Whether a company is acquiring the essential raw materials needed to make its core product, or just buying paper towels for the break room, every business relies on others to provide the materials, supplies, and services they need to operate. Purchasing these goods and services is commonly known as procurement. Armed with efficient procurement strategies, businesses can save money and smooth operations, while hopefully building strong relationships with trusted suppliers. Nevertheless, procurement isn’t without its fair share of challenges.

From supply chain disruptions to quality and compliance issues, procurement hurdles can significantly impact a company’s profitability and competitive edge. But for every difficulty, there are myriad ways for procurement teams to prevail. This article will delve into some of the most common procurement challenges and explore strategies that effectively tackle them head-on.

What Are Procurement Challenges?

Procurement challenges are the obstacles and difficulties that businesses must overcome to acquire the goods and services their operations require, including raw materials and supplies. Challenges can occur at any stage of the procurement process, from choosing the right suppliers to managing the budget, so businesses must take a comprehensive approach when identifying and addressing the top issues.

Overcoming procurement obstacles is an important element for businesses to maintain their competitive advantage, especially during periods of supply shortages and rising costs, because inefficient procurement processes can result in higher costs, lower quality goods and services, administrative and supply chain bottlenecks and missed opportunities for innovation and growth. By proactively planning for procurement challenges, businesses can select and buy goods more efficiently, bolster their bottom line through cost savings and foster stronger supplier relationships. This, in turn, can lead to greater customer satisfaction and increased profitability, while also creating a more resilient and flexible supply chain operation that’s better positioned for long-term success.

Key Takeaways

- Identifying and resolving procurement challenges help businesses increase margins, improve efficiency, build strong supplier relationships, and maintain their competitive advantage.

- Businesses should adopt strategies that support their specific procurement needs, such as improving vendor communication, mitigating supply chain risks, controlling unauthorized spending, or leveraging innovative technology.

- Continually implementing current best practices that address procurement issues helps companies remain flexible in an increasingly complex global market.

13 Procurement Challenges and Strategic Solutions

Businesses face a medley of procurement hurdles that can cut into margins and weaken their ability to quickly and efficiently deliver goods and services to their customers. But by anticipating these challenges and optimizing their procurement processes, companies can minimize or eliminate the impact while reducing costs in the process. Here are 13 common procurement challenges and strategic solutions to overcome them.

1. Ineffective Vendor Communication

A communication breakdown with a vendor can lead to misunderstandings, delayed or incorrect orders, and supply chain disruptions that hamper a business’s ability to produce its goods and services in a timely manner. Poor communication can strain vendor relationships, making it difficult to negotiate favorable terms or resolve issues in the future.

To enhance communication, businesses can establish clear expectations and communication channels with vendors, typically with the help of software platforms and portals that support open collaboration. This collaboration may consist of regular check-ins, defined points of contact, and standardized processes for sharing information and order updates.

2. Vendor Compliance Issues

For a business to continually meet its own standards, it must be sure that their vendors are also complying with contractual obligations, quality standards, and any relevant regulations. If vendor noncompliance leads to production problems or delays, it can leave a company with dissatisfied customers and possibly legal liabilities and reputational damage. It can also result in wasted time and resources spent addressing and rectifying compliance failures through increased quality control checks or costly recalls.

Companies should establish robust onboarding processes to clearly communicate expectations and requirements before placing any orders. After contracts are signed, regular audits and performance evaluations can help businesses identify any compliance gaps early on, before they become major headaches. Additionally, prioritizing vendor relationships, coupled with ongoing internal training to adapt to new procurement trends and standards, can foster a culture of compliance and continuous improvement for both parties.

3. Excessive Expenditure

One of the procurement team’s primary goals is to find the right balance between quality and cost when purchasing supplies and materials. Without proper controls and oversight, procurement costs can escalate, due to excessive spending on orders and storage. This can come from direct factors, including fraudulent or maverick/unauthorized spending, or administrative weaknesses, such as a lack of spend visibility or ineffective negotiation strategies. Recent inflation spikes have made controlling spending even more critical, with 84% of respondents to KPMG’s 2023 Global Procurement survey choosing “inflationary pressure/increase in commodity prices” as one of the top three external challenges.

To curtail procurement costs, businesses should implement—and educate staff on—sound spend management practices, such as explicit purchasing policies, limits, and approval workflows, as well as regular expense audits. These policies can be bolstered by digital tools that help teams analyze spend data and offer market research to identify savings opportunities. Adopting strategic sourcing initiatives and fostering competition among suppliers can help businesses secure more favorable pricing and contract terms.

4. Inaccurate Data Capture

Accurate and timely data helps businesses make decisions based on the current state of operations, rather than on an outdated or distorted view of performance. However, because of complex global supply chains, many businesses struggle to capture and maintain reliable procurement data. According to the KPMG survey, “limited data and insights” was the No. 1 ranked internal challenge, with 54% of respondents listing it as a top-three internal challenge. This data access struggle can be exacerbated by slow and tedious manual processes and siloed business systems that lead to incorrect records, over or under supply ordering, missed deadlines, and poor spend visibility.

Businesses can invest in digital, cloud-based procurement solutions that can automate data capture and provide a centralized data source for authorized users to access as needed. These systems often leverage technologies, including artificial intelligence, to extract data from invoices and other documents while maintaining data management standards. Additionally, many of these systems integrate with other platforms, such as sales, inventory management, and enterprise resource planning systems, to give business leaders a holistic view of procurement and its impact on the organization. This data-driven view helps leaders identify and address inefficiencies to strengthen operations.

5. Inefficiencies From Manual Processes

Manual procurement processes for tasks such as placing individual orders or processing invoices and managing contracts can be time-consuming and error-prone, slowing down and frustrating staff. These inefficiencies can lead to longer order-fulfillment times, delayed payments, cash flow issues, increased employee turnover, and reduced visibility.

To streamline procurement processes, businesses can implement software that automates key aspects of procurement workflows, such as making recurring purchases and automatically approving invoices that fall within normal business parameters. These solutions enable businesses to reduce manual effort, minimize errors and accelerate procurement cycles. Additionally, adopting electronic invoicing and payment processing can help simplify and improve supplier communication by automating these routine tasks to free up staff to focus on more complex problems that demand attention.

6. Underperforming Suppliers

Businesses need reliable suppliers to maintain production. When suppliers consistently underperform, businesses can face missed deadlines, quality issues and shutdowns. But supplier performance is about more than just delivering orders on time. Companies must consider every aspect of the supplier life cycle when assessing performance, including openness to initial negotiation and evaluation, onboarding, risk management and collaborative problem-solving. If suppliers can’t consistently provide high-quality goods and services — and provide evidence of and transparency into that quality — businesses may need to leave them behind for more reliable vendors.

Tracking supplier performance requires first assessing what the business expects from its vendors in order to establish benchmarks. While key performance indicators (KPIs), such as on-time delivery rates and supplier defect rates, can measure aspects of supplier performance in line with objective metrics, it’s up to the business to prioritize and weigh those metrics against costs and create “performance scorecards” for their suppliers. For example, a high-end custom furniture manufacturer may value order precision, whereas a restaurant’s priority may be on-time delivery of perishable goods. However a company weighs these factors, performance monitoring should establish clear metrics to regularly evaluate and compare vendors. By quickly identifying problems, businesses can work with their suppliers to draft improvement plans or, if necessary, transition to alternative suppliers before customers are affected.

7. Impact of Rising Inflation

Inflation—meaning a sustained increase in general prices for goods and services—can make it more difficult for businesses to maintain profit margins as the price of their raw material and other inputs rise. Inflation can be particularly painful for companies that offer long-term contracts or fixed-price agreements to their customers, since they may not be able to adjust prices to compensate for rising costs such as raw material or shipping.

During times of rising prices or economic uncertainty, procurement teams likely need to conduct more frequent market analyses, monitoring pricing trends and adjusting their procurement strategies accordingly. Businesses should also take extra care to explore cost-saving measures with suppliers, such as taking advantage of bulk and early payment discounts. Internal improvements, including reducing waste or optimizing inventory management, can help offset the impact of rising procurement costs. And if a business does have to raise its prices due to rising input costs, it should be transparent with customers about the reasons and try to implement incremental increases to avoid sticker shock that might drive customers to the competition.

8. Supply Chain Disruptions

Supply chain disruptions can come due to natural disasters, war, public health crises, or the failure of a critical supplier in a network. Such disruptions can cause critical material shortages and delays in production and fulfillment, which in turn can give rise to increased costs as businesses scramble to lock in alternative suppliers and place emergency orders. In severe cases, supply chain disruptions can force companies to pause operations, potentially resulting in significant financial losses and reputational damage.

Businesses can prepare for disruptions with a proactive and multifaceted approach that includes developing contingency sourcing plans and diversifying their supplier base to reduce reliance on any single supplier or region. In addition to diversification, companies can work to enhance relationships with existing key suppliers that can help them prepare for unpredictable disruptions more effectively through preferential or at least transparent treatment, and trusted information sharing based on a strong supplier relationship. These contingency plans can help minimize impacts when supply chain disruptions hit.

9. Comprehensive Risk Management

Procurement operations face a wide range of risks, but these risks aren’t necessarily equal for all businesses. Managers and decision-makers must develop a comprehensive risk management strategy that prioritizes their own most pressing dangers. This deliberate approach helps companies anticipate the potential harm the most critical risks can bring, including revenue loss and reputational damage.

To effectively prioritize risks and allocate efforts and resources accordingly, businesses should develop a risk management framework that includes regular assessments, contingency planning, and ongoing KPI monitoring. This assessment typically involves conducting both external supply chain vulnerability assessments and developing an internal culture of risk awareness that encourages cross-functional teams to identify and address nascent risks before they become major problems. For example, if a business’s suppliers are all located in a hurricane zone, diversifying procurement activities by engaging with some suppliers in another geography can help fend off shortage risks during an upcoming storm season.

10. Effective Contract Management

Contracts are the foundation of most procurement relationships, as they outline the terms, conditions and expectations for buyers and suppliers. Managing contracts effectively is often a complex process, especially for businesses with large and diverse supplier networks. Without a strong contract management team, businesses may miss savings opportunities, increase their exposure to risk, and strain their vendor relationships.

Effectively managing contracts often begins with a centralized contract management system that provides visibility into all contracts across the company and helps businesses avoid overlooking any vendor responsibilities. Procurement teams should be trained to use this system to track key contract milestones, such as renewal dates and regular performance assessments. Such systems can also automate time-consuming contract tasks, such as notifying relevant parties when those milestones are reached. Additionally, contract standardization done in collaboration with legal teams can help align contracts with business objectives and comply with pertinent regulations.

11. Talent Acquisition and Development

As procurement becomes more technology- and data-driven, businesses need a diverse and skilled workforce that can implement innovative new strategies and tools to navigate complex supply chains. However, many businesses struggle to recruit and retain top talent, particularly in highly competitive industries and tight labor markets. In fact, in Deloitte’s 2023 Global Chief Procurement Officer survey, only 10% of top-performing procurement leaders answered “completely” when asked whether they believe their teams have the skills and capabilities to deliver their strategy. This talent gap can lead businesses relying on outdated and inefficient methods, potentially causing them to fall behind their competitors.

By prioritizing talent acquisition and development through targeted recruitment campaigns, competitive compensation packages, and ongoing training and professional growth opportunities, businesses can build procurement teams that possess the skills they need to succeed. Giving procurement teams up-to-date- technology to run their operations can help make their work more satisfying, since they’re working more on problem-solving and analysis rather than routine manual tasks. Additionally, fostering a culture of collaboration among the members of the procurement team can encourage employees to share ideas and work together to find new, effective ways to improve operations. Many businesses team up with local communities, such as universities and professional organizations, to develop talent pipelines and internships to maintain a consistent flow of new and qualified talent.

12. Dark Purchasing

Dark purchasing, also known as maverick or rogue spending, includes goods or services purchased outside of standard procurement processes and without proper approvals. This form of uncontrolled spending often stems from unclear or time-consuming purchasing guidelines, giving employees added incentive to work around them, and it can lead to higher costs, inaccurate budgets, and reduced visibility into spend and inventory data. Dark purchasing also undermines efforts to negotiate better volume-discount deals with suppliers.

Companies can restrict dark purchasing by improving spend visibility and control through clear procurement policies and approval procedures. They can also implement technology that makes buying through approved channels efficient and predictable, so people have less incentive to skirt the rules. After creating these policies, businesses should educate employees on the importance of following them and train them on new processes. Such compliance will allow businesses to better track and manage overall spending, improving operations companywide. For example, businesses can use software to enforce purchasing policies, route approvals and monitor spending in real time, automatically flagging potential dark purchases for review. Additionally, regularly analyzing spending and updating protocols can help managers and decision-makers identify areas with high dark-purchasing rates and provide insights into why they keep occurring and how to minimize them.

13. Budget Constraints

Procurement teams are in a constant state of managing competing priorities—secure high-quality materials while spending as little as possible. This can be particularly challenging during times of rising prices, or decreased sales that lead to tighter budgets. Budget constraints tighten can often tighten quickly if business conditions change, and if procurement teams can’t effectively and swiftly manage within new constraints, this can lead to overspending, reduced profitability, inventory imbalances, and strained relationships with business leaders.

Through a strategic and data-driven approach and close collaboration with finance teams, procurement departments can better align their strategies with larger business goals by prioritizing spending on the basis of needs and urgency. These needs will be constantly evolving, and procurement staff must steadfastly monitor and adjust spending patterns throughout the procurement life cycle whenever necessary, often aided by spend analysis tools that can pinpoint over-budget areas. Additionally, exploring alternative sourcing strategies, such as consolidating suppliers or switching to more affordable components or more dependable providers, can reduce costs and help businesses optimize spending for long-term savings. This kind of proactive budget management can demonstrate the strategic value of procurement, while building trust with internal stakeholders and securing the resources needed to maintain production.

Overcome Procurement Challenges With NetSuite

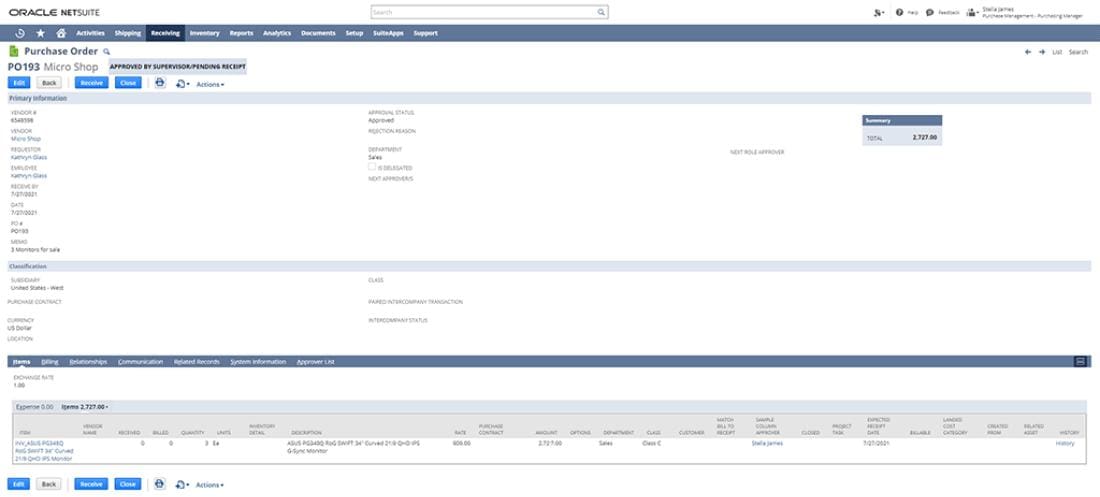

Procurement challenges can look different year to year for a given business, and procurement teams need a comprehensive strategy to monitor the risks and minimize any operational impacts. NetSuite Procurement helps companies streamline their processes, increase their visibility, control costs, and improve their relationships with suppliers. NetSuite’s cloud-based solution enhances procurement operations through automated requisition and purchase order management, increased real-time spend visibility, and robust supplier management tools. With its centralized data management and advanced analytics tools, NetSuite Procurement provides detailed and actionable insights to help decision-makers identify savings opportunities and mitigate the diverse risks faced by today’s businesses.

NetSuite Procurement also offers benefits that drive long-term success, such as automating manual processes and enforcing purchasing policies to reduce the risk of dark purchasing and help ensure compliance with buying guidelines. This cloud-based solution’s workflow management tools also foster better communication and collaboration with business partners and suppliers, leading to improved efficiency and innovation. And the system is customizable and scalable, empowering businesses to remain flexible as their needs and market conditions evolve.

Regardless of a company’s industry or size, procurement challenges can significantly impact a business’s bottom line and its ability to deliver for its customers. By implementing targeted strategies such as by improving vendor communication, controlling spend, enforcing policies, and leveraging technology, businesses can optimize their procurement processes and build a stronger, more resilient supply chain, saving money while they’re at it. As best practices and industry conditions change, businesses must have the strategy and tools to continually adapt to new challenges to remain competitive.

Procurement Challenges FAQs

What are the challenges of procurement?

Procurement challenges vary depending on a business’s size, type and industry, but they commonly include excessive spending, ineffective vendor communication, compliance requirements, and risk management. These challenges can arise from internal inefficiencies and changing business needs, or from external factors, such as market fluctuations, supply chain disruptions, and supplier performance failures.

What are some common weaknesses in procurement?

Common procurement weaknesses include lack of visibility into spend data, time-consuming manual or inefficient processes, poor supplier relationship management, quality control issues, and inadequate risk assessment. These weaknesses can lead to overspending, bottlenecks, and missed innovation and savings opportunities.

What are procurement inefficiencies?

Procurement inefficiencies are processes or practices that waste time, money, or resources when obtaining supplies and materials. Some common examples include delays caused by unnecessary or redundant manual data entry, poor supplier communication, and inadequate performance monitoring.

What is poor procurement?

Poor procurement is any ineffective or suboptimal procurement practice that fails to achieve its goals and deliver value for the business. This can result in high or unpredictable costs, low-quality output, supply chain disruptions, or weak vendor relationships.

What are the constraints of procurement?

The constraints of procurement include budgetary and staffing limitations, timeline pressures, regulatory requirements, and organizational policies. Procurement teams must navigate these constraints to deliver the best value for customers and meet the business’s operational needs.