Navigating a complex network of suppliers can be challenging for businesses, especially those that are growing and struggling to maintain their competitive edge. Managing suppliers is far from simple and involves a multitude of critical tasks, including identifying and selecting the right partners and ensuring consistent quality. To succeed, businesses must master these undertakings while also remaining flexible enough to adapt to never-ending changes in market conditions and customer needs. If a business missteps and doesn’t carefully manage its supply chain, disruptions, financial losses, reputational damage and missed innovation opportunities can ensue.

To effectively manage its suppliers, a company needs a detailed framework that starts with finding suppliers that fit its needs and ends with closing the books on its final order. This article explores the intricacies of supplier life cycle management (SLM), including key stages, benefits, best practices and technology’s role in modern SLM practices. These factors work together to help business leaders build resilient, agile and competitive supply chain operations.

What Is Supplier Life Cycle Management?

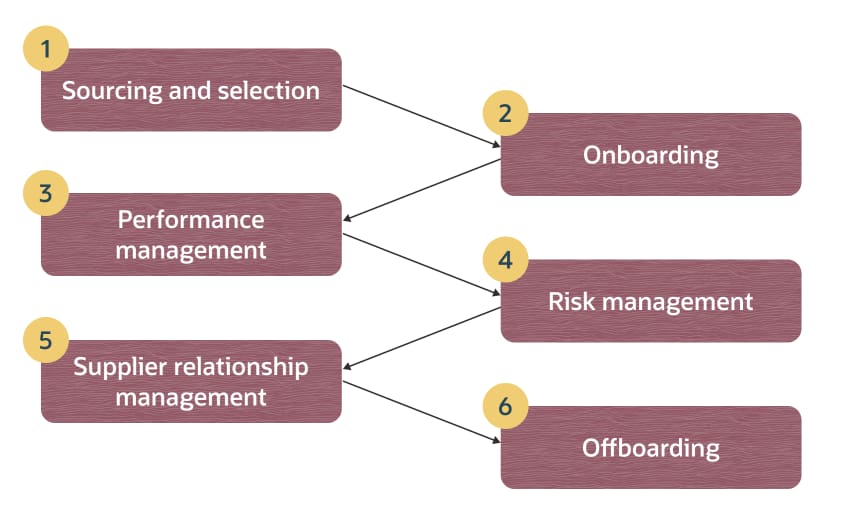

SLM, also commonly known as vendor life cycle management, is a comprehensive approach that businesses can follow to manage their relationships with suppliers throughout the entire length of their partnership. It encompasses all stages of supplier interaction, from initial sourcing and selection to onboarding, performance management and, if applicable, offboarding. The primary objectives of SLM are to improve supply chain operations, reduce costs, mitigate risks and create mutually beneficial relationships with suppliers from day one through final delivery of goods or services.

SLM takes a holistic view of the supply chain. As such, it encompasses the similar, but more granular, concepts of procure-to-pay, which focuses on procurement financial management, and source-to-contract, which manages finding suppliers from which to source products and services. These processes, along with other aspects of supply chain management, combine to create a robust SLM system that enables businesses to work with the most reliable, high-performing suppliers available, contributing to their overall success.

Key Takeaways

- SLM is a detailed approach to managing supplier relationships and performance.

- Implementing best practices and leveraging technology can help businesses optimize their supply chain.

- Effective SLM helps businesses build more resilient, agile supply chains to stay competitive in today’s global marketplace.

Supplier Life Cycle Management Explained

The supplier life cycle begins with sourcing and selection, with businesses identifying and evaluating potential suppliers based on criteria such as material/service quality, cost, delivery time and how the vendor aligns with company values. Then companies onboard their suppliers to integrate them into their systems and processes, set expectations and establish lines of communication. Once contracts are enacted and/or orders are placed, businesses monitor performance against relevant metrics and key performance indicators (KPIs) to minimize risks and find areas for innovation and improvement. Throughout each step of the supplier life cycle, managers and contact points should prioritize building strong, collaborative relationships with vendors through regular communication, information sharing and a commitment to continuous improvement.

Eventually, the life cycle may come to an end, either due to project completion, changes in business needs, market fluctuations or performance issues. Offboarding suppliers involves transitioning away from the partnership while still maintaining a positive relationship. This way, if it needs change and a vendor is needed once again, the relationship can resume smoothly and efficiently. By understanding and effectively managing each of these stages, companies can increase their supply chain visibility and build a network of vendors that aligns with their overall goals and remains flexible as market conditions evolve.

Why Is Supplier Life Cycle Management Important in Modern Business?

Modern businesses often rely on external suppliers that each constitute a single link in a larger supply chain. Because of this arrangement, managing supplier relationships involves navigating an intricate system of interactions, expectations and risks throughout each supplier’s life cycle. By adopting a structured approach to SLM, businesses can improve their product quality, optimize their processes, save money and create a more reliable and satisfactory customer experience. Furthermore, SLM helps companies ensure that their suppliers align with their values and goals, such as sustainability and ethical sourcing practices. This adds transparency that allows businesses to build resiliency and deliver for customers in their own, unique way as they maintain their competitive advantages and appeal while minimizing costs.

Procurement Life Cycle Management vs. Supplier Life Cycle Management

Procurement life cycle and SLM are closely related concepts, but they focus on different aspects of the supply chain. Procurement life cycle management focuses on the internal processes and activities pertaining to acquiring goods and services, including placing, paying for, receiving and processing orders. In contrast, SLM prioritizes a business’s end-to-end relationship with its external suppliers, including monitoring ongoing performance and establishing improvement initiatives during the duration of the partnership.

While procurement life cycle management is primarily concerned with the transactional aspects of buying goods and services, SLM emphasizes the importance of building and maintaining long-term, collaborative relationships with key suppliers to create a lasting and reliable supply of high-quality products and services. Ultimately, both approaches are essential parts of effective supply chain management, and businesses must balance strategies from both to streamline processes and forge individualized and targeted procurement relationships with suppliers.

6 Stages of Supplier Life Cycle Management

SLM is a multistage process that allows businesses to control and influence supplier relationships from start to finish. Some companies may want to expand the following six common stages of SLM — such as a pharmaceutical company that adds steps to ensure that all suppliers meet safety, licensing and regulatory requirements — so businesses should be sure to consider their specific circumstances when developing their SLM protocols.

1. Sourcing and Selection

First and foremost, businesses must identify and evaluate potential suppliers to find those that can meet their specific needs and requirements. This stage involves defining clear criteria for supplier selection, such as quality control standards, cost, location and delivery time. Businesses often conduct extensive research on each candidate through peer reviews, live demos and samples during contract negotiations to find the right suppliers at the best price. For instance, an environmentally conscious business may conduct additional research to determine which potential suppliers use sustainable practices when producing their raw materials. Early research investments, in both time and resources, help businesses lay the foundation for successful supplier relationships and minimize the risk of encountering future issues.

In today’s market, companies also invest in technology that can enhance aspects of SLM. According to KPMG’s 2023 Global Procurement survey, the top six technologies integrated into the sourcing and selection process are spend analytics tools (90%), e-sourcing platforms (83%), contract management software (83%), market intelligence tools (79%), supplier relationship management software (76%) and artificial intelligence (AI) and machine learning (51%).

2. Onboarding

Once the selection process is complete, a business can integrate chosen suppliers into its systems and processes, including opening communication channels, providing access to key systems, defining roles and responsibilities, establishing performance expectations and ensuring compliance with legal and regulatory requirements. This is often done through targeted software, such as a supplier management platform, or as part of a larger enterprise resource planning (ERP) system. For example, a supplier may be able to log in to a business’s portal to input account information, update order statuses, send messages and process payments, keeping all relevant information in one centralized location. Effective onboarding also helps businesses and their vendors set realistic management standards and clear goals.

3. Performance Management

Supplier performance management involves ongoing monitoring and analysis of targeted and relevant KPIs. Common procurement KPIs include contract compliance rate, supplier lead time, vendor availability and supplier defect rates, though KPI analyses are often most useful when contextualized over time alongside other data. By continually monitoring metrics like these, managers can identify strengths and weaknesses, ensure that suppliers are meeting their contractual obligations and provide data-supported feedback and support. Performance management also allows businesses to shed subpar vendors and recognize and reward top performers, thereby incentivizing continual improvements and high-quality service while maximizing the mutual benefits of each partnership.

4. Risk Management

To mitigate potential supplier-side risks, businesses can conduct regular supplier audits that include financial stability assessments and create contingency plans to reduce the impact of any supplier slowdowns, shortages or exits from the market. These plans may include diversifying suppliers, automating inventory alerts and reorders and monitoring the market and supply chain in real time. Such efforts help companies develop proactive risk management strategies, such as relying on regionally diverse suppliers to avoid weather-related shortages, to minimize risk exposure as they build a more stable and agile supply chain operation.

5. Supplier Relationship Management

Supplier relationship management (SRM) helps businesses maintain positive relationships with their vendors, potentially leading to preferential treatment, such as priority status during shortages, more generous credit terms and discounts. SRM processes include participating in joint problem-solving sessions, recognizing exceptional supplier performance and engaging with executives. Additionally, this collaboration helps businesses leverage their suppliers’ expertise to access new markets or technologies and ultimately expand their customer base and grow. SRM also helps both parties quickly inform each other when issues arise or market disruptions occur.

6. Offboarding

Eventually, most business relationships come to an end. This could be for several reasons, including poor performance, an expiring contract, evolving business requirements or a combination of factors. To transition away from a supplier relationship in a structured and professional manner, businesses should clearly communicate the offboarding process, including all relevant documentation, final payments and performance evaluations. Additionally, businesses should close out all accounts and reclaim any required knowledge, equipment or intellectual property to maintain their data security and privacy. This detail-oriented approach helps businesses protect their reputation and stay on good terms with outgoing suppliers in case they need to do business again in the future.

Benefits of Supplier Life Cycle Management

Implementing an SLM strategy can offer numerous benefits that can potentially improve the performance and resilience of both the business and its vendors. Some key benefits of SLM include:

- Improved efficiency: SLM identifies redundancies and inefficient processes, helping managers find areas to automate and allowing them to centralize supplier data. This streamlining reduces manual effort and minimizes errors.

- Optimized cost management: Through ongoing sourcing and performance adjustments, SLM can help companies reduce their procurement and administrative costs and increase their return on investment (ROI) for raw materials and services.

- Strengthened risk management: By incorporating robust risk assessments into their SLM processes, such as tracking on-time delivery rates and order quality and accuracy over time, businesses can better identify and address potential supplier risks. Then, managers can plan accordingly to minimize their impact and protect the bottom line.

- Enhanced supplier selection: SLM protocols provide a structured and detailed approach to finding and selecting suppliers. This empowers businesses to choose the partners that best meet their unique criteria, such as commitment to social responsibility initiatives or using only high-quality materials in their offerings.

- Fostered supplier relationships: By fostering communication and trust through open collaboration, businesses can use SLM tactics to build strong, long-term and mutually beneficial relationships with their suppliers. For example, if customer preferences shift, a clothing retailer can work with its suppliers to design new items that will satisfy this new demand without breaking the bank.

- Improved supplier performance: By adopting an active management style, businesses can gain insights into supplier performance that allow them to adjust their ordering processes and offer feedback to make regular improvements. If a supplier has slow delivery times, for instance, a business can work with the vendor to streamline the ordering process by setting up automatic monthly deliveries, ensuring that supplies arrive when they’re needed.

- Bolstered supply chain resilience: Through comprehensive contingency planning and real-time monitoring of market factors, such as supplier reliability and material availability, SLM helps companies build a more agile and resilient supply chain that can adapt quickly to changing conditions. For instance, by keeping a diverse active supplier list, businesses can increase or decrease a supplier’s order share as needed when performance or price fluctuates.

- Increased visibility: Managers and decision-makers can leverage SLM systems to gain greater visibility into their supplier base, enabling them to monitor orders, deliveries and performance in real time. This data helps managers identify problems before they begin to affect customers, as well as to seize opportunities as they arise.

- Improved compliance and regulatory adherence: Careful SLM quality control processes help businesses make sure their suppliers are complying with all relevant laws, regulations and industry and sustainability standards. This is especially important for companies in heavily regulated industries, such as healthcare or food service, where compliance failures can lead to significant penalties, including fines, legal trouble and reputational harm.

Challenges of Supplier Life Cycle Management

Implementing and maintaining an effective SLM strategy requires careful planning and diligent adjustments. Anticipating the following four common challenges, and understanding how to overcome them, can help businesses be prepared.

- Supplier risk assessment and mitigation: Identifying, assessing and managing risks posed by suppliers can be complex and time-consuming, especially for vendors with low transparency into their operations and sourcing strategies. When allocating procurement orders, businesses should develop comprehensive risk assessment frameworks that consider myriad factors for each vendor, including financial stability, operational reliability, percent share of total orders and compliance rates. These factors are often assessed through targeted KPIs, such as percentage of spend for each supplier. For example, if a single supplier makes up 75% of spending for a specific material, diversifying can minimize the risk of stockouts if that supplier faces an unexpected slowdown.

- Supplier performance measurement and improvement: Collecting clear, meaningful and timely performance metrics for a diverse supplier base can be challenging. To report real-time results, many businesses use analytics tools that leverage automation and AI to provide comprehensive reporting, often through customizable dashboards and user-friendly interfaces.

- Data quality: Data is only useful if it can be trusted, but ensuring the accuracy, completeness and timeliness of data across multiple suppliers can be difficult. Still, through data governance and validation tools, leaders can feel confident that they’re making decisions based on the most up-to-date and relevant information available, instead of playing catch-up with backward-facing data.

- Technology integration: Integrating SLM processes and systems with existing systems, such as inventory or sales platforms, can be complex and resource-intensive. Rather than using disparate and siloed systems, many businesses seek out comprehensive ERP solutions with built-in SLM modules and features that provide seamless data flow and minimize information gaps and user frustrations. ERP systems also give decision-makers, at all levels, a holistic understanding of operations to keep supplier strategies in line with larger business goals.

10 Best Practices for Implementing Supplier Life Cycle Management

To create an effective SLM strategy, business leaders should develop a systematic approach that considers their unique procurement needs and goals. The best practices outlined below can help companies employ the right tools and processes to get the most out of their supplier relationships.

- Architect a strategic supplier ecosystem: To develop a comprehensive supplier strategy that aligns with overall business objectives, first identify the key capabilities and competencies the company requires. Then assess each potential supplier’s performance and create a framework to track progress toward specific goals. These goals should aim for creating an effective supplier ecosystem that’s well suited to meet the business’s needs and its customers’ expectations.

- Arrange suppliers by value and risk: Segment the supplier base based on specific metrics, including strategic importance, spend volume and risk exposure. Armed with this information, managers can better prioritize and allocate resources. For example, a business that relies on a single supplier for the majority of its supplies may schedule monthly calls to map out future orders but only send an email to the sales team when ordering from a smaller vendor.

- Define and measure supplier success metrics: Choose clear, relevant and measurable KPIs that teams can use to assess supplier performance and internal efficiency, such as lead times, ROI, quality and rejection rates and purchase order (PO) accuracy. By regularly updating these chosen metrics, businesses can continually identify new areas to target for improvement and keep supplierstrategies aligned with big-picture goals as the company’s needs evolve.

- Conduct comprehensive supplier assessments: Implement a consistent supplier assessment process that analysts and decision-makers can follow to evaluate suppliers’ capabilities, performance and potential risks. These assessments should review a combination of quantitative and qualitative methods, such as supplier audits, surveys, direct feedback, KPI trends and performance scorecards. These diverse sources help create a more holistic view of supplier performance and track how it impacts the company’s bottom line and ability to deliver for customers.

- Cultivate mutually beneficial supplier partnerships: Foster collaborative relationships with strategic suppliers based on trust, transparency and shared value creation. Regular communication helps suppliers and businesses engage in joint problem-solving to innovate, optimize costs and enhance supply chain efficiency. A retailer, for example, can collaborate with its suppliers to adapt to any new trends and to stock new, high-demand items ahead of a busy season, increasing sales for both parties.

- Implement a dynamic supplier performance management system: Develop a responsive management system that can monitor and report on supplier performance and offer actionable feedback and suggestions. These systems can track supplier performance against defined and customizable benchmarks and KPIs, as well as identify trends and add context to data, facilitating swift and data-driven decision-making. Many businesses integrate their supplier management systems with sales and inventory systems, for example, to ensure that all aspects of procurement are working together to deliver for customers.

- Proactively identify and mitigate supplier risks: Establish a timeline for regular risk assessments, scenario planning and contingency strategies to make sure all mitigation strategies are up to date and in line with current market threats and conditions. To achieve this, periodically monitor supplier financial health, operational stability and compliance with current regulations to proactively identify and plan for any potential risk exposure. For example, a manufacturing business should monitor environmental regulations and communicate any updates with its suppliers to adjust processes in advance and maintain compliance as standards evolve.

- Optimize supplier processes through automation: Leverage tools that can automate and streamline management processes, such as software that can onboard new vendors and generate contracts. Businesses should carefully choose their automation investments to balance budget limitations against potential benefits, such as reducing manual effort and errors when creating POs. These targeted improvements enable faster, more efficient workflows that fit within the business’s scope and strategies.

- Leverage data analytics to drive supplier insights: Implement data analytics tools to gain deeper and more relevant insights into supplier performance, risk and opportunities. Many business platforms, including procurement ERP systems, have built-in data features that leverage advanced analytics tools and AI to analyze large datasets and better identify patterns and predict trends. These tools can comb through large datasets significantly faster than manual analysts, empowering decision-makers to make proactive strategic pivots and seize competitive advantages.

- Foster a culture of continuous improvement: Encourage a culture of continuous improvement at all business levels that values innovation, collaboration and learning. Through regular engagement with suppliers and investments in internal skills development, team members can share best practices, uncover hidden improvement opportunities and implement comprehensive initiatives that drive mutual growth and success. For example, by training staff in the ins and outs of the supply chain, employees can more effectively work with suppliers to streamline deliveries and increase margins for both parties.

6 Key Features of Supplier Life Cycle Management Systems

SLM systems provide a centralized platform for managing all aspects of supplier relationships. Below are six key features businesses should consider when selecting an SLM system to meet their specific requirements.

1. Supplier Onboarding and Qualification

SLM systems typically include a streamlined and automated process for onboarding new suppliers, replacing the time-consuming and error-prone manual processes of the past. These systems often have built-in features, such as customizable registration forms, document upload and management capabilities. They also have consistent workflows for collecting and verifying essential information, including relevant company details, certifications and compliance standards, to ensure consistent details across the supplier list and provide side-by-side comparisons. Additionally, SLM systems may support qualification processes that allow decision-makers to rate potential suppliers against predefined criteria and requirements when choosing new vendors.

2. Supplier Performance Management

An SLM system should provide tools for choosing, defining and tracking diverse KPIs, such as material quality, delivery speed, cost and responsiveness. Many systems automatically collect and analyze performance data, generate scheduled or ad hoc performance reports and monitor improvement initiatives’ progress and impact. Additionally, an SLM system should organize and segment suppliers based on specific performance criteria, allowing businesses to focus their efforts on targeted improvement strategies with the highest ROI potential. For example, if costs are rising for one type of material, an SLM system could group suppliers that offer that material together to help managers find ways to reduce costs without impacting quality.

3. Contract Management

Effective contract management helps managers ensure that all supplier relationships are governed by clear, legally compliant and mutually beneficial agreements. An SLM system should offer robust contract management capabilities that include contract creation, storage and retrieval. The system should also support the development of standardized contract and clause templates, as well as approval workflows to streamline the contracting process. Additionally, SLM systems often monitor contract compliance, manage contract amendments and renewals, and assess supplier performance in relation to contractual obligations. This provides assurance that suppliers are following their contracts and meeting their expectations, and, if they fall behind, the system can automatically send alerts to all relevant parties.

4. Risk Management and Compliance

To help businesses manage risks, many SLM systems identify and assess supplier vulnerabilities, including data security breaches and regulatory noncompliance, and offer actionable suggestions to minimize exposure. This often involves ongoing monitoring of supplier status, such as financial position, as well as external pressures, such as material availability and evolving industry standards and government regulations. For example, a healthcare company could use an SLM system to track all suppliers of personal protective equipment on one dashboard, allowing managers to more effectively implement a diversification strategy that makes sure stock is up to standard and that inventory levels remain high during the upcoming flu season.

5. Collaboration Tools

Many SLM systems have built-in platforms that facilitate communication and collaboration between companies and their suppliers. These platforms include features such as secure messaging, document sharing and payment portals, as well as increased transparency into orders and project updates. These tools allow companies to work with suppliers to build trust, develop new products, decrease miscommunications and work on focused initiatives. In fact, “increasing level of supplier collaboration” was the top strategy for delivering value in Deloitte’s 2023 Global Chief Procurement Officer survey, with 61% of respondents prioritizing it.

6. Advanced Reporting and Data Analytics

Due to recent technological advancements, sophisticated reporting and data analytics tools are more affordable and accessible than in the past, especially for small and medium-sized businesses. These technologies help companies quickly and securely collect large amounts of data from throughout their supply chain and offer suggestions to users, such as addressing a supplier’s increasing delivery time before it begins affecting production schedules. This data can then be used to reveal growth opportunities and inefficient processes, often organized in intuitive and customizable dashboards and reports and aided by data visualization tools, such as charts and graphs. By leveraging these tools, businesses can easily benchmark supplier performance, run side-by-side comparisons and identify trends quickly to inform future strategic pivots. Additionally, many SLM systems can integrate supplier data with more comprehensive systems, such as an ERP solution, to provide a big-picture view of procurement and its impact on overall profitability.

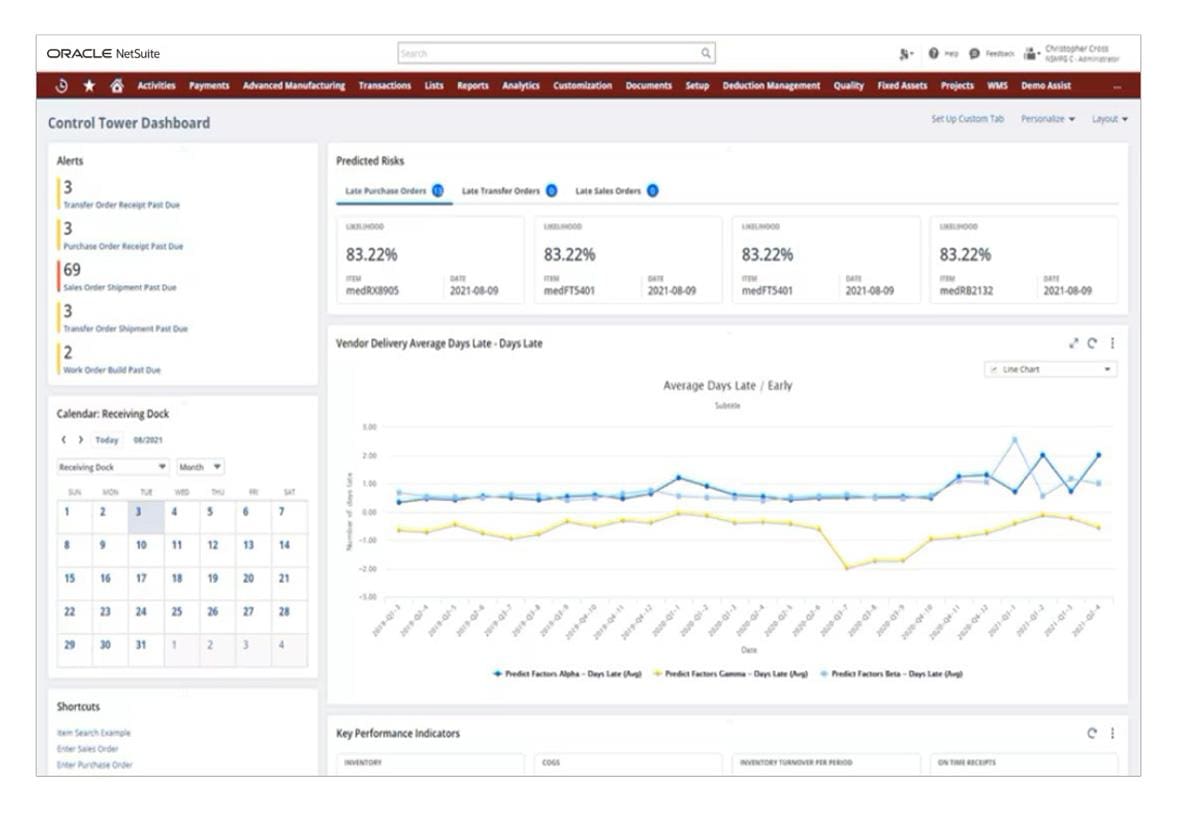

Optimize Supplier Management With NetSuite Solutions

As global supply chains continue to become more complex and vulnerable to disruption, businesses need sophisticated tools to stay ahead of the competition. NetSuite’s supply chain management software is a powerful platform that helps businesses optimize their SLM processes with end-to-end visibility into operations — from demand planning and inventory management to order fulfillment. With features such as real-time inventory tracking, automated replenishment, collaborative portals and advanced analytics, NetSuite enables businesses to monitor and improve their supply chain at every stage of the supplier life cycle and to build a more agile and resilient network.

NetSuite’s supply chain management software can also integrate with other features of NetSuite ERP, including NetSuite Procurement, to give businesses a more comprehensive solution for managing the supply chain. With features such as self-service supplier portals, automated PO generation and real-time spend tracking, NetSuite enables businesses to onboard and manage suppliers efficiently and reduce manual data entry, while gaining visibility into supplier performance. This deeper transparency empowers businesses to find places to reduce costs, improve compliance and build stronger, more collaborative relationships with their suppliers.

Strong supplier life cycle management is an important part of building resilient, agile and competitive supply chains — an increasingly critical step in navigating today’s global marketplace. By following up-to-date best practices and leveraging key features of SLM systems, business leaders can maximize the benefits gained from their supplier relationships, as well as mitigate risks and drive ongoing improvement. With a carefully planned and targeted supplier management plan in place, companies can build long-term success with a supply chain operation that is both strong and flexible, even in the face of changing market conditions and evolving customer demands.

Supplier Life Cycle Management FAQs

What is vendor management workflow?

Vendor management workflow is the series of steps and processes that managers and procurement staff use to manage supplier relationships. A typical workflow includes vendor selection, onboarding, performance monitoring, risk assessment and contract management. These steps work together to help businesses ensure that vendors meet expectations and contribute to ongoing success.

What is life cycle management in supply chains?

Life cycle management in supply chains refers to the end-to-end management of a product or service and its associated suppliers, from onboarding to offboarding and everything in between. It involves coordinating and optimizing all supplier processes and activities across the supply chain, including sourcing, manufacturing, logistics and customer service. Effective management helps ensure that products are delivered to customers efficiently and cost-effectively.

What is the supply chain management (SCM) life cycle?

The supply chain management (SCM) life cycle encompasses the entire journey of a product or service within the supply chain, beginning with identifying a need and ending with supplier offboarding when their services are no longer required. It focuses on managing the flow of goods, information and finances across the entire supply chain network, often involving multiple stakeholders, including suppliers, manufacturers, distributors and retailers. These parties work together to collaborate on ways to optimize performance, minimize costs and meet customer demands.