Keeping shelves stocked and customers happy isn’t as simple as making and following an accurate demand forecast—as difficult as that can be sometimes. Manufacturers must also manage inventory and coordinate with suppliers and distributors to make sure their products are in the right places throughout their supply chains, all while keeping costs under control. That’s where distribution requirements planning (DRP) comes in.

What Is Distribution Requirements Planning (DRP)?

DRP relies on demand forecasts to help companies determine how much stock they need, when they need it, and where it should be in their distribution networks. When done right, it prevents stockouts and overstocks and maintains consistent product availability. But it isn’t foolproof. Supply chain disruptions, inaccurate data, and sudden demand shifts make it difficult to execute distribution requirements plans effectively.

In DRP, demand forecasts feed into plans for ordering, receiving, and distributing the right amount of inventory for manufacturers to produce the finished goods needed to satisfy expected demand. The final step is to distribute those finished goods to retailers, distributors, or warehouses that align with where customer demand is expected to be high, low, or in between. DRP is essential to successful supply chain management because it helps businesses optimize product availability, minimize costs, and increase customer satisfaction.

Successful DRP strategies depend on accurate analysis of inventory levels and requirements, so that companies can calculate replenishment quantities separately for each product and location and order them with sufficient lead time. Time-phased distribution plans, aligned with production and transportation schedules, play a major role in the process. Manufacturers and distributors use DRP to better manage their roles in the supply chain. Retailers have traditionally used DRP to manage their inventory.

Manufacturers also use material requirements planning (MRP) techniques, which helps them make enough goods to meet demand from distributors and customers. Both DRP and MRP are often integrated within an overarching enterprise resource planning (ERP) system.

Key Takeaways

- Distribution requirements planning systems use forecasts to determine how much product a company should produce—and when and where it’s needed—to meet expected customer demand.

- By aligning production, inventory, and distribution with customer demand, DRP helps businesses better manage their costs.

- DRP standardizes and streamlines processes from supplier to store, providing enhanced supply chain visibility.

- Real-time data on orders, inventory, and logistics helps companies to make more informed, proactive decisions.

- DRP relies on accurate data and predictable conditions, but those are never guaranteed. External factors, such as supplier delays, transportation constraints, and unexpected demand shifts, can throw even the best plans off course.

Distribution Requirements Planning Explained

Effective DRP usually requires manufacturers, suppliers, distributors, and retailers to work together to optimize inventory availability throughout their joint networks. There are two discrete methods companies can use, though, in practice, most distribution plans combine aspects of both.

- Push method: With this approach, manufacturers analyze forecasted demand to decide how much inventory to produce and where to ship it in their distribution networks. Companies “push” products downstream from factories to distribution centers or retail locations, without waiting for actual customer orders. By producing a large volume of product at one time, businesses can take advantage of economies of scale to achieve cost savings. But if demand unexpectedly changes, they risk overstocking or understocking at specific locations; either scenario can eat into those savings.

- Pull method: This method minimizes that risk by only distributing products based on actual customer orders or other demand signals. Retailers and distributors monitor sales data and stock levels and “pull” products from their upstream suppliers when they’re needed. The pull method can cause other problems at scale, however. For example, local managers are often the people who place distribution orders. If one location experiences a spike in demand, and the manager places a new bulk order in response, it might not be an issue. But if that happens across all locations, the distributor will get flooded with orders—and might not be able to fulfill them all. This is called the bullwhip effect.

The best DRP strategies combine the push and pull methods to achieve maximum levels of efficiency and customer service. A manufacturer may use push strategies in the early phase of production by ordering raw materials and components in bulk, making standard parts and semifinished goods, and shipping these to regional distribution centers. It would then switch to pull strategies by doing final assembly and/or customization in response to customer orders. This hybrid approach is common in the furniture industry, for example; and apparel companies may use push strategies for basic clothing and pull strategies for trendy or seasonal items. Hybrid approaches customarily require highly accurate forecasts and optimized back-end processes.

How Does DRP Work?

DRP systems start by using forecasts to determine how much product a company needs to meet expected demand, as well as when and where that product is needed. Then, inventory management practices are used to analyze current inventory levels, safety stock requirements, and replenishment lead times. Combining all this information allows manufacturers to create plans for distributing the right amount of goods to the right locations at the right time.

Using Demand Forecasts

Demand planning isn’t part of DRP—it’s a precursor—but its forecasts play a major role in the process. They predict future demand for a product by evaluating several factors, including:

- Company decisions: pricing, advertising, access to customers

- Customer decisions: loyalty, reviews, referrals

- Macro trends: seasonality, global events, cultural shifts

- One-off events: placement on a popular TV show, a viral social media moment

Accurate demand forecasts equip DRP systems to optimize the distribution and replenishment of inventory, helping companies build stronger relationships with their distributors, retailers, and customers.

Inventory Management

One key goal of inventory management is to maintain an up-to-date view of stock levels throughout the supply chain by tracking raw materials, components, works in process, and finished goods from purchase to sale. To do this, participants in the distribution network, from manufacturers to warehouse managers to retailers, take inventory counts and analyze sales data. They then use this information to calculate the right safety stock levels on a per-product and per-location basis—and determine how much lead time they’d need to reorder those goods to meet anticipated demand.

Among the common challenges that companies encounter with inventory management are inaccurate counts and inefficient processes, which can cause stockouts and order delays, and poor utilization of warehouse space, which can eat into cost savings.

DRP systems help companies address these issues by automating much of the process. They can automatically monitor stock levels, issue low-stock notifications, and use analytics powered by artificial intelligence to more accurately determine optimal safety stock levels, overall inventory levels, and product reorder dates. Through proper inventory management, businesses put themselves in position to fulfill customer orders quickly, yet minimize excess stock. This reduces storage costs and product waste and improves cash flow.

Inventory management also involves bigger-picture tasks, such as evaluating and optimizing warehouse layouts and capacity, monitoring turnover rates, and working with suppliers to streamline the reordering and delivery processes. DRP technology can assist with much of this work, as well.

Distribution and Replenishment Planning

Armed with accurate demand forecasts and updated inventory insights, companies are now ready to create distribution and replenishment plans. To do so, they must first calculate their economic order quantities (EOQs), using a formula that considers demand, setup costs, and holding costs to determine the right amount of product to order.

Those quantities then form the basis of distribution plans and time-phased replenishment schedules that detail when, where, and how specific amounts of goods will move throughout the supply chain, progressing from suppliers and manufacturers to distributors and retailers. These plans span production schedules to specific transportation routes, with the goal of aligning all involved parties in order to reduce costs and ensure timely deliveries.

DRP software streamlines much of this process. It can automatically calculate EOQs, create replenishment schedules, and produce distribution plans. Once these schedules and plans are finalized, they can be fed into a company’s order management system.

Benefits of DRP

DRP helps businesses deliver products quickly, accurately, and consistently, resulting in happier customers. It provides up-to-date demand forecasts and real-time inventory visibility, enabling smarter decisions about procurement and order fulfillment—decisions that can reduce costs and create new growth opportunities. By reducing or eliminating excess inventory and stockouts, companies that use DRP can keep their supply chain operations running smoothly and profitably.

- Improved cost management: DRP lets manufacturers take greater control of their costs by aligning production and inventory with customer demand. They spend less on buying, transporting, and storing stock that they don’t need, and they can more efficiently procure the goods that they know will sell.

- Better customer experience: Demand forecasting, inventory management, and distribution replenishment combine to help companies maintain product availability, avoid delays, and deliver the right products on time. By consistently making products accessible when and where they’re needed, companies provide a better customer experience and build brand loyalty.

- Improved visibility: DRP standardizes and integrates manufacturer, distributor, and retail data and processes, providing enhanced supply chain visibility. Real-time data on orders, inventory, and logistics empowers companies to make more informed, proactive decisions so they can meet customer demand, avoid bottlenecks, and otherwise do business more efficiently.

- Reduced stockouts and overstocks: Enhanced inventory management, based on accurate forecasts, lowers the risk of stockouts and overstocks. Having the right amount of stock on hand helps businesses retain customers, eliminate waste, and avoid excess inventory write-offs.

- Enhanced demand management: DRP enables companies to use their forecasts in multiple beneficial ways. With accurate projections in hand, they can take proactive measures to influence customers and build demand to achieve their growth goals. Demand management strategies coordinate operational and marketing teams so they can generate and capture demand, leading to increased sales.

Challenges of DRP

Although DRP bestows significant benefits across the supply chain, it’s not a magic pill. DRP relies on accurate data and predictable conditions, but those are never guaranteed. Plus, external factors, such as supplier delays, transportation constraints, and unexpected demand shifts, can throw even the best plans off-kilter. To overcome these and other DRP challenges, businesses must maintain careful oversight of their systems and remain flexible.

- Distribution complexity: Technology can process and analyze data in an instant, but other supply chain processes are constrained by the limitations of the physical world—and DRP can’t solve those problems. The system might immediately notice an item is running low, but it still takes time to deliver new stock across dispersed locations. Outside factors, such as adverse weather, other natural events, and geopolitical turmoil, can complicate those efforts.

- Supplier delays: Global supply chain pressures can make it difficult for manufacturers to procure the materials they need on time. Even in times of relative stability, the fact remains that manufacturers have little direct control over the third parties that are responsible for much of their supply chains. Suppliers’ capacity constraints, quality control, communication gaps, and even simple transportation mishaps can all contribute to unexpected delays.

- Data inaccuracy: Manufacturers’ DRP approaches normally rely on data from distributors and retailers, as well as their own and their suppliers’. If there are errors, they often are not discovered until it’s too late—after the downstream companies have placed orders based on that incorrect information and/or the manufacturer has begun to act on the data. Plus, inaccuracies across multiple stores will have a compounding effect; what seems like a minor blip in one store could actually be a serious problem if it’s happening networkwide.

- Unpredicted demand shifts: DRP systems that don’t work in real time can’t keep up with sudden changes in customer demand. Say a system runs a batch job once a week, on Sunday night. If a product is featured on a Monday morning news show and demand spikes, that leaves six full days where the DRP system doesn’t have the information it needs to react effectively.

DRP Table

Many manufacturers use DRP tables to provide a unified view of their inventory, plus details on when to reorder stock and plan production. The example DRP table below shows a hypothetical furniture manufacturer’s simplified four-week plan for one product that it distributes through two different distribution centers. It includes location-specific information for expected unit sales each week (“Forecasted demand”); expected inventory to start each week (“Projected on hand”); planned unit deliveries to the center (“Scheduled receipts”); additional orders needed to meet demand (“Planned order receipts”); and when the order should be placed for it to arrive on time (“Planned order release”). To learn how to read the table, start with Week 1’s projected on hand inventory for Distribution Center 1 (DC1), subtract forecasted demand, and then add scheduled receipts to arrive at the projected inventory for Week 2 (150 – 100 = 50; + 200 = 250). Apply the same math for each subsequent week.

The table shows, for example, that DC1, which is experiencing average demand of 105 units per week, needs an additional 200 units in Week 4 to maintain its standard buffer stock level of two to three weeks’ worth of stock in future weeks. The additional units needed by both distribution centers is 350 units, which is the number of extra units the Manufacturing Plant will produce during Week 3.

A DRP table can be as simple as a spreadsheet that a company manually updates at regular intervals, or it can be an automated, real-time dashboard that’s part of a broader ERP system.

DRP Table for Dining Chair Model "A"

| Week 1 | Week 2 | Week 3 | Week 4 | |

|---|---|---|---|---|

| Distribution Center 1 | ||||

| Forecasted demand | 100 | 120 | 90 | 110 |

| Projected on hand | 150 | 250 | 130 | 240 |

| Scheduled receipts | 200 | 0 | 200 | 0 |

| Planned order receipts | 0 | 0 | 0 | 200 |

| Planned order release | 0 | 0 | 200 | 0 |

| Distribution Center 2 | ||||

| Forecasted demand | 80 | 70 | 100 | 90 |

| Projected on hand | 100 | 180 | 80 | 140 |

| Scheduled receipts | 150 | 0 | 150 | 0 |

| Planned order receipts | 0 | 0 | 0 | 150 |

| Planned order release | 0 | 0 | 150 | 0 |

| Manufacturing Plant | ||||

| Gross requirements | 0 | 0 | 350 | 0 |

| Projected on hand | 400 | 400 | 50 | 350 |

| Planned production | 0 | 0 | 300 | 0 |

Distribution Requirements Planning (DRP) vs. Material Requirements Planning (MRP)

DRP and MRP are both processes for optimizing supply chain activity to meet customer demand. DRP helps businesses efficiently move finished or semifinished products through the distribution side of the supply chain, whereas manufacturers use MRP to guide how they procure materials and assemble products.

MRP determines the raw materials and other supplies that will be needed and sets dates by which finished products must be assembled. By providing these and other insights into supply and demand, it helps manufacturers refine their production schedules and improve the timeliness of material deliveries. Without the planning support of MRP, manufacturers may find themselves unable to meet demand, because they won’t be able to procure the raw materials they need, resulting in lost sales or canceled contracts. The chances of incurring additional production delays also increase. Poor planning can also lead manufacturers to overestimate demand, resulting in excess inventory and increased costs.

By implementing MRP, manufacturers reduce their supply chain complexity and improve production yield.

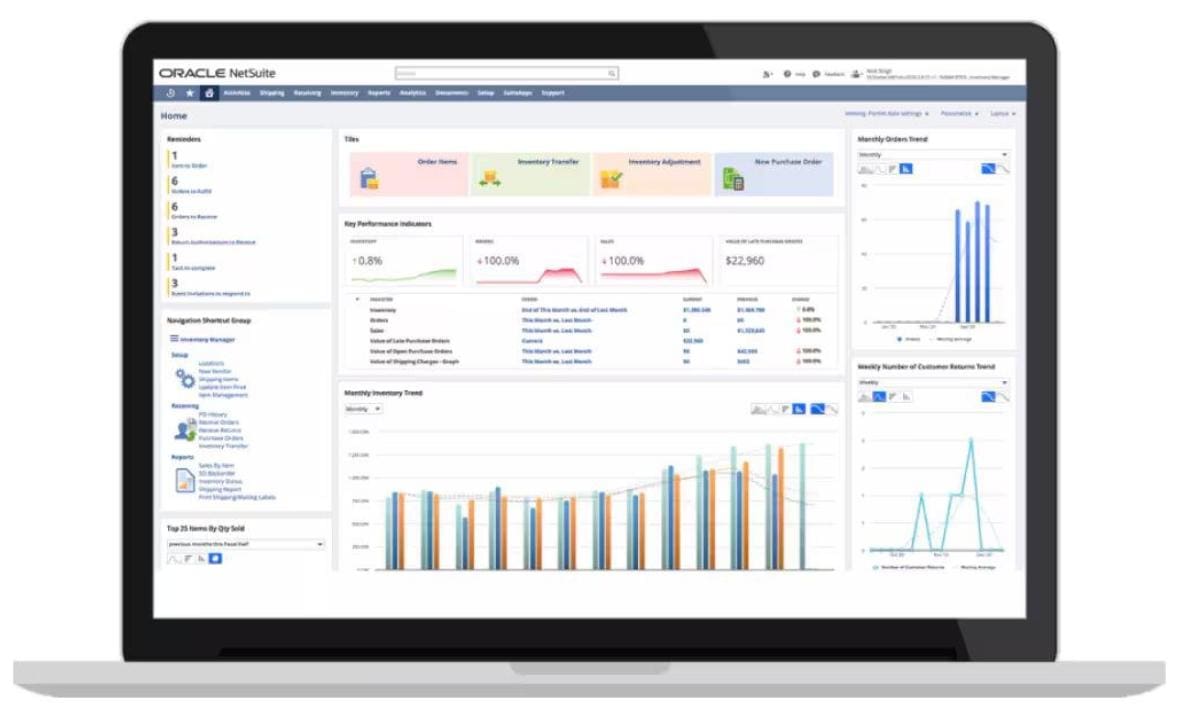

ERP With DRP Capabilities: The Best of Both Worlds

Retailers, distributors, and manufacturers often find themselves using multiple disconnected systems to manage their operations. But that’s a setup ripe for errors, inefficiencies, and higher costs. NetSuite’s ERP for manufacturing provides a unified, cloud-based platform for planning, coordinating, and controlling manufacturing supply chains. It lets manufacturers automate ordering, optimize logistics, and strike the right balance between supply and demand. Companies throughout the supply chain and across industries—from medical devices to consumer packaged goods—rely on NetSuite to streamline operations, provide better customer service, and ultimately grow their businesses.

NetSuite Manufacturing ERP

Distribution requirements planning helps ensure sufficient product availability at all the locations where that product is in demand, while avoiding overstocks. It aligns supply chain operations with customer demand, reducing costs and improving efficiency. DRP can be conducted manually, but automated processes encompassing data from several integrated systems—such as demand forecasting, inventory management, and distribution planning—can multiply DRP’s potential benefits. Embracing DRP can better equip companies to deliver prompt, quality products and services—and that’s what customers demand most of all.

Distribution Requirements Planning FAQs

What is the distribution requirements planning process?

The distribution requirements planning process is how a company determines the right amount of goods it needs to meet demand at each location in its distribution and retail network. It involves demand forecast analysis, inventory and order calculation, and logistics optimization.

When should distribution requirements planning be used?

Businesses use distribution requirements planning to optimize inventory and streamline ordering. By doing so, they improve their cost management, enhance the customer experience, achieve greater supply chain visibility, and reduce instances of stockouts and overstocks. DRP is especially important in industries where supply chains are complex, or where demand regularly fluctuates.

What is the difference between DRP and ERP?

Distribution requirements planning (DRP) software is specialized; it focuses on ordering and receiving the right amount of goods needed to meet demand. Enterprise resource planning (ERP) software is more broadly used for planning and managing virtually all business processes, including accounting, finance, manufacturing, project management, customer relationship management, procurement, and supply chain management. DRP can be a subset of ERP.