Mean time to repair (MTTR), which measures how long it takes to restore a system after something breaks, is an important business metric that ties directly into the bottom line and customer satisfaction. The faster the MTTR, the less downtime a system experiences and the more productive a business can be. For critical systems, such as manufacturing equipment and financial technology, lower MTTR directly translates into improved profitability. Proactive management of MTTR takes operational discipline, strong asset management, and effective allocation of maintenance resources. This article explores how MTTR is calculated, the factors that impact this metric, and what businesses can do to improve their MTTR numbers.

What Is Mean Time to Repair (MTTR)?

MTTR is a field services and incident response metric that companies use to measure how efficiently a team or individual handles incidents and/or maintenance calls. MTTR represents the average time it takes to diagnose and fix systems that are malfunctioning or broken, be they machines, computers, networks, or software.

MTTR is often used in concert with mean time between failure (MTBF), an operational resilience metric that tracks the average time between malfunctions. Taken together, these two metrics provide a solid assessment of a system’s resilience and can make it easier for business leaders to track how equipment problems and repair work affect uptime and profitability.

Key Takeaways

- MTTR calculates the average time it takes for a company to repair a system.

- MTTR directly impacts system uptime and is a crucial business performance metric.

- Poor MTTR can indicate issues with field service management and asset management.

- Factors that impact MTTR include the age and complexity of a system, the skills of a maintenance team, the tools available to technicians, and the knowledge base and standard procedures that guide them.

- Strong asset management and preventative maintenance, along with effective allocation of response resources, can drive down MTTR.

Mean Time to Repair Explained

MTTR stands as a key metric for field service management, maintenance teams, incident response teams, and any other group or individual responsible for keeping equipment or facilities up and running. This includes everything from manufacturing equipment and car fleets to computers and software. MTTR is often used as a key performance indicator (KPI) by a range of business and technical decision-makers across industries because it acts as a bellwether of efficiency and resilience on a number of fronts. For example, poor or declining MTTR can often offer clues about:

- Operational inefficiencies

- Problems with field service processes

- Poor incident response planning

- Resource allocation issues within maintenance teams

- Operational costs of aging equipment

- System quality issues causing increased downtime

More importantly, MTTR performance has a direct downstream impact on the bottom line. The longer repair windows are open, the more downtime an organization experiences, and the more integral the malfunctioning system is to productivity or creation of goods, the more costly that downtime will be. Additionally, excessive MTTR can negatively impact customer satisfaction as well as the employee experience.

Because MTTR is tied to so many crucial operational and maintenance processes, this metric is often used as part of service level agreements (SLAs) to set speed of service expectations for maintenance and service contracts. In addition, many companies use MTTR for internal benchmarking and to track the performance impact of process changes. Often, MTTR is used in combination with other important maintenance KPIs, such as MTBF, to provide a fuller picture of the availability and reliability of equipment and technology systems.

One of the blind spots of using MTTR as a performance metric to reduce downtime is that it doesn’t reflect the full downtime that a system suffers during an outage. For example, if there are issues in identifying a problem, there could be significant lag time between when the malfunction occurs and when the repair process begins. This can be of particular concern for IT use cases, such as software performance management or cybersecurity, in which a malfunction may be less apparent than when a physical piece of equipment simply stops running. In these situations, companies often use a different MTTR—mean time to recovery—which is the average time it takes to recover from a system failure, from the inception of the issue until it’s fully resolved. This factors detection time into the equation.

How to Calculate Mean Time to Repair

MTTR calculates the average amount of time that repair windows are open. To determine MTTR, take the total amount of time an asset (or set of assets) is down during repair over a given time period and divide that number by the total number of incidents or service calls made for that asset (or set of assets) over that same time period:

MTTR = Total downtime/Total number of incidents

So, if a maintenance team overseeing a manufacturing production line spent 40 hours assessing and fixing downed machinery on that line in a financial quarter, and it made those repairs across 25 incidents, the MTTR would be:

MTTR = 40 hours/25 incidents = 1 hour and 36 minutes

The total repair time is usually calculated from the time maintenance staff is alerted about an issue through the time the system is once again operational. This includes the time it takes to diagnose and assess the issue on the front end of the process, as well as the time taken to test the fixes on the back end. Companies typically won’t include the lead time it takes for parts to be delivered, but they will include the time it takes to find and use spare parts they already own.

Seven Factors Influencing Mean Time to Repair

MTTR performance can be affected by a number of influences, from how well teams collaborate to how skilled they are at making fixes. The state of the systems themselves and the environments in which they operate also play a role in determining how long it typically takes to repair them. The following list breaks down seven of the biggest factors affecting MTTR.

1. Equipment Complexity and Condition

The complexity and condition of the equipment under repair play a huge role in MTTR. A complex machine with a lot of integrated circuitry, proprietary software, and many custom parts, for instance, will likely take considerably more time for a crew to assess and fix than a simple mechanical device. Similarly, aging and/or poorly maintained equipment often takes much longer to repair than newer machinery and could potentially experience additional breakage during the initial repair, contributing to higher MTTR in the process.

2. Availability of Spare Parts

While supply chain delays typically aren’t reflected in MTTR performance, inventory management headaches most definitely affect this metric. If maintenance crews have a hard time tracking down and obtaining spare parts from their internal inventory stores, this will lengthen measured repair windows and drive up MTTR over time. Not only do spare parts need to be readily available, but the maintenance team also needs to know their whereabouts and how to physically access them in a speedy manner in order to shorten MTTR.

3. Tools and Technology

The right tools and technology to diagnose and fix issues can make all the difference in improving MTTR. If technicians are working without the proper tools, they could end up worsening problems and lengthening repair times. And just as with spare parts, if technicians must constantly hunt to find specific tools purpose-fit for repairing specialty equipment, this will adversely affect MTTR.

4. Maintenance Team Skills and Availability

Skilled and experienced maintenance teams make fast repairs. If a company doesn’t have enough talent to respond to incidents and malfunctioning equipment, MTTR will suffer. Skilled and knowledgeable maintenance technicians can quickly diagnose issues, identify the necessary parts and tools, and efficiently carry out repairs. Additionally, the availability of maintenance personnel is essential. When a sufficient number of technicians are on hand to respond to equipment failures, repairs can be initiated promptly, thereby reducing MTTR and increasing asset reliability.

5. Documentation and Knowledge Management

When tasked with fixing complex systems or maintaining a wide range of equipment, documentation and knowledge management are key for speeding up MTTR. Clear and concise documentation on affected systems can greatly reduce recovery time, as technicians have access to the necessary information to diagnose and resolve issues quickly. A robust knowledge management system, such as a comprehensive knowledge base, allows IT teams to resolve incidents faster by providing crucial problem management records, step-by-step response practices, and workarounds. Additionally, incident postmortems and lessons learned from previous issues can be documented and shared, allowing teams to prevent future incidents or resolve them more efficiently the next time they occur.

6. Maintenance Procedures and Policies

Well-defined repair processes can greatly improve MTTR compared with having technicians stumble their way through ad hoc repairs. Formalizing maintenance procedures and policies makes it easier for companies to optimize repair times, especially across a team with varying skill sets and experience levels. What’s more, when businesses develop and enforce maintenance procedures, they’re better able to maintain standards for quality and safety as well.

7. Environmental Conditions

Environmental conditions are an external variable that can play a big role in MTTR performance. Equipment in hazardous, remote, or extreme weather environments is harder to access and also likely to require more extensive repairs than systems in ideal environments. While maintenance organizations can’t always control environmental conditions, they can mitigate these issues with appropriate tools and procedures that make it easier and safer to do unplanned maintenance in harsh conditions. For example, having the right personal protective equipment, such as cold-weather gear, can help technicians safely perform unplanned maintenance tasks in extreme temperatures. Similarly, having access to the necessary tools and equipment, such as portable lighting, generators, and specialized repair kits, can make it easier for teams to diagnose and fix issues in remote or difficult-to-access locations.

Benefits of Measuring Mean Time to Repair

Measuring MTTR can help businesses hold teams and individual technicians accountable for performance standards on multiple levels. Other benefits include:

- Enhanced benchmarking capabilities: MTTR offers a reliable metric for comparing operational performance of an organization or team against industry standards. Similarly, it can be used to compare internal teams or even the individual performance of maintenance staff, incident responders, or field service employees.

- Improved maintenance efficiency evaluation: High MTTR can indicate inefficiency in maintenance procedures. Tracking MTTR over time while making improvements can help maintenance teams optimize their processes for speed and efficiency.

- Smarter resource allocation: Poor MTTR performance could indicate issues in allocation of maintenance resources—not only staff, but also tools and spare parts. Companies that notice certain equipment or facilities with high MTTR compared with broader benchmarks may want to allocate more tools or technicians to improve those numbers.

- Maximized equipment uptime: Faster MTTR means more uptime. Companies that identify and address the issues delaying repairs and negatively impacting MTTR will boost their equipment uptime and business productivity in the process.

- Substantial cost savings: Driving down MTTR and boosting uptime will ultimately result in substantial cost savings. Speedy return to service helps companies avoid lost productivity and increase production capacity.

Challenges of Measuring Mean Time to Repair

While MTTR provides valuable insights into repair efficiency, measuring it accurately can be challenging, with even minor errors skewing results and undermining the metric’s ability to indicate real performance. By addressing the challenges below, analysts can gain meaningful and reliable conclusions from MTTR that drive measurable improvements:

- Data quality and availability: Accurate MTTR calculations require consistent data collection for all repair incidents. Complete records demand either significant manual data entry or potentially costly investments in sensors and unified systems that communicate and analyze this data in real time.

- Current failures and dependencies: When multiple systems fail simultaneously or cascade downstream, technicians often struggle to isolate and calculate individual repair times. System dependencies blur the lines between separate repair activities, distorting the timing for repairs to specific machines or systems.

- Manual triage: Manual incident reporting and repair protocols often lead to significant delays between failure occurrence and repair initiation, creating uncertainty about failure timing that directly impacts MTTR calculations. Inefficient or unclear prioritization of repairs can create gaps between perceived urgency and actual system needs, leading to skewed MTTR conclusions.

- Resolution time: Distinguishing between temporary fixes and permanent resolutions can be challenging, especially when dealing with intermittent failures or complex systems. Quick workarounds might restore functionality, but true repair times can vary if issues resurface.

- Defining repairs: Technicians may follow different standards for calculating the beginning and end of repairs. These inconsistencies can significantly impact MTTR, compromising the accuracy of both benchmarks and performance evaluations.

Industry Application of Mean Time to Repair

MTTR is used by a range of industries to measure maintenance and resilience performance. The following are four of the most common industry use cases.

Manufacturing

With some of the highest downtime costs of any industry, manufacturing firms pay particularly close attention to MTTR benchmarks for assets across production lines, warehouses, and other mission-critical facilities. Reducing MTTR is crucial for minimizing lost production time, meeting customer orders, and improving overall equipment effectiveness. Manufacturers aim to lower MTTR by standardizing repair procedures, providing technicians with better tools and training, leveraging predictive analytics, and optimizing spare parts inventory.

Energy and Utilities

Energy and utilities companies strive to maintain uninterrupted service to meet high customer expectations and maintain the integrity of their infrastructure. MTTR serves as a crucial performance metric to help companies in this industry expedite repairs, restore services promptly, and limit the consequences of downtime on consumers and businesses that depend on their critical infrastructure.

Information Technology (IT)

IT firms use MTTR to track how effectively they resolve software glitches, server failures, and cybersecurity incidents. With businesses depending on continuous access to applications and data, MTTR is a common performance benchmark to show how successfully IT departments maintain internal systems and digital infrastructure. Comparing MTTR to other metrics, such as total number of incidents or users affected by outages, helps IT teams better assess performance.

Telecommunications and ISPs

Telecommunications companies and internet service providers (ISPs) manage geographically distributed infrastructure that makes quick repairs a challenge, compounded by the urgency to get critical connectivity services back online. Network outages can affect thousands of customers simultaneously, making rapid repair response an important part of maintaining SLAs and increasing customer retention. Providers use MTTR to measure field technician performance and optimize dispatch protocols for tower repairs. MTTR also helps companies evaluate how accurately remote diagnostic tools identify issues, such as cable cuts, equipment failures, or signal degradation, to make sure teams arrive quickly and with the equipment they need to complete the repair.

Finance and Banking

Financial institutions must maintain the reliable availability of payment processing systems, systems of record, and even ATMs in order to maintain the trust and satisfaction of their customers. As such, finance and banking firms use the MTTR metric to help gauge their teams’ effectiveness in detecting, assessing, and resolving technical issues that could threaten the transactional resilience of the institution.

Strategies for Improving Mean Time to Repair

Field service management and maintenance teams can tackle lengthy repair windows through the following strategies, all of which serve to improve MTTR:

- Implement routine checks: Routine checks of equipment for significant wear and tear and other signs of damage can help direct preventative maintenance that forestalls the kind of major malfunctions that require significant time to repair.

- Use predictive maintenance: Predictive maintenance takes routine checks to another level by using Internet of Things sensors, telemetry, and other tools to more accurately predict when preventative care should be taken to avoid hard-to-fix failures.

- Enhance training and skill development: Bolstering the skills of maintenance technicians and incident responders through regular training improves productivity and accelerates technicians’ ability to assess and fix the systems under their care.

- Create repair-task SOPs: Repair-task standard operating procedures (SOPs) and incident response playbooks offer step-by-step guidance to staff out in the field, reducing the amount of time they spend figuring out what to do next in their service work.

- Create maintenance checklists: Maintenance checklists are a manual method for keeping technicians on task with routine maintenance that keeps machines from succumbing to hard-to-fix outages.

- Leverage maintenance management software: As opposed to simple checklists, maintenance management software adds tracking, automation, and alert capabilities to help companies streamline management of both planned and unplanned maintenance.

- Use remote monitoring: Remote monitoring makes it easier to continuously check the status and condition of systems in order to detect damage earlier so technicians can make fixes before bigger problems arise.

- Optimize spare parts management: Keeping track of an organized inventory of spare parts, establishing naming and coding standards for these parts, and managing inventory based on criticality can speed up MTTR by reducing the time it takes to find and obtain necessary parts during repairs.

- Keep detailed records of maintenance activities: Detailed records of maintenance activities make it easier to plan out preventative maintenance and can help technicians more quickly assess problems when systems break down.

- Encourage feedback from maintenance staff: Establishing a feedback loop for maintenance staff to communicate about what works and what doesn’t during an outage or incident can help inform future SOPs and streamline processes.

- Employ advanced diagnostics and mobile tools: Advanced diagnostics and mobile technologies allow maintenance teams to dramatically reduce MTTR by streamlining the repair process. Smart sensors and monitoring systems rapidly detect failures the moment they occur, allowing for immediate response. Integrated mobile tools, meanwhile, provide technicians with advanced diagnostics capabilities, empowering them to quickly pinpoint root causes and determine the optimal repair approach.

- Establish rapid response teams: Keeping rapid response teams on call for critical systems can eliminate lengthy wait times that stem from managing technicians across a large portfolio of assets. Having pros waiting to jump on outages immediately can have a decidedly positive impact on MTTR.

- Use instant communication platforms: For complex systems and serious outages, maintenance and incident response teams will need to collaborate closely to assess, fix, and test repairs. Messaging systems are vital for keeping everyone on track without having to wait for email responses or returned phone calls.

- Prioritize safety and compliance: Prioritizing safety and compliance is key for improving MTTR. By giving technicians the proper training and personal protective equipment and following standardized safety protocols, companies can minimize delays and disruptions caused by accidents or injuries during the repair process. Adhering to relevant industry regulations and internal compliance standards also helps streamline repairs by providing clear guidelines on how to safely diagnose, maintain, and restore equipment. When safety and compliance are top priorities, technicians can work more efficiently without worrying about potential hazards, and companies can avoid costly fines or production shutdowns due to regulatory violations.

Additional Metrics to Measure Incident Response

MTTR is just one piece of the incident response puzzle, measuring repair efficiency only once work begins. Businesses only tracking MTTR miss insights into system reliability, failure patterns, and detection capabilities that directly impact operational performance, which reduce the need for repairs altogether. The complementary metrics below work alongside MTTR to provide a comprehensive view of maintenance protocols and system health.

Mean Time Between Failure (MTBF)

MTBF calculates the average time between system failures to quantify equipment reliability. By dividing total operational hours by the number of failures during that period, companies can estimate when equipment is likely to fail and schedule preventative maintenance accordingly. While MTTR shows how quickly teams fix problems, MTBF reveals how often those problems occur, helping companies budget their maintenance resources and determine whether it’s more cost-effective to repair or replace aging equipment.

Mean Time to Failure (MTTF)

MTTF measures the average lifespan of non-repairable components or systems—like lightbulbs, hard drives, or disposable sensors—from initial operation until permanent failure. Unlike MTBF, which only applies to systems that businesses can repair and return to service, MTTF applies to items that must be replaced entirely when they fail, allowing organizations to plan replacement schedules, maintain sufficient spare parts inventory, and calculate the total cost of ownership for finite equipment.

Mean Time to Acknowledge (MTTA)

MTTA tracks response time when incidents occur by measuring the time between a system alert and acknowledgement from a technician. This metric reveals gaps in alert systems, on-call procedures, and escalation policies, as high MTTA values indicate that alerts are going unnoticed or getting buried under false positives. By monitoring MTTA alongside MTTR, maintenance teams can assess whether extended downtime stems from delayed response times or slow repairs.

Mean Time to Detect (MTTD)

MTTD measures the average time between equipment failures and when the failure is identified, either by monitoring systems or personnel. Long detection times impact customer experiences and system availability, especially for intermittent outages or gradual degradations that don’t trigger alerts. Companies use MTTD to evaluate their monitoring coverage, sensor placement, and alert thresholds, as faster detection often leads to simpler repairs and reduced overall downtime.

Mean Time to Identify (MTTI)

MTTI calculates the time from initial problem detection until teams correctly diagnose the root cause, quantifying the gap between identifying a failure and understanding what needs fixing. High MTTI often indicates inadequate documentation or training, insufficient diagnostic tools, or knowledge gaps among maintenance personnel. This metric guides investments in training, tools, and procedures to reduce resolution times and prevent misguided repair attempts that could worsen the original issue.

Reduce Your MTTR With the Right Tool: NetSuite

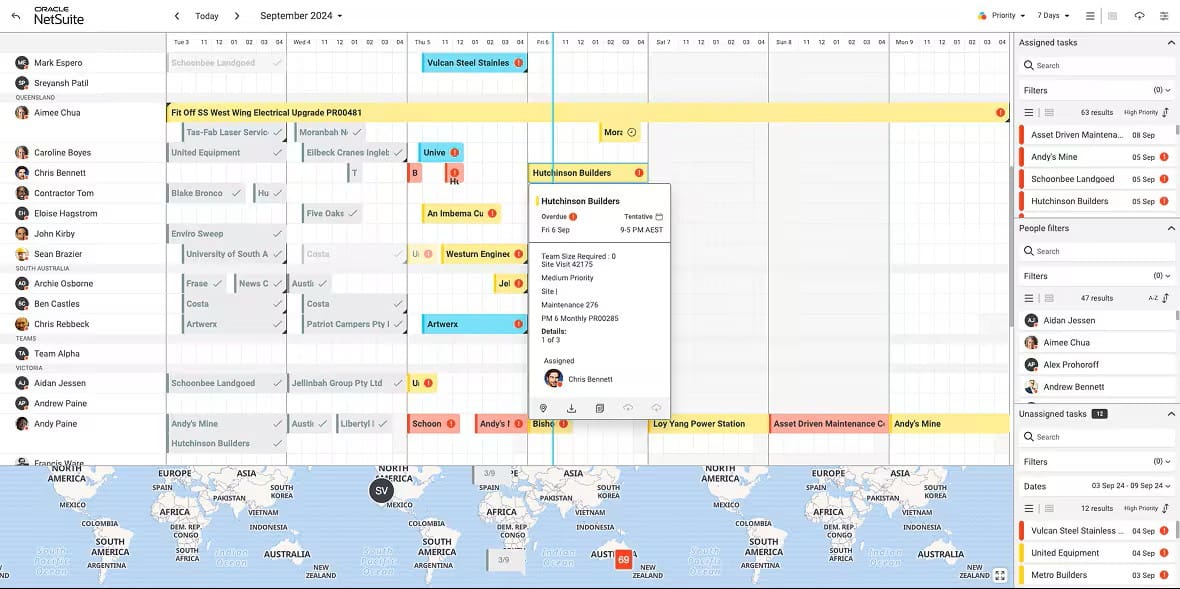

Improving MTTR requires meticulous attention to detail and effective planning. NetSuite Field Service Management software can help field service organizations increase efficiency and free themselves of the operational burdens that drag down their MTTR performance. NetSuite provides an integrated platform that makes it simple to do drag-and-drop scheduling, optimize office-to-field communication, and automate workflows for technicians tasked with fixing equipment out in the field.

NetSuite Field Management also provides a single place to manage assets, track preventative maintenance, and keep tabs on spare parts inventory. Everything is supported by robust reporting and analytics that allow decision-makers to optimize workflows along the way.

NetSuite Field Service Management Dashboard

MTTR is a critical metric for business performance across a range of sectors. Maintenance teams, field service organizations, and incident responders that commit to driving down MTTR can help businesses maximize operational resources and minimize downtime. Through a layered approach that invests in tools, training, and processes around diagnosing and fixing problems—as well as optimizing preventative maintenance—companies can make continual gains on their MTTR performance.

Mean Time to Repair FAQs

How do you calculate mean time to repair?

Mean time to repair is calculated by taking the total repair time and dividing it by the number of outages or incidents during a given time period.

What is an acceptable MTTR?

The acceptability of mean time to repair (MTTR) is highly dependent on the systems in question and the industry a company operates in. An acceptable MTTR in a non-critical IT server may be five hours, while a critical program logic controller in a power plant might have an MTTR of five minutes.

What is the mean time to repair format?

Mean time to repair is typically expressed as a value of time, such as seconds, minutes, hours, or days.

What are the four key metrics of MTTR?

The acronym MTTR can stand for one of four different metrics: mean time to repair, mean time to respond, mean time to recovery, or mean time to restore.

What are MTTR and MTBF?

Mean time to repair (MTTR) and mean time between failure (MTBF) are two operational reliability metrics. MTTR is the average time it takes to repair a malfunctioning system, while MTBF is the average time between outages due to equipment failure.