Supplier relationship management has assumed rising status as a best practice amid recurring supply chain disruptions, digital transformation, volatile market trends and other modern realities of running a business. Finding the right vendors sets the stage for effective supplier relationship management.

Procurement professionals have little time to spare for keeping suppliers in line with their expectations for quality, reliability and reasonable pricing. Yet, they’ve got a lot on the line, both in the direct procurement of raw materials, components and wholesale goods and in the indirect procurement of the goods and services needed to run their businesses. For one thing, top management has turned its focus to supply chain performance as a strategic priority and competitive differentiator. For another, the continuity of today’s digitally transformed business depends on suppliers of cloud-based applications and services.

This article explains how to find the best suppliers for the job and why it’s important to get off on the right foot when managing vendor relationships.

How to Find the Right Suppliers

In procurement, finding the right suppliers is job No. 1. Its importance is compounded by the fact that companies today need to engage more suppliers than ever, building their supply chain’s resilience by keeping alternative vendors on deck.

This proliferation of supplier relationships naturally makes the job more complicated. Yet, many small and midsize businesses (SMBs) don’t have full-scale procurement teams with formal policies in place to handle it the way larger companies do. SMBs may rely on only one or a few people to procure everything from a cloud service for payroll to a bulk shipment of widgets for the production line. To step up, SMBs need supplier selection processes that are watertight, documented and repeatable. As in any business endeavor, personal connections and good business sense can contribute in a big way to finding the right supplier. But vendor selection has to be approached as a science, as well as an art.

Procurement professionals should parse through industry directories; read reviews; keep up-to-the-minute databases; employ advanced software, such as artificial intelligence (AI); and then review scorecards and graphic dashboards that visually weigh the relative pluses and minuses of each available vendor. Ideally, supplier assessments should be conducted within an automated, integrated workflow, instead of relying on a manual collection of data from disparate forms, spreadsheets and systems. Vendor relationship management software can help companies make an informed choice and then maintain a close engagement.

To find the right supplier, a selection process should analyze the 14 traits listed below, covering everything from cost and compliance to communications and customer service. Note that this list can also provide a framework for incorporating service level agreements (SLAs) into contracts with winning bidders.

Key Takeaways

- Supplier relationship management has taken center stage amid volatile market trends.

- First and foremost, procurement professionals need to find the right suppliers and then manage those relationships closely.

- Digital tools, such as vendor relationship management systems, facilitate this increasingly complex challenge.

The Importance of Finding Reliable Suppliers

Any procurement professional can recite a litany of ways that vendors have failed them: faulty goods, missed delivery dates, service outages, price shocks, supplier bankruptcies, data breaches, unethical behavior, to name a few.

Incidents like these undermine fundamental procurement priorities, such as reliability, quality and cost control. At a higher level, these failures can depress sales, disrupt operations, harm a business’s brand reputation and dim its prospects for profitability and growth. That’s why procurement professionals need, first and foremost, to find the right vendor for every requirement and then manage supplier relationships closely. Notably, supplier evaluations aren’t one-and-done processes; they need to be refreshed periodically across current suppliers and competitors that might replace them.

14 Key Characteristics to Look for in a Supplier

Supplier risk represents a very real and ongoing concern that requires strategic analysis and proactive management. On the other hand, suppliers can become loyal partners in elevating their customers’ businesses, and an effective supplier selection process can help foster this potential upside.

A request for proposals (RFP) is one of the most common tools to help find the right supplier. Other bidding processes may be more or less formal, depending on variables like an existing relationship with a supplier. In a typical selection process, an RFP might be issued to a prequalified group of potential suppliers, triggering competitive bidding. If properly written, an RFP will surface both sought-after characteristics and potential risks, as vendors respond to a buyer’s requirements, answer explicit questions about their abilities and provide evidence to support their responses.

An RFP represents just one part of a larger toolkit. As described later in this article, procurement professionals take a range of deliberate steps to discern a potential supplier’s ability to deliver on quality, price, regulatory compliance and other must-haves. These steps include:

- Checking references

- Requesting samples

- Signing up for service or software trials

- Conducting competitive benchmarking

- Inspecting facilities

Altogether, the vendor selection process should rate candidates on the following 14 characteristics.

-

Quality

A vendor’s ability to deliver high-quality products or services relies on particular attributes, such as expertise, experience and operational reliance on quality-control systems. Buyers can check out a supplier’s certifications for quality assurance programs, issued by industry associations or the International Organization for Standardization. Industry awards, online reviews and testimonials on a supplier’s website may also reflect on quality.

But before evaluating a bidder’s commitment to quality, a buyer needs to define what quality means in terms of performance, features, durability, service uptime and other measures. Procurement professionals should communicate these specific metrics to potential suppliers and apply them in the selection process. Otherwise, ambiguities could muddy the process and eventually lead to substandard goods, shoddy services, canceled orders, disrupted operations, lost revenue or reputational damage.

-

Cost

In procurement, price isn’t synonymous with cost, but a cost-effective procurement strategy combined with a competitive bidding process can deliver savings on both. When it comes to pricing, contract details, such as order quantities and vendor payment terms, can be used as levers to negotiate discounts. Beyond the price, establishing the total cost requires considering transportation, storage and other factors before selecting a vendor.

Generally, quality shouldn’t be sacrificed in favor of price. Nor should a company take on too much inventory to get volume discounts, only to tie up capital, drive up storage costs or risk overstock losses. Rather, a cost-effective strategy aims to find the right supplier of a product or service in the right quantity and quality for the best possible price.

Yet, even the most cost-effective procurement strategy can be undermined within a company, due to ad hoc, unmanaged spending by various subsidiaries, departments and staff members. SMBs without bona fide procurement teams and established policies may need to start from scratch, assessing current spending across all contracts and services within the company. Then, using supplier management software integrated into other business systems, SMBs can channel departmental purchasing to authorized suppliers with prenegotiated contracts to more effectively manage spending.

Bottom line: Companies with highly effective procurement practices operate at 21% lower cost than their peers, according to The Hackett Group, a market research and consulting firm.

-

Delivery

Procurement professionals should use key performance indicators (KPIs) to assess a supplier’s ability to deliver reliably, accurately, on time and even in an emergency. Important KPIs include:

- Supplier lead time: Knowing and relying on a consistent supplier lead time enables efficient production and inventory scheduling, versus costly production stoppages and inventory stockouts.

- On-time delivery rate: Late deliveries from suppliers can delay a company’s shipments to its end customers, risking customer dissatisfaction and canceled orders.

- Early delivery rate: This may sound like a plus, but early deliveries can actually disrupt internal procedures and inventory management.

- Fulfillment accuracy: Shortfalls between what’s ordered and what’s delivered may disrupt production; on the other hand, overages can create inventory cost and management issues.

- Supplier availability: Issues inevitably come up, and companies need to know they can rely on expedited handling of last-minute orders.

- Ease of returns: Suppliers should have reverse logistics in place, along with policies governing the return of damaged, defective and unwanted goods.

- Service uptime: Services procured to support vital business processes need to be delivered without unplanned downtime.

Collecting data like this during an RFP process provides a starting point. Next comes benchmarking against other suppliers in the same industry. Once companies choose a vendor, they should monitor KPIs on an ongoing basis as part of supplier relationship management.

-

Production Capacity and Performance

Especially amid a global labor shortage, it’s important to query potential suppliers on their current production capacity and performance — and how they would overcome future obstacles to maintain a steady output. Buyers should ask about planning for downtime, human errors, degradation of quality and drivers of costs. Past experience catering to similar companies can also indicate a bidder’s ability to handle requirements specific to a buyer’s industry.

Again, the first step is to know thyself. Procurement professionals need to establish minimum and maximum expectations for production output, reliability and quality, and communicate these to bidders. Expectations should be prioritized and based on various aspects of a buyer’s business, including:

- Current demand

- Projected demand

- Inventory

- Safety stock policies

- Contractual obligations

- Quality standards

- Demand variability

-

Financial Stability

The extent of financial concern about a vendor isn’t limited to the worst-case scenario — which would be that the vendor is here today and gone tomorrow. A financially struggling supplier that still has its doors open can begin to miss deadlines, cut quality or hike prices. So, it’s best to assess financial stability before getting into a supplier relationship.

Publicly available data can help, such as credit reports and financial statements for companies traded on the stock exchange. Buyers can also consult specialized online databases and apps to spot indications of financial instability. These platforms help buyers access and compare financials, and they also provide alerts for changes in such metrics as cash flow. Industry news and reports may provide additional insights, as can online peer reviews that may reflect on payment practices within a vendor’s supply chain. Onboarding alternative suppliers as backups, meanwhile, can lower the risk of significant harm from a single supplier’s financial instability.

-

Customer Service

An important part of supplier relationship management is assessing a potential vendor’s customer service infrastructure, in terms of the size of the customer service team, its training and the systems it uses to keep communications channels open. Checking customer testimonials and reviews can reveal how well or poorly these all work in practice.

Buyers must detail their customer service requirements during the bidding process, including the list of communications protocols discussed in the section below. Treating customer service as a two-way street can enhance collaboration. Sometimes, what might be a meaningful product improvement to a buyer could be a simple change for a supplier to make — but not if they don’t know about it.

-

Communication

Communications protocols lay the groundwork for good customer service and supply chain visibility. Suppliers must be prepared to meet clear expectations about when, why and how to communicate with buyers. Buyers should set those expectations — and test a vendor’s openness and ability to meet them — during the supplier selection process. Depending on the nature and significance of the relationship, communications protocols could include:

- Preferred channels of communication, such as collaboration platforms, vendor relationship management software and supply chain management systems

- Regular reports, including specific invoice data, general monthly reports on KPIs and inspection reports

- Response times, including for emergencies

- Escalation protocols beyond the initial point of contact

- Triggers, such as shipment delays, service downtime or pricing changes

- Data security and privacy

- Documentation, such as recordings of discussions for future reference

-

Compliance

A company has to put a lot of faith in outside suppliers of goods and services. Its business continuity, regulatory/legal compliance and brand reputation could all take a hit from a supply chain breakdown or service disruption. For example, regulators often point out that while a company can outsource a business process, such as bookkeeping, it cannot outsource compliance with related regulatory requirements.

“Trust but verify” should be the golden rule. Buyers should check a bidder’s qualifications, scan the backgrounds of its owners or directors and review its history and reputation. It may even be necessary to look beyond the supplier itself to inspect the vendors that it uses. The more regulated the industry, the more critical the need to assess vendor compliance, including directly questioning adherence to regulatory requirements during the vetting process.

-

Environmental Impact

Environmental sustainability has returned to the top of companies’ compliance agendas, after sliding a bit during pandemic and inflationary times. Its importance has only increased as companies await new climate disclosure requirements from the U.S. Securities and Exchange Commission.

With a company’s supply chain often accounting for most of its carbon footprint, vendor selection needs to include an evaluation of a supplier’s energy consumption, as well as its approach to programs in areas like materials procurement and waste management. When procuring services, a company should be aware that major cloud service providers publish their steps to minimize the environmental impacts of data centers and provide metrics enabling customers to estimate their share of emissions via their monthly invoices.

In addition to a supplier’s own statements, evidence of environmentally sustainable operations is provided by third parties, such as the Carbon Disclosure Project, and in media coverage. Related questions and requirements should also be incorporated into the RFP process.

-

Corporate Social Responsibility (CSR)

It’s not just regulators that are interested in business integrity and environmental responsibility. Consumers, employees and business partners favor buying from and working with companies that demonstrate corporate social responsibility (CSR) and the associated values of environmental, social and governance (ESG) and diversity, equity and inclusion (DEI).

Procurement professionals understand that the CSR practices of suppliers can reflect positively or negatively on their own company. A first step in procurement is for buyers to communicate their company’s values. Potential vendors should have their CSR values openly stated on their websites and in their annual reports. And while checking for environmentally sustainable operations, as described above, a procurement professional should also look at human resources practices, community engagement, philanthropy, supplier diversity policies, ethics codes and other CSR hallmarks.

-

Risk Assessment

Ensuring the resiliency of supply chains and continuity of business operations has come to trump cost considerations at many companies, in the wake of pandemic and post-pandemic disruptions. Companies should make it a point to find out if suppliers have solid risk management strategies in place, such as business continuity, disaster recovery and compliance management programs, to address potential operational, regulatory and other issues. Another part of the equation is whether a vendor’s business operations themselves pose risk. For instance, are its essential facilities located in politically unstable countries? Could its weak corporate culture expose a buyer to fraud? Does the bidder prioritize cybersecurity?

Internal teams should conduct evaluations across all vendors, at least to some degree, since even the smallest supplier could represent a weak link that elevates risk. It’s practical to organize vendors by high, medium and low risk and/or potential impact, and then conduct due diligence accordingly. For key vendors being considered, companies can also seek external input from market intelligence companies that specialize in quantifying supplier risk. Additionally, procurement officers should analyze risk surrounding the actual products or services they’re buying. For example, will newly purchased software be secure, manageable and compliant with relevant regulations?

-

Innovation

A company that prides itself on innovation stands to benefit from partnering with innovative suppliers. Working together with its major suppliers, a company can drive its business forward, as innovative components and other inputs enable product upgrades or as new services fuel business process improvements.

Indicators of a potential vendor’s level of innovation may include publication of thought leadership, its investment in research and development as a percentage of revenue and its reputation for cutting-edge products or services.

-

Continuous Improvement

Day-to-day, continuous improvement nurtures an innovative product or service by making incremental changes in quality and surrounding business processes. Think of bug fixes in a software program.

Buyers can nudge their suppliers to continually improve by maintaining up-to-date SLAs and monitoring KPIs within a collaborative supplier relationship management program. Starting with the vendor selection process, though, they should seek out those suppliers with a track record of continually moving the dial on product excellence. Signs that a bidder might struggle to perform include its reliance on manual procedures for its own business processes, lack of standardized quality management systems or poor inventory management.

-

Long-Term Relationship Potential

Loyalty has its rewards in supplier relationship management. Buyer-supplier collaborations can streamline supply chains as communications deepen, a supplier’s understanding of its buyer’s business increases, and issues with quality and delivery are reduced. Better pricing can be negotiated as contracts are extended and renewed. The benefits of innovation and continuous improvement have the time to kick in.

Performing due diligence on potential bidders can provide some indication of whether a relationship will be able to stand the test of time, although this attribute can be difficult to predict. Insights can come from the reviews of other customers. And, when approaching a major bid, participation at industry events can provide the opportunity for face-to-face time with candidates. Their communication style and cultural fit will be of paramount importance.

Checklist for Finding and Managing the Right Suppliers

As part of the end-to-end procurement process, finding the right supplier begins with a selection plan, complete with assigned tasks and deadlines. Here is an overall checklist that can accommodate a thorough search.

-

Source Suppliers

The sourcing stage is when a company determines its needs, creates a purchase request and begins to identify vendors. Steps include:

- Establishing criteria that a supplier must meet, such as quality and delivery KPIs

- Setting a range of price points and capabilities to winnow down later

- Deciding on the type of bidding, whether open, limited or sole source

-

Vet Potential Suppliers

A company should do extensive due diligence on major suppliers — and not overlook smaller suppliers that, though small, could nevertheless introduce risk into its supply chain. Steps to narrow the field of likely candidates include a prioritized review of the 14 traits listed above, tapping the following sources to understand a vendor’s business situation and validate its product claims:

- Online reviews and testimonials

- Awards, certifications and accreditations

- Market research reports and industry news

-

Establish Contact and Request Quotes

Streamlining the bidding process should aim to minimize the cost of administration without sacrificing essential information about the characteristics desired in a winning bidder. Companies should build in efficiencies by:

- Communicating explicit requirements

- Establishing KPIs from the start

- Centralizing quote submission on a digital platform

Request a Quote and Manage Vendor Relationships With NetSuite

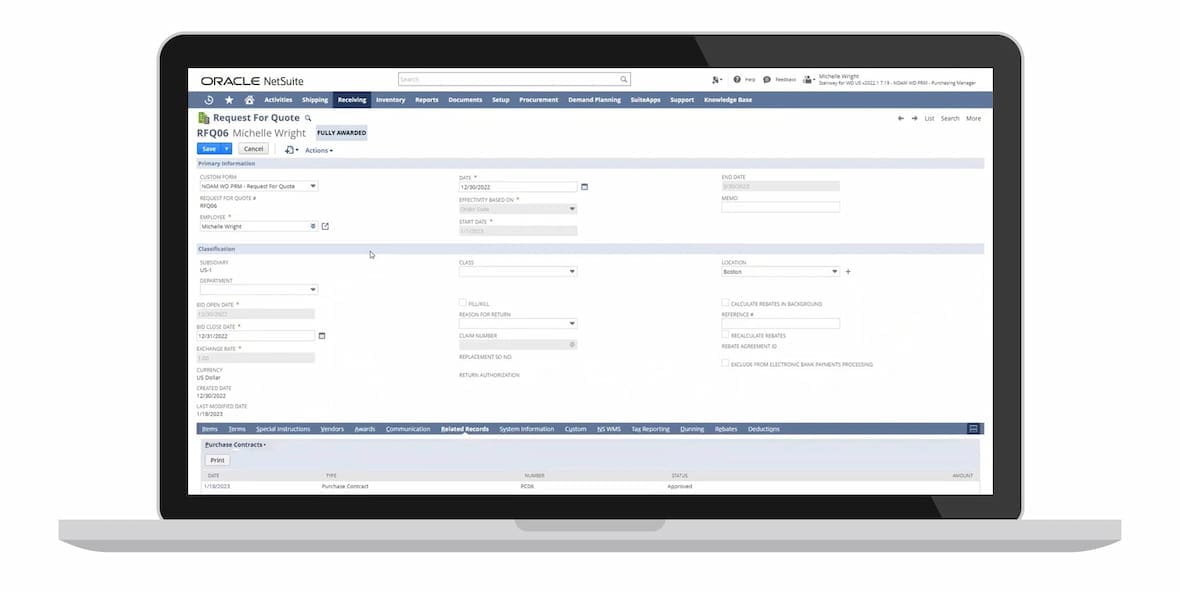

The request-for-quote feature of a vendor management system helps companies streamline their competitive bidding processes. -

Evaluate Samples and Prototypes

A clear cost/quality analysis may require hands-on experience with a product or service, which buyers can get in the following ways:

- Signing up for a free trial of a cloud-based platform or software-as-a-service

- Conducting side-by-side comparisons of a product’s or prototype’s features and functions

- Including internal stakeholders and customers in the evaluation

-

Negotiate Terms and Contracts

Buyers can enter negotiations on a solid footing once armed with the knowledge accumulated by vetting suppliers, testing their offerings and comparing their pricing against that of the competition — as well as a clear understanding of their own objectives and limitations. This facilitates:

- Negotiating price, based on an understanding of the supplier’s own strategic goals, competitive positioning, operations and costs

- Leveraging payment terms, such as discounts for prompt payment or volume purchasing

- Instituting risk management provisions and SLAs in writing

- Ensuring exit terms, in the event that things go wrong

-

Build and Manage Supplier Relationships

Successful negotiations should form the basis of a mutually beneficial relationship that yields rewards in terms of cost, quality and efficiency. This is when supplier relationship management kicks into high gear, providing:

- Digital facilitation of day-to-day activities, such as status updates and invoicing, on a vendor management system

- Personal engagement to foster collaboration while also reinforcing deadlines and quality control

- Problem-solving protocols

-

Monitor and Review Supplier Performance

Regularly evaluating suppliers helps to continually improve their performance, discover growth opportunitiesand strengthen relationships based on:

- Scorecards tracking adherence to KPIs and SLAs

- Constructive feedback

- Digital communications within the buyer’s preferred vendor management platform

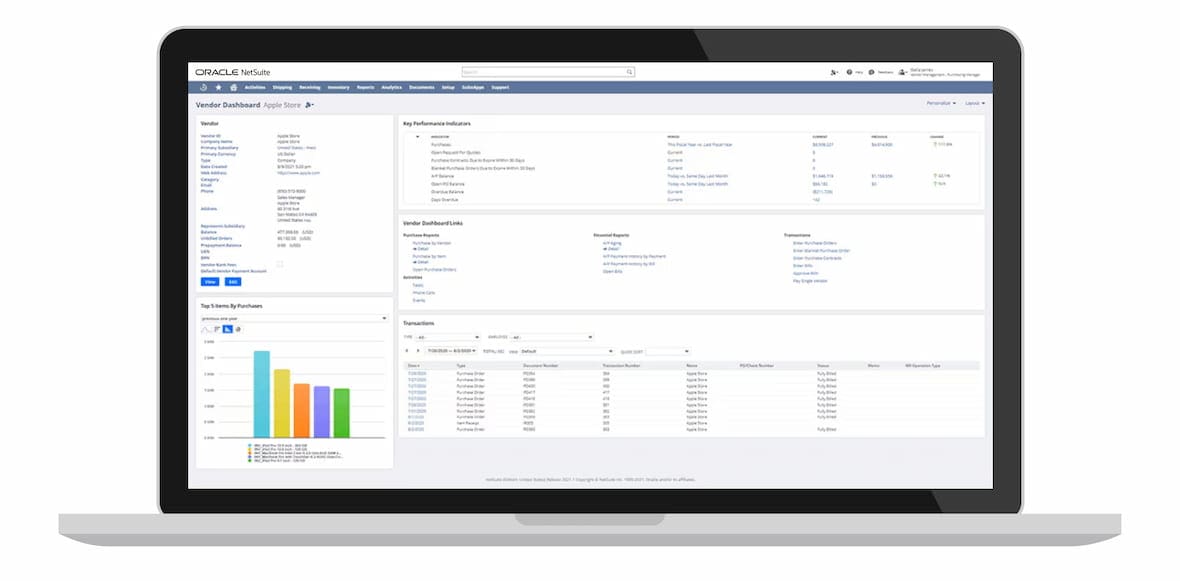

Dashboards Help Track Key Performance Indicators

Vendor management systems organize all information related to each vendor within a central record -

Leverage Technology for Supplier Management

Ongoing innovations are automating and integrating tasks, from the beginning to the end of the procure-to-pay process and from finding the right supplier to managing the vendor relationship. These technologies include:

- Data analytics, such as AI, to automate supplier profiling and evaluation

- Vendor management software to centralize bidding and monitor vendor performance

- Self-service capabilities for suppliers to submit bids, provide updates and check invoice status

Limit Risk With NetSuite’s Supplier Relationship Management Software

NetSuite vendor management empowers procurement professionals with centralized information on each vendor under consideration during a bidding process. Suppliers can upload their bids into the system for evaluation. And relationships with winning bidders can be monitored and managed based on preset KPIs and SLAs. Communication and collaboration between procurement staff and vendors can flow more manageably, while reducing email clutter.

With supplier relationship management as a growing focal point in business strategy, operations and sustainability, procurement professionals need to rise to the challenge early and often — starting with finding the right suppliers. Vendor selection is both an art and a science. Technological advances, such as digital vendor relationship management systems, address the scientific side of choosing the right vendor to deliver the right product or service with the right quantity, quality and efficiency. Armed with a powerful foundation of knowledge and insights for vendor evaluations, negotiations and management, procurement professionals can fully exercise their business acumen and take their art of supplier selection and management to a new level.

Finding the Right Supplier FAQs

What are the five key criteria when selecting a supplier?

Procurement needs vary, but the most important vendor selection criteria usually revolve around quality, cost, delivery, customer service and risk management.

How do I choose a company supplier?

A request for proposals (RFP) is a common tool for finding the right supplier, asking vendors to respond to a buyer’s requirements, answer pointed questions about their abilities and supply evidence to support their responses. A range of additional tactics, such as market research, product sampling and service trials, is also used to discern a contract bidder’s ability to deliver on quality, price and other must-haves.

What are the four stages of supplier selection?

The four most basic stages of supplier selection — after establishing selection criteria — are research, evaluation, selection and negotiation.

How do I find the perfect supplier?

Perfection may be an unrealistic goal in vendor selection, but to come as close as possible, a company must first be clear about its own requirements for quality, price, delivery and other essentials. Then, it should ask explicit questions about vendors’ operations and abilities and compare their answers with market research. To find the perfect product or service might also involve product sampling and service trials.

How do I find trusted suppliers?

Trust is hard to evaluate before entering a vendor relationship, but indicators can include the supplier’s stated principles, validation of those principles by industry awards and the testimonials of other customers, and the track record that surfaces when conducting market research. A buyer should also try to gauge cultural fit and communication style during the early stages of vendor selection.