The already intense pressure on ecommerce fulfillment teams has increased lately and from both ends of the supply chain. Upstream, global trade friction is causing delays in international product sourcing and hindering production; downstream, customers are demanding faster, more reliable delivery. It takes strategic planning, enabling technologies, and rigorous cost controls to meet these and other fulfillment challenges without running over budget. But done right, fulfillment can help deliver customer satisfaction, repeat business, and profitability. This article provides a guide to the models and leading practices for ecommerce fulfillment.

What Is Ecommerce Fulfillment?

Ecommerce fulfillment encompasses the “last mile” of a company’s supply chain—all the logistics involved from the moment a customer orders a product online until they receive the merchandise. Functions include inventory management; picking, packing, and shipping; and the reverse logistics required for handling returns and exchanges.

Customers expect fast, accurate, and trackable deliveries and returns—often specifying when they want them. And they usually want it all for free. Compare this scenario to five years ago, when US consumers demanded an average delivery speed of 5.7 days, according to a 2024 Forrester study; that timing has now fallen to 2.5 days and is expected to decrease to 1.5 days within another 5 years, the study found.

For e-tailers, demands like these can be costly amid challenges such as disrupted supply chains, labor shortages, and volatile shipping prices. So although companies may even compete on the basis of fulfillment, they must do so efficiently to protect their operating margins.

Key Takeaways

- Ecommerce fulfillment encompasses the entire logistics process from online order to customer receipt, focusing on delivery speed and accuracy amid rising pressures.

- Successful ecommerce fulfillment relies on integrated core components, including order, inventory, and warehouse management systems, to ensure efficient operations.

- E-tailers employing a flexible, scalable fulfillment model—be it 3PL, in-house, dropshipping, or hybrid—can more readily meet customer expectations and improve their profitability.

Ecommerce Fulfillment Explained

It’s widely recognized that B2C and B2B customers purchase across multiple channels, such as online marketplaces, social media, and merchants’ websites. They also demand shipping options beyond home or office delivery, including pickup points and parcel lockers.

To meet these requirements efficiently, many e-tailers operate global multichannel, multicarrier fulfillment networks. They also employ various warehousing strategies, maintaining central and regional facilities and shared warehousing spaces to strategically position inventory nearer to customers. Some merchants use automated systems to dynamically select optimal logistics and delivery partners based on real-time price and speed requirements. Others rely primarily on their online marketplace operators to store, pick, pack, label, and ship deliveries for them.

Conducting ecommerce internationally amplifies the complexities involved, due to diverse customer expectations, customs, logistics, and other hurdles. Overseas customers increasingly expect a shopping experience that mirrors that of their domestic counterparts, including transparent shipping costs, reliable tracking across continents, and sometimes optional expedited international delivery, even if it comes at a premium.

Video: What is Order Fulfillment?

How Is Ecommerce Fulfillment Uniquely Different From Standard Order Fulfillment?

Ecommerce fulfillment differs from standard order fulfillment primarily in scale, speed, and customer expectations, particularly for B2C transactions but also in B2B settings. Unlike traditional fulfillment models that often deal with bulk shipments to retailers or distributors, ecommerce fulfillment involves processing high volumes of smaller, direct-to-consumer or direct-to-business orders. This requires advanced logistics for rapid fulfillment and returns management, often within narrow delivery windows.

B2C fulfillment is particularly challenging due to consumers’ high expectations for rapid deliveries of lower-value products, as well as their tendency to return or exchange purchases. To that end, there’s nothing simple about handling large numbers of individual deliveries and returns in locations that could range from a bustling urban center to a remote rural area. By comparison, B2B ecommerce orders are usually higher in value, with business buyers focused more on the reliability of deliveries than their speed.

Core Components of Ecommerce Fulfillment

Fulfillment is notoriously complex and challenging. Whether in B2C or B2B contexts, successful ecommerce fulfillment depends on the interworking of the following core components to deliver orders accurately, on time, and within budget.

Order Processing

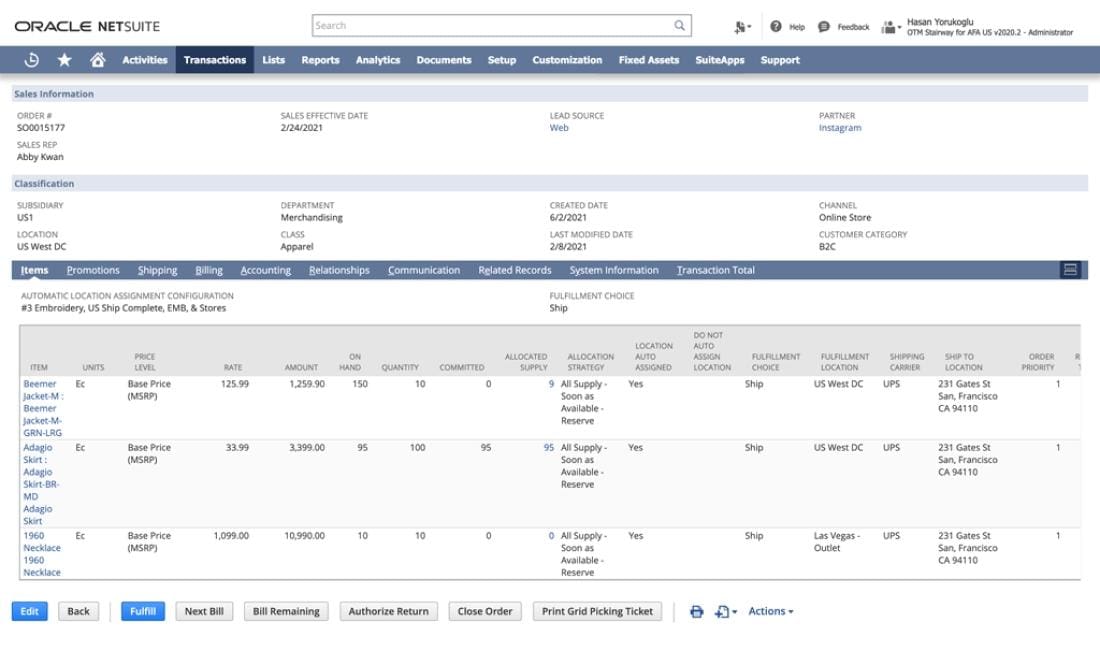

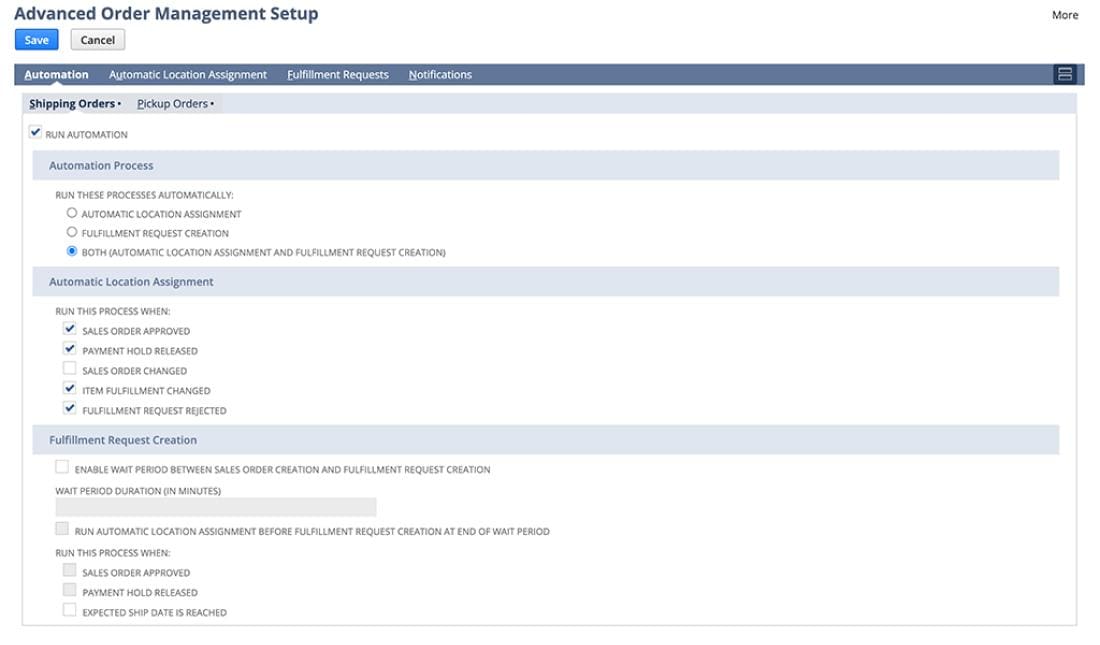

Order processing is usually automated, using a combination of real-time data analyses and predefined business rules for optimal handling. This process often involves order management systems and/or warehouse management systems that kick in after the few seconds it takes payment processing companies to screen purchase details for fraud and authorize the transaction. Just as quickly, the business systems running in the background check for product availability and route the order to the best warehouse or fulfillment center based on inventory availability and proximity to the final destination.

Inventory Management

Inventory management sees to it that businesses order the right stock, in the right quantities, at the right time—and store it in the right locations for rapid order fulfillment. Inventory management systems capable of trend analysis from procurement to sale help ensure that stock levels will be sufficient so that customer orders can be fulfilled reliably.

The highest levels of efficiency are possible when inventory, warehouse, order, and supply chain management systems are integrated or even combined within a single enterprise resource planning (ERP) system. Each system serves a different function:

- An inventory management system provides overarching visibility, coordination, and control of all stock on hand and in production.

- A warehouse management system operates within the walls of a specific facility.

- An order management system governs the lifecycle of a particular order. Modern systems support a feature of great interest to customers: automated delivery updates. Transparency in shipping ranked #2 in a 2024 consumer preference survey by McKinsey, behind the cost of delivery and ahead of speed and ease of returns.

- A supply chain management system coordinates the strategic sourcing and end-to-end flow of goods, information, and finances across all supply chain touchpoints.

Shipping

The shipping component of ecommerce fulfillment involves selecting appropriate carriers, generating shipping labels, securely packaging products, and ensuring accurate and timely delivery. Because shipping is so central to customer satisfaction, e-tailers typically offer a variety of options, such as standard, expedited, same-day, or international shipping.

Many e-tailers use multicarrier shipping strategies to achieve the necessary speed, geographic reach, and reliability in hitting promised delivery windows. A business may select different carriers based on destination, cost, delivery time, package size, or customer preference. Rules-based software can assist in the process to cherry-pick among ever-changing shipping rates and terms. Building in flexibility helps reduce shipping costs, minimize errors and delays, and maintain service levels across diverse markets.

Seasonality adds another layer of complexity to shipping. During peak periods, such as holidays, fulfillment centers and carriers often face capacity constraints and increase their rates. Indeed, 64% of US ecommerce companies say they are unable to deliver as quickly as their customers expect during those times, according to Forrester. For holidays and during other surges in demand, planning ahead with scalable shipping strategies and carrier diversification can aid in maintaining delivery promises and avoiding disruptions.

Returns

Customers want free, easy returns—and e-tailers that don’t promise this service up front face the prospect of abandoned shopping carts. However, this component of ecommerce fulfillment, known as reverse logistics, can prove to be the most difficult and costly of all, with returns projected to reach $890 billion in 2024, representing 16.9% of annual retail sales, according to the National Retail Federation.

Reverse logistics includes generating return labels, inspecting returned goods, restocking inventory when appropriate, and issuing refunds or exchanges. Automating parts of the returns process and integrating return data with inventory and accounting systems can help reduce errors and recover value more quickly by speeding up refunds and restocking.

Ecommerce Fulfillment Models

Handling the growing complexity of ecommerce fulfillment at high volume and speed can create a situation fraught with inaccuracies, delays, and other difficulties. To avoid problems like these, e-tailers will choose one or more fulfillment models that best meet their needs, based on several factors—for example, size of their business, types of products, and requirements, such as cost, flexibility, scalability, and control. But the choice is not always straightforward. For instance, sellers of perishable goods or highly specialized products might choose between in-house handling for control or specific third-party logistics (3PL) handling for expertise. Many merchants also use hybrid approaches, as described below.

Third-Party Logistics (3PL)

Many e-tailers outsource part or all of their warehousing and shipping operations to 3PLs. With established networks of warehouse and transportation companies, 3PLs work with merchants to process orders and negotiate shipping and storage costs from carriers.

Pros and cons:

Outsourcing lets e-tailers focus on their core business while simplifying fulfillment and lowering capital investment. Orders can even go directly to a 3PL, which will handle everything from warehousing to packing and shipping. Another benefit of using a 3PL is its access to the latest logistics technologies, such as robotics in the warehouse and AI for plotting shipping routes. Advanced technology is part of the reason that ecommerce 3PL customers reported substantial business benefits in working with 3PLs, such as a 29% improvement in both on-time delivery and pick-to-ship cycle time, alongside a 28% reduction in cost per order, per Forrester’s US survey. Merchants contracting with 3PLs can also tap into their expertise and scalability for growth and periods of peak demand. The potential downsides of using 3PLs include the ceding of direct control, which can be exacerbated by communications issues.

In-House Fulfillment

In-house order fulfillment requires hiring staff and investing in facilities and technologies to store, pick, pack, and ship orders and handle returns. Small e-tailers may begin using in-house fulfillment and then outsource as they grow, though many also rely on the fulfillment services of major online marketplaces. At the same time, a very large company might have the volume to negotiate its own shipping discounts and the wherewithal to optimize warehouse operations on its own. Merchants of customized goods often lean toward in-house fulfillment.

Pros and cons:

Among the advantages, in-house fulfillment can give merchants more control over the process, customer experience, and their brands. Yet it requires significant up-front and ongoing investment in infrastructure and personnel, as it also diverts management focus from the core business. This arrangement can also prove to be less flexible and scalable when handling peaks and troughs in demand.

Multichannel Fulfillment

E-tailers must handle orders that come in from multiple buying channels—whether via online marketplaces, social media, or their own websites—and go out to different delivery channels, ranging from home delivery to various pickup locations. A merchant’s shipments may go out from its warehouse, directly from a supplier, or via a 3PL. Regardless, the customer experience should be uniformly timely and trouble-free, which is where tools, such as order management software and omnichannel inventory dashboards, come into play.

Pros and cons:

Multichannel fulfillment meets customers where they are (and where competitors are, too). E-tailers sell through an average of 5.4 channels, according to Forrester, and deliver for in-store pickup, to dedicated lockers, and on doorsteps. When integrated with 3PLs’ systems, digital orchestration of this intricate requirement provides visibility into inventory across all internal and external stock, thereby routing orders to the most cost-effective location for fulfillment and shipping and delivering precisely where and when the customer requests. The biggest risk in all this complexity is the potential for higher costs if it is not managed effectively.

Dropshipping

Dropshipping eliminates most fulfillment burdens. In this model, the e-tailer acts mainly as a storefront and marketing business. Instead of producing or storing its own inventory, the merchant purchases items from third-party suppliers only after receiving a customer order. The order is forwarded to the manufacturer or distributor, which directly ships the product to the customer.

Pros and cons:

This fulfillment method can help an e-tailer establish its business without assuming big up-front costs for inventory and warehousing. The flexibility to offer a wide range of products is practically unlimited. Yet a merchant’s control over product quality, shipping speed, and the customer experience can be very limited.

Ecommerce Fulfillment Challenges

Complex customer expectations, rising costs, and stiff competition in the retail sector all amplify the day-to-day challenges of running ecommerce fulfillment efficiently. Farther up the supply chain, meanwhile, a volatile international trade environment is complicating inventory management and slowing deliveries. Here are four common fulfillment challenges:

- Supply chain disruptions: Fulfillment can be hindered by numerous disruptions in the global supply chain, such as extreme weather events, supplier issues, and on-again, off-again tariffs and trade barriers. Nearly three-quarters of small-business owners expect negative impacts from changes to trade and tariff policies, according to the Small Business CEO Confidence Index.

- Meeting customer demand: Among ecommerce trends that include AI shopping assistance and the growth in product subscription models, customer demands for expedited, flexible fulfillment are arguably the most challenging to meet. According to McKinsey, more than 90% of consumers are likely to abandon an online purchase upon learning it will involve high shipping costs, and about 65% will do the same if the return policy is inflexible. Two-day delivery is becoming the norm, and more than half of consumers say it’s important to be able to schedule deliveries.

- Managing inventory: E-tailers need to minimize stockouts, which can erode sales, and avoid overstocking, which increases costs, while managing a large number of products across multiple locations. This complicated balancing act requires tight tracking, demand forecasting, and warehouse management. But often outdated fulfillment processes, disconnected systems, and manual data entry get in the way.

- Maintaining profit margins: Profitability can be eroded by fulfillment issues large and small. At the large end of the scale, the cost of logistics inputs, such as fuel, is volatile, with carriers like FedEx and USPS continually adjusting pricing structures and fuel surcharges. Among smaller issues, e-tailers need to keep a constant eye on order sizes and weights to avoid unexpected surcharges. A UPS survey shows 9% of merchants absorbing expedited shipping costs—which cuts into their margins; 35% charging customers for expedited delivery; and 55% bundling shipping into the price of their goods. That said, merchants must still compete on product price.

Tips for Selecting the Right Fulfillment Strategy

In the Forrester study, 85% of US ecommerce executives said better fulfillment practices deliver significant competitive advantage. To gain an edge, McKinsey advises focusing fulfillment strategies on three key elements: keeping delivery promises, finding optimal trade-offs between delivery reliability and speed, and leveraging technologies for real-time tracking and status updates to consumers.

- Understand your customers’ expectations: Knowing what online shoppers expect can result in a better customer experience and repeat business. Customer insights also ease fulfillment pressures. For example, product subscriptions are increasingly popular among consumers, and they can also help maintain margins by stabilizing order frequency, improving inventory planning, and building predictable revenue. Spending thresholds for free shipping should be carefully weighed against customer resistance, but the right threshold may nudge consumers to buy more. And although consumers generally favor free shipping, many are willing to pay a premium for environmentally sustainable shipping.

- Strengthen inventory management: Demand forecasting, reliable tracking systems, and clear control policies can strengthen inventory planning and purchasing. E-tailers can also buffer against unexpected fluctuations in demand or supply chain disruptions by establishing minimum and maximum stock levels, automating reorder thresholds, and holding safety stock. With volatile trade policy and tariffs in the global supply chain comes the need to reassess the entire supply chain to strengthen supplier relationships, reevaluate purchase timing and inventory volume, and consider new pricing models.

- Compare solution costs: The most cost-effective fulfillment model for any particular e-tailer will depend on order volume, product characteristics, desired level of control, growth projections, available capital, and other factors. An analysis of which model works best should consider all direct and indirect expenses. For instance, outsourced 3PL solutions offer the potential for cost savings through their negotiated shipping rates and efficient processes, but they also include account management fees and surcharges for specialized needs or high volumes. In-house fulfillment may be even more expensive to scale and also may exact opportunity costs by diverting a company’s management attention and investment capital.

-

Identify any necessary technology integrations: Application programming interfaces (APIs) and portals make multiple technology integrations possible on the road to ecommerce fulfillment. That’s reassuring to know because the systems directly and indirectly involved can be many, depending on the size and complexity of the ecommerce business, the chosen fulfillment model (in-house, outsourced, or hybrid), the various channels to market, and the specific software solutions being used. Integrations can include ecommerce platforms, order management systems, warehouse management systems, inventory management systems, shipping carrier portals, accounting software, ERPs, CRM systems, analytics and reporting tools, and automation and robotics systems.

In a simple example of an order placed with an online store, an ecommerce platform’s API makes order data available for integration with the e-tailer’s order management system, which creates the order and sends it to the merchant’s warehouse management system. From there, the data is passed on via the shipping carrier’s portal, which shares tracking information back through all the APIs above to update order status for both the e-tailer and its customer.

- Determine how flexible your fulfillment solution needs to be: E-tailers are always having to flex due to fluctuating order volume, expansion of product lines, new sales channels, changing customer demands, and other reasons. With global trade issues disrupting supply chains, fulfillment teams need to be even more able to adjust to potential cost increases, product shortages, and customs delays. Seasonality is a good example of all this. With many e-tailers’ profitability hinging on holiday shopping, their systems need to be ready to handle the year-end spike in deliveries. Merchants should identify which fulfillment models, technologies, and policies are needed to flex when the time comes.

- Plan for future needs: The flexibility described above provides the foundation for future-proofing an ecommerce business. Merchants should periodically analyze current order volumes and patterns, rate their fulfillment performance, monitor market intelligence, and gather feedback from customers. Then, they can use predictive analytics and other tools to project future growth and change in alignment with their company’s strategic plan.

A Unified Ecommerce Solution With NetSuite

Ecommerce fulfillment involves many moving parts. SuiteCommerce is a unified ecommerce solution that integrates seamlessly with NetSuite’s ERP system and specialized software to address a business’s range of fulfillment needs. From order processing and routing through shipping and returns management, having one cloud-based platform that offers a coherent perspective on customer, order, inventory, and other vital information fuels real-time business visibility and facilitates customer-tailored service across all sales channels. The result is a more efficient, accurate, and cost-effective fulfillment process that ultimately leads to improved customer satisfaction and a stronger bottom line.

Fulfillment is no longer a back-office ecommerce function but a significant driver of customer loyalty, competitive advantage, and profitability. Understanding the various fulfillment models, from insourced control to outsourced scalability, is the critical first step for e-tailers to strategically align operations with their customers’ needs and their own strategic goals. Overcoming inherent challenges, including supply chain disruptions and demanding customer expectations, calls for a unified approach that facilitates flexible fulfillment models powered by integrated systems. As ecommerce continues to evolve, merchants that embrace agile, data‑driven fulfillment strategies will be best positioned to outmaneuver competitors, win customers, and drive long-term profitability.

Ecommerce Fulfillment FAQs

How much do ecommerce fulfillment services cost?

Ecommerce fulfillment rates vary significantly among logistics providers and shipping companies, and they also fluctuate over time. Common cost components include account setup fees, receiving fees for unloading shipments, monthly storage fees, per-order pick-and-pack pricing, shipping costs, a monthly account management fee, and technology integration fees. To estimate costs, determine your average order profile, project the monthly volume, obtain detailed quotes, ask about hidden fees, and weigh the costs against potential savings in time, resources, and the impact on customer satisfaction.

What is considered a perfect order in order fulfillment?

A perfectly fulfilled order is one that satisfies the customer completely by being delivered on time, undamaged, and with appropriate documentation. Every aspect of the order fulfillment process from order entry to final delivery is executed flawlessly, according to the customer’s expectations and the company’s standards. Achieving perfect orders consistently is a key goal for e-tailers since it can lead to customer satisfaction, loyalty, and repeat sales.

What is direct order fulfillment?

Direct order fulfillment is synonymous with in-house fulfillment. In this model, the merchant handles the entire fulfillment process, including storing inventory, picking and packing items, and shipping orders directly to the customer. This contrasts with outsourcing fulfillment to a third party or using a dropshipping model, where an e-tailer acts only as an online storefront that curates a portfolio of products but leaves the physical logistics to the brands it markets. Direct order fulfillment gives a merchant more control over the customer experience but requires investment in infrastructure and resources.