Do more with less: It’s a mantra most companies — and their often-frustrated employees — have been hearing for decades. But, for manufacturers, it also underpins a systematic methodology aimed at steadily improving product quality, operational performance, customer satisfaction and profitability. This approach, known as lean manufacturing, requires businesses to see themselves through the eyes of their customers to determine where value is created and what can be left behind without hurting quality.

This article explores how manufacturers can integrate lean manufacturing into every facet of their business, ultimately creating a fine-tuned manufacturing machine that benefits themselves and their customers alike.

What Is Lean Manufacturing?

Lean manufacturing seeks to refine the manufacturing process by minimizing waste while increasing the value offered to customers. To achieve this goal, manufacturers must scrutinize every process, tool and workforce action, in search of any inefficiency, big or small, that wastes time, money or talent.

But shifting to the lean manufacturing approach is not as easy as flicking a light switch. It starts with broad operational visibility and a nuanced understanding of customer preferences, because even small oversights can lead to revenue loss from mismanaged inventory or unexpected slowdowns. Lean manufacturers run risks because of their increased vulnerability to disruptions because of reduced buffer inventory, low downtime and high demands on employees, and limited flexibility in the face of demand fluctuations. The good news is, even a gradual adoption of lean practices can result in substantial cost savings, increased revenue and high customer satisfaction.

Key Takeaways

- Lean manufacturing centers on continually improving a business’s ability to meet the evolving demands of the market while balancing efficiency and customer value.

- In lean manufacturing, waste refers to any process or step that does not add value for the customer.

- By infusing lean practices into every organizational level, manufacturers empower their workers to identify weaknesses, offer suggestions and implement strategies for innovation.

Lean Manufacturing Explained

Many manufacturers emphasize efficiency in their overall business strategy, but the lean model goes deeper than surface-level process fixes, fostering a culture of improvement that relies on every employee — from the shop worker to the executive — to seek out areas to innovate and optimize. By empowering staff to identify new ways the business can serve their customers, manufacturers can become more responsive to market shifts and reprioritize plans in order to stay ahead of the competition.

Lean manufacturing relies heavily on the related concepts of waste and value. Waste is any process or action requiring time, talent and money that does not add value to the finished product or service; value is what customers care about — features and functions — and are willing to pay for. Lean manufacturers strive to minimize or eliminate any process that increases costs without a proportional increase in value.

Manufacturers have been implementing lean practices for decades, but the introduction of sophisticated digital tools, including data-analysis and automation software, has helped them more accurately forecast and meet demand, increase operational efficiency and track the effects of every change they make. In turn, managers and business leaders are able to keep improving their processes, yet minimize any risk of possibly cutting too much or harming the business’s long-term financial health.

The Origins of Lean Manufacturing

Lean principles have been used by manufacturers in various forms for centuries, but the beginning of the modern lean technique is typically credited to Ford Motor Co. founder Henry Ford. Ford’s assembly-line system broke down vehicle manufacturing into a series of simple, repeatable steps. This approach reduced waste and increased output, allowing Ford to produce cars at an unprecedented scale and price.

Most of the core principles of lean manufacturing were solidified a few decades later in post–World War II Japan. Toyota Motor Co. executives Taiichi Ohno and Eiji Toyoda began developing a more flexible and efficient production process to overcome limited resources amid nationwide pressure to rebuild the Japanese economy. Their system, which came to be known as the Toyota Production System, or TPS, was influenced by Ford’s methods but went further, by minimizing the amount of inventory on hand until it was needed and emphasizing a strong focus on quality control.

Lean manufacturing spread worldwide, due, in part, to John Krafcik — a researcher in the MIT International Motor Vehicle Program who would go on to lead Hyundai Motor America, among other roles — who coined the term in the 1988 article “Triumph of the Lean Production System.” Krafcik analyzed the successes of lean manufacturing plants in Japan, North America and Europe; described his tenure as an engineer at NUMMI, a GM-Toyota factory in California; and concluded that lean manufacturing operations simultaneously achieved “high levels of productivity, quality and mix complexity.”

Since then, others have influenced lean practices and added their own guidance, including James P. Womack and Daniel T. Jones in their 1990 book, “The Machine That Changed the World,” and the subsequent “Lean Thinking” in 1996. Their work solidified the five core principles of lean manufacturing (detailed below). Today, manufacturers continue to follow this guidance, albeit with some adjustments and the assistance of modern business software, to improve their operations and better serve their customers.

How Does Lean Manufacturing Work?

Lean manufacturing aims to increase the value offered to customers while decreasing costs and waste. Manufacturers accomplish this through a systematic approach in which every single aspect of their processes, from initial product design to the final quality check, is analyzed. Any waste identified, such as duplication of effort, can then be targeted for elimination. Solutions include reorganizing workflows, reducing inventory levels and improving floor layouts to facilitate a smoother manufacturing flow.

A key element of lean manufacturing is its reliance on a “pull” system — producing products based on actual customer demand — rather than on a forecast-driven “push” system. In other words, with lean manufacturing products are derived from real-time sales data, significantly reducing the risks of overproduction and excess inventory.

Another cornerstone of lean manufacturing is called “Kaizen,” a Japanese word for continuous improvement. Kaizen embodies an ongoing effort to incrementally perfect products, services and/or processes so as to reduce costs and boost quality. (More on these concepts to come.)

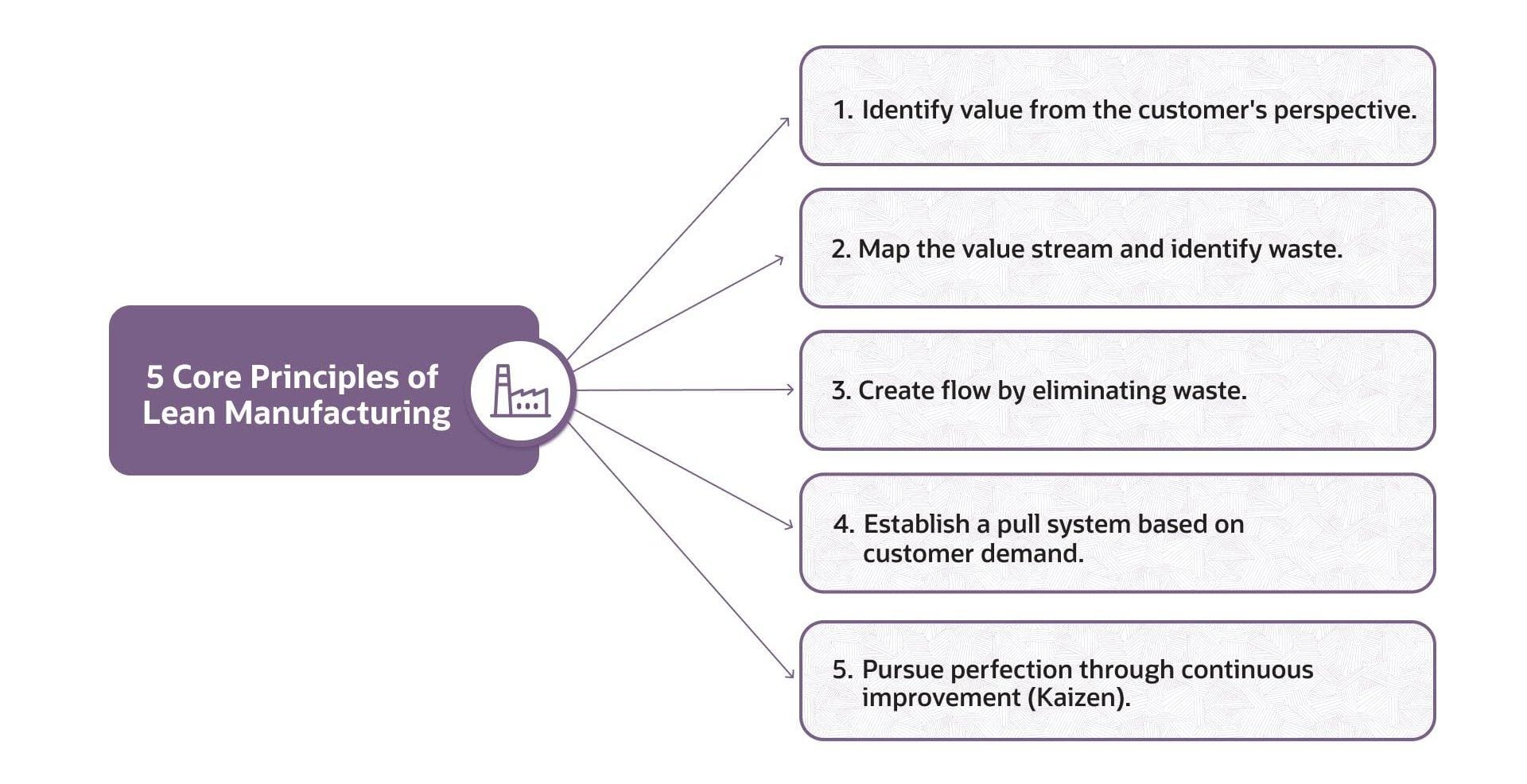

5 Core Principles of Lean Manufacturing

The five core principles of lean manufacturing do not just represent a how-to for anyone interested in learning more; they constitute a philosophy that shapes the culture within an organization, driving all processes toward greater efficiency and heightened customer satisfaction. By following these principles, manufacturers can both eliminate waste and bolster business performance.

-

Identify Value From the Customer’s Perspective

Are high-quality products a priority among customers? How about good value for the money? Or perhaps products customized to their specific needs is a must? Before making a single process change, manufacturers must first understand what their customers value. Methods for achieving this include getting direct feedback, requesting product reviews, initiating surveys and conducting in-depth market research, all complemented with sales and returns data analysis. This customer-centric approach ensures that every process improvement aligns with customer expectations, rather than being strictly aimed at cutting costs.

-

Map the Value Stream and Identify Waste

A value stream includes every activity involved in the production and delivery of a product. By charting all activities from raw materials procurement and supply chain management to final product delivery, manufacturers can visualize where value is — and isn’t — added. Any step that fails to enhance value in the eyes of the customer is considered waste and flagged for improvement or removal.

-

Create a Flow by Eliminating Waste

Once each process is mapped, businesses can begin to eradicate redundancies and inefficiencies so as to create a smoother flow of goods from start to finish. This can be achieved through production line reconfiguration and improved synchronization across workflows, for example. Lean manufacturers must also prepare their workforce for adapting to new ways of working amid the ever-improving environment that lies at the heart of a lean operation.

-

Establish a Pull System Based on Customer Demand

By using a pull system, manufacturers align their manufacturing output with real-time customer demand for goods. They wait until orders are placed to begin production, minimizing the risk of sitting on unsold goods and wasted resources. However, the “catch” here is that the pull approach requires a quick order turnaround, which, if it can’t be fulfilled or experiences delays, may prompt customers to turn to the competition. With careful planning and demand analytics, however, manufacturers can minimize their risks and effectively meet demand.

-

Pursue Perfection Through Continuous Improvement (Kaizen)

Realistically speaking, perfection in business may be as obtainable as the Holy Grail, but it doesn’t stop lean manufacturers from constantly tweaking their workflows to deliver the highest level of customer value. Businesses that follow Kaizen, the Japanese term for “good change” or continuous improvement, rely on employees at all levels to contribute any and all ideas for incremental improvements. Not only can this help the company identify problems before they mushroom, but it also feeds into high morale among employees, who feel heard and become more vested in their work.

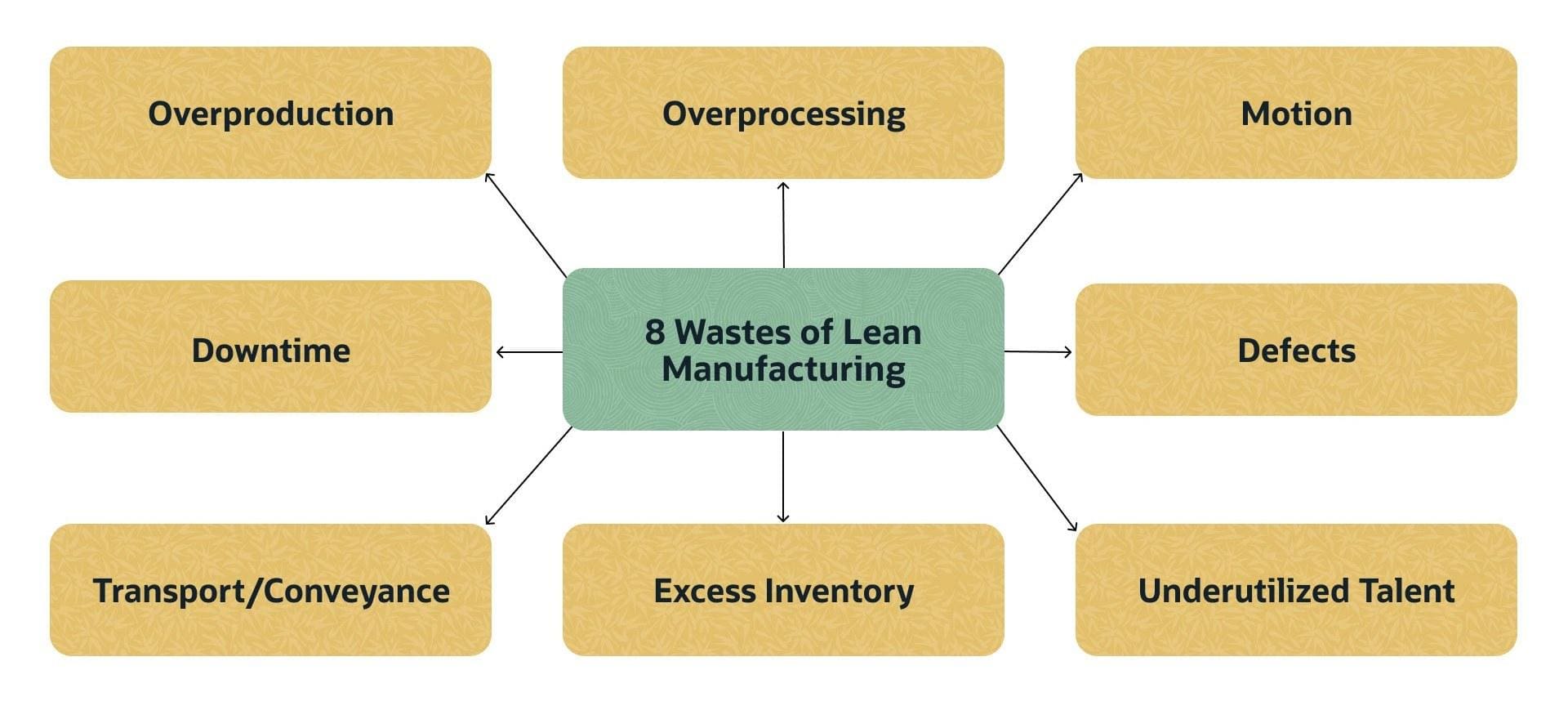

8 Wastes Prevented by Lean Manufacturing

Lean manufacturing’s primary mission is to eliminate “muda,” the Japanese term for waste that came about during development of the Toyota Production System. Waste refers to any activity that consumes resources but doesn’t create value for the customer. This includes material wastes, such as unsold inventory and defective goods, and intangible wastes, such as idle machinery and the unnecessary transport of goods. Here are eight common wastes to weigh when implementing lean practices.

-

Overproduction

When a manufacturer produces more product than is demanded, it wastes more than just tangible inventory. Overproduction ties up labor, equipment and capital that could have been used for other purposes, including growing the business. Excess inventory also leads to higher carrying costs, such as for the storage of excess inventory, and the possibility of dead stock, which negatively impacts revenue, cash flow and profitability.

-

Downtime

Whether the result of poor resource management, a sudden shortage of raw materials or a piece of machinery that goes on the blink, downtime wastes precious production time. It also rears its head in the form of workers having to wait to perform their jobs while, for example, that piece of machinery is being repaired. The resulting bottlenecks in operations or drops in efficient labor and maintenance planning can increase lead time — the elapsed time between the beginning of the manufacturing process to its ending— and cause missed deadlines and fulfillment delays. It may also result in overtime payment for staff scrambling to close the gap.

-

Transport (Conveyance)

Transport, aka conveyance, is the physical movement of materials, components or finished goods; if not planned carefully, it can turn into a major source of waste. Manufacturers can combat the time- and cost-draining problem by allocating resources in a way that reduces the movement of materials between locations, for instance, by optimizing floor plans, strategically placing workstations and even reorganizing materials on a workbench to speed up assembly — anything that minimizes transport time and maximizes the flow of materials and goods.

-

Overprocessing

Manufacturers sometimes do more work than necessary without benefiting the customer — the opposite of lean manufacturing. Overprocessing may present itself as using more advanced or expensive equipment than necessary, employing redundant quality-control checks or adding extra features that customers are not looking for.

-

Excess Inventory

Whether it’s raw materials, works in process or finished goods, lean manufacturing strives to minimize how much inventory is on hand at any given time. As is the case with overproduction, an inventory surplus increases carrying costs and ties up capital that could have been used to pursue another opportunity. Lean manufacturers counter this issue with a type of inventory management strategy called just-in-time (JIT), which means they bring in needed materials as close to production as possible.

-

Motion

Motion refers to any movement — of inventory, machines or people — that brings zero value to the manufacturing process, such as moving goods from one workstation to the next and then back to the first, rather than progressing linearly along an assembly line. Equipment also can be burdened by unnecessary motion, such as a worn-out machine arm that could have completed its processes in half the time, using a fraction of the energy, if it had been maintained according to schedule. These delays accumulate over time and can significantly eat into lead times, as well as wear on workers and equipment.

-

Defects

Defective goods are one of the most direct and measurable forms of manufacturing waste. Defects are typically identified during quality-control checks or, unfortunately, after a customer initiates a return, but both instances end in one of two wasteful outcomes: reworking or scrapping. Lean manufacturers prioritize catching defects early through advanced quality-control processes, such as automated monitoring, robust employee training and proactive equipment maintenance.

-

Underutilized Talent

The traditional lean manufacturing model included only the above seven waste categories, but today’s model adds a critical new category: underutilized talent. Workers have a front-row seat to operations and can provide valuable insights about the inefficiencies they see and experience. They may even have thought through some potential solutions to improve their workflows. Lean manufacturers listen and recognize the potential of staff who could perhaps fill higher-level roles, such as a factory worker with untapped managerial skills.

Benefits of Lean Manufacturing

While all businesses likely strive for operational and cost efficiencies, lean manufacturers go the extra mile to promote continual, targeted refinements across every facet of their businesses. This culture of forever improving can lead to a wide array of business benefits, chief among them:

- Waste reduction: By systematically identifying and eliminating unnecessary steps, resources and time in their processes, manufacturers can rein in their operating costs and become more efficient. Waste reduction also involves careful demand planning and JIT practices so as not to overproduce or stock more materials than necessary.

- Enhanced productivity: Even small adjustments in a workflow, such as moving employee workstations closer together, can streamline the manufacturing process and lead to a greater volume of product output.

- Financial advantages: Through cost reductions and productivity improvements, lean manufacturers can maintain or even increase output — in both quantity and quality — without increasing production costs or raising prices. Each improvement helps strengthen the bottom line, building a leaner and more profitable operation.

- Superior customer service: Lean practices enable manufacturers to produce higher-quality products and achieve faster delivery times, both of which make for happy customers. Unlike traditional cost-cutting measures, lean improvements emphasize customer-focused value and keep customer service at the forefront.

- Employee involvement: Lean manufacturers that encourage staff to identify waste and implement process improvements benefit from a more engaged and competent workforce that, in turn, works harder and fosters company loyalty.

- Quality enhancement: Poor quality control during the manufacturing process allows defective products to slip through the cracks, potentially leading to product recalls, lost business and a damaged reputation. By monitoring for quality throughout the manufacturing process, businesses reduce the likelihood of waste and customers taking their business elsewhere.

- Resource efficiency: Efficient resource allocation ensures that every step of the manufacturing process has what it needs when needed, minimizing downtime, transport and motion, and excess inventory. Achieving this balance requires careful inventory management, which can help lower overhead and reduce material costs without affecting output or quality.

- Improved lead times: By streamlining processes and minimizing time wasted between manufacturing steps, lean manufacturers achieve faster production cycles, thereby speeding up lead times and order fulfillment rates.

- Increased employee satisfaction: In lean systems, managers empower their employees to speak up about inefficient processes and provide suggestions for improvement. When their ideas are implemented, employees feel heard, which often engenders higher morale and increased productivity.

- Sustainability: Reducing waste does more than just save money; it is also a core aspect of reducing a business’s carbon footprint and minimizing scraps. Today’s customers value sustainability initiatives — with lean practices, businesses can build a more environmentally conscious business that attracts customers while improving profitability.

- Innovation: Lean organizations are constantly seeking ways to streamline their processes, with new ideas originating from employees, upper management and external sources. As new technologies, materials, methods and best practices arise, lean manufacturers can fold them into workflows to continuously improve operational efficiency.

- Better inventory management: Lean organizations tend to have minimal inventory reserves because they produce just enough products to meet actual customer orders. This reduces their carrying costs and related storage needs, freeing up capital to invest in, for example, the latest high-tech equipment.

Challenges of Lean Manufacturing

Despite its many benefits, lean manufacturing also presents a handful of challenges that, if not planned for in advance of implementation, can hinder progress and create waste — the exact opposite of what the methodology seeks to accomplish. Here are five challenges to consider, as well as how to counter each one.

- Lack of training: To foster a culture of continuous improvement, manufacturing staff must understand how, where and what kind of improvements will benefit the company. Without effective training, staff may not fully grasp the tenets of lean manufacturing and end up suggesting or making changes that sacrifice quality for efficiency or that introduce waste into workflows.

- Resistance to change: Tied to lack of training and a general uneasiness about change, employees who don’t grasp the benefits of lean manufacturing — who feel this new way of working is arbitrary or pointless — might push back on the process. Productivity and a willingness to look for inefficiencies may also be stymied. Open communication and transparency are key to lean adoption.

- Lack of leadership commitment: Maintaining a lean operation requires full support from the organization’s upper echelon, without which initiatives could fall flat and even create more waste and inefficiency. Leaders who express their commitment to lean manufacturing can help rally the proverbial troops to embrace this more efficient way of working.

- Insufficient data: JIT manufacturing, a core lean concept, relies heavily on real-time data that signals customer demand, setting off a chain of events that includes ordering inventory and scheduling production. This data is also used to gauge performance. Clearly, the absence of accurate and timely data will hinder an organization’s ability to meet customers’ needs. Modern manufacturers typically rely on business software, often integrated into a more comprehensive enterprise resource planning (ERP) system, to collect and validate this crucial data, as well as to organize it into accessible reports that business leaders can then use to inform lean-focused decisions.

- Too many changes: Implementing too many simultaneous changes can overwhelm and confuse employees, causing frustration, productivity slowdowns and issues with product quality. A clearly defined incremental approach gives workers time to familiarize themselves with new protocols and techniques and ensures that new workflows are manageable and effective before they are widely adopted.

11 Steps to Implementing Lean Manufacturing

Without a clear and detailed implementation plan, manufacturers risk making too many cuts that could decrease the quality and value of their products, while increasing pressure on their employees. These 11 steps provide a strategic framework to help manufacturers adopt lean initiatives and minimize any risks.

-

Understand Lean Principles

To fully understand lean principles, manufacturers must go beyond following a list of rules and instead use lean practices to guide every decision and action they make. At its core, lean manufacturing is a holistic approach that identifies which processes add value and which ones are wasteful. Once determined, the wasteful processes can then be streamlined or eliminated.

-

Identify Value From the Customer’s Perspective

Before making any changes, manufacturers must first identify what customers value in their products. The obvious way to find out what drives customers’ purchases and loyalty is to solicit their direct feedback, through surveys, focus groups, interviews, feedback forms or social media. External market research and sales data analysis are also important indicators. These initiatives help manufacturers ensure that they are not wasting time and resources on undesired features.

-

Map the Value Stream

By charting the entire life cycle of a product from raw materials to final delivery, manufacturers can visually see where value is, and isn’t, being added during the manufacturing process. Decision-makers can identify bottlenecks, redundancies and any other flaws that inflate costs and extend lead times. Given today’s pace of change, value-stream mapping should be an ongoing practice, ensuring that the business is adjusting its processes and workflows to meet evolving demand.

-

Create Flow

Any lag between manufacturing steps increases lead times and can impact customer satisfaction. With lean processes, products move smoothly from one step to the next without interruption or delay. Manufacturers can achieve this by reconfiguring production lines and workspaces to enable a steady and ongoing stream of production. These improvements range from small changes, such as rearranging the factory floor, to bigger capital investments, such as purchasing high-efficiency manufacturing equipment.

-

Establish a Pull System

By adhering to JIT manufacturing principles, companies produce only what is needed, when it is needed. This pull approach to demand requires flexibility and fast communication among departments, starting when a member of the sales team registers an order. ERP software, which integrates multiple departments into a single platform, goes a long way toward facilitating these efforts, automatically notifying all relevant parties about timelines and next steps. It also monitors progress and flags unexpected slowdowns or issues. This information can extend to customers, communicating progress on their orders and expected shipment.

-

Pursue Perfection Through Continuous Improvement (Kaizen)

Kaizen is founded on the belief that a process is always ripe for improvement. It fosters a culture of collective responsibility and innovation from every team member. Kaizen backs both small, incremental changes and large overhauls in the name of building a more efficient operation, with all ideas considered as the business inches closer to a lean model.

-

Train and Engage Employees

Effective employee engagement requires more than formal training. By bringing employees into problem-solving and decision-making roles, businesses can harness employees’ unique insights and front-line experiences. This level of engagement also improves implementation success, as employees will know exactly what needs to be done and why, rather than just checking boxes on a list handed down by their supervisors. This kind of collaborative approach boosts both morale and commitment to the company’s strategies.

-

Use Lean Tools and Techniques

The lean tools and techniques discussed in this article, including value-stream mapping, JIT manufacturing and Kaizen, provide a framework for assessing and improving every step of the manufacturing process. They help manufacturers visualize the flow of production and identify and eradicate non-value-adding activities, from the smallest inefficiency to major bottlenecks.

-

Measure and Monitor Performance

Not every well-intended improvement will yield the desired results, which is why manufacturers should measure and monitor their performance over time to inform future adjustments and strategies. Key performance indicators, such as lead time, cycle time, excess inventory, return rates and capacity utilization, can shed light on the effects of lean initiatives.

-

Cultivate a Lean Culture

Successful lean manufacturers make sure that continuous improvement is second nature for everyone in the organization. To do this, they emphasize the importance of every individual’s role in identifying problems. They not only welcome everyone’s suggestions but also implement and analyze the impact of suggestions that are enacted. By communicating openly and relentlessly pursuing waste elimination in daily activities, manufacturers can help their workforce fully embrace a lean-supporting mindset.

-

Adapt and Evolve

Creating a lean manufacturing operation is challenging enough, but maintaining it can be tricky without that forward-thinking mindset (often bolstered by robust data analytic software), one that allows businesses to anticipate market shifts, adopt new technology and quickly respond to changes in consumer behavior. Manufacturers that encourage innovation and prioritize flexibility can continue to deliver for their customers long into the future.

Lean Manufacturing Examples

Nike, the athletic clothing and footwear company, adopted a lean approach to manufacturing over a decade ago. It created its “Manufacturing Index,” used to score how well the company adheres to the lean principle of continuous improvement. The index establishes clear benchmarks and performance indicators, aiding leaders and management in evaluating performance and minimizing miscommunications. Decision-makers use this data to improve several aspects of manufacturing beyond output and productivity, such as sustainability, defective product rates and lead times, as well as employee metrics, like overtime and labor-standard violations.

Agricultural machinery manufacturer John Deere, founded in 1837, has also embraced a lean manufacturing operation. During production, John Deere employs fully automated quality-control mechanisms that continually inspect products for defects so that errors can be caught early, minimizing the risk of waste due to fixing or throwing away faulty goods. This emphasis on quality and efficiency helps John Deere meet product demand in a timely manner, conserve materials and maintain competitive prices. It also allows John Deere to stay flexible when demand changes and new products come to market.

Implement Lean Manufacturing With NetSuite

Going lean requires that manufacturers undergo a transformative shift at every level of the organization. It also requires extensive data to identify weaknesses, develop strategies and monitor every initiative’s impact. NetSuite’s cloud-based ERP platform gives manufacturers real-time visibility into operational and financial performance, enabling them to streamline processes and better align operations with lean principles. The solution offers a suite of applications that manages everything, including accounting, production, inventory and beyond.

NetSuite empowers decision-makers to adopt lean manufacturing principles throughout the manufacturing process, from raw materials to final delivery. By providing a centralized and secure data source, workers at all levels can easily communicate and operate from the same up-to-date guidelines. By leveraging real-time data and analytics capabilities, manufacturers can align operations with lean principles by quickly and accurately tracking actual demand, mapping value streams and creating a more seamless operational flow. With NetSuite, business leaders can free up time and resources to focus on innovation and staying ahead of the competition.

Lean manufacturing is a customer-focused business approach that prioritizes balancing efficiency with value. To maintain lean operations, manufacturers must always be on the lookout for activities that create waste, as well as empower employees to find potential areas of improvements throughout every task they encounter. This forward-thinking practice creates a culture of continuous improvement that helps businesses adapt, innovate and thrive.

Lean Manufacturing FAQs

What is a good example of lean manufacturing?

One of the most, if not the most, famous lean manufacturing examples is the Toyota Production System, adopted by that automaker after World War II. The system focuses on just-in-time inventory management and continuous improvement to minimize waste and maximize efficiency. By producing goods only as they were needed, Toyota was able to overcome resource scarcity and economic turmoil to become a global leader in automobile manufacturing.

What is the goal of lean manufacturing?

The goal of lean manufacturing is twofold: to reduce waste and to maintain or add value for customers. Manufacturers balance these goals by taking a detail-oriented look at every step of the manufacturing process and improving or eliminating any steps that do not add value for customers.

Who benefits from lean manufacturing?

Both manufacturers and customers benefit from lean manufacturing. Manufacturers reduce their costs, wasted materials and effort, while customers receive higher-quality products as they want them. Additionally, customers are often able to buy goods at lower prices from lean manufacturers, due to the efficiencies gained by these improvements.

What does lean manufacturing mean?

Lean manufacturing is a systematic approach to streamlining production by identifying and eliminating waste throughout the manufacturing process. This waste typically includes unnecessary or redundant steps, excess inventory and any other processes that do not add value from the customer’s perspective.

What are the 5 principles of lean manufacturing?

The five principles of lean manufacturing are:

- Identify value from the customer’s perspective.

- Map the value stream and identify waste.

- Create a flow by eliminating waste.

- Establish a pull system based on customer demand.

- Pursue perfection through continuous improvement (Kaizen).

What are the four Ps of lean manufacturing?

The 4 Ps of lean manufacturing are:

- Purpose: Why is the manufacturer in business and what are its core values?

- Process: How does the business manufacture its products and achieve its goals?

- People: Who are the workers who are identifying and implementing lean improvements?

- Performance: How will leaders test results and continuously improve operations?

Is lean manufacturing the same as Six Sigma?

No, lean manufacturing and Six Sigma are different, albeit similar, business philosophies. While both aim to improve efficiency and reduce waste, lean manufacturing prioritizes streamlining production to improve the flow of goods, whereas Six Sigma focuses on decreasing variation to reduce defects and improve product quality.