The prospect of lower operating costs, increased productivity, and higher-quality products is enticing manufacturing companies to embrace automation. It’s also good news for the makers of industrial automation and control systems: The global market value for their solutions is expected to reach $307.7 billion by 2030—an 86% increase over $165.1 billion in 2023.

This article explains how manufacturing automation works, its benefits, and how companies across all industries, including food and beverage, automotive, and aerospace, are using it to their advantage.

What Is Manufacturing Automation?

Manufacturing automation is made possible using software, machines, and other technologies to produce, assemble, and package goods. By decreasing or eliminating human intervention, production processes can run more efficiently, accurately, and safely, paving the way for manufacturers to simultaneously increase output while reducing costs. Automation also frees employees to spend more time on oversight and other strategic tasks.

Key Takeaways

- Robots and other automated machines are able to complete tasks more efficiently and accurately than humans, which saves manufacturers time and money.

- Despite the up-front costs associated with deploying automation tools, businesses are seeing a return on investment more quickly than ever before.

- Some systems are designed for high-speed, high-volume production of one product type, while others accommodate multiple tasks and product types.

- Even in sectors that haven’t completely embraced automation, beneficial use cases are emerging.

Manufacturing Automation Explained

Automated manufacturing dates back to at least 1784, when a Delaware mill converted grain into flour with a machine invented by Oliver Evans. Automated looms, controlled by paper punch cards, emerged in the 1800s. But it wasn’t until 1946 that D.S. Harder, an engineering manager at Ford Motor Co., coined the term “automation” in reference to the automaker’s moving assembly line.

These days, manufacturing automation has been fueled by advancements in robotics, analytics, and the Internet of Things (IoT). Emerging technologies—particularly artificial intelligence—are also creating even more opportunities for manufacturing innovation. Support is clear, with 97% of industrial manufacturing CEOs surveyed by EY saying that use of digital technology to drive growth and streamline operations was an important near-term priority.

Examples of equipment that automates manufacturing include computer-controlled machines, robots, and robotic vehicles. Robots have been a key element in automated manufacturing for decades, performing tasks that would otherwise be time-consuming or even dangerous for human workers. Modern robotic automation can perform more complex and intelligent work, such as synthesizing compounds for medications or assembling large airplane parts.

Other examples include automated assembly lines, which repeatedly create and assemble parts in accordance with their design specifications. Sensors and devices with computer vision provide new data sources, automating inspections and quality control. And enterprise resource planning (ERP) software consolidates associated data, giving manufacturers new visibility and insight into their operations.

Types of Manufacturing Automation

Not all manufacturing jobs require the same level of automation. Some systems are designed for high-speed, high-volume production of one product type, with little to no variation. Others can accommodate multiple tasks and product types but are not ideal for mass production. Flexible automation systems fall in between.

-

Fixed automation:

Fixed automation, also known as hard automation, refers to a system with simple onboard programming purpose-built to quickly produce high volumes of one product. Automotive assembly lines rely heavily on this approach, with machines designed to create distinct car parts, such as gears.

The downside of fixed automation is that, as its name suggests, it is fairly rigid. To make a change in production, a manufacturer would have to shut down its assembly line and manually swap out one machine for another—a costly and laborious endeavor.

-

Programmable automation:

Programmable automation is used to produce multiple types of products in batches. It’s best suited for lower-volume production requirements or products with shorter shelf lives. For example, frozen food companies use programmable automation to prepare and package their goods quickly, so they can get them out to stores as soon as possible.

Although more versatile than fixed automation, programmable automation still involves some downtime when changing tasks because manufacturers have to install new programming on the machines. This downtime can add up, hurting the system’s overall efficiency.

-

Flexible automation:

The downtime costs associated with fixed and programmable automation have given rise to flexible automation, which enables manufacturers to produce multiple product types at the same time. Flexible automation systems connect to networks, which means they can receive new programming for production orders without significant downtime. The trade-off is that these machines can’t accommodate as many different product types. As such, they are a good fit for real-time, on-demand production use cases, such as producing a variety of gears for different car models.

Benefits of Manufacturing Automation

Automation’s reach goes far beyond increased production capacity. It also reduces operating costs, improves product quality, and enhances safety, all of which boost efficiency. Beyond the factory floor, automation brings additional benefits, such as real-time data collection and analysis, that help manufacturers better manage their resources.

Here is a closer look at these and other benefits of manufacturing automation.

- Lower operating costs: Robots and other automated machines can complete tasks more efficiently and precisely than humans, which saves manufacturers time and money. Deploying automation tools involves up-front costs, but businesses are seeing quicker returns on investment than ever—in one to three years, according to McKinsey, versus the five- to eight-year ROI experienced from the 1980s to the early 2020s.

- Improved product quality: By minimizing the chances of human error and ensuring consistency, automation also contributes to better products with fewer defects. Automated quality control helps manufacturers further minimize mistakes occurring during the production process. The resulting products are also safer for consumers, helping businesses avoid negative publicity, fines, or product recalls.

- Improved workplace safety: The same strategies and tactics that go into creating top-notch products also lead to safer workplaces. Manufacturing has always involved hazards, including putting people in close contact with heavy machinery and chemicals. Automation minimizes the risk to employee safety by limiting human involvement in these processes.

- Reduced production waste: Inconsistent and/or manual manufacturing processes often result in defective products, and every one represents a waste of materials. Automation helps cut down on this waste by creating higher-quality products.

- Increased productivity: Software, robots, and other automated machines can work around the clock with no breaks, which means they can produce more products than humans in the same amount of time. This added capacity grants companies more flexibility to increase or decrease production in response to changing market conditions. Reducing the variability inherent in human work habits and schedules also increases the accuracy of forecasts and projections.

- Improved data collection: Automated systems track and analyze data in real time, using IoT-enabled sensors, robots, and other technologies. The information gleaned from these systems supplies manufacturers with deeper insights into factory floor operations, production outputs, and the overall supply chain, empowering them to make smarter business decisions.

- Increased resource management: Automation brings together disparate processes and systems so that manufacturers can reduce their overhead and make better use of available resources, including manual labor. They can also analyze the comprehensive data at their disposal to identify operational inefficiencies or other areas in need of improvement, some of which can be addressed automatically. For example, sensors that monitor the on-hand availability of raw materials can trigger dynamic changes when detecting shortfalls in production schedules, ensuring that the company will continue to meet demand.

- Happier customers: Automation enables manufacturers to build high-quality products in sufficient quantities to meet demand in a timely fashion, which ultimately results in greater customer satisfaction. Companies that establish themselves as reliable suppliers strengthen both their reputations and client relationships, fueling long-term growth.

- Optimized use of floor space: Automation allows manufacturers to make better use of their production space in several ways. For example, robots designed to take up less floor area can work in more confined spaces. They can also move materials directly from one machine to another without requiring huge staging areas. And automated storage and retrieval systems let manufacturers take greater advantage of vertical space.

Manufacturing Automation Tools

Manufacturing automation relies on a variety of tools and technologies. Some of these tools perform physical processes, while others use sensors and software to provide the data and insights needed for effective automation. Some of the most commonly used automation tools in modern manufacturing include:

Computer Numerical Control (CNC) Machines

CNC machines use software programs to control a variety of manufacturing tools, such as drills, welding machines, and 3D printers, without direct human involvement. The word “numerical” refers to the use of numbers—i.e., degrees, speeds, or coordinates—to provide instructions.

Manufacturers first use computer-aided design (CAD) software to define their desired production output—for example, a banister post that a lathe will create from a piece of wood. Computer-aided manufacturing (CAM) software then generates specific directions that match that design. Next, post-processing software translates those directions into a language that the CNC machine understands. Depending on the design, one tool may be programmed to perform multiple tasks, or several tools might work together to complete the finished product.

CNC machines are more efficient and productive than manually or mechanically controlled machines. On the downside, they carry high initial costs and take time to set up properly. As such, they are best suited for larger-scale manufacturing jobs.

Programmable Logic Controllers (PLCs)

PLCs are small, ruggedized computing devices that monitor and direct industrial machines and manufacturing processes. They are capable of inputting and outputting data, which means they can transmit specific commands across multiple machines, based on their programming and the current conditions they observe—a key component of manufacturing automation. For example, a PLC can read the internal pressure of a machine and then open or close a valve, if necessary, to return the pressure to its desired state, as dictated by its programming.

Common use cases for PLCs include assembly lines, conveyor systems, temperature-control machinery, and other similar, highly repeatable standardized processes. As an added bonus, their design also enables them to perform process fault diagnosis, i.e., identifying and determining fixes for the causes of malfunctions and other production errors.

Manufacturing Execution Systems (MES)

Manufacturing execution systems are software platforms that help businesses track and manage inventory and production in real time. They integrate with sensors, barcode scanners, and other data collection tools to monitor inventory as it moves through the entire manufacturing process. They also allow companies to analyze the quality of their production.

By feeding this information from process control systems on the production floor to ERP systems in the back office, an MES provides the insights that businesses need to run their operations more efficiently and cost-effectively. Plant managers, engineers, and operators can gain more visibility into production activities to better evaluate their performance and identify bottlenecks. MES platforms are used in multiple industries, but they are most prevalent in highly regulated sectors to ensure compliance and traceability.

Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs)

AGVs and AMRs are self-guided machines that move throughout industrial buildings transporting materials, cleaning equipment, and performing other types of tasks.

- AGVs travel fixed paths in warehouses or machine shops. They rely on sensors, wires, or magnetic strips to guide them because they don’t typically have much built-in computing power. Spacious, uncluttered floors are the best environments for these vehicles.

- AMRs, on the other hand, use GPS, AI, and machine learning (ML) to more independently navigate their surroundings, and they can be remotely programmed to travel multiple routes. Equipped with sensors to detect and avoid obstacles along their travels, they are a better fit for more crowded and active production floors.

Common AGV and AMR use cases in manufacturing include transporting raw materials from the warehouse to the assembly line (or between different assembly line processes), packaging finished products, and moving them on to distribution. AMRs provide additional capabilities, such as sanitizing and maintaining machinery and performing quality-control checks.

Computer Vision

Manual quality control and safety monitoring are error-prone and inconsistent processes. One momentary lapse by an employee could cause them to overlook a production mistake or potential hazard. What’s more, the cost of sufficiently staffing these functions can be prohibitive.

Computer vision relies on machines to detect and interpret visual information. Manufacturers use the technology to automate quality control, safety monitoring, and other important tasks. For example, inspection systems powered by computer vision notice and report on product inconsistencies, defects, and workplace safety issues, such as a product that spilled on the floor or a worker not wearing the proper protective gear. With the added power of AI and ML, these systems can even spot these potential issues in advance.

Enterprise Resource Planning (ERP) Software

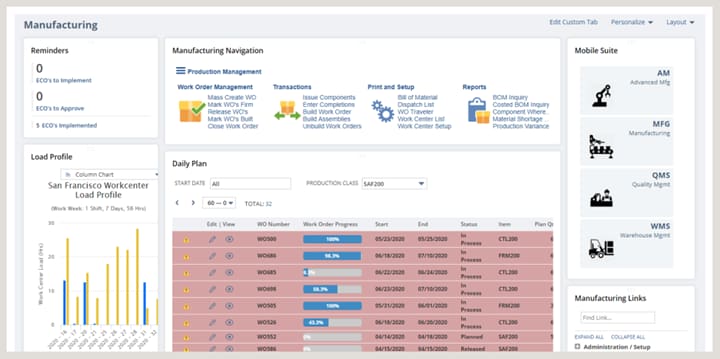

ERP software helps companies manage their entire manufacturing operation, including production planning, inventory management, and quality control, from one platform. ERP aggregates and analyzes data from multiple business systems and smart machines on the factory floor to provide complete visibility into the production process. With derived insights in hand, manufacturing managers and business leaders can make well-informed and proactive decisions about ways to increase productivity and lower costs.

Manufacturing ERP systems also support automation in several ways. Automated inventory management ensures sufficient stock levels to meet projected demand. Quality-control automation minimizes product defects. These systems even integrate with CAD and CAM software to help companies design and create products accurately and consistently. Other common features include automated scheduling, order planning, demand forecasting, and bills of material management. All told, the use of ERP in manufacturing automation helps businesses improve efficiency, eliminate waste, keep employees safe, and maintain regulatory compliance.

Use Cases of Manufacturing Automation

Automation plays a critical role in multiple industries. In the heavily regulated pharmaceutical and food and beverage sectors, for example, automation reduces recall risks. Aerospace and automotive manufacturers rely on automation for large-scale fabrication and precise assembly. And even in industries that haven’t completely embraced automation, such as construction, beneficial use cases are emerging.

-

Construction:

Approximately 31% of construction companies actively used robotics in 2024 for bricklaying, demolition, prefabrication, and other complex tasks, while 35% were in piloting phases, according to BuiltWorlds’ 2024 “Tools, Equipment, and Robotics Benchmarking Report.”

For example, by building precast walls and even entire rooms on a production line, construction companies can accurately and uniformly produce higher volumes of these structures, then deliver them to their respective jobsites when ready. In the future, task-specific mobile robots are expected to become more common on construction sites, as well.

-

Automotive:

Most of the automotive industry has embraced manufacturing automation. The production, assembling, and welding of specific parts are frequently automated tasks in auto plants. Machines can also perform simple, repetitive tasks, such as installing windshields and mounting steering wheels, as well as more advanced processes, such as assembly-line inspections. In addition, manufacturers are using robotic process automation (RPA) to track and replenish inventory, aggregate data collected from sensors, and complete other manual tasks more efficiently. RPA bots can even shut down machinery in the event of a dangerous situation, such as an unprotected employee getting too close to a welding machine.

-

Pharmaceutical:

Pharmaceutical companies’ use of robots, software, and intelligent machines to automate various manufacturing processes is, in many ways, a necessity, as it enables them to adhere to the industry’s extremely high-quality standards, ensure regulatory compliance, and maintain the safety and efficacy of medications.

Automated pharmaceutical manufacturing accurately formulates, mixes, and packages medications for distribution. For example, automated pipetting systems replace the manual work of transferring liquid from one chamber to another. They also synthesize compounds more precisely and consistently than lab workers, resulting in fewer errors. Similarly, specialized machines automatically fill and cap medicine bottles at high speed, increasing production output. By reducing human involvement in these and other processes, automation also reduces the risk of contamination.

-

Textiles:

More textile manufacturers are turning to automated technologies; with the market projected to grow by 3.2% every year from 2024 to 2029—a total increase of $664 million—that’s not surprising. Automated spinning, weaving, knitting, dyeing, and finishing processes are helping manufacturers improve efficiency and reduce waste.

Common automation applications used in the industry include machine loading, robotic sewing and printing, and fabric testing, spreading, and cutting. Many of these technologies work together to create final products. For example, manufacturers use CAD software to automatically design products and make patterns, and robots then cut, sew, and print fabrics according to those specifications. Textile manufacturers also rely on automated quality control to fabricate consistently better products with fewer defects.

-

Aerospace:

The aerospace industry manufactures aircraft wings, engines, fuselages, and other heavy components—and relies on equally heavy machinery to assemble them. Automation is the key to increasing efficiency and protecting workers throughout these and other processes. For example, AGVs move large materials across the production floor, and robots work together to perform a broad range of fabrication and assembly tasks, such as trimming, drilling, fastening, and painting. Automation also aids the rigorous inspection process, helping manufacturers ensure compliance with the industry’s stringent standards.

By cutting down on the heavy lifting and repetitive manual work that can injure workers, aerospace automation keeps employees safe and reduces costs. With machines and robots completing this work more accurately and quickly, companies can increase their production capacity.

-

Food and Beverage:

Food and beverage companies use robotics, conveyor systems, AGVs, AMRs, and other automated systems to harvest, process, and package their goods. AI-powered robots with computer vision pick fresh produce, examine it, and sort it based on size, color, texture, and other indicators of quality. Once those foodstuffs are in the plant, specialized machines are able to clean, cut, and even cook them, then package them up for distribution.

Automation leads to greater product consistency and quality, which decreases the chances of contamination and product recalls. It also protects employees by minimizing their work in dangerous environments—for example, automated sawing machines can be used to precisely cut large chunks of frozen meat. Additional benefits include optimized production, more flexibility in responding to changing demand, reduced food waste, and enhanced regulatory compliance.

-

Medical Devices:

Medical device manufacturing automation streamlines the process of making a wide variety of equipment, from thermometers and syringes to hearing aids and dialysis machines. Companies use a combination of CAD systems, CNC machines, robots, AI, ML, and sensors to automate the design, manufacturing, and packaging of these devices. For example, a robot can heat and seal an infusion pump in its packaging, ensuring sterilization. Together, automated technologies increase the speed and flexibility of these processes, which helps manufacturers overcome the challenges of increasing costs and supply chain disruptions.

NetSuite ERP Supports Your Automation Goals

Successful manufacturing operations require up-to-date, accurate data, plus well-defined processes and proper planning. NetSuite’s cloud-based manufacturing ERP provides total visibility and in-depth insights, so you can make your operations more efficient, productive, and safe through automation. Real-time shop floor updates enable more flexible capacity planning and production scheduling; they also improve the way companies monitor the health and safety of their equipment. Manufacturers across industries, from construction to medical devices and beyond, rely on NetSuite to improve how they control, coordinate, and manage their operations with automation.

NetSuite Advanced Manufacturing Center

Manufacturing automation has evolved from its origins as simple machines for grinding wheat to present-day AI-powered robots that build spacecraft. The traditional benefits of automation—efficiency, productivity, and accuracy—remain significant drivers behind its adoption. But advancements in technology are also opening new doors. Modern manufacturers can use automation to reduce waste, enhance safety, optimize their entire supply chains, and make proactive, data-driven decisions to grow their businesses. Whereas automation was once just a tool, it’s now a strategic asset.

Manufacturing Automation FAQs

What is the primary goal of manufacturing automation?

The primary goal of manufacturing automation is to make production processes more efficient. By offloading repetitive and often hazardous manual tasks to robots and other machines, automation helps companies safely increase output, improve product quality, and reduce costs.

What are the 5 basic components of an automated system?

The five basic components of an automated system are energy, sensors, control devices, decision-making capabilities, and programming. Together, these components enable computers and robots, plus other machines and entire systems, to perform tasks without direct human involvement.

How does manufacturing automation work?

Manufacturing automation works by programming robots and other machines to complete specific tasks that humans previously performed manually. Thanks to AI and machine learning, these systems can respond dynamically to changing conditions.