Even well-oiled operations can run into unexpected slowdowns for reasons including equipment issues, inefficient workflows, labor shortages, and material delays. The resulting bottlenecks snarl output and disrupt flow. And with costs rising, supply chains growing more complex, and delivery windows shrinking, the pressure to quickly resolve these constraints mounts. Fortunately, when they are equipped with the right tools and approaches, manufacturers can tackle bottlenecks early enough to keep production flowing smoothly from one workstation to the next.

What Is a Manufacturing Bottleneck?

A manufacturing bottleneck occurs in a production process whenever demand outpaces capacity. If one step can’t keep up with the rest of the line, it creates a backlog that slows output and can affect everything from product quality to worker morale and profit margins.

In much the same way as the narrow neck of a bottle slows the stream of a liquid, a manufacturing bottleneck limits the flow of a production process because overall throughput can’t exceed the pace of the slowest point, even if every other step is operating at maximum efficiency. Tracking the way materials and goods move through each phase of production helps pinpoint where these slowdowns begin.

Key Takeaways

- Bottlenecks in the manufacturing process arise when capacity becomes limited enough to restrict output both at that stage and across the entire operation.

- Identifying bottlenecks requires a mix of data analysis, on-the-floor observation, and employee feedback.

- Relieving bottlenecks can boost throughput and productivity, often without requiring a major capital investment.

- Resolving bottlenecks is an ongoing and iterative process, as eliminating one obstruction often reveals others.

Manufacturing Bottlenecks Explained

Manufacturing bottlenecks can disrupt an entire production system. Even minor slowdowns at a single workstation can throw off the flow, causing upstream processes to accumulate work-in-process inventory while downstream operations sit idle, waiting for materials. The result? Higher production costs, underutilized labor and equipment, longer lead times, delayed shipments, and, ultimately, disgruntled customers.

Chronic bottlenecks incur less obvious costs, too: additional storage expenses for unfinished goods, overtime pay for the labor needed to catch up, rushed orders that increase error rates, or potential contractual penalties for missed delivery deadlines. Identifying and resolving these production constraints is crucial for any manufacturer hoping to maintain production efficiency, especially during periods of rising costs, economic uncertainties, and supply chain slowdowns.

According to the National Association of Manufacturers’ “Q3 2024 Manufacturers’ Outlook” survey, wages and raw material/other input costs are expected to increase 2.7% over the next year, and inventories are expected to fall 0.9%. In this kind of economic pressure cooker, even small process improvements can help control financial pressure, protect margins, and amp up competitiveness.

An Example of a Manufacturing Bottleneck

Let’s consider a furniture manufacturer moving raw materials, such as wood and metal, through a typical production flow:

- Materials enter the shop floor at a rate of 100 units per hour.

- The cutting and preparation departments process materials at a rate of 100 units per hour.

- Assembly completes only 60 units per hour.

- Finishing can process 100 units per hour but rarely works at capacity, because assembled items arrive too slowly.

In this scenario, assembly is the bottleneck because it constricts total output to 60 units per hour, despite the higher capacity levels of other departments. As a result, cut and prepared parts pile up at the point of assembly, cluttering storage space and increasing the potential for damage. Even if the cutting or finishing departments were expanded, production still wouldn’t exceed 60 units per hour until the assembly bottleneck is addressed.

So, the company decides to move one worker each from cutting and finishing to assembly. This adjustment balances throughput across the production stages, reducing work-in-process buildup and creating a more consistent flow from one step to the next.

What Causes Manufacturing Bottlenecks?

Manufacturing bottlenecks can pop up anywhere from material sourcing to packing and shipping, ranging from mild setbacks to major disruptions. Some are easy to spot while others develop gradually or emerge only under certain conditions, such as during peak demand periods or when machinery is running at nearly full capacity. Detecting the underlying source helps manufacturers fix the real problems, not just the symptoms, and respond more effectively to changing production demands. Common causes include:

- Ineffective processes: Poorly designed or outdated workflows can slow production. These inefficiencies often result from piecemeal improvements that ignore the bigger picture. Common signs: redundant work, excessive material handling, and frequent workarounds.

- Equipment failures: Scheduled maintenance and unexpected breakdowns can interrupt production flow and create temporary bottlenecks. Even brief stoppages can trigger major delays in sequential processes where each step depends on the one before it.

- Labor shortages: Gaps in staffing or training can reduce output at certain workstations or across entire departments. Even with equipment and materials ready, unfilled roles or unskilled workers can slow operations and limit productivity.

- High defect rates: Rework and scrap pull resources away from normal production, reducing capacity and slowing flow. When defective items re-enter the production line, they take up space and time that would otherwise go to new production.

- Poor forecasting: Inaccurate demand predictions can lead to staffing, inventory, or equipment shortfalls that contribute to bottlenecks that may not show up until actual demand exceeds expectations, especially if forecasts underestimate true outcomes. Conversely, overestimating demand can create backups by tying up resources in idle labor, unused machines, or surplus inventory.

- Miscommunication: Information breakdowns and poorly integrated data between departments can lead to delays, production errors, and rework. When teams receive incomplete specifications, conflicting priorities, or late-stage change instructions, they may pause work to await clarification or proceed incorrectly, initiating avoidable bottlenecks and undermining efficiency.

- Material shortages: A lack of raw materials or components stalls production, leaving labor and equipment underused. These shortages commonly result from supplier issues, quality problems, inventory mismanagement, or broader supply chain slowdowns.

- Supply chain disruptions: External supply chain disruptions caused by transportation delays, vendor problems, weather conditions, or geopolitical events can slow or stop the flow of materials and create sudden bottlenecks. Even manufacturers with efficient operations are vulnerable to these unpredictable impediments, which rely on strong contingency planning to manage.

Types of Manufacturing Bottlenecks

Not all manufacturing bottlenecks are the same. They vary in how often they appear, how easy they are to predict, and where they occur in the production process. Understanding these differences can help manufacturers apply the appropriate mitigation strategies, since fixing a recurring equipment issue demands a different approach from solving a one-off material delay. Common culprits:

- Static bottlenecks: These occur consistently in the same part of the process, often due to the use of equipment with fixed capacity limits, such as an older heat-treatment furnace that can handle only 50 components per hour while upstream and downstream processes can manage 80. Static bottlenecks are typically identified through capacity analyses.

- Dynamic bottlenecks: These kinds of bottlenecks shift within the production process and are generated by variable causes, such as product mix, batch size, or staffing levels. Because they fluctuate, they’re harder to identify and often require real-time performance monitoring software or other similar tools to resolve. For example, a computer-controlled milling station may become a bottleneck during complex jobs, while during simpler runs, the blockage might shift to assembly as output speeds up.

- Short-term bottlenecks: Temporary slowdowns may be caused by equipment failure, power loss, material delays, or unplanned absences. These are often resolved through the adoption of contingency measures, such as emergency maintenance, overtime shifts, backup systems, or expedited deliveries.

- Long-term bottlenecks: Persistent constraints can stem from systemic process issues or equipment limitations that regularly restrict output. Overcoming long-term bottlenecks often requires significant investments—such as for new machinery, redesigned processes, or workforce expansion—to permanently increase capacity.

How to Identify Manufacturing Bottlenecks

Manufacturers rely on a combination of analytics, direct observation, and employee insights to identify bottlenecks. While some blockages cause obvious, visible delays, others subtly limit capacity or introduce inconspicuous inefficiencies. Resolving these constraints—obvious or not—requires going deeper than identifying superficial symptoms.

One common identification technique is through the “Five Whys” approach, a structured method that involves asking “why” multiple times to trace a problem back to its root cause. Suppose a machine stops working. You ask:

- Why? The fuse blew.

- Why? The motor overheated.

- Why? It wasn’t getting enough lubrication.

- Why? The lubricant reservoir was empty.

- Why? No one was assigned to check and refill it while the usual worker was on parental leave.

Sometimes you only need to ask “why” three times, sometimes more than five—but five is the typical starting point.

By layering techniques like this with the methods discussed below, manufacturers can verify problems before attempting to develop solutions, which minimizes the risk of wasting resources on symptomatic issues or creating new bottlenecks elsewhere.

Map Your Production Process

Start by visualizing your production flow by creating value stream maps and process flow diagrams. Include every production step in order, along with cycle times, wait times, and capacity limits. These time-based metrics help pinpoint where delays occur and where output lags behind demand. Be sure to show how each step is dependent on the one before it, as linking processes can reveal where an upstream delay may be unobtrusively limiting downstream tasks. Use these visual tools to identify where inventory accumulates, materials slow down, or certain processes operate at capacity while others remain underused.

Solicit Employee Feedback

Talk directly with floor-level employees, including operators, maintenance staff, and supervisors. They often have the most practical view of production limitations and tend to encounter bottlenecks firsthand. They might even be using informal workarounds that haven’t been documented or communicated to management. Set up regular, blame-free feedback channels (for example, short huddles, suggestion boxes, or digital forms) to help workers feel comfortable reporting issues without fear of criticism. These insights can reveal dynamic or hidden bottlenecks that data alone might not catch, especially those triggered by specific conditions, such as shift changes or resource gaps.

Review Lagging KPIs

Track performance metrics regularly to uncover small inefficiencies that may not be apparent on the production floor. Key performance indicator (KPI) patterns, such as declining equipment performance, increased cycle times, or rising overtime hours, can highlight emerging bottlenecks. Monitor trends at both the system and the workstation level. Systemwide KPIs, such as increasing work-in-process inventory, can reveal that a jam is forming, while workstation-level metrics help pinpoint where it’s occurring, such as on an understaffed line.

Analyze Time-Series Data

Use historical data collected over extended periods to spotlight bottlenecks that might otherwise be mistaken for routine or seasonal fluctuations if reviewed without context. By comparing long-term performance across different product mixes, batch sizes, staffing configurations, and time frames (day-to-day, week-over-week, seasonal, etc.), manufacturers can uncover correlations that show when and why bottlenecks occur. Many manufacturing and ERP systems offer built-in tracking and analytics tools that automate this process and generate visualizations that blend real-time and historical data for faster, more intuitive analyses.

Look for Backlogs, Missed Deadlines, and Delayed Movement

Though data and analytics are invaluable, the most obvious signs of bottlenecks are often found on the shop floor: material pileups and idle workstations that lead to missed deadlines. Conduct regular shop floor walkthroughs to detect slowdowns, focusing on staging areas, work-in-process zones, and underused equipment. Note patterns in late deliveries, especially by product type or production path, to identify where delays occur most frequently. Your direct observations not only help confirm data-driven bottlenecks but can also prompt immediate action, such as reassigning cross-trained staff from idle stations to support affected areas.

Strategies for Eliminating Manufacturing Bottlenecks

Identifying a bottleneck is only the beginning. To resolve it effectively—and prevent it from resurfacing—manufacturers need targeted, cost-effective strategies tailored to each circumstance. No single fix applies to every situation, so it’s important to prioritize improvements based on their impact, implementation time, and cost. And since easing one bottleneck often exposes another, eliminating these occurrences should be approached as an ongoing, iterative process.

Optimize Workflows

Even small workflow improvements, such as repositioning equipment or eliminating redundant steps, can have a measurable impact on production flow. Start by reviewing each element of the production cycle for inefficiencies: Look for unnecessary steps, excessive movement, duplicated tasks, or misaligned procedures. Consider applying lean manufacturing principles to improve processes and eliminate waste, keeping only the actions that directly add value for the customer. Also examine how work is distributed across stations; rebalancing tasks or breaking down complex processes into manageable actions that can be performed in parallel can ease pressure and minimize delays.

Cross-Train Employees

According to Supply Chain Management Review’s analysis of Q3 2024 US census data, 20.6% of US manufacturing plants couldn’t operate at full capacity due to labor and skill shortages. Cross-training employees helps overcome this challenge by creating a more flexible workforce that can step into multiple roles. When bottlenecks arise, managers can reassign trained workers quickly, avoiding the need for overtime work or to onboard new staff.

To get started, assess which employees are qualified for which tasks and who possess necessary proficiency levels. Then, focus training efforts on critical shortfalls, especially in areas that experience frequent bottlenecks. Cross-training also helps maintain production flow during staff absences, shift changes, or demand spikes and supports employee development, job satisfaction, and even retention.

Invest in Increasing Capacity

When internal process improvements aren’t enough to resolve persistent bottlenecks, it may be time to invest in additional capacity. This can include upgrading machinery, adding parallel equipment at key steps, or expanding staff in overloaded areas. Digital tools, such as real-time performance monitoring systems or manufacturing ERP platforms, can improve information flow to hasten decision-making.

To prioritize investments, calculate the full cost of the bottleneck—including lost output, quality issues, and overtime—and weigh it against the cost and timeline of the proposed solution. Although these capacity investments can require substantial capital, they often yield long-term gains in output and flexibility.

Improve Inventory Management

To prevent material-related bottlenecks, evaluate how inventory is positioned throughout your operation. Strategic placement keeps essential materials available where and when they’re needed, without overcrowding shelves or workstations. One effective approach is to use a tiered inventory management strategy: Keep higher buffer stocks for components prone to delay, and lower stock levels for reliable, fast-turnover items. Modern inventory systems can automate this process by setting minimum and maximum stock thresholds based on lead times, turnover rates, and production schedules. Such tools can also alert relevant staff when inventory levels fall outside the target range or trigger automatic reorders through integration with suppliers.

Reorganizing storage locations—such as placing high-use materials closer to their point of use or using first-in, first-out systems for perishables—can also trim retrieval time and keep production moving.

Review Production Schedules

Plan more thoughtful sequencing by reviewing how jobs are scheduled on the line. Group similar products or processes in close proximity to reduce changeover time by minimizing equipment adjustments and tool changes. When setting production schedules for more complex or resource-intensive products, stagger them to avoid overwhelming staff and overloading equipment. For high-volume production or mass-produced items, consider scheduling longer, uninterrupted production runs to increase efficiency—but weigh the benefits against potential downsides, such as excess inventory or quality issues arising from overworked equipment.

Cloud-based scheduling tools are useful, as they can help managers quickly track performance, spot inefficiencies, and make adjustments either from the office or on the shop floor.

Leverage Automation

Manufacturers can replace error-prone, manual processes with automated solutions, such as robotic systems, automated material handling, and computer-controlled equipment. These tools are particularly useful when dealing with repetitive tasks or administrative delays (think: approval processes, document routing, and order status updates).

To ease the transition, start with small-scale automation projects that address specific bottlenecks, rather than attempting a full-scale facility overhaul. This tempered approach not only streamlines backlogged manual processes but also allows workers to spend more time on complex tasks that require human judgment, such as spotting additional downstream bottlenecks.

Proactively Scan for Bottlenecks

Don’t wait for missed deadlines or complaints to alert you to the need for action. Monitor operations regularly to catch bottlenecks before they can slow production. Set up routine reviews of early indicators of potential problems, including performance metrics, employee feedback, and shop floor observations. For known or recurring bottlenecks, develop contingency plans that outline preapproved responses, such as reallocating staff or dipping into safety stock. This gives teams a clear plan of attack should warning signs appear. Some manufacturers also assign a cross-functional bottleneck response team to rapidly assess and address slowdowns as they arise, as well as to identify the next likely blockage once the current one is resolved.

Identify Bottlenecks Faster With NetSuite for Manufacturing

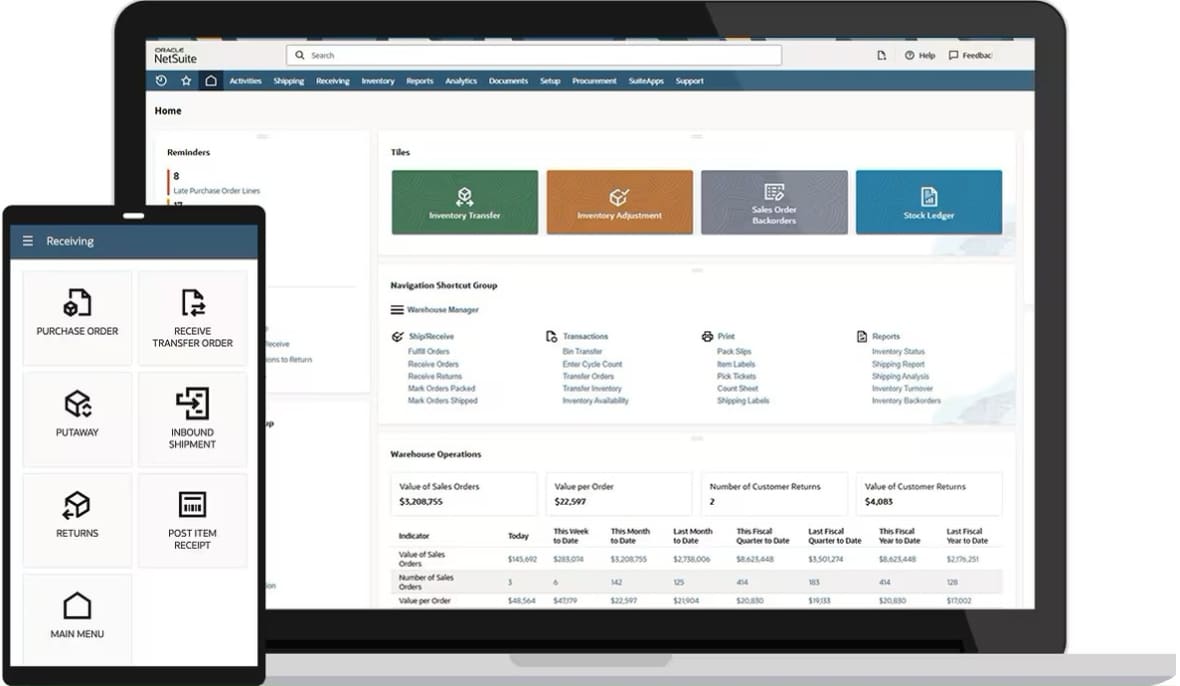

Many manufacturers don’t spot bottlenecks until it’s too late. Siloed data and fragmented systems limit visibility, leading to rushed fixes, delayed orders, and frustrated customers. NetSuite for Manufacturing offers a unified, cloud-based platform that combines production planning, inventory management, and performance monitoring to give managers and decision-makers the transparency they need to identify and address bottlenecks early, whether that means adjusting workflows or scaling capacity.

NetSuite includes real-time dashboards that highlight key metrics, such as work-in-process levels, machine utilization, and cycle times, making it easier to detect workstation constraints and production flow issues before they escalate. The system’s built-in work order management and capacity planning tools help manufacturers restructure production around bottleneck-prone areas so that essential materials, labor, and machinery are always available when needed. Plus, NetSuite’s analytics tools visualize performance trends over time, helping to separate natural fluctuations from genuine bottlenecks. They can also measure the effectiveness of improvement efforts.

By bringing production, inventory, and resource data into a single system, NetSuite helps teams shift from reactive troubleshooting to proactive bottleneck management that supports long-term results.

NetSuite’s Cloud-based Dashboard

Bottlenecks are an inevitable part of manufacturing, but when businesses have the right tools and strategies in place, their impact can be diminished. By understanding the types of bottlenecks that occur and implementing a systematic approach to detect and address them, manufacturers can cope with the disruptions. Certain tactics, such as cross-training employees and monitoring performance in real time, can help teams quickly respond to roadblocks, improve production flow, and protect throughput—despite being faced with today’s labor shortages, rising costs, and supply chain uncertainties.

Manufacturing Bottlenecks FAQs

What is one tool used to identify bottlenecks in manufacturing?

One commonly used tool is value stream mapping, which visually outlines each step of the production process. By documenting these processes according to metrics like cycle times, wait times, and inventory levels, manufacturers can pinpoint where materials, information, or workflows slow down—and where strategic improvements can ease the flow.

How do you remove process bottlenecks?

To remove process bottlenecks, first accurately identify the site. Then apply targeted solutions to alleviate it. Approaches might include redesigning workflows, reallocating resources, cross-training employees, or automating tasks. Once resolved, continue monitoring the process, as elimination of one bottleneck often reveals another.

Why is it important to identify bottlenecks in a manufacturing system?

It’s important to identify bottlenecks because they limit the overall output of a manufacturing system, regardless of how efficient other steps may be. Left unaddressed, bottlenecks can increase costs, extend lead times, overwhelm work-in-process inventory, and degrade customer satisfaction. Solutions designed to relieve bottlenecks can help manufacturers improve productivity, often involving relatively low investment.

What happens if a bottleneck occurs on the production line?

If a bottleneck occurs on the production line, it can slow the entire production process by capping output at the pace of the slowest step. This causes unfinished work to pile up upstream and leaves workers and machines downstream underutilized. The result is reduced throughput, higher operational costs, and longer lead times. If left unaddressed, persistent bottlenecks can hurt productivity, profitability, financial stability, reputation, and even competitive standing.