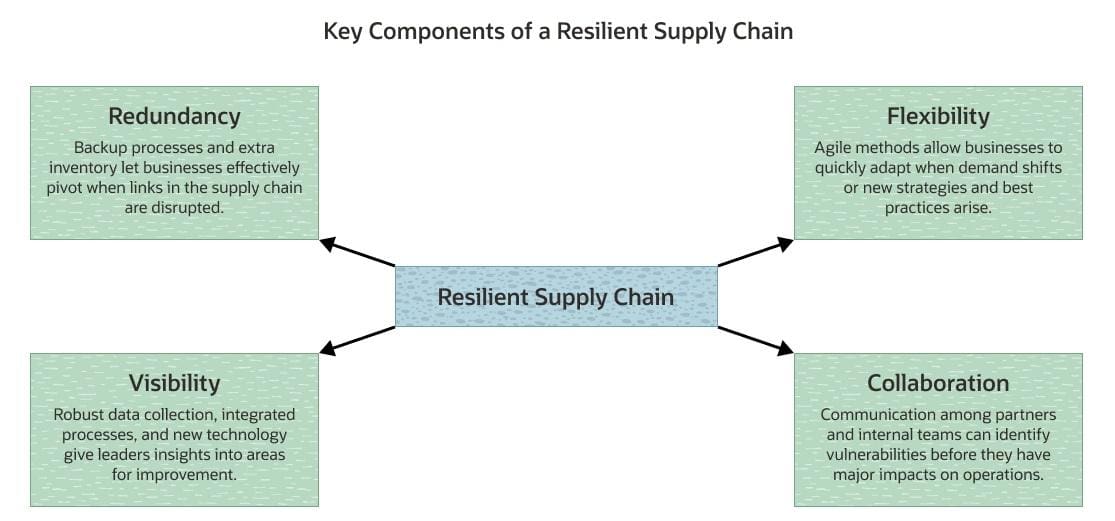

Key Components of a Resilient Supply Chain

Every business has its own supply chain, equipped with unique ways to satisfy its needs. But most resilient supply chains will likely share these four key components:

Contingency

Contingency often takes two forms — backup processes, and extra supplies and inventory. For the former, many businesses foster relationships with additional vendors and spread responsibilities throughout multiple locations. By maintaining multiple pathways for supplies and goods to flow through, businesses can avoid shutdowns by increasing the capabilities of one path to compensate for a bottleneck or slowdown in another. The other form of contingency, holding additional supplies and inventory, helps maintain business continuity during periods of material scarcity or slowdowns. For example, if an equipment malfunction causes a factory to slow production, businesses can rely on a safety stock of finished goods to meet promised order fulfillments and delivery times. However, neither form of contingency comes without costs, and businesses should consider what levels of redundancy they can afford. A hasty, ill-informed decision can negatively impact profit margins and make reducing the risk of a disruption more costly than the risk itself.

Flexibility

A resilient supply chain must emphasize flexibility, as rigid operations are more likely to break under pressure. Flexible, or agile, supply chains can quickly switch to alternative processes to avoid major slowdowns when changes are needed, such as pivoting to a new production method when consumer demand shifts. This is especially important for ecommerce businesses with potentially viral products, as having to sluggishly slow down or ramp up production can lead to high carrying costs for unsold inventory or empty shelves, respectively, not to mention the related risks of dissatisfied customers and unrealized profit potential.

In addition to optimized production and inventory allocation, flexible supply chains can effectively switch processes when standard operating procedure becomes bottlenecked or inefficient. For example, if ports become congested, a flexible supply chain can quickly move shipments to air and/or truck freight, bypassing crowded ports and maintaining delivery standards. Flexibility is often achieved through comprehensive and automated data collection to give leaders access to detailed metrics, such as supply levels, production rates and other relevant key performance indicators (KPIs). Many business platforms automatically flag problem areas for review, helping managers detect issues early and make changes to address them before they affect customer satisfaction.

Visibility

Fortifying the supply chain requires a high level of visibility, as problems cannot be solved until they are identified. Businesses must monitor their supply chain and track any changes in capacity or lead times. This can present challenges, as visibility may require additional investments and new technology. Data collection and analysis tools are often integrated with a business platform, such as an enterprise resource planning (ERP) system, to give decision-makers a more complete view of their supply chain. This data is often organized into customizable reports that can be generated to show as much or as little information as needed, giving analysts quick access to all the information relevant to the issue at hand. Visibility into this data helps businesses see areas where slowdowns occur and informs decisions on how to improve overall supply chain performance. Supply chain audits, often conducted by external experts, can also shed light on problem areas that require special attention. Once a business achieves the visibility needed to gain a holistic view of the supply chain, it can find and implement ways to strengthen operations and build a more resilient operation.

Collaboration

Effective collaboration requires trust and transparency with partners to identify root causes of problems and implement strategies to address weaknesses. This often necessitates data sharing and open communication among suppliers and distributors so that all parties understand each other’s needs, capabilities and vulnerabilities. Collaboration is also critical for internal teams, as upstream and downstream communication is necessary to prevent unforeseen consequences to supply chain improvements. For example, say a business wants to increase its output by investing in more efficient manufacturing equipment. Before purchasing that equipment, the business should work with its suppliers to ensure that procurement can increase to match the new rate at which raw materials will be needed. Similarly, distributors and shipping teams should collaborate with manufacturers to prevent warehouses and loading docks from becoming cluttered and reaching capacity while output is rising, delaying orders. By improving collaboration, an otherwise fragmented supply chain can be integrated, leading to streamlined operations, reduced costs and increased customer satisfaction.

Best Practices for Building Supply Chain Resilience

Building a resilient supply chain is not a one-size-fits-all solution. It requires continual monitoring and adjustment as markets evolve and new challenges arise. These best practices can help businesses build a more resilient supply chain to maintain that adaptability.

-

Develop a Risk Management Plan

-

Simulate Supply Disruptions

-

Consolidate Organizational Responses Proactively

-

Diversify Suppliers

-

Collaborate With Suppliers and Partners

-

Continually Monitor and Adapt

-

Understand and Leverage Data

-

Invest in Demand Planning

-

Implement Capacity and Inventory Buffers

-

Build Checks and Balances

-

Invest in Sustainability

-

Invest in Technology

Risk management plans are essential for building a resilient supply chain. Creating an effective risk management plan requires analysts to identify and assess risks to operations before developing contingencies. No business has unlimited resources, and, therefore, it must take care to prioritize risks, typically according to urgency, resource requirement or loss potential. Analysts often develop risk management plans in collaboration with stakeholders and the managers who will be implementing them to ensure that everyone involved can react quickly when needed; this collaboration also provides opportunities to discuss any overlooked details or collateral impacts. By creating detailed risk management plans, organizations can respond effectively to disruptions and strengthen the overall resilience of their supply chain.

Maintaining supply chain resilience requires more than good instincts and guesswork. Many businesses use planning and forecasting technology that allows decision-makers to run what-if scenarios to ensure that decisions are well informed and backed by data. Some business platforms create a digital twin of supply chain operations to simulate how proposed changes or disruptions will impact operations and give analysts tools to dive deep into existing workflows to increase visibility — all without impacting the actual operations themselves. These what-if scenarios and simulations are especially useful for businesses facing tough decisions on prioritizing fixes, as two vulnerabilities may have similar short-term repercussions but could have major differences over the long-term. For example, two vendors may offer similar terms and prices, but if one has longer lead times, that slowdown could create bottlenecks and delay the entire order fulfillment process, especially if an external disruption occurs. This compounded slowdown can eventually lead to disappointed customers and a drop in sales. Sophisticated simulations can help businesses prioritize and implement improvements that fit their needs and help leaders remain confident that their decisions are based on detailed data, not hunches.

When a problem arises, businesses with planned and consolidated organizational responses are better prepared to address the issue and adapt than businesses scrambling to add staff to hastily assemble teams. Proactively facilitating coordinated responses helps businesses effectively allocate resources and assign responsibilities ahead of time, minimizing the time between identifying a problem and implementing a solution. Proactive planners have more time to effectively study and adjust previous responses to create the best path forward, rather than focusing on firefighting and damage control. This strategy also fosters collaboration among multiple departments and stakeholders to bring in expertise that can be the difference between a rushed bandage and a thoughtful response that addresses the root causes of the disruption.

Supply chains that rely on a single source for raw materials are vulnerable to disruption if their supplier shuts down. The shutdown could be a temporary or permanent closure that limits access to the materials needed to keep a business operating smoothly. Many of these shutdowns are caused by regional occurrences, such as weather events, and 86% of the 1,500 global supply chain decision-makers surveyed for the Interos Annual Global Supply Chain Report said their organization “currently has too many suppliers concentrated in one area.” Businesses using regionally diverse suppliers can minimize the risks of a shutdown from a natural disaster or sudden global trade upheaval and can prevent one slowdown from fully interrupting operations. Diversifying suppliers may require additional time and resources to manage effectively, but many businesses use software with supplier relationship management integration to collect and compare data, such as supplier performance and costs, which can lead to more efficient procurement and stronger negotiating power.

Partners are often on the front lines of the supply chain segments that present visibility challenges to businesses. For example, an IT business may rely on computer chips from an overseas vendor, but it may not have access to real-time data on the availability of the materials that are used to create those chips. According to the 2023 HUBS Supply Chain Resilience Report, raw materials shortages were responsible for 2022’s top supply chain disruption, with 61% of respondents saying the disruption impacted their business. By establishing and maintaining healthy relationships with suppliers, businesses have a front-row seat to these issues and can get a head start on mitigating their impacts. Businesses can also apply what they learn from their suppliers’ expertise to strengthen operations throughout the supply chain, creating a more streamlined and resilient organization from procurement through final delivery. This same collaboration can apply to other partners, such as distributors, retailers or even customers, who can offer valuable feedback on the quality of goods, delivery times, the overall ordering experience and whether expectations were met.

A supply chain perfectly suited to navigate today’s economy — if such a thing existed — might not be as effective next year, next quarter or even tomorrow, as market conditions are constantly evolving and new challenges arising. Fresh strategies and best practices help businesses keep up with changing demand patterns and keep customers coming back. Innovative technology, such as automated data collection, is often leveraged to give stakeholders a real-time view of business performance. All of this helps maintain a state-of-the-art supply chain, rather than one better suited for last year’s market. But when transforming their supply chains, businesses must make sure to balance new advancements and methods with tried-and-true strategies that are still relevant and effective. Institutional knowledge, experienced staff and long-standing company policy still play crucial roles in problem-solving and keeping staff on the same page. Whatever balance of old and new techniques a business chooses to follow, strategy should be implemented deliberately, and goals and methods should be clear to all relevant parties. Disjointed and siloed operations can lead to chaos, as inefficient redundancies slow the flow of goods and issues go undetected.

Businesses need large amounts of reliable data from both internal and external sources to monitor any changes or threats to the supply chain. When using information from external parties, such as self-reported vendor data or market research, it is important to check for accuracy and potential biases. Decision-makers relying on inaccurate or incomplete data are more likely to draw incorrect conclusions and may implement strategies that address only symptoms of problems — or worse, add inefficiencies or new bottlenecks into the supply chain. Many businesses use ERP platforms or control towers to validate and organize this data into accessible and easy-to-understand formats, often through intuitive dashboards. Business leaders can use these systems to analyze overall performance KPIs to see big-picture trends and zoom in to more granular information to find specific areas for improvement.

11 Critical Supply Chain Metrics to Track

Building a resilient supply chain requires forecasting and planning to give decision-makers an accurate picture of future challenges and expectations that the supply chain will have to meet. Demand forecasting models typically use data, such as historical sales, market research and seasonal adjustments, to give businesses a road map to follow when planning production rates. But demand planning is more than just forecasting. It incorporates supply chain management and inventory allocation to minimize waste and increase the resiliency of every step of the supply chain that companies rely on to meet customer demand. Businesses that view demand as a holistic business strategy — rather than just focusing on whether inventory matches projected sales numbers— can find more areas where order lead times can be decreased, and the entire customer experience can be more satisfactory and efficient.

Even the most sophisticated forecasting models cannot account for every variable and are rarely perfect, especially in the ecommerce world. Establishing buffers in the supply chain, such as holding excess inventory or producing goods above forecasted values, can reduce the likelihood of stockouts and backorders and can help keep operations flexible and resilient, even in the face of fluctuating demand and disruptions. Businesses operating with small margins or producing customized goods may not find the higher carrying costs and muted distinctiveness of their products worth the investment, but for businesses offering mass-produced or standardized goods, a cushion against demand variability can provide a competitive advantage when products go viral or shortages occur.

Overreliance on any single business process can spell disaster if that process breaks down. Businesses can reduce this risk by building redundant operations that can take on more responsibility when parallel workflows fall behind. These redundancies are often regionally diverse to help minimize shutdowns from natural disasters or trade-route bottlenecks. Many businesses are also reshoring or nearshoring parts of their operations to keep some processes closer to home base and less dependent on international trade agreements, tariffs and global freight pressures. However, creating backup processes takes time and resources, and requires monitoring to keep them agile and ready to act when disruptions occur. Many businesses rely on software to track these redundancies and effectively manage goods and materials. By using technology, like centralized databases and automatic alerts, these systems can strike the desired balance between limiting costs and minimizing risks, ultimately creating a more resilient supply chain.

Many consumers value environmentally conscious companies and choose to shop for products that are sustainably sourced and produced. But in addition to luring “green” customers, sustainability can also help businesses add resilience to their supply chains by creating more long-term viability, reducing dependence on external vendors and reducing waste. The high-efficiency equipment that often comprises a sustainable supply chain can also reduce utility bills and raise productivity — if the business can afford the initial investment to overhaul processes into a more sustainable operation. Additionally, as governments set new environmental regulations and policies, businesses that emphasize sustainability early and independently are more likely to stay ahead of the curve and continue making investments at their own pace, giving them more control over when and how much they spend to reach benchmarks that fit the company’s values.

Supply chain technology has come a long way in recent years, and businesses can leverage it to manage complex operations and build a more resilient supply chain. Centralized systems, such as ERP software or supply chain control towers, are powerful tools that can integrate data and workflows throughout an entire organization and give stakeholders the end-to-end visibility they require to find areas for improvement and track performance. Remote workstations and mobile technology, for example, keep information flowing upstream and downstream, regardless of how widespread a company’s operations may be. This open communication can quickly alert relevant parties about any slowdowns or changes in pertinent information, giving managers the best chance to fix problems before they intensify and create major delays. With modern technology, businesses can access many essential supply chain management tools with the touch of a button, and effectively leveraging these tools can keep even complex, global supply chains running smoothly and efficiently.

Technology’s Role in Supply Chain Resilience

Maintaining a resilient supply chain in today’s market presents many challenges, and business leaders need to use every tool at their disposal to effectively manage their operations. By implementing the latest technology, supply chain managers can remove guesswork and ensure that their decisions are well informed and focused on long-term success.

Rise of Digital Supply Chains

In the past, supply chains needed auditors monitoring the front lines — counting boxes, timing shipments and reporting on every aspect of the operation. But today, many businesses leverage virtual systems, known as digital supply chains, to control processes and increase visibility from the first step of the supply chain through final delivery of products. These digital supply chains use sophisticated technology, such as Internet of Things devices, to track goods as they move through the supply chain. The virtual system then mines that data and integrates it with other information to create a holistic and real-time picture of the supply chain that authorized users can access to monitor performance and spot places for improvements. Digital supply chains can also foster more rapid collaboration, as information is updated in real-time and all relevant parties can access data and communication from a single centralized program.

Data Analytics and Artificial Intelligence in Supply Chain Resilience

Due to the sheer volume of variables involved with maintaining a resilient supply chain, businesses will likely need to increase their analytics capabilities as they grow, often by implementing artificial intelligence (AI) to help analyze and forecast everything from customer demand to freight-disrupting weather. AI can be used to reveal insights into the supply chain’s strengths and weaknesses and can give actionable suggestions to reduce risks and increase efficiency. Machine learning can also be employed to identify patterns and help analysts pinpoint root causes of problems when making data-heavy improvements, such as inventory optimization. Data analytics tools that use AI technology can enhance decision-making capabilities and improve response times to disruptions, building a more resilient supply chain that can adapt to changing market conditions and deliver superior customer service.

Benefits of Technology in Improving Supply Chain Resilience

Just about every aspect of a supply chain can be improved with technology, but businesses must take care to prioritize their investments based on their needs. Companies that use resources without proper and deliberate planning may end up with expensive but near-useless systems. For example, some manufacturers might be able to install 3D printing technology to quickly create customized products on demand, with minimal recalibration and disruptions to standard operations — but factories that produce only one type of good, one that’s open to few changes or fluctuations in design, may not benefit from this type of equipment overhaul. Some supply chains can also be improved with automated robots that perform tasks like inventory sorting, picking and processing, freeing up staff for tasks that require manual intervention. Many similar automated systems and other beneficial technologies can be managed from anywhere, and be scaled in pace with a business’s growth, with a cloud-based system, such as an ERP solution.

Government’s Role in Supply Chain Resilience

Functioning supply chains are necessary to keep a nation’s economy thriving and goods flowing from businesses to customers. Governments can create guidelines, policies and regulations to help both private and public supply chains remain resilient, even in the face of global challenges. For example, in February 2021, the U.S. government issued the Executive Order on America’s Supply Chains to make sure American supply chains retain the resilience they need to ensure “economic prosperity and national security” in the face of such far-reaching and diverse threats as “pandemics and other biological threats, cyber-attacks, climate shocks and extreme weather events, terrorist attacks, geopolitical and economic competition, and other conditions” that can cause shutdowns.

The government set out to achieve this goal by directing heads of government agencies and leaders in industry, academia, labor unions and other outside stakeholders to collaborate and conduct a full review of critical goods, materials and the manufacturing capabilities of the nation’s supply chains to measure their current risks and resiliency. This collaboration led to a detailed report, released in February 2022, that laid out successes and failures in America’s supply chains, with recommendations for future investments, including quadrennial reviews to create an ongoing system of continuous improvement. Governments from all over the world are taking similar steps to bring in leaders from public and private sectors to ensure that supply chains remain resilient and secure as market conditions evolve.

Supply Chain Resilience Examples

Every business faces unique challenges and will likely need well-planned and deliberate strategies to build resilience into their supply chain. Here are some examples showcasing how companies in diverse industries have overcome their supply chain challenges and improved operations.

- Winky Lux, a New York-based health and beauty company, was experiencing supply chain delays due to inefficiencies in its financial, inventory and ecommerce systems. When purchase orders changed, multiple systems needed to be updated, and communication delays with overseas suppliers led to rushed shipping to ensure that goods arrived on time, often costing up to seven times more than standard shipping rates. By upgrading to a centralized ERP system that could integrate with its ecommerce and suppliers’ systems, Winky Lux was able to eliminate most manual processes and speed up supply chain operations. This upgrade brought more resiliency to Winky Lux’s supply chain, reduced costs and delivered a more reliable experience to its customers — and led to a forecasted 40% sales growth.

- MRS Packaging, a food and beverage company located in Dubai, needed to prioritize inventory optimization when it upgraded its supply chain to minimize the risk of perishable goods spoiling. As part of that effort, MRS expanded its demand planning with the help of a new ERP system, enabling it to generate accurate forecasts. This created a more flexible supply chain, capable of meeting customer demand and cutting excess inventory by a third — all while eliminating stockouts. This increased resilience gave the company more freedom to focus on growth and invest in new endeavors, such as more sustainable packaging and healthy snacks.

- New Jersey-based Seaman’s Beverage and Logistics requires a supply chain capable of complying with multiple sets of regulations, including various distributor types, local laws and changes in alcohol regulations. If the company does not remain vigilant while importing and shipping its products, it can accrue costly fines and reputational damage. By leveraging its ERP system, Seaman’s can maintain a flexible and scalable supply chain that can adjust quickly to changing regulations and keep customers notified of any changes to their orders. The system also gives decision-makers suggestions about improving metrics, such as profitability per case of product, emphasizing both efficiency and resiliency.

-

The coronavirus outbreak impacted men’s apparel brand Alton Lane well before it began spreading rapidly in the United States. Alton Lane sources fabric for its custom suits, shirts and pants from England, Portugal and Belgium. That fabric is sent to tailors in Western Europe and Asia, who turn it into the brand’s clothing and accessories.

When the coronavirus reached Italy, the fabric mills Alton Lane uses in that country shut down for a few weeks, breaking a key link in its supply chain. However, the redundancy the Virginia-based retailer built into its supply chain prevented this from being a crippling event.

Alton Lane was able to quickly reroute orders. It has factories in Spain, Portugal, Germany, Thailand and Vietnam, and it helped that certain Italian mills had fabric stored at a distribution center in Hong Kong. The retailer has continued to make almost every product it sells, with the exception of belts, as just one factory manufactured those.

This supply chain resilience paid off in another way. Alton Lane faced a dip in sales as it temporarily closed all 12 of its showrooms, where it does most of its fittings and business. But as it redirected orders, certain partners gave the brand breaks in exchange for receiving a larger book of business.

Build Resilience in Your Supply Chain With NetSuite SCM

Building a resilient supply chain requires robust and regular data collection, plus analytics to ensure that operations remain resilient when market conditions change and customers’ needs evolve. With NetSuite Supply Chain Management (SCM), businesses can track and oversee processes from initial procurement to final delivery. NetSuite’s cloud-based SCM software can streamline communications among internal teams and business partners, such as suppliers, to ensure that everyone is working together to meet a business’s needs.

With NetSuite SCM’s real-time tracking, inventory management and order updates as goods flow through the supply chain, decision-makers can be confident that they are making well-informed improvements and increasing overall operational efficiency. The software’s integrated demand planning, predictive analytics and forecasting capabilities not only build but maintain a resilient and flexible supply chain, capable of scaling as a business grows and delivering for customers — both today and tomorrow.

Supply chains are more complex than ever, and identifying, prioritizing and mitigating the risks they face can present major challenges to businesses of any size. But building a resilient supply chain is not impossible, and by following best practices, such as diversifying suppliers, simulating disruptions, building redundancies and more, businesses can add resiliency to their organization without sacrificing the flexibility required to keep up with ever-changing customer demand. Businesses willing to invest in technology to attain the visibility necessary to effectively manage the supply chain may be better prepared for tomorrow’s challenges — but only when investments are made deliberately to address the business’s specific needs. By effectively leveraging technology and preparing for potential disruptions, business leaders can establish resilient supply chains, while reducing costs and delivering a better customer experience.

Supply Chain Resilience FAQs

What is supply chain resilience?

Resilience refers to a supply chain’s ability to anticipate, adapt to and recover from disruptions, uncertainties and risks while maintaining business continuity. It requires flexibility to respond quickly to disruptions, minimize negative impacts and recover operations, and it is often achieved through leveraging new technology, such as artificial intelligence and machine learning, to collect and organize data and gain the visibility needed to maintain a resilient supply chain.

What is a supply chain resilience example?

Winky Lux, a New York-based health and beauty company, was able to create a resilient supply chain by upgrading to a centralized system that could integrate with its ecommerce and suppliers’ systems, thus streamlining operations and speeding up communication with overseas suppliers. This reduced shipping costs and increased customer satisfaction, leading to a growth in sales.

How do you build supply chain resilience?

Businesses can build supply chain resilience by focusing on four key components of their supply chain.

- Redundancy, which creates backup processes and inventory that businesses can use when disruptions occur.

- Flexibility, which allows businesses to quickly adapt to and mitigate the negative effects of changing market conditions.

- Visibility, which is critical to maintaining a resilient supply chain, as it allows managers and business leaders to identify weaknesses and find areas for improvement, potentially avoiding disruption.

- Collaboration among partners and internal teams, which yields insights into how best to manage risks and ensure that contingency plans will be executed quickly and efficiently.

What role does risk management play in supply chain resilience?

Risk management plays a crucial role in supply chain resilience because it identifies, assesses and mitigates potential risks, allowing organizations to proactively plan and implement strategies to maintain continuity and minimize any undesirable impacts on supply chain operations. Risk management also helps businesses prioritize the risks that are most relevant to their organization so they can decide what steps to take to manage them effectively.

What are some common threats to supply chain resilience?

Supply chains can be threatened by internal inefficiencies, such as production bottlenecks; wasteful manufacturing processes; or poor communication among links in the supply chain. They can also be threatened by external disruptions, such as trade wars, international conflicts or natural disasters.

How can businesses prioritize investments in supply chain resilience?

Businesses can prioritize investments in supply chain resilience by conducting a supply chain audit to identify vulnerabilities and prioritize areas of improvement. This helps businesses understand the costs and benefits that improvements can bring and helps leaders decide which ones are necessary and how much the investment should be. Businesses can also run scenario simulations during planning phases to weigh their investment options.

How can sustainability practices improve supply chain resilience?

Investing in sustainability practices can strengthen supply chains by reducing waste and reliance on external suppliers. Additionally, sustainable operations typically use high-efficiency equipment that can cut costs and boost productivity, creating a supply chain more capable of maintaining output during slowdowns. Proactive sustainability investments can also keep businesses ahead of new government standards, allowing businesses to invest at their own pace and control expenses, while upholding their values.

How can companies build a culture of resilience within their organizations?

Companies can build a culture of supply chain resilience by fostering a proactive mindset that focuses on the importance of early detection and problem-solving throughout the organization. Business leaders can emphasize the importance of employees as front-line assets in identifying supply chain weaknesses and valuable components of the solution — in both the planning and implementation phases. By integrating resilience considerations into training and performance metrics, employees can be empowered to anticipate, adapt to and respond effectively to disruptions, ensuring the long-term success and sustainability of the supply chain.

How can organizations stress-test their supply chains to identify potential weaknesses?

Organizations can stress-test their supply chains through scenario simulation and rigorous evaluations to identify potential weaknesses, often employing external and independent supply chain auditors. This involves identifying potential risks, such as natural disasters, supplier failures or market fluctuations, and assessing the impact on different aspects of the supply chain, such as inventory levels, lead times and customer service. By analyzing the outcome and performance under these potential circumstances, organizations can identify vulnerabilities, bottlenecks and areas for improvement. This process helps organizations proactively address weaknesses, enhance resilience and develop contingency plans to mitigate risks, creating a more resilient supply chain.