For businesses in today’s world of quick shipping and order fulfillment, the reliability of machinery and systems is more important than ever. Companies across various industries must overcome the challenge of minimizing downtime—or at least predict when repairs will become necessary—to avoid unexpected shutdowns and the financial losses and reduced customer satisfaction that come with them. This is especially important today, as unplanned downtime grows more expensive every year, according to Siemens’ “The True Cost of Downtime 2024” report—in the automotive industry, for example, an hour of downtime costs double what it did in 2019; in heavy industry, it’s four times higher. The report also estimates that the world’s 500 biggest companies lose almost $1.4 trillion a year through unplanned downtime, equivalent to 11% of their revenue.

Given these financial pressures and potential losses, how can businesses take a more proactive approach to maintaining their equipment? To effectively balance routine maintenance and the slowdowns necessary to accommodate them, businesses need quantifiable metrics that inform when and where repairs should be made to minimize interruptions and maximize profits. This article explores a critical metric for predicting when equipment will fail—mean time between failures (MTBF).

What Is Mean Time Between Failures (MTBF)?

MTBF is a reliability metric for repairable systems or components, measuring the average time machinery operates between failures. Maintenance teams and managers use MTBF to predict equipment failures and schedule preventive maintenance.

By tracking this metric over time, businesses can allocate resources to assets that require the most attention and make informed decisions when choosing whether to repair or replace machinery. For instance, if a packaging machine has an MTBF of 500 hours, maintenance staff might inspect and service it after 450 operating hours, reducing the risk of an unexpected break. Businesses commonly track MTBF alongside other reliability metrics, such as mean time to repair (MTTR), to create a more complete picture of equipment performance. While MTBF tracks failure frequency, MTTR shows repair duration—together, these metrics help managers plan production schedules and rotate maintenance to minimize downtime.

Key Takeaways

- MTBF is a reliability metric used to predict equipment performance and inform maintenance and investment decisions.

- A high MTBF shows a lower likelihood of equipment failure, while a low MTBF may suggest that new maintenance policies or more reliable equipment could improve operations.

- MTBF is calculated by dividing total operational hours by the number of failures within a given period. It’s influenced by design quality, user handling, and operating conditions, among other factors.

- Businesses can improve MTBF through proactive measures, including maintenance policies and improvements from vendors and equipment makers that minimize the strain on equipment.

- By improving MTBF, businesses can reduce costs, extend the life of equipment, and increase customer satisfaction.

Mean Time Between Failures Explained

MTBF is a particularly valuable metric for businesses that rely on continuous capabilities or in situations where equipment failures can result in significant financial losses or safety risks. A high MTBF suggests that equipment or systems fail infrequently, allowing businesses to maintain their operational continuity and minimize losses from interruptions. A low MTBF, on the other hand, may point to aging equipment, a poorly trained workforce, or other inefficiencies that can significantly impact the bottom line. But because MTBF is a descriptive, not prescriptive, metric, it can only give averages to guide further study. Analysts and decision-makers can then use this as a starting point for investigations into why failures are occurring and where they can make improvements.

For long-term planning, businesses can track trends in MTBF over time to inform decisions regarding asset management and acquisition. By analyzing MTBF data for all their equipment, companies can identify patterns and potential weaknesses in their operational processes. This analysis empowers businesses to implement targeted improvements, leading to better resource and investment allocation for high-quality components or more reliable systems. For example, if a machine’s MTBF is decreasing and repairs no longer fully fix the problem, it may be time to replace the machine entirely. Otherwise, unexpected breakdowns will likely increase—in both frequency and severity—leading to increased downtime, tied-up maintenance staff, and, ultimately, revenue loss. Through regular analysis of MTBF, often with the aid of automated software-generated reports and alerts, businesses can better prioritize capital investments, maximize investment returns, and build sustainable, long-term growth.

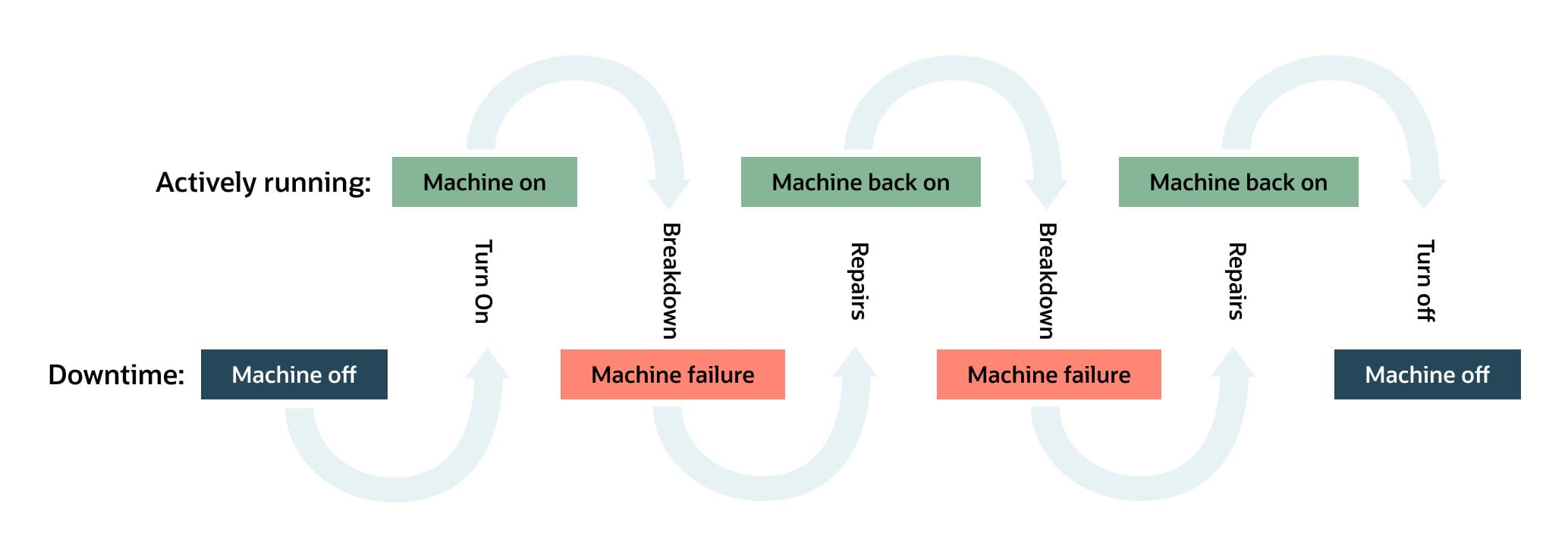

Machinery Uptime Vs. Downtime During an Average Workday

Why Measure Mean Time Between Failures?

MTBF provides the foundation for equipment-focused financial planning, including budgeting for maintenance teams, forecasting annual repair costs, justifying capital expenditures, and demonstrating ROI for higher-quality equipment. Without this metric, businesses may miss failure patterns and neglect routine maintenance, leading to emergency repairs with inflated labor costs and expedited shipping for replacement parts. For example, a food processor tracking MTBF might discover that its old conveyor system is breaking down every month, leading to repair costs and downtime that justify the cost of a full replacement that only requires semi-annual servicing.

Beyond cost control, MTBF measurement helps companies maintain operational consistency and continuity. By minimizing unexpected shutdowns and delays, organizations can reliably meet customer commitments, building trust and increasing repeat business over time. Companies often use MTBF benchmarking to compare performance against industry standards, assess reliability of facilities, and identify efficiency improvements. Regular MTBF analysis also supports regulatory compliance in industries like pharmaceuticals and aerospace, where documented reliability data proves equipment is up to safety standards.

How to Calculate Mean Time Between Failures

Calculating MTBF is a straightforward process that requires only two numbers: total operational hours and the number of times a machine failed over that same period. Once those figures are determined, either through manual tracking or automated data collection tools and sensors, failures are divided into the total to calculate MTBF. Written as a formula, MTBF is:

MTBF = Total operational hours / Number of failures

For example, say a delivery truck operates for a total of 1,800 hours in a year. During this period, the truck failed and required maintenance five times. Using the MTBF formula, the calculation would be:

MTBF = 1,800 hours / 5 failures = 360 hours

This result shows that, on average, the trucks run for about 360 hours before a failure is likely to occur. Businesses can then use this metric to plan maintenance and reliability assessments, such as bringing trucks in for tune-ups and routine checks after they pass certain benchmarks. In this case, maintenance teams would perform routine tune-ups every 300 hours of operation to minimize the chance of trucks’ reaching their predicted failure point without maintenance. These kinds of proactive steps help companies optimize their service schedules and improve equipment uptime, while minimizing unexpected breakdowns and unplanned business interruptions.

Eight Factors Influencing Mean Time Between Failures

A variety of factors can influence MTBF, each playing a significant role in how frequently failures occur and how they can be mitigated. These factors apply across the entire lifecycle of machinery, ranging from initial equipment design to end-of-life performance monitoring. By understanding these issues, businesses can enhance their operational reliability and reduce downtime. Here are eight key factors that significantly impact MTBF.

-

Design Quality

Some equipment is more durable than others, and businesses should have a general sense of the quality and design strengths and weaknesses when determining reliability and MTBF. When purchasing new equipment, companies should ask the manufacturer for an estimated MTBF to inform expected long-term ROI calculations. A well-designed system that accounts for potential stressors and operational demands is less likely to fail prematurely, especially if those designs include guidance and easily accessible parts for repair, replacement, and routine maintenance.

-

Manufacturing Processes

The processes used to manufacture equipment can also impact its reliability, and even strong designs can lead to unreliable equipment if they’re not coupled with strong quality control standards and high-quality materials. Inconsistencies in manufacturing operations can introduce defects that shorten the lifespan of components and decrease the MTBF, as well as increase the complexity and scope of repairs when they become necessary. Through careful research and vetting, companies can choose reliable equipment vendors and maximize their MTBF for all new machines as they grow and replace outdated assets.

-

Operating Conditions

Operating conditions, including temperature, vibrations, and environmental exposure, significantly affect MTBF. Equipment used in harsh or variable conditions is typically more prone to failure unless specifically designed to withstand such environments. For example, a company may have two factories—one on the coast and one inland—with radically different MTBF, as the extra humidity rusts and wears down machinery on the coast faster than the dry inland air. To extend MTBF, businesses should choose machinery built with specific environmental conditions in mind, as well as regularly monitor performance and adjust environmental conditions when possible.

-

User Handling

It’s impossible to eliminate errors and mistakes entirely, but they can be mitigated by robust staff training and the elimination or improvement of unnecessarily complex workflows and machinery. By referencing detailed operational guidelines, employees can minimize improper use and overloads, reducing wear and tear and failures. These guidelines are most helpful when they are accessible and readily available, often posted near the machinery itself or in digital handbooks. This helps arm both new and established staff, as well as repair technicians, with the most up-to-date and efficient methods when operating or repairing equipment.

-

Wear and Tear

While the goal is to extend MTBF as far as possible, businesses must be realistic—all equipment will eventually fail, after all. But even with that foregone conclusion, companies can take steps to extend machine life and predict when failures will occur. Natural wear and tear over time degrades the performance of components, and regular maintenance and timely replacement of worn-out parts are critical in managing this degradation. Before, during, and after repairs, maintenance technicians can leverage technology, such as Internet of Things (IoT) sensors, to track key performance metrics (KPIs) and gain insights into where wear and tear is occurring and what steps are necessary to get everything back up to speed.

-

Technology and Material Advancements

Even businesses with highly efficient machinery may still have room to improve their MTBF when new technology or materials enter the market. Companies often integrate new features and techniques into existing systems to enhance their durability and reliability. For example, human-robot collaborative technology, known as “cobots,” can be installed on assembly lines to boost worker performance and safety. Additionally, new materials, such as stronger metal alloys or 3D-printed components, can help businesses improve the durability or customizability of their equipment, raising MTBF without replacing the entire machine. These advancements may also increase the volume and/or quality of goods, expanding inventory capabilities.

-

Quality of Maintenance

One of—if not the—biggest factors influencing MTBF is the quality and frequency of maintenance performed on equipment. Carefully planned and executed preventive maintenance helps technicians address potential issues before the machine fails. But when failures do occur, technicians need the right tools and techniques to repair machinery correctly, rather than relying on shortcuts that may result in further breakage in the future. Companies can track and measure technician performance using employee-focused metrics, such as technician productivity, first-time fix rates, MTTR, and other relevant KPIs. By prioritizing expert repair and maintenance, businesses can make sure that MTBF remains high, and, when the time comes, the right equipment is replaced at the right time to maintain output and high-quality standards.

-

Software Reliability

In systems where software plays a critical role, software bugs, decay, or compatibility issues can lead to system failures, even if physical machinery components are undamaged. To minimize these risks, businesses rely on software engineers with relevant expertise to run regular software updates and rigorous testing. These updates can also enhance other aspects of equipment, bringing in new features as they become available. For example, software inside manufacturing equipment can be upgraded to integrate the latest technology, such as AI or machine learning, to improve diagnostics and increase transparency of performance.

Benefits of Measuring Mean Time Between Failures

Beyond the direct benefit of reducing equipment failures, measuring and improving MTBF offer numerous advantages across various business operations. Here are eight specific benefits afforded by measuring MTBF and how a company can leverage them to build a more sustainable and competitive brand:

- Enhanced product design: By regularly measuring MTBF, companies gather critical data about which components or systems frequently fail and under what circumstances. Engineers and designers can use this data to refine product designs and increase the durability and reliability of machinery. These improved designs lead to fewer failures, reducing repair and replacement costs while boosting market competitiveness.

- Optimized maintenance schedules: Maintenance managers use MTBF to estimate equipment’s expected operational lifespan, allowing them to schedule inspections, service, and replacements before failures are likely to occur. This minimizes unexpected breakdowns, keeps equipment operating at peak efficiency, and extends an asset’s life, maximizing productivity and informing new equipment purchases.

- Efficient resource allocation: By predicting potential breakdowns with MTBF, companies can better manage inventory levels for both finished goods and supplies. Strategic resource allocation helps businesses maintain a lean operation, reduce waste, and improve the bottom line without harming the customer experience. For example, businesses can temporarily increase production before scheduled maintenance to make sure customer demand can be met while equipment is turned off. Similarly, raw material inventory can be allocated accordingly, preventing clutter and excessive carrying costs while production is halted for maintenance.

- Effective risk management: Measuring MTBF allows companies to identify and assess areas with high risks of failure. Due to limited resources, businesses often must choose which weaknesses to address first, and MTBF data helps companies prioritize risks that can cause severe operational disruptions, financial loss, or safety incidents. By understanding and managing these risks, companies can maintain a safer working environment and effectively protect their assets and profits.

- Increased customer satisfaction: Reliable products and minimal service interruptions boost customer satisfaction by making sure customers can trust that the business will fulfill their orders quickly and accurately. Customers satisfied with their experience are more likely to provide positive reviews and recommend products to others, contributing to the company’s long-term growth and success.

- Enhanced brand reputation: Companies that consistently produce durable and reliable products—without overexerting their equipment and causing failures—are better positioned to serve customers and outshine the competition. This reputation for quality can become a key differentiator in competitive markets by attracting more customers and opening up new business opportunities.

- Reduced downtime: One of the most direct benefits of improving MTBF is reducing the time equipment needs to be shut off, thereby minimizing halted production until repairs and maintenance are completed. With fewer failures, production lines run more smoothly and for longer periods without interruption. This efficiency boosts output and reduces the costs associated with downtime, such as lost productivity and expedited shipping costs for parts, replacement equipment, and delayed customer orders.

- Effective lifecycle management: By tracking MTBF over time, companies can better predict when machinery is slowing down or breaking, helping business leaders schedule equipment replacements and budget for capital expenditures with greater accuracy. This detail-oriented approach allows a company to rely on up-to-date technology and practices, while strategically phasing out older equipment to minimize the negative impact on operations and finances.

Industry Application of Mean Time Between Failures

MTBF is used throughout different sectors, each with its own unique set of challenges and operational demands. These differences come from the various types of equipment that industries use and how technicians in the field maintain and repair that equipment. Below are five industries that use MTBF to manage their assets and improve reliability.

Manufacturing

According to Siemens’ “The True Cost of Downtime 2024” report, the average plant suffers 25 downtime incidents a month, leading to 27 hours of lost productivity. For many manufacturers, equipment quality and performance are the primary drivers of their output and, therefore, success. MTBF gives manufacturers insights into machinery performance, helping managers prioritize production line improvements where they will have the biggest impact. High MTBF values are indicative of reliable machinery and a smoother production process, which can be analyzed to inform future workflows, equipment purchases, and product designs. Low MTBF, however, indicates frequent stoppages and should be addressed through more robust maintenance practices and/or higher-quality equipment investments.

IT and Data Centers

For service providers in the IT and data center sector, shutdowns and equipment failures do more than just halt their customers’ direct operations; they can impact the functionality and security of every department that relies on this critical digital infrastructure. Technicians and IT professionals can track the MTBF of their equipment—both on-premises and at customer facilities—to keep servers and network equipment operating continuously, often by building redundant, backup systems to switch to when systems are being worked on or approaching a projected failure period. Maintaining a high MTBF is especially important for critical IT infrastructure, as it keeps data processing and storage services running without interruption. To prevent failures and data loss, many providers offer cloud-based software, such as ERP systems, to allow customers to focus on running their businesses, while outsourcing much of their IT responsibilities to external experts in the field.

Healthcare

In healthcare, equipment reliability is a matter of life and death. Healthcare companies can use MTBF to track and predict the reliability of medical devices and equipment, including MRI machines, patient monitoring systems, and life support machines. Healthcare facilities can also use MTBF data to schedule maintenance activities, balancing the impact on patient services with care quality and regulatory standards. A longer MTBF means that healthcare providers can more confidently trust that their equipment will function properly when needed, an essential part of patient care and safety. Lower MTBF metrics suggest that purchasing more reliable equipment may be necessary to consistently deliver high-quality care and good patient outcomes.

Telecommunications and ISPs

Telecommunications companies and ISPs use MTBF to monitor network reliability across distributed infrastructure, including switches, routers, transmission equipment, fiber-optic systems, and customer-premises devices. Minor network failures can cascade through interconnected systems, affecting thousands of customers and triggering service level agreement penalties that can lead to significant refunds or lost revenue as customers switch to more reliable competitors. By tracking the MTBF of critical network components, maintenance teams can predict potential failure points and schedule repairs during overnight hours or predetermined windows when network traffic is minimal. Providers also use MTBF to identify aging equipment and plan phased replacements to maintain service continuity while spreading costs across budget cycles.

Defense and Military

Due to its high-pressure and unpredictable nature, the defense and military industry demands equipment that can perform reliably under extreme conditions. MTBF is a key factor in the design and procurement of military hardware, from communication systems to vehicles and weaponry, as this equipment must reliably function for entire military operations or else troops and other personnel risk major consequences. The military uses MTBF data to conduct rigorous testing before deployment and to develop in-the-field maintenance schedules, keeping equipment available and ready whenever and wherever it’s needed.

Challenges in Calculating Mean Time Between Failures

Calculating MTBF is more than just plugging numbers into a formula—accurate results depend on data integrity and environmental realities that can skew results. If not properly accounted for, these distortions can mislead teams and undermine maintenance decisions. Challenges when calculating precise MTBF include:

- Scheduling maintenance: Frequent maintenance can artificially inflate MTBF by preventing natural failures from occurring. If routine adjustments and component replacements happen too often, MTBF calculations won’t reflect true asset reliability under normal operating conditions, leading to businesses spending more on maintenance costs than necessary.

- Maintaining data availability and quality: Accurate MTBF requires comprehensive uptime and failure records across asset history. Incomplete logs, informal feedback processes, lost historical data, and repair technicians prioritizing speed over thoroughness all lead to undocumented active production hours and failures, reducing the relevance and accuracy of maintenance metrics.

- Defining failure: If teams aren’t following clearly defined definitions of what to consider a failure, it creates inconsistencies across assets or time periods. A minor glitch might be logged as a failure by one technician and ignored by another, making MTBF less useful when comparing interdepartmental performance.

- Identifying point of failure: Multicomponent systems make it difficult to pinpoint which part failed and when, obscuring the true source of problems. This often leads to calculation errors that misrepresent an asset’s reliability when it was actually a connected system’s failure.

- Calculating time frame: Simple averages don’t account for the random nature of failures. To assure accurate MTBF calculations, the observation period must be long enough to capture a representative number of failures; too short a time frame can skew results and not reflect true reliability.

10 Strategies for Improving Mean Time Between Failures

To improve MTBF, businesses must understand exactly why equipment is failing and where other weaknesses are prevalent, such as consistent user error or subpar materials. Because there’s no one-size-fits-all approach to MTBF, decision-makers should consider a variety of strategic measures and implement the ones that cater to their specific needs. After improvements are made, analysts should carefully track how they impact operations, informing future strategies and course corrections. Below are 10 potential strategies to improve MTBF:

- Enhance design quality: Improving the design quality of components and systems can significantly improve MTBF. This involves choosing suppliers that offer high-grade materials, incorporating strategic redundancies and emphasizing maintenance priorities in new designs. These efforts can both extend equipment’s operational life and reduce the likelihood and cost of failures.

- Implement rigorous testing: Rigorously testing equipment before deployment and after maintenance can address potential failures and give technicians new insights into other, potentially widespread issues. Stress, endurance, and environmental testing confirm that equipment can withstand operational demands and help businesses establish clear guidelines on the optimal conditions for getting the most out of machinery.

- Adopt preventive maintenance: Effective preventive maintenance requires regular inspections and the systematic replacement of worn parts before they fail. Maintenance workers typically schedule these repairs based on historical data and manufacturer recommendations. Regularly scheduled, temporary downtime can reduce the occurrence of unexpected breakdowns and increase overall efficiency.

- Improve manufacturing processes: By enhancing precision and control, businesses can optimize their manufacturing processes, significantly improving the quality of final products and the strain put on equipment. Additionally, quality control measures throughout the manufacturing process help identify defects and inefficiencies that could potentially jam systems and lead to increased wear and tear and equipment failures.

- Use data and analytics: Businesses have access to sophisticated data analytics tools that can provide detailed, real-time insights into equipment performance and failure trends. Many business solutions, including ERP systems, leverage historical data and predictive analytics to foretell when a failure is most likely to occur and make actionable suggestions to address issues before they happen.

- Uphold proper usage and handling: Misuse or improper handling of equipment and systems often leads to increased wear and tear or outright failure, and operators must be properly trained to minimize user error and equipment damage. Additionally, this training should be ongoing and provide clear operational guidelines, helping to guarantee that both new and established employees use current best practices and safety protocols when operating machinery.

- Conduct a root cause analysis: When failures occur, maintenance workers should identify the root cause, not just the symptoms, to make certain that repairs last. For example, if a specific machine arm is continually breaking, it may be from a weak internal mechanism rather than faulty arm components. By addressing underlying issues like these, businesses can improve the overall reliability of a system rather than waste time and resources with temporary stopgaps. Additionally, some root causes may be systemic issues, and identifying one can lead to companywide fixes, significantly improving the operation as a whole.

- Establish condition-based maintenance: With the rise of IoT devices, mobile sensors, and other sophisticated monitoring technology, businesses can analyze the conditions of machinery in real time, quickly identifying any changes in conditions and performance. Using this information, often accessible through customizable dashboards or automatically flagged alerts, maintenance teams can prioritize urgent fixes when conditions change and thereby minimize major losses.

- Identify the most frequent causes of failure: Through analysis of maintenance records and failure data, businesses can identify patterns and common causes of failures throughout their organization. By making systemic improvements, rather than just chasing one problem at a time, businesses can improve their maintenance workflows and significantly strengthen MTBF.

- Minimize repair times: Honing repairs can improve MTBF by minimizing downtime and improving the first-time fix rate. This can be achieved by having spare parts readily available and investing in higher-quality tools and better technician training. Businesses can also use advanced diagnostic tools and software to address other, potentially unrelated issues when making repairs. This proactive approach saves time and resources by reducing the number of service calls needed to maintain day-to-day operations, as well as lowering the overall number of repairs.

Other Key Metrics that Measure System Reliability

MTBF assesses only one aspect of equipment performance. The complementary metrics outlined below provide additional context on a company’s response times, diagnostic efficiency, and recovery speed. Used together, these metrics reveal deeper insights into reliability and whether teams can quickly recover when problems occur.

-

Mean time to repair (MTTR):

MTTR measures the average time from initial failure to full restoration, including detection, diagnosis, repair, and verification. While MTBF indicates reliability, MTTR focuses on how efficiently teams fix problems. Together, they determine system availability. -

Mean time to failure (MTTF):

MTTF measures the average lifespan of non-repairable components that must be replaced, rather than fixed, when they fail. Unlike MTBF, which tracks failure intervals for repairable systems, MTTF captures the single failure point that ends a component’s life, such as a dying light bulb or burnt-out fuse. MTTF helps businesses plan replacement schedules and maintain appropriate inventory for consumable parts in line with expected needs. -

Mean time to acknowledge (MTTA):

MTTA measures the time between detecting a failure and when a human acknowledges the issue. This metric quantifies reaction times by capturing how quickly maintenance workers respond to problems flagged by automated systems. Lower MTTA means faster incident response, helping teams clear false positives that clog work queues and take resources away from genuine issues. -

Mean time to identify (MTTI):

MTTI tracks the time it takes to pinpoint root causes after failures are detected. Long MTTI often stems from insufficient training, expertise gaps, or poor documentation, while shorter times indicate effective monitoring and diagnostic processes that help teams quickly isolate root causes. When teams can quickly pinpoint the source of failure, they avoid temporary fixes that only mask symptoms and lead to recurring breakdowns.

Minimize Mean Time Between Failures With NetSuite

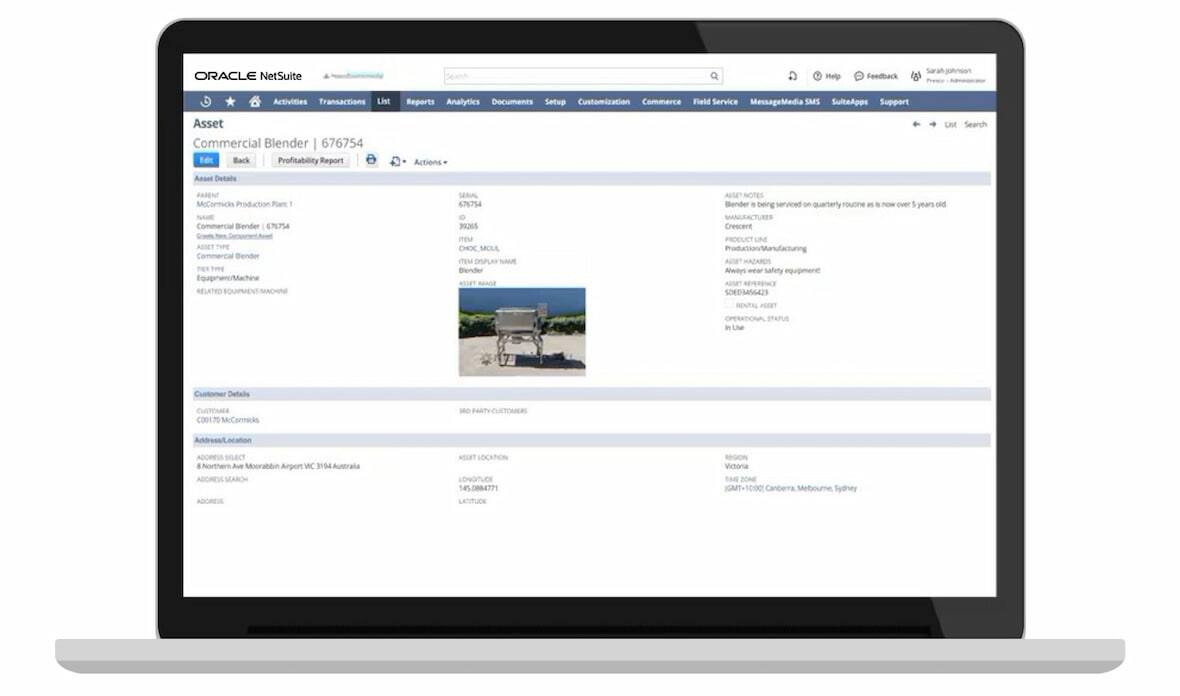

With NetSuite Field Service Management, businesses can leverage real-time tracking, advanced scheduling, and predictive maintenance capabilities to proactively manage their assets. NetSuite can unify and process large volumes of data to identify when equipment might fail and drive data-driven decisions to act in a timely manner. Managers can use NetSuite’s drag-and-drop scheduling and dispatch features to allocate their maintenance teams more effectively, delivering better results and communication without taking on new hires.

NetSuite Field Service Management

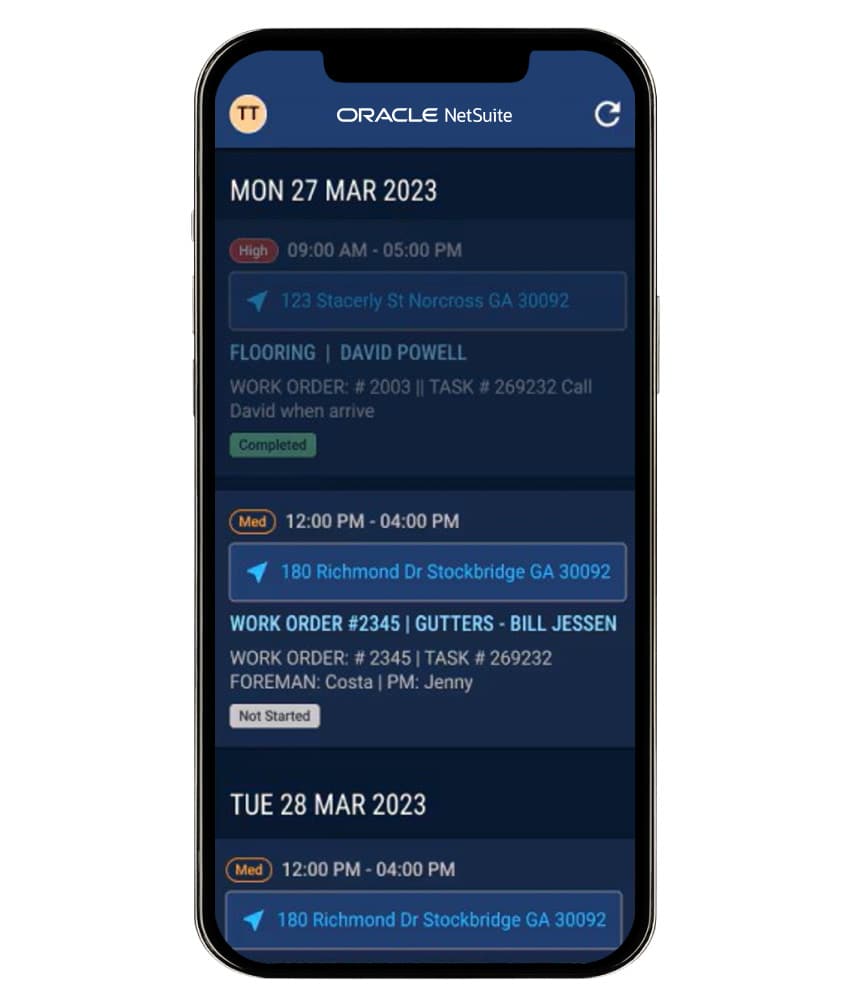

In addition, NetSuite Field Service Management’s mobile optimization gives both technicians and the home office access to real-time job and technician status updates. This transparency helps companies allocate resources where and when they need to be, increasing first-time fix rates and customer satisfaction. And with NetSuite’s asset management capabilities, business leaders have a centralized location to monitor all equipment from installation to decommission. NetSuite empowers businesses to focus less on playing catch-up and repairing faulty assets and more on using their equipment to better serve their customers and grow.

NetSuite Mobile App

As businesses work to gain, maintain, and expand their competitive advantages, improving MTBF is a critical way to extend the operational lifespan of their equipment, reduce downtime, and optimize maintenance processes. Furthermore, the insights gained from monitoring MTBF over time help managers foster a proactive maintenance culture, while also empowering business leaders to make informed decisions about asset management and investments. By emphasizing MTBF analysis, companies can better serve their customers, create a more sustainable and effective production environment, and, ultimately, increase profitability.

Mean Time Between Failures FAQs

What’s the equation for MTBF?

Mean time between failures is calculated by dividing total operational hours by the number of failures during the given period. This metric provides an average time that equipment will run before requiring maintenance or repairs. The formula is:

MTBF = Total operational hours / Number of failures

What is considered a good MTBF?

A good mean time between failures (MTBF) rating varies significantly across different industries and equipment types, but a relatively high MTBF typically indicates better reliability. Simple systems or those designed with an emphasis on longevity will likely have a much higher expected MTBF than systems that require regular maintenance and adjustments.

How do you calculate reliability from MTBF?

Generally speaking, the higher the mean time between failures, the more reliable the equipment is. Calculating this figure accurately requires more than just a simple equation, so businesses will typically rely on sophisticated software to automatically calculate and report any changes in equipment’s reliability.

What is an acceptable MTBF?

An acceptable mean time between failures (MTBF) depends on the specific requirements and context of the equipment’s use. For high-pressure industries, such as aerospace or healthcare, a longer MTBF is crucial to minimize risks. In less-critical applications, a shorter MTBF may be acceptable if the cost of downtime and maintenance is lower. It’s up to the individual company to weigh the costs and benefits of equipment before investing in and establishing maintenance protocols.

What are MTTF and MTTR?

Mean time to failure is a similar metric to mean time between failures but is used for non-repairable or one-time-use systems, such as light bulbs, as it calculates the average time to complete failure. Mean time to repair, on the other hand, measures the average time required to repair a system or component after a failure.

How do you calculate MTTR and MTBF?

Mean time to repair (MTTR) and mean time between failures (MTBF) are calculated in similar ways, with both comparing the time spent on a specific task (repairing or operating, respectively) with the number of times that task occurs.

The formula for MTTR is:

MTTR =Total downtime / Number of repairs

The formula for MTBF is:

MTBF =Total operational hours / Number of failures

What is mean time between defects?

Mean time between defects (MTBD) is similar to mean time between failures, but rather than focusing on equipment, MTBD focuses on the production process, specifically the average time between flawed goods. It’s calculated by dividing the total operational time by the number of defects detected, providing insights into the quality and consistency of the production process. It’s important to remember that MTBD, like other metrics, is only an average and not a perfect predictor of future behavior.