Value chain and supply chain experts aside, most business professionals remain bewildered about the similarities and differences between these two key disciplines. Why? Because virtually all the available explanations fail to state what’s obvious to the experts: All of the supply chain is inside the value chain. The crucial difference, it turns out, is point of view. The company is the protagonist of its supply chain story, which is all about obtaining what’s needed to produce goods and services and deliver them to the customer. But the customer is the protagonist in the value chain story, because value only happens when the goods or services are in customers’ hands.

The two disciplines are distinct from each other in their workflows, but they both ultimately serve the common goal of creating a strong company with good profitability.

What’s the Difference Between Value Chain and Supply Chain?

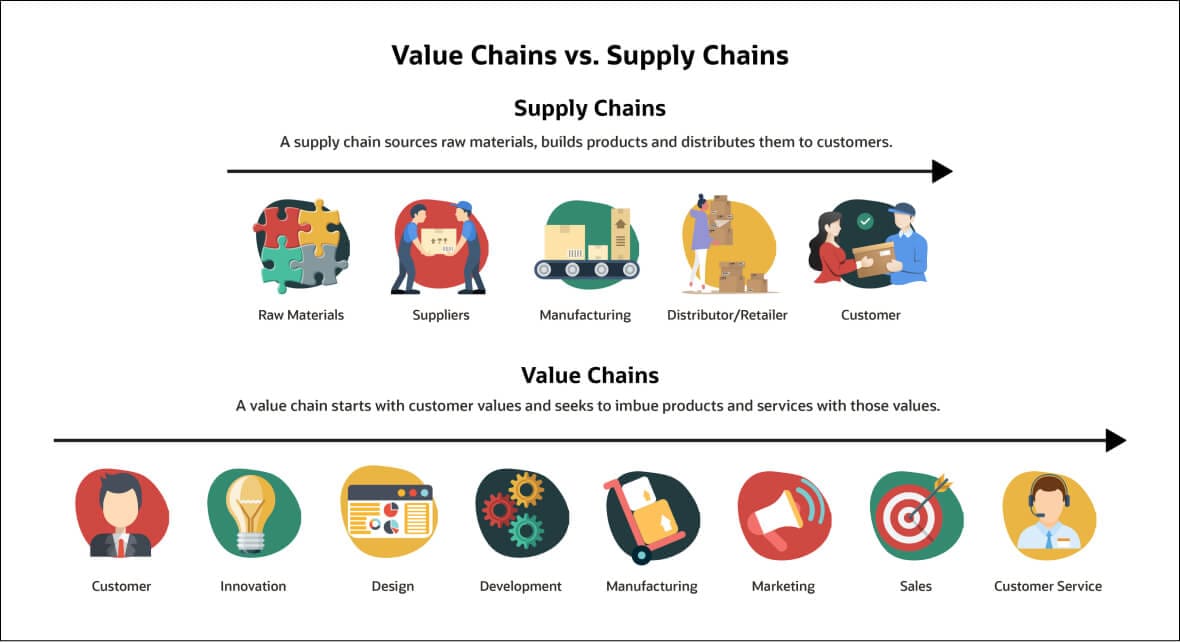

The main difference between a value chain and a supply chain is that the supply chain deals with building the product and getting it to the consumer, while the value chain looks for ways to enhance the product’s value as it moves along that supply chain. The performance of any company depends a great deal on the success of its supply chain: Is it cost-effective, fast enough and reliable enough to manufacture quality products and keep them flowing out to customers, generating revenue and throwing off profit? But business performance depends just as much on the value that customers perceive from those products and services.

Consider the difference in perceived value between the 2022 editions of the BMW X3 and Ford Escape Titanium. They have equivalent horsepower (248 and 250, respectively), passenger volume and cargo volume, and the Ford’s EPA mileage is slightly better (26 vs. 24 MPG, combined city and highway). Yet the BMW gets a 20% price premium — for starters. Since the companies’ options offerings are so different (the Escape price bundles in virtually all available options while the X3 does not), the X3’s top price is 72% higher than the Escape’s, according to Consumer Reports. X3 buyers clearly place a higher value on their purchase than Escape buyers. Much of the difference can be attributed to value-chain thinking, from the two companies’ choices to spend (or not) on the quality of interior surfaces to extra efforts aimed at eliminating cabin noise to market positioning.

The value chain, first articulated by Harvard business professor Michael Porter in his 1985 book “Competitive Advantage: Creating and Sustaining Superior Performance,” is the lens through which companies figure out how to produce products that offer customers greater value than the intrinsic job they do. While a digital supply chain integrates all of a company’s activities surrounding the production and delivery of its products — from sourcing raw materials to transporting them to factories to manufacturing and distributing the products — a value chain analyzes these supply chain activities in the context of customer requirements and looks for opportunities to add value to the products and, in turn, the business as a whole. Innovation, visibility, research and development, design, marketing, sales and customer service are the key aspects of a value chain.

Here’s where the two disciplines intersect: Once the value chain team identifies how to add customer value to a product, it’s usually, though not always, the supply chain that makes it happen. “Usually,” because product marketing and brand building can also create customer value, and those are not considered part of the supply chain.

Key Takeaways

- Value chains can increase profitability for a company by identifying ways to add characteristics that customers would appreciate, such as improved product quality or new product features.

- The supply chain focuses on logistics and production and ends with the customer, whereas the value chain starts with the customer in mind and seeks to increase value as products move through the supply chain.

- A robust customer service implementation can enhance product value and create a competitive advantage for the business.

Key Differences

“Supply chain” and “value chain” are terms that often may be used interchangeably, but there are quite a few differences that stand out between the two.

Definition:

A supply chain is mostly physical. It’s a set of linked companies and individuals that produce a product or a service. In the case of manufactured products, supply chains involve obtaining raw materials and taking the steps necessary to transform them into finished goods and deliver them to the customer. Value chains focus first on what a customer wants; using that as a starting point, a value chain analysis finds ways to add value to the product throughout the supply chain in the form of qualities or functions that customers would prize.

Process:

Supply chains are considered to be operational management processes and are mostly logistical. Supply chain thinking is all about how to accomplish manufacturing and distribution tasks efficiently and at low cost. Value chains are seen as business management processes and are mostly analytical. Value chain processes are about gathering information to discover what customers value and figuring out how to imbue the product with those qualities.

Activities:

This is where the differences between supply chains and value chains become clear, because value chain activities encompass a broader set of business functions. This is especially noticeable when it comes to interaction with customers. Supply chains are all about getting physical things transported and manufactured cheaply, quickly and correctly, but value chain activities can also include advertising to drive demand for products and market research activities to solicit feedback from customers (e.g., surveys) to make sure the business is actually delivering the value it believes it is. Value chains also include innovation, design and product development activities. Beyond those primary activities, Porter’s value chain model defines most other business operations as “supporting activities,” including human resources, procurement, and technology.

Order:

Supply chains are about production, so supply chain thinking is often linear — they’re called assembly “lines” for a reason. But value chain thinking might affect any supply chain step, in any order, based on customer feedback. For example, if customers don’t like plastic straws anymore, a beverage maker may need to start sourcing paper straws to stick on the side of its juice boxes. Once that decision is made, there may be knock-on effects, such as economies of scale or order-volume discounts available by sourcing the boxes themselves from the same suppliers as the straws.

Objective:

The main objective of a supply chain is to continually improve the efficiency and reliability of a production process. The main objective of a value chain is to enhance the customer experience — which creates competitive advantage. Consider product packaging. Supply chain thinking leads to using the least expensive packaging that can be made flawlessly while protecting the product. A value chain mentality should lead to that plus a great unboxing experience. There’s a big difference between a customer cutting themselves on plastic clamshell packaging and being so delighted by their packaging experience that they post an unboxing video of their purchase to YouTube.

Steps:

Value chains have more steps than supply chains. With supply chains, you’re figuring out how to best achieve known physical results. With value chain thinking, you’re questioning whether different physical results may be desirable as well. Consider vanilla ice cream. Supply chain thinking starts with “What’s the cheapest and most reliable way to get vanilla that meets our criteria?” Value chain thinking starts before that. It might, for example, ask questions such as “How much do our customers value Tahitian vanilla? And would the extra expense be counterbalanced by how much happier they’d be and how much more they’d be willing to pay for ice cream made with it?” If the answers are “a lot” and “yes,” respectively, that changes the relevant supply chain problem from “Get vanilla” to “Get Tahitian vanilla.”

Using Value Chain Tenets in the Supply Chain

How can businesses use value chain thinking in their supply chains to create value for customers that goes beyond the costs of the goods or services they provide? Here are the three crucial areas where value chains intersect supply chains, and the kinds of value-creating opportunities that may arise in each.

Inbound Logistics:

This first area involves receiving, storing, and managing the incoming resources needed for the product. The obvious value is ensuring that the right amount of materials are on hand and in proper condition to produce the items, thus minimizing the time it takes to manufacture them. Using value chain thinking, a business might induce its suppliers to add value by managing inventory in a way that enables just-in-time delivery, reducing the company’s own inventory management burden.

Manufacturing and Production:

Adding value in this area can include finding ways to reduce costs without impinging on the quality of the final product. That may mean developing software or machinery to speed up the process, improving quality control to reduce unsellable merchandise or finding a supplier that charges a lower price. Value chain thinking might also lead to a production process that allows for bespoke or customized versions of the product.

Outbound Logistics:

Now it’s time to get these products to customers, be it directly from existing orders or from the shelves of retail stores. Such activities involve storage, collection, and distribution of goods. A company could add value by delivering directly to a customer’s business instead of a store, or by removing an older item when a new one is delivered. Mattress companies, for example, cart away the old mattress when making a delivery, as do most appliance sellers.

Enhance Value at All Stages of Your Supply Chain With NetSuite

From demand planning and inventory management to quality management and advanced manufacturing, the many modules in NetSuite Supply Chain Management give companies a detailed, end-to-end view of their supply chains — making it easier to implement the value-adding opportunities that value-chain thinking reveals. The modules help companies monitor and analyze how materials come in from suppliers, get produced and then are ultimately shipped out and distributed to customers. Making sure the workflow runs smoothly and efficiently benefits the company across the board, bringing value of its own to your supply chain.

Beyond empowering value chain thinking within the supply chain, NetSuite’s supply chain management software can help resolve many of the day-to-day challenges businesses face. Its forecasting tools can minimize stockouts and factor in lead times to shorten or eliminate production delays. It also offers real-time recording and monitoring of production data, financial reporting, inventory and outstanding orders to make sure all phases of the supply chain operate with the same set of data. With NetSuite’s assortment of supply chain modules, businesses can connect all parts of their production workflow from start to finish.

Supply chains focus on logistical and manufacturing efficiency, while value chains prioritize the creation of customer value. Combining both disciplines, so that value chain activities and their resulting outputs enable the supply chain to inject greater customer value into products and services, can increase a company’s profitability in multiple ways, build brand credibility and, ultimately, provide competitive advantage.

Value Chain vs. Supply Chain FAQs

How do I leverage VCM and SCM to grow my business?

The relationship between a company’s value chain and supply chain can help the business grow. The role of value chain management (VCM) is to identify ways to add more customer value to the company’s products and services, whether that value comes in the form of new product features, higher quality than that offered by competitors or better after-sales support. The point where VCM and supply chain management (SCM) activities intersect — namely, in inbound logistics, operations and outbound logistics — creates the opportunity to leverage the value chain thinking and outputs that imbue the company’s products with greater customer value. And greater customer value can lead to faster business growth.

What are value chain products?

Value chain products are, simply, products. The value chain is a business management concept focused on creating more customer value, and it can be applied to the production of any product or service.

What is value chain example?

Every business has a value chain, whether its managers deliberately use value chain thinking. To illustrate the value chain discipline in action, consider a luxury carmaker whose research indicates that its customers highly prize a quiet interior cabin, adjustable lumbar support in both driver and passenger seats, sufficient power for quick passing on the highway, good handling, and a smooth ride. Producing a vehicle with those characteristics presents design challenges, materials challenges, manufacturing challenges and, beyond all those, pure cost challenges — for example, the cost of adding a lumbar adjustment to the passenger seat, a rare feature in any car, may be hard to justify. But if the carmaker’s research is correct, the resulting vehicle would create so much more perceived value than found in competitors’ autos that it would command a pricing premium that makes up for the added cost and effort, and then some.

Is the supply chain part of the value chain?

Yes. The entirety of a company’s supply chain is considered part of the value chain. In addition, the value chain includes activities beyond those of the inbound logistics, operations, and outbound logistics of the supply chain. Those additional activities include both primary ones, such as marketing and sales and customer service, and supporting activities, such as HR, procurement, technology, and company infrastructure.

What is supply chain and value chain?

A supply chain consists of the group of people, vendors, materials, and activities involved in the creation, production, and distribution of a product. A value chain looks at all the steps involved in bringing a product from the ideation phase to sellable item, and it seeks ways to bolster the value to the customer. Typically, that can be done by decreasing production costs or boosting quality and credibility of the product to create more of a feeling of need for the goods or services.