Any given product — from the smartphone in your hand to the shirt on your back to the MRI machine at your local hospital — has taken a long journey, often around the world and through the systems of many different companies, to make its way to you. The process begins with the collection and processing of raw materials, fashioned into individual components that ultimately come together into a finished product, which is then shipped off to a distributor, wholesaler, retailer or directly to the end customer.

This complex global network is a supply chain. And product manufacturers, which sit somewhere in the middle of this network, oversee and optimize that supply chain to ensure that they’re able to meet customer demand with quality products efficiently and economically. This is so important to manufacturer profitability and competitiveness that supply chain management is one of the most important capabilities for a manufacturer today. By implementing enterprise software and supply chain best practices, manufacturers can increase visibility into their supply chain networks to streamline processes and minimize costs while maintaining product quality and the agility necessary to adapt to issues, changes or trends in supply chain management.

What Is Supply Chain Management in Manufacturing?

At the heart of any manufacturing company is its supply chain, a set of interconnected processes often performed by different companies that work together to make products and deliver them to customers. Managing and optimizing this network of suppliers and activities, from securing raw material to fulfilling orders, is no small task. A breakdown at any stage of a manufacturing supply chain can throw a wrench into the works. Greater oversight is the goal of supply chain management, which can encompass everything from negotiating vendor contracts to inventory management to product shipping and returns.

A manufacturing company succeeds when it makes the right products, at the right cost, at the right time for its customers. Thus, effective supply chain management is an existential necessity for these companies. Manufacturers must keep their supply chains running smoothly and cost-effectively to meet demand, despite the potential for disruption both upstream and downstream. In order to accomplish this, they can harness the volumes of data generated by supply chain processes; analyze this information, ideally in a timely manner; and feed relevant insight to supply chain managers and business decision-makers. That’s why manufacturers invest in modern supply chain technologies and processes and fine-tune them over time to balance costs, quality, agility and speed at every phase of the manufacturing process.

Key Takeaways

- Effective supply chain management is an essential capability for manufacturers, offering an array of business benefits.

- Manufacturers must optimize their supply chain networks to control costs, increase efficiency, maintain product quality and protect their margins.

- Today’s manufacturing supply chains are complex, global, dynamic and often disrupted.

- Supply chain managers look to unified supply chain management platforms to deliver the visibility and insight required to run their supply chain networks optimally in varying conditions.

Supply Chain Management in Manufacturing Explained

To achieve profitability and growth, a manufacturer must optimize its supply chain in ways that keep costs in line and improve efficiency while maintaining product quality. That’s why supply chain management is such an important capability in the manufacturing sector. Supply chain management covers everything from the cost, quality and sourcing of raw materials to the cost and scheduling of outbound logistics and delivery of finished goods to customers.

Every company in a supply chain network plays a role. When it comes to product supply chains, a manufacturer sits somewhere in the middle of the network. Thus, supply chain managers at manufacturing companies oversee and optimize processes both upstream (the preproduction processes leading up to the manufacture of the finished product) and downstream (the postproduction processes that take place after production is complete). Upstream supply chain management includes finding and evaluating suppliers, developing quality standards for vendors and raw materials, and determining the timing and quantity of purchases. Downstream supply chain management involves getting the finished product to customers through wholesalers, distributors or retailers.

Cost is an important driver of supply chain effectiveness and competitiveness, but there are also other key factors to manage, including quality of materials and products, the ways they are sourced, the timeliness and completeness of logistics and delivery and the agility with which a manufacturer responds to issues in the supply chain network. The importance of dealing with supply chain disruption was made evident during the COVID-19 pandemic, as many manufacturers were unable to keep up with shocks to the system, both upstream and downstream. A 2022 report by the World Manufacturing Foundation notes that of all industries, manufacturing was the hardest hit by supply chain disruptions, with more than 60% of manufacturers experiencing supplier delays.

Supply chain management is most effective when it is set up to manage the entire set of supply chain processes end to end, with good visibility into supplier and internal inventories, production, sales and distribution. Because supply chain management involves so many touchpoints where value can be added or lost, the quality of a manufacturer’s supply chain management practices and processes can have a significant impact on revenue, profitability, growth and customer experience.

How Supply Chain Management Is Different for the Manufacturing Industry

A well-run manufacturing supply chain involves the orchestration of materials and components, human resources and machines, logistics and transportation, often operating consecutively — and sometimes concurrently. In order to optimize this extended supply chain network, manufacturing supply chain managers must have good forecasting data and capacity planning processes, the ability to work within many constraints and the capacity to deal with potential disruption arising at any point in the supply chain.

Complicating matters even more, manufacturing supply chains are more fragmented than ever before. Once upon a time, a manufacturer might control every aspect of production, from raw materials to customer delivery. Thanks to technology advances, globalization and trade agreements, most manufacturers today have broken down production into many more discrete parts, managed by a variety of partners all over the world. Though these long, lean, global manufacturing supply chains can lead to lower prices and access to specialized materials, capabilities and skills, they also introduce significant risks for businesses, especially when there is a lack of transparency across the extended supply chain.

Manufacturing supply chains are complex webs, no two exactly alike. But one thing all manufacturers have in common is the premium they place on time and money in the supply chain. It can be extremely challenging to increase profitability in manufacturing, but one of the best opportunities to boost margins is with better supply chain management. The better a manufacturer can manage efficiency and cost within its supply chain, the better its chance of boosting profitability. On the other hand, any challenge or setback in the supply chain can have a severe impact on profitability. Running an efficient, economical and resilient supply chain is important for any industry, but it’s especially critical for manufacturers.

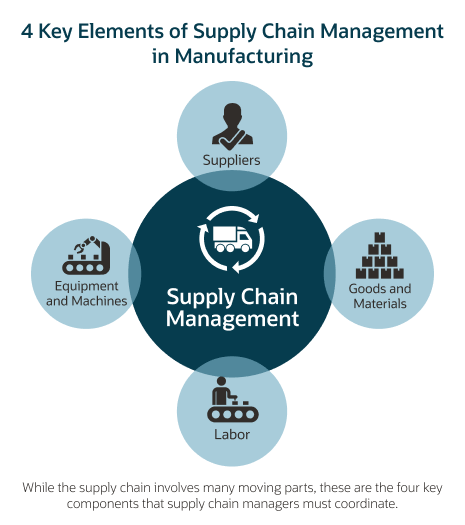

Key Elements of Manufacturing Supply Chain Management

Supply chain management in manufacturing involves considerable coordination, collaboration and decision-making to increase efficiency, lower costs, improve quality and adapt to changing conditions as a manufacturer oversees the holistic process of transforming raw materials into finished products ready for sale. While there are hundreds or thousands of moving parts in the end-to-end manufacturing supply chain, four key elements are of particular importance for supply chain managers to coordinate in order to streamline operations, enhance product quality, improve competitiveness and boost profitability.

- Suppliers: Modern manufacturers must coordinate and collaborate with a host of suppliers — from which they purchase raw materials, parts or components — in order to make and deliver their products on time and on budget. In today’s global manufacturing environment, companies tend to work with many different suppliers that are often geographically dispersed.

- Goods: Of course, manufacturers must also manage the materials and goods that they procure from their network of suppliers as they make their way from supplier to warehouse or production facility, throughout the manufacturing process. Whether it’s cotton fabric to be sewn into dresses, silica used to flatten and smooth microchips in semiconductor fabrication or metal to be engineered into a car part, manufacturers must make decisions about inventory levels, quality, timing and more to ensure the most effective use of their production lines. They must also manage their finished goods from the plant through customer order fulfillment.

- Labor: None of this happens without a lot of skilled people involved. Effective labor planning and scheduling is an important aspect of supply chain management. Data and insight about incoming deliveries, production planning and customer demand is essential to the optimal scheduling and deployment of skilled labor in manufacturing.

- Equipment: Going hand in hand with labor is the equipment used to manufacture completed products. Supply chain managers work with production designers and engineers to ensure that the company makes the necessary investments in manufacturing equipment, and with production managers to ensure that parts, assemblies and machines are accessible when needed, based on available supplies and customer demand.

Manufacturing Supply Chain Management Benefits

Supply chain management can make or break a manufacturer. Companies that do it well can boost their profitability, get their products into customers hands faster and potentially increase their sales and revenues. Manufacturers that hit snags in supply chain management can experience production halts and delays, dissatisfied customers and big hits to revenue and profitability. The benefits of investing in supply chain management best practices and technologies include:

- Streamlined operations: Well-designed supply chain management processes result in greater efficiency, increased production and lower costs. With greater visibility into the end-to-end supply chain, manufacturers can better align manufacturing inputs with their output goals.

- Improved product quality: Manufacturers with robust supply chain management processes and tools can more effectively oversee, prevent and address issues in product quality at every point, from raw materials to finished goods. Greater control over supply chain processes means fewer recalls and lawsuits and greater customer satisfaction.

- Reduced waste: Supply chain managers can eliminate waste at multiple junctures in the supply chain by rightsizing procurement levels to align with customer demand, identifying wasteful production practices and reviewing and addressing issues, such as defective parts or wasted time and materials. This increased control limits the likelihood of both costly shortages and excess inventory.

- Economies of scale: Better oversight of and insight into the supply chain can empower manufacturers to take advantage of greater economies of scale in a number of ways. By increasing production, they may be able to price their products lower than competitors are able to do. By consolidating their supply chain procurement with key partners, they may negotiate better prices or terms with suppliers.

- Reduced lead times: The more effectively a manufacturer manages the major inputs of production — suppliers, goods, labor and equipment — the quicker it can make its products and get them out to customers.

- Optimized resource utilization: Greater holistic insight across the supply chain enables a manufacturer to make data-informed decisions about how best to apply its resources. A manufacturing company can streamline production, labor and equipment schedules, staff up for big warehouse shipment deliveries and adjust staff when shipments are delayed.

- Enhanced visibility: Manufacturers that centralize their supply chain management achieve greater visibility across the supplier network and the production process. This enhanced view enables them to make better decisions about materials procurement and production timelines, for example, which refines the supply chain process.

- Immediate feedback loops: Sometimes, longer-term supply chain decisions may need to be revisited. Manufacturers that invest in supply chain management systems and tools can incorporate immediate feedback loops into their supply chain processes, using metrics at each step in the supply chain to inform continuous improvement strategies founded on current or anticipated conditions. The ability to make changes based on fast feedback loops makes manufacturers more adept at responding to changes or disruptions in their supply chain networks.

- Ability to adapt to market changes: As mentioned above, the more effective and expansive a company’s supply chain management processes are, the more agile they can be in responding to market changes, including issues with a supplier, shifts in customer demand or global disruption, such as a pandemic or geopolitical crisis.

- Early identification of disruptions: With the right supply chain data and advanced analytics, manufacturers can head off supply chain issues early on — sometimes, even before they occur. By identifying warning signs within the network, manufacturers can address disruption before significant damage is done.

- Diversification of suppliers: Supply chain diversification — that is, expanding supply sources to a larger pool of partners or contracting with suppliers in different regions — can be a valuable strategy for improving supply chain responsiveness and resilience. Robust supply chain management processes and software make it possible to manage a broader band of suppliers and can be useful in determining when greater diversification is needed.

- Compliance with regulations: Supply chain management and enterprise software, and the greater visibility across a manufacturer’s end-to-end network they provide, make it easier for manufacturers to comply with mandatory government regulations.

- Better overall performance: Good supply chain management not only lowers costs, increases efficiency and improves quality, but it can also have a positive impact on the top line. In fact, Deloitte found that 79% of companies with what it describes as superior supply chain capabilities have higher levels of revenue growth than others in their industries.

Manufacturing Supply Chain Management Best Practices

There’s no shortage of issues facing supply chain managers in manufacturing today. Among them are the increasing complexity of global supply networks, an array of evolving regulatory issues, political and trade instability, demand fluctuations and forecasting challenges. Amid this turmoil, maintaining an efficient, economical and resilient manufacturing supply becomes an ongoing challenge. Here are some of the best practices that have been proven to bolster supply chain management and help manufacturers overcome these hurdles.

- Leverage advanced analytics. The more complex a manufacturer’s supply chain, the more data is involved in effective supply chain management. By investing in advanced analytics capabilities, a manufacturer can, for example, parse data in real time and set up alerts to flag inventory issues before they turn into bigger problems. Thanks to advancements in data storage and cloud computing, these advanced analytics are accessible by and affordable for businesses of all sizes.

- Foster collaboration across the supply chain. Increased coordination, data sharing and decision-making among supply chain partners enables manufacturers to both plan more effectively and respond more quickly to disruptive events. Deeper partnerships yield more effective and resilient supply chains.

- Cultivate long-term partnerships. Transactional relationships have their place, but key suppliers and partners in the supply chain are best treated as long-term collaborators. Cultivating strong relationships with suppliers, distributors and logistic providers in good times can ensure that these partners will be willing to step up during challenges. Most manufacturers find that these relationships benefit all parties.

- Adopt lean principles. Lean approaches leverage continuous improvement methods to reduce the waste of time, materials and labor in the supply chain. Lean principles can boost efficiency, save money and provide greater value to customers. Many manufacturers see value in lean inventory management, for example, whereby they store only the materials they need at all stages of production.

- Use advanced systems and just-in-time practices. Advanced inventory management software and other supply chain tools can enable practices like just-in-time inventory to maximize efficiency and minimize waste. Doing this well requires effective demand planning and accurate and frequently updated forecasts. Adopters of these approaches must recognize that over-optimization can make them more susceptible to unanticipated disruptions in their supply chains. Another approach, just-in-case manufacturing, prioritizes stocking surplus inventory and outpacing the current demand to fulfill orders on time.

- Maintain a continuous-improvement mindset. Improving supply chain management and operational efficiency in manufacturing is never finished; it requires ongoing effort. As supply chain conditions change, new trends emerge, customer demand shifts and technology advances, supply chain managers must be prepared to review and rethink their approaches.

- Implement real-time analytics. Real-time analytics in supply chain management can alert supply chain leaders to looming stockouts, supply and demand shifts, and changes in market pricing and benchmarking data, for example. With real-time insight, manufacturers can better manage inventory levels, labor and production schedules and warehouse operations.

- Embrace green practices. Companies that have established ambitious sustainability goals at the enterprise level naturally must extend these efforts into their supply chain operations, which can have an outsized impact on their environmental footprint. Green supply chain practices — including reducing waste and emissions, increasing recycling and upcycling, minimizing packaging and optimizing transportation and logistics — are becoming essential aspects of supply chain management. Because customers increasingly seek to understand the total environmental impact of the products they purchase (from raw materials sourcing to delivery), greater information sharing among supply chain partners is required.

- Prioritize agility and open communication. The ability of a manufacturer to respond quickly and effectively to changes in customer demand, market conditions and other external factors is more important than ever in today’s dynamic economy. Yet, such adaptability can be difficult, owing to the global, distributed nature of most manufacturing supply chains. Increased data sharing and open communication among partners in a manufacturing supply chain are crucial to enabling greater foresight and agility.

- Integrate technology. Implementing integrated manufacturing software elevates a manufacturer’s supply chain management efforts by harmonizing data across major supply chain processes. Most modern enterprise resource planning (ERP) systems integrate procurement, vendor and order management, inventory management and accounting with manufacturing data. Leading enterprise software also includes customer relationship management, quality assurance and product return capabilities. Thanks to the shift to cloud delivery, these ERP systems are now cost-effective choices for small and midsize manufacturers, as well.

- Provide excellent after-sales support. Supply chain management isn’t all about upstream optimization, and it doesn’t end once finished products are in customers’ hands. Investing in after-sales support is known to lead to higher customer satisfaction, which can make a difference in limiting unnecessary returns — as well as the added supply chain costs they require.

- Train staff regularly and monitor performance. Employee performance — whether in warehouses and plants, supplier relations, or production scheduling and engineering — is an essential ingredient in effective supply chain management. Keeping employee skills up-to-date is important, particularly as manufacturers face increased challenges in attracting and retaining talent. Monitoring ongoing supply chain performance by tracking key metrics, such as cycle time, order fill rate and inventory turnover, is equally as important.

The Quick Guide to Supply Chain Analytics

Master Manufacturing Supply Chain Management With NetSuite

The goal of manufacturing supply chain management is to ensure that a company is able to meet its customer demand in a timely and cost-effective manner. That’s much easier said than done in today’s manufacturing environment of globally dispersed supply chains, changing customer demand and ongoing disruption to supply chain networks.

To balance all these demands, leading manufacturing supply chain managers look to enterprise technology to deliver greater visibility into the depths of their supply chains and enable more control over their end-to-end supplier networks. Today’s global supply chains produce vast amounts of data that can be analyzed to drive improved, data-informed decision-making. Top-tier ERP systems integrate the systems used to run various aspects of manufacturing — procurement, inventory, operations, distribution, supply chain, accounting — bringing together all this data and analyzing it for usable insights.

NetSuite supply chain management ERP software lets companies oversee the flow of goods from suppliers through manufacturing and into customers’ hands. The software’s procurement capabilities communicate with suppliers and ensure accuracy throughout the purchasing process. Then, integrated demand planning, inventory management and predictive analytics optimize production strategies, ensuring that supply plans are executed and products are delivered as promised. Advanced data analytics produces insights that supply chain managers and manufacturing leaders can use to reach decisions that guarantee the consistent flow of materials and products throughout their supply chains. And because the solution is cloud-based, it’s accessible to and affordable for manufacturing operations of all sizes.

Supply chain management is one of the most important capabilities for any modern manufacturing company. As supply chains have grown more complex and global, the task of coordinating the efforts of the many parties involved in various stages of production and distribution can be daunting. In order to balance the often competing demands to minimize costs, maximize efficiency, deliver real-time transparency and maintain adaptability, supply chain managers and manufacturing leaders need a reliable flow of accurate data from their supply chain networks, as well as the ability to analyze that data and distribute the insights to those who need them to make the best decisions. Adopting a unified ERP platform ensures that manufacturers have access to accurate and timely data about their end-to-end supply chain operations so they can streamline processes, respond to changing conditions and drive greater profitability and growth.

#1 Cloud ERP

for Manufacturing

Supply Chain Management in Manufacturing FAQs

What is manufacturing supply chain management?

Manufacturing supply chain management refers to the processes and systems a manufacturer uses to oversee and optimize all aspects of producing and distributing its products, from obtaining raw materials to delivering finished goods to customers. Manufacturing supply chains tend to be among the most complex to manage, involving the orchestration of suppliers, materials, labor and equipment across an often vast and distributed network. In order to perform supply chain management effectively, manufacturers adopt enterprise resource planning (ERP) systems that integrate and analyze data produced at various points in the manufacturing process to generate decision-making insights.

Is manufacturing the same as supply chain management?

A supply chain is a network of companies and processes required to create a product or service and deliver it to customers. All manufacturers must manage a supply chain, which consists of the set of processes (often performed by different companies) necessary to manufacture a physical product. A manufacturing supply chain extends from the raw materials phase to the fabrication of finished products, all the way through to the delivery of the products to end customers.

But although all manufacturers have a supply chain to manage, not all supply chains necessarily involve manufacturing. Some companies, such as retailers and services firms, may have supply chains that don’t include production or manufacturing.

What are manufacturing and supply chain operations?

Manufacturing and supply chain operations are the primary methods by which a product manufacturer effectively and economically makes its products and delivers them to customers. Manufacturing refers specifically to the fabrication and packing of a final product in a production facility. The manufacturing supply chain, however, extends farther upstream to encompass the preproduction processing of raw materials, parts and components required to make the final product, and farther downstream to the postproduction distribution and logistics required to deliver that product to distributors, wholesalers, retailers or end customers.

What are the six types of supply chain management?

All supply chain managers in manufacturing seek to balance efficiency and responsiveness to some degree. How they accomplish this will vary according to the supply chain model used. There are six primary types of supply chain models that a manufacturer might employ: continuous flow, fast chain, efficient chain, agile, custom-configured and flexible.