International logistics is an increasingly important discipline for the global economy as more companies use it to reduce costs and take advantage of highly specialized capabilities in different industries and regions worldwide. Though the potential pitfalls are many, investing in good technology and procedures and finding the right international partners can help build more competitive businesses—businesses capable of sourcing, hiring, and delighting customers around the world.

What Is International Logistics?

In business, international logistics is the study, planning, and implementation of how a business moves physical goods and materials from supplier to customer in a way that involves crossing at least one international border. It also includes the international movement of money and information. Said another way, it’s simply business logistics that span two or more countries.

Key Takeaways

- International logistics involves moving physical goods, money, and information across international borders.

- Great international logistics management requires working on multiple horizons: mapping out supply chains years in advance, staying weeks ahead of orders, and having systems that let the business collect, process, and act on data in real time.

- Good partners and technology providers are essential to early success in international logistics.

International Logistics Explained

There are many well-developed best practices for managing logistics in general:

- Optimizing supply chains.

- Managing inventory.

- Staying on top of, but never too far ahead of, demand.

- Getting shipments from suppliers to customers as efficiently as possible.

The additional challenge of crossing international borders can make logistics wildly more complicated than local or national businesses. But it doesn’t always have to be a roadblock.

For most companies, international logistics start as a “learn by doing” exercise—solving problems as they arise while the business grows in scope and complexity. Eventually, though, the best way to optimize international logistics isn’t just to continually adapt to constraints and challenges as they arise; it’s to see the whole picture and optimize around the complete set of global constraints and options available to the business.

In that approach, strategies that never would have occurred to business managers (e.g., putting a warehouse in a country where there are no customers or hiring employees in a city where there are zero sales or production facilities) may become great ways to improve operations.

Components of International Logistics Management

International logistics management encompasses multiple interconnected elements that keep the global supply chain in motion. With the right tools and strategies in place, these components can work together in service of a common goal: to effectively deliver for customers. Here is a breakdown of the key components:

- Coordinating product distribution: Successful international logistics requires businesses to maintain optimal inventory levels while carefully moving goods across multiple transportation modes, warehouses, and distribution centers. This involves balancing storage costs with delivery speeds and coordinating with various carriers and customs agents to ensure smooth transitions between shipping phases.

- Planning the transportation process: Logistics teams must choose specific combinations of shipping methods—sea, air, rail, and road—to fit their needs, while also considering cost, speed, reliability, and other factors. When developing their transportation strategies, managers must also account for seasonal variations, peak shipping periods, and potential disruptions to mitigate risks.

- Monitoring the transportation of goods: Modern businesses rely on advanced tracking tools, including Internet of Things sensors and cloud-based transportation management systems, to follow the whereabouts of shipments throughout their journeys. These technologies enable real-time monitoring of delivery progress and controlled environments for sensitive cargo, such as perishable ingredients. Ongoing monitoring allows businesses to identify delays or disruptions and proactively keep all relevant parties in the loop.

- Complying with customs and regulations: International shipments typically require complete and accurate documentation before acceptance, so managers must understand the exact import/export requirements for each country they do business in. Additionally, businesses should monitor changes in international trade regulations to maintain proper licenses and certifications for cross-border shipping.

- Responding to risks in the supply chain: Global supply chains are complex and vulnerable to slowdowns. Savvy businesses expect the unexpected, with contingency plans prepared in advance for an array of potential disruptions, from weather events to geopolitical upheaval. Furthermore, by building relationships with multiple suppliers and carriers, businesses have alternative partners at the ready should a disruption occur.

- Optimizing logistics costs: Through supply chain analysis, businesses can identify opportunities where they can reduce costs without compromising service quality. Key areas for optimization include inventory carrying costs, transportation expenses, customs duties, and administrative overhead, which, importantly, should also be factored into a business’s pricing strategy.

- Maintaining customer satisfaction: Customers expect businesses to provide timely deliveries, real-time tracking information, and quick issue resolution if problems arise. Meeting their expectations takes a high level of responsiveness, clear communication (with partners, too), and the ability to meet service-level agreements, such as guaranteed delivery times or order accuracy targets.

Importance of Logistics in Global Trade

International logistics has taken on new importance in the modern era. As economies grow, they naturally allow for increased specialization. In other words, individuals and businesses can focus on doing fewer things but doing them better. A small town might have one bakery, while a city often has specialty shops for cupcakes, donuts, and pies, along with broader bakeries. Such specialization spurs competition and creativity, as well.

In national economies, regions can specialize, too, attracting a critical mass of talent and capacity that allows for greater productivity and innovation than would otherwise be possible. The United States has seen the development of many such regions. For example, auto manufacturing in Detroit drew on specialized businesses from the surrounding states to make high-precision car components.

Over the last century, costs and time delays associated with international communications have plummeted. International shipping has scaled to the point where the cost per pound or cubic foot to send large quantities of physical products or materials is often a negligible component of the overall price. English has more non-native speakers than native ones, allowing for a standard means of communicating in almost every business center worldwide. Translators and translation software are both available when a common tongue is not.

The ability to operate internationally—to source, sell, and hire from around the globe—is an opportunity for many businesses and a mandate for others that want to stay competitive. But once a business starts straddling its operations across international borders, its logistics become international logistics. And that’s why international logistics is more important than ever before.

Goals of International Logistics

The main goals of international logistics are, by and large, like any business logistics process: to ensure efficient and reliable operations that run smoothly and predictably while driving down costs and reducing uncertainty. Beyond that, good international logistics management can yield improved relationships with customers, partners, and even with prospects. Let’s go through these goals one at a time.

-

Cost Efficiency

This is usually the first goal that prompts businesses to focus on optimizing international logistics. Doing business across international borders can be expensive. There are multiple tax regimes to understand and manage, tariffs and other costly requirements, and the costs of long-distance shipping. These costs add up. By understanding all the cost structures and options, from international real estate opportunities to regulatory frameworks, businesses can respond to complex and sometimes changing constraints to reduce costs. This is where casting a wide net and attention to detail matter.

-

Reliability

With international logistics, one misunderstanding of a local rule could result in an entire shipment being unusable (for example, if it gets confiscated or a perishable shipment is turned away or stalled). More common threats to timeliness and predictability also loom, from delays in processing and mistakes in filling out forms to last-minute changes in import, export, or travel policies. Having dedicated people, services, and technology to spot and respond to these challenges can go a long way toward making an international operation more dependable. In some cases, “reliability” is just another way of saying “viability” because, without this, some businesses wouldn’t be able to survive.

-

Relationships

Building a good international logistics operation often means making friends in many places. And when you have a reliable, efficient operation, it’s easier to build friendships. Growing businesses that pay their bills on time are a favorite of suppliers. Being the company that gets customers what they need, when they need it, at a fair price, builds loyalty. In some cases, an international supply chain may be the one competitive advantage that attracts customers, especially for product categories where offerings have low differentiation. Multiple office supply stores have gone out of business over the past few decades, for example, while those that remain have done so on the back of logistical expertise. They can get customers not only what they need but also when and where they need it, with comparatively high reliability.

4 Critical Elements of International Logistics

A company’s international logistics must follow best practices in each of the following operational elements to reliably and consistently execute while adapting to changing circumstances. Good international logistics managers will spend at least some time thinking about each of these and laying the groundwork for it.

-

Transport Visibility

Sometimes called “supply chain visibility” or simply “visibility,” this is the ability to see where goods are at any point from origin to buyer. Excellent visibility means being able to track every parcel, every order, and every unit and locate it—in real time—in your supply chain and physical space. Which products are on which truck, and where are those trucks? What are the contents of each warehouse, and how much of that stock is scheduled to leave within the next 24 hours? Transport visibility gives businesses data they can use in real time, data to respond to upcoming demand, and data to learn from their history—successes and failures alike.

-

Chain of Custody

Chain of custody is an extension of transport visibility—knowing where your goods are and were at all times—but it adds a new data element: knowing who did what with or to the goods. This information isn’t usually needed daily, but having it helps companies track down the source of problems when things go awry. When did damaged merchandise get damaged? Are there any individuals, organizations, or facilities in the supply chain that have a higher rate of error than others (or more than is reasonable)? What opportunities are there for something to go wrong (which, in turn, can help you think about how to prevent this)?

Chain of custody is one of the logistics elements that can get particularly tricky with international shipping, as goods may need to travel across many modes of transport and via multiple carriers. A FedEx tracking number, for example, does little good once the package is on a shipping container and no longer in FedEx’s care, and neither will that shipping container’s information do any good once its goods are offloaded. The number of opportunities to lose track of things is magnified when operations go international, which is why this can be difficult and crucial to get right.

-

Traceability to Origin

This element is also like visibility and chain of custody but in reverse. Instead of knowing where things are and where they’re going, traceability to origin (sometimes called backward traceability) is about where the goods came from and where all of the components came from.

For international operations that source from all over the globe, it’s not always enough to know that a car rolled off the line in Michigan, was sent to a dealership in New Hampshire, and then bought by a customer who drove it to their home in Massachusetts. Knowing where every part of that car came from is important, too, in some cases for simple inventory and supply chain management concerns, but also for safety and, as of August 2022, for tax credit purposes.

The U.S. Inflation Reduction Act changed the old electric vehicle tax credit to the clean vehicle tax credit, the amount of which is determined based on where the components of the vehicle and its battery were manufactured and assembled. Traceability to origin is even more critical in the case of a problem or recall. If it’s found that some metal gears manufactured in China have a structural defect, or a brake pad made in Canada will need replacing earlier, knowing exactly where every component came from in every unit sold isn’t just good for business and customer relationships; it can save lives.

-

Integrity of Consignment

This element is the essential goal of all the others. Integrity of consignment means the product reached the intended recipient in proper condition and was handled appropriately per the terms of the contract and/or reasonable expectations of the recipient. This obviously means intact, fully present, and usable, but it could also include issues related to proper handling in transit. A perishable good may be fine to use upon arrival, but if it was improperly stored in transit, its useful life could be greatly reduced and costly to the recipient. The integrity of that consignment would have been compromised.

Examples of International Logistics

Examples of international logistics are everywhere—it’s probably harder to find a large company’s product that isn’t an example. The clothes you’re wearing, the last vehicle you rode in, and the device you’re using to read this article almost certainly crossed international borders or have components that did. But examples of international logistics best practices and money-saving maneuvers are often hidden from plain sight. In other words, it’s well known that many modern products are assembled out of parts and materials from all over the world, but far less obvious is what the company had to do to get it to you quickly and cheaply. Sometimes the secret isn’t just in smooth daily operations but in decisions made years earlier to put a business in a position to execute.

Here are examples of two areas in which international logistics plays a crucial role: where to locate facilities and finding the right business partners.

Locating Facilities

Ever wonder why United Parcel Service (UPS) has its biggest shipping facility, at over 5 million square feet, in Louisville, Kentucky? That isn’t where UPS is headquartered (which is Atlanta); Louisville doesn’t have one of the world’s most active airports (the world’s busiest would be, again, Atlanta); and it’s not that there are a lot of customers or executives in Louisville, either. What Louisville has going for it is that it’s close to the population-weighted geographic center of the United States, which minimizes total transport distances when running a hub-and-spoke system. That, in turn, minimizes flight times and fuel costs and gives employees on the ground more precious minutes to get cargo from the plane it arrived on to the plane it needs to leave on.

Though Anchorage, Alaska, is a town of fewer than 300,000 people, its airport is the fourth-busiest air cargo hub on the planet, and many companies run logistics through there. Why? Because it’s a convenient stopover between North America and Asia. Not many customers live there; not many businesses have major operations or production there. But it’s critical to getting goods (especially time-sensitive products, like perishable inventory) back and forth promptly and cost-effectively.

The key insight for international logistics is that businesses don’t have to put supply chain facilities in places that are close to their offices or customers. They need to put them in places that provide the highest logistical value for international operations. Sometimes that means putting a warehouse in a country where a business has no customers because it’s near the factory or on the way to the customers, and it’s a cheap and convenient place to serve as a hub in your own network. Sometimes that means building factories in places with easy access to an efficient seaport and a major airport. And sometimes, it even means forgoing economies of scale on the production side to account for the international logistics challenges.

For example, three factories in three different countries may not produce the same low-average unit cost as one mega factory would, but if doing that solves a variety of political, legal and transportation challenges, the decision to make things more expensively could ultimately pay for itself 10 times over.

Finding the Right Partners

International logistics is complicated, and growing companies don’t need to reinvent every wheel. There are plenty of B2B services companies that specialize in helping product-selling businesses navigate international logistics challenges, from law firms with years of working across a specific international border to trucking fleets with drivers who have passports and the language skills and experience needed to operate where your business needs transportation.

So businesses facing major international logistics challenges should think “3PL”—third-party logistics. Global 3PL providers might be able to solve some international logistics problems in a way that makes economic sense for your business. Especially for small and medium-sized businesses growing into international markets and diversifying their supply chains across international borders, the path to success is often and increasingly the one walked with the right partners.

International Logistics Process

No two companies will have the same processes for international logistics. But every company that wants to enjoy long-term success will go through similar steps to set up their international logistical process and ensure excellent execution.

Setup

Setting up an international logistics operation requires getting the right physical, digital, and human assets in the right places. Sometimes you can get all three accomplished at once by finding the right partner (i.e., a 3PL provider with shipping, warehouses, expertise, and data tracking). Sometimes, though, and especially at large scale, a business needs to do some or all of that on its own.

-

Physical assets: It’s important to design and locate physical assets, such as factories, warehouses, and transportation hubs, with your whole logistics network in mind. Don’t ask, “Where’s a good place for a warehouse based on activity in this area?” Instead, ask, “Where will a warehouse add the most good to the system as a whole?”

Maybe one warehouse is overburdened, so building a second warehouse next door seems like a good idea that will solve the problem. And it might. But it could be that the burden would be similarly alleviated by positioning the new warehouse somewhere much more convenient for your trucking network. That would not only alleviate the warehouse burden but reduce annual fuel costs as well.

- Digital assets: For digital assets, think about building the capacity to collect, store, organize, and analyze data. International logistics create a lot of data points, especially when a business is tracking everything properly. Smart companies store that data to learn from and improve operations. Access to data in real time, organized in useful ways, can help companies better respond to disruptions, emergencies, and sudden opportunities. According to Ti Research’s 2024 State of Logistics: Road Freight survey, digitization was the number one key investment focus area for the upcoming year, specifically in data analytics and real-time visibility.

- Human assets: For human assets, international logistics adds a new dimension to the "right people in the right places" paradigm. In addition to all the personnel the business would need for a normal logistics operation, you’ll need people who understand the relevant laws, taxes, tariffs, cultural customs, local players and languages in all the jurisdictions in which the business operates.

Execution

Once all assets are in place, excellent execution requires the business to establish clearly defined roles and responsibilities so that those assets can execute their functions consistently.

- Warehouses: In the case of a warehouse, that might mean making sure it’s well run, operates at or slightly under capacity, and is properly maintained.

- Data management: In the case of an enterprise-level data collection and management system, that means keeping it maintained and secure, and not letting errors and problems compound. When it comes to assuring the quality and usefulness of digital assets, proactive beats reactive and reactive beats complacent. So keeping up with the latest data technology is important not only for maintaining international logistics capabilities, but expanding to always remain competitive.

- Management: And in the case of people, execution means they do their jobs well and consistently. From a management perspective, that only happens when two things are true: the business recruits the right people for the right roles, and it has defined and resourced the roles to encourage success in employees and partners. That second one is essential because recruitment will always be challenging, and international logistics requires bringing together people with all kinds of backgrounds from different parts of the world. Ensuring they have proper training, clearly defined roles and procedures, and the resources necessary to do their jobs well is crucial for competent execution. For great execution, make sure your people have a voice that can be heard when problems and opportunities arise.

International Logistics Channels

International logistics has three essential process flows that sometimes are grouped into distinct “channels” so companies can focus on them one at a time. Although international logistics is fundamentally about moving physical goods and materials across borders, when you do that, money and information must flow as well. The following channels reflect those three critical flows:

-

International Distribution Channel (Movement of Physical Goods)

This is the main thing we talk about in international logistics: moving physical things across borders. Transportation, storage, production, delivery, and the entire physical supply chain are covered in this channel. While this is the “main event,” so to speak, it’s helpful to remember that it’s only one of three channels, and it couldn’t happen without the other two.

-

International Transaction and Payment Channel (Movement of Money)

Except for very rare barter transactions, when goods move across borders, so does money—often in the opposite direction. With international logistics, this can be considerably more complicated than when operating within the same country.

Which currency will you and your customers be using to pay for things? What payment options will you request or offer? What are the reporting and tax requirements of both countries involved in the transaction? Are you using any payment processing services, and what associated fees do they have?

This can become enormously complex for a business striving to do everything it can to make life easy and painless for customers while at the same time shopping or negotiating for favorable arrangements from suppliers.

-

Documentations and Communications Channel (Movement of Information)

When conducting business across international borders, good communication is essential. It minimizes the chances of misunderstandings and makes everything run smoothly. The communications channel includes correspondence and conversations, contracts and formal agreements, documentation from notes to government forms—and, increasingly, shared data for tracking, verification, and analytics.

International Logistics: The Flow of Goods, Data, and Money

Challenges of International Logistics

International logistics managers face many challenges daily, and the past few years have seen a rise in the severity of those challenges. The fundamental problem is that growing supply chains run through more jurisdictions and require more personnel. So they accumulate more possible points of failure and bottlenecks as they expand. Let’s look at a few of the most common international logistics challenges, keeping in mind that this list is representative, not comprehensive.

-

Traversing geography:

Supply chains are just physically longer when they cross international borders, sometimes including oceans. Things take longer to get from point A to point B, requiring more investment in transportation and, often, multiple modes of transport. Ships, airplanes, trucks, trains, vans, cars, bicycles, and, increasingly, aerial drones can be part of getting materials and goods from their origin into the hands of the consumer. More miles and more modes of transport don’t just elongate timelines, it introduces challenges and bottlenecks, as well.

-

Personnel:

Moving things along stretched supply chains requires a lot of people. Businesses need drivers and mechanics for the vehicles, people to load and unload physical items multiple times in a journey, technology people to manage data gathering, and more. A good 3PL partner can help with a lot of this, but at the end of the day, it’s your business’s product and customers, so you need to be confident that your supply chain isn’t only well-designed but well-staffed, too.

-

Translation difficulties:

This is a whole category of challenges, as many things need to be translated or converted in an international supply chain. Language needs to be common or translated—and not just regularly spoken languages, like English and Mandarin, but also industry-specific jargon that’s often needed to achieve clarity on goals and problems. Currencies need to be converted. Tracking systems need to talk to each other. Troves of data need to be integrated. Most of these challenges fall within the transaction and communication channels, but they’re no less important to a reliable operation than the movement of physical goods.

-

Government rules and regulations:

Every country has different laws and regulatory frameworks in which businesses must operate, and making sure an entire global supply chain is compliant with all the applicable rules is difficult. These challenges range from acquiring permissions to paying taxes to making sure all your documentation and forms are filled out correctly and submitted as required. When it comes to regulatory legal advice, always consult an expert attorney (or, in the case of a global distribution network, several attorneys).

-

International taxes and tariffs:

Each country has its own tax structures, including value-added taxes (VAT), goods and services taxes (GST), tariffs, and customs duties, each potentially impacted by the type of good and its country of origin. These costs can quickly compound and impact margins, especially when businesses ship or process materials and products across multiple countries. Beyond the direct financial impact, companies must also ensure proper classification of goods and timely payment of all required fees, as well as regularly update their protocols to satisfy new or changing regulations. Failure to properly manage these obligations can result in costly delays, fines, or even the seizure of goods at customs checkpoints.

-

Political risk:

Sometimes the politics of a country changes with little or no warning. Traveling employees might go from not needing a visa to needing one. An airport might suddenly not be allowed to fly a route your business depends on. A labor strike could cripple a port’s operations for days or weeks. There could be huge delays at the border if a politician thinks he or she can score points by tightening security measures. And, as in 2022, a nuclear superpower might invade a country critical to the global supply chain, and, as a small American business, there’s very little you can do about it but find a way to cope. Despite some logistics innovations historically coming from military efforts, wars are, on balance, as overwhelmingly bad for economies as they are for humanity.

Major Regulations that Affect International Transportation

Several key regulations govern international transportation and logistics processes. To maintain smooth cross-border operations, international businesses often bring in compliance experts or deploy sophisticated business platforms to better understand, and therefore reliably comply with, these rules. The following six categories affect most international transportation, but businesses should always verify specific regional regulations before entering new markets or updating protocols.

- Customs documentation requirements: Each country has its own list of required documentation for imports and exports, including commercial invoices, bills of lading, certificates of origin, and packing lists. These documents must be accurate and complete to avoid delays or outright rejections at customs checkpoints.

- Safety and security regulations: When transporting hazardous materials, businesses must follow relevant international agreements, such as the International Maritime Dangerous Goods (IMDG) Code and air cargo security requirements. These shipments often require specific packaging, labeling, and handling procedures to demonstrate compliance and, ultimately, ensure a safe and smooth supply chain.

- Environmental regulations: Many countries enforce environmental protection measures for transporting goods, such as emissions standards for vehicles and ships or requirements for sustainable packaging materials. For example, the International Maritime Organization’s (IMO) regulations on ship pollution and the European Union’s packaging waste directives set sustainability standards for international shipping businesses.

- Trade agreements and restrictions: Free trade agreements, sanctions, and embargoes can affect which goods businesses can transport between specific countries. These agreements often set rules for origin requirements, mandatory documentation, licenses, and specific duty rates.

- Transportation-specific rules: These regulations include rules for mode-specific transportation, such as maximum vehicle weights, driver hours of service, and container specifications. These guidelines vary significantly among countries and regions and affect route planning, shipment allocation, and delivery schedules.

- Digital trade regulations: Some countries require electronic customs declarations, advance cargo information, and digital documentation for all imports. Systems like the EU’s Import Control System 2 (ICS2), for example, mandate electronic submission of safety and security information before participating countries can accept goods.

Ways to Make International Logistics More Efficient

One of the challenges with international logistics is keeping everything running reliably and efficiently. There are so many moving parts that it’s easy for costs to creep upward, especially when connecting systems that weren’t designed to do so. By implementing these best practices within its operations and with its partners, a business can counteract some of the most common and costly sources of inefficiency.

Standardization

This approach has been employed successfully for centuries, from the days of the Roman army to today’s global franchise businesses. Customization is time-consuming and confusing, especially when a business is managing a lot of people, vehicles, facilities, and operating processes.

Having all data delivered in the same way and representing the same things lets a business compare parts of its operation in an apples-to-apples way. Having everyone use the same forms and protocols means you don’t need to waste time studying each one, and employees can quickly glean the necessary information. Having everyone in sync on vocabulary and processes means steps become rote and can happen faster.

Sometimes, people on the ground will push back against standardization, and for reasons that seem sound—one-size-fits-all solutions, for example, often lend themselves to improvements in practice. But just because something could be improved in one location or for one part of a supply chain doesn’t mean the savings would be worth the cost of introducing exceptions to otherwise standardized procedures. Good leaders will pay attention to and thoughtfully consider situations where exceptions produce more value than they take away by adding friction to the system.

Improve Visibility

One of the best ways to fight inefficiency is to improve the quality, timeliness, and comprehensiveness of tracking information. Knowing where everything is to the meter and the minute can be a huge advantage in managing a dynamic supply chain, especially where partners are involved that could benefit from predictability and advance notice of what you’re doing. The data generated by visibility enhancements can help a business target and diagnose other sources of inefficiency, as well.

Controls

As operations spread across geographies, nations, and partners, implementing controls can help operations function within established parameters, particularly when they’re hard to observe directly. Giving formal responsibility for outcomes and metrics to people on the ground and conducting regular internal audits can keep operations running smoothly and according to spec. It can be wise for auditors to adopt a mindset of being there to help the team, as formal audits can be intimidating and can create an adversarial tone with important teams and partners if not handled with care.

Communication

The importance of good communication among team members may seem obvious, but large organizations partnering with other large organizations often have real barriers to quick conversations among people looking to coordinate efforts, ask questions, or spread best practices. There are stories from real businesses where two people needed permission from both of their bosses (which was only sometimes forthcoming) to have a 15-minute conversation to ask each other questions and coordinate on a logistical task. It’s better to do the opposite: Don’t just let your employees talk to the people they need to talk to; encourage them and make it easy.

Solid Partnerships

Having the right partners can make or break a global supply chain. Working far apart in disparate time zones, operating in different business cultures, speaking different first languages, and having different areas of expertise makes it hard for some businesses to build productive, trusting relationships. But it’s worth the investment. Good partners get to know each other’s businesses, are proactive about helping each other, and share information that may be useful about preparing for changing economic conditions. The difference between a partner you must manage aggressively and a partner you can build with can be the difference between growth and stagnation for international businesses.

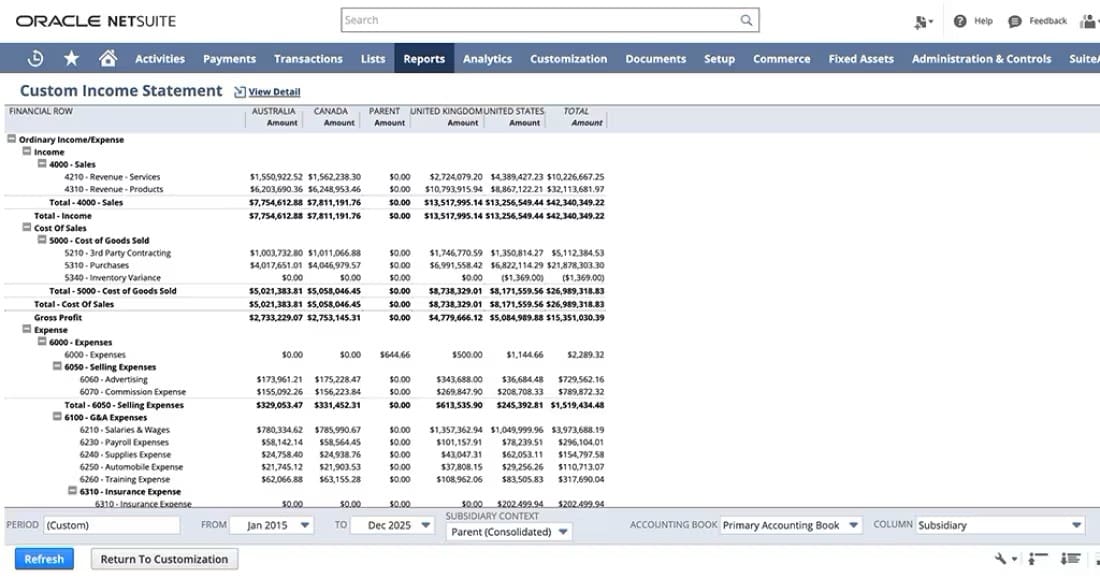

Use NetSuite for Transportation and International Logistics

Good data collection, management, and analysis are crucial for businesses looking to overcome the challenges of international logistics. NetSuite Enterprise Resource Planning (ERP) can merge a business’s financial management, inventory management, staff management, and product distribution data into a single platform for transportation and logistics that provides real-time updates for decision makers, managers, and business partners.

The logistics necessary for the efficient functioning of a large global supply chain can be intimidating. So it’s important for a small business looking to grow internationally to remember that international logistics operations usually start small and grow over time, along with the level of the company’s cross-border business.

Most often, the best way to move forward is with good tools and business partners. No one company will provide everything a business needs, from software to legal expertise to shipping, but if your operations are expanding internationally, it’s never too soon to start looking for the tools and future partners that will take your business to the next international level.

NetSuite Enhances International Management

International Logistics FAQs

What are the components of international logistics?

When dealing with business logistics of any kind, international or not, the Chartered Institute of Logistics and Transport has defined “7 R’s” that define the components and goals of whatever system a business is building and using. The seven are: to get the right quantity (1), of the right product(s) (2), in the right condition (3), to the right customer (4), at the right price (5), at the right place (6), and the right time (7).

What is the importance of logistics to international business?

The difference between good and bad implementations of international logistics can produce such drastic swings in costs and reliability that good international logistics is a survival necessity for many businesses operating in a global economy. Meanwhile, as regions and countries specialize in different things, many industries are in a position where, to remain competitive, they have no choice but to consider expanding their supply chains internationally.

What is an international logistics manager?

An international logistics manager plans and/or oversees parts of a supply chain that span one or more international borders. They deal with the assembly, shipping, storage, distribution, and delivery of physical products.

What is logistics in international trade?

Logistics in international trade is the art and science of moving physical goods from supplier to customer across at least one international border.