Efficient, resilient supply chains depend on strong suppliers. But even the best can fall short if clear expectations, consistent oversight, and ongoing collaboration are lacking. This article explores how manufacturers can reduce risk, control costs, and achieve desired business outcomes by following a structured, data-driven approach to improving supplier performance.

What Is Supplier Performance Management?

Supplier performance management (SPM) is the practice of evaluating and improving how external partners contribute to a manufacturer’s operational goals, quality standards, and delivery expectations. It involves measuring suppliers’ efforts against predefined criteria to make sure they’re meeting contractual obligations.

SPM aims to optimize output, reduce risk, and drive continuous supply chain improvement. Additionally, regular performance reviews help preserve high standards and strengthen relationships.

Key Takeaways

- SPM allows manufacturers to spot and address underperformance before problems escalate, enhancing business continuity and decision-making prowess.

- Communicating expectations, tracking key performance indicators (KPIs), and sharing feedback help build strong partnerships with high-performing suppliers.

- Technology improves SPM by automating data collection, centralizing information, and providing accurate, real-time insights.

Supplier Performance Explained

On-time and accurate deliveries, consistent product quality, and controlled costs are hallmarks of a high-performing supply chain. They result in fewer delays, returns, and last-minute fixes, freeing up time and resources. They also indicate a supplier’s ability to keep pace with increasing demands, maintain standards across locations, and deliver on promised commitments. On the flip side, when suppliers fail to meet the requirements of purchase agreements, production slows and expenses rise.

Supplier management—the tracking of KPIs to identify which vendors are the most dependable—contributes to more stable supply chains and fewer disruptions. On-time delivery, defect rates, lead times, and other metrics provide a clear view into day-to-day operations, making it easy to objectively compare suppliers, spot trends, and address poor performance.

Supplier Relationship Management vs. Supplier Performance Management: What’s the Difference?

The primary difference between supplier relationship management (SRM) and SPM is that SRM is strategic and SPM is tactical. SRM involves developing long-term supplier relationships by focusing on collaboration, shared goals, and joint value creation—for example, a manufacturer and supplier that work together to build a new product. SPM deals with assessing supplier performance by monitoring and analyzing delivery times, defect rates, pricing accuracy, responsiveness, and other KPIs.

Quarterly business reviews and strategic planning are highlights of SRM, whereas SPM relies on weekly updates and monthly scorecards to identify and address late shipments, quality problems, and other issues. SPM is often a component of SRM, because strong supplier performance is a cornerstone of a successful relationship.

Why Is Supplier Performance Management Important?

SPM is important because it allows teams to take corrective action before minor setbacks, such as repeated delays or rising defect rates, become larger problems. SPM also supports better business continuity and provides data for better operational decision-making. If one supplier often misses delivery windows while another’s consistent output directly results in cost savings, those insights can inform future choices about contracts, sourcing, and vendor consolidation. Suppliers that meet quality and lead-time targets keep production schedules and customer commitments on track, while failures create a ripple effect across multiple departments, including procurement, logistics, and even customer service.

SPM is especially important in complex, distributed supply chains because it grants clearer visibility into demand shifts and disruptions. It also creates a structure for holding suppliers accountable and providing valuable feedback. In doing so, SPM creates strong supplier relationships that are built on honesty and transparency, which ultimately results in a more reliable and cost-effective supply base.

Supplier Performance Management in Three Steps

SPM embodies a clear process centered on accountability and continuous improvement. Follow these steps to work closely with suppliers and strengthen their performance over time:

- Communicate performance expectations: Agree on specific KPIs that align with broader business goals. These typically include delivery timeliness, product quality, and pricing accuracy. Clearly document these expectations in contracts or service-level agreements.

- Monitor performance metrics: Use scorecards, audit reports, and spend analysis tools to regularly measure supplier performance against the chosen KPIs. Review trends over time to identify recurring problems and benchmark KPI results across the supply base.

- Provide feedback and iterate: Highlight strengths, identify problem areas, and take action before issues escalate. Work with suppliers to address underperformance gaps by adjusting processes, providing extra training, or making changes to existing agreements.

Challenges That Cause Supplier Performance Issues

A wide range of internal and external factors can cause disruptions that affect product cost, quality, and delivery timelines—even when strong supplier relationships with clear expectations exist. Being prepared for the following challenges can help manufacturers build more resilient supply chains:

- Logistics disruptions: Port delays, labor strikes, and extreme weather can disrupt delivery schedules, stall production, and increase shipping and storage costs. Backup plans and diversified logistics strategies help prevent these events from impacting the entire supply chain.

- Inaccurate forecasting: Off-base demand projections may result in excess or insufficient inventory, either of which is costly. Unpredictable order sizes and frequent last-minute changes complicate production and inventory planning and increase the risk of delays.

- Cash flow issues: Late payments and budget shortfalls strain supplier relationships. Financial instability undermines trust, making suppliers less willing to commit resources or prioritize production.

- Increased costs: Suppliers may pass along extra costs associated with rising materials, labor, and transportation prices, potentially making them too expensive to continue working with. Quality problems can also arise if suppliers feel pressure to cut corners.

- Compliance violations: Vendors’ failure to meet regulatory standards or contractual agreements can result in fines, shipment holds, and damage to brand reputation in the eyes of their customers. Clear expectation-setting with ongoing oversight helps avoid these situations.

- Technological limitations: A lack of advanced automation systems may make a supplier more prone to delays. Limited data integration capabilities can lead to miscommunication and impaired decision-making if they’re based on inaccurate or outdated information.

- Poor inventory management: Inaccurate inventory tracking causes suppliers to accept orders they can’t fill on time, disrupting production and fulfillment schedules. Regular communication and planning are key to maintaining reliability.

- Miscommunication: Unclear goals, misaligned expectations, and incorrect data complicate SPM. Suppliers that feel confident in their customers’ evaluations are more likely to cooperate with performance management efforts and improve their service levels.

- Changes in supplier personnel: Communication breakdowns are to be expected when key supplier employees leave or roles shift, resulting in quality and delivery lapses. Proper knowledge transfers, including updated process documentation, help circumvent these concerns.

- Inconsistent quality control: Quality fluctuations disrupt production and weaken customer trust. The rework and returns required to remedy quality issues add to costs and hurt efficiency.

Commonly Used Supplier Performance Metrics and KPIs

By understanding the metrics that provide insights into reliability, quality, cost, and compliance, manufacturers can objectively measure supplier performance. Here are the most widely used supply chain KPIs for evaluating vendors and maintaining optimal operations.

-

On-Time Delivery

A supplier’s ability to deliver orders by an agreed-upon date is a key indicator of reliability. It’s especially important for businesses relying on tight production schedules and time-sensitive shipments, such as automotive manufacturing or ecommerce fulfillment centers, where delivery delays can halt production and disrupt fulfillment. Most companies set on-time delivery goals at or above 95%, signaling a supplier’s consistently strong planning and logistics abilities.

-

Order Accuracy

This metric measures how often a supplier delivers the correct quantities of the right items. Tracking order accuracy by supplier or product type identifies problems—such as incorrect labeling, picking errors, and incomplete shipments—that lead to rework, delays, and customer complaints. Clear purchase orders and strong communication can increase accuracy rates.

-

Fill Rate

Fill rate reflects a supplier’s ability to completely fulfill orders without splitting or backordering shipments. High fill rates mean fewer emergency purchases and production delays, plus more stable inventory levels. Lower rates may indicate persistent shortfalls, inventory planning issues, or supplier capacity limitations.

-

Lead Time

Lead time—the number of days that elapse between order placement and delivery—informs production planning and inventory management. Short, consistent lead times reduce the need to hold large safety stock, providing greater flexibility. Unstable lead times, on the other hand, may indicate problems with suppliers’ internal processes, logistics partners, or raw material sourcing. Tracking average lead time and its variability across the supply base helps pinpoint the reasons for delays and sharpens the accuracy of production scheduling.

-

Defect Rate

This KPI is the percentage of delivered units that are damaged, built to incorrect specifications, or otherwise fail to meet quality standards. High defect rates slow production, increase returns, and affect overall product safety and performance. Close monitoring allows for early intervention, which helps prevent quality issues from worsening.

-

Cost of Poor Quality (CoPQ)

CoPQ quantifies the financial losses associated with rework, returns, warranty claims, inspections, process audits, and other quality-related failures. Companies often measure CoPQ by internal and external failure costs, appraisal costs, and prevention costs. By tying quality issues to financial impact, manufacturers can improve margins and justify investments in supplier training and quality control systems.

-

Cost Reduction Contribution

Cost reduction contribution is a key metric in strategic supplier relationships, where both parties aim to cut waste and improve efficiency. This KPI evaluates supplier efforts to shrink costs, such as through price negotiations or process improvements. Documenting these cost savings helps demonstrate ROI and recognize high-performing suppliers.

-

Total Cost of Ownership (TCO)

TCO incorporates all expenses related to a supplier’s goods and long-term contracts, which allows companies to prioritize suppliers that offer long-term value and operational alignment. TCO includes acquisition, shipping, storage, maintenance, support, and disposal costs over the full lifecycle of a product or service—in addition to its purchase price. Accurate TCO calculations require input from multiple departments, including finance, procurement, and operations.

-

Compliance and Safety Documentation

This metric monitors how often suppliers attach required compliance and safety documentation—such as certificates of analysis, safety data sheets, or proof of regulatory adherence—to their deliveries. It protects a company’s reputation and confirms supply chain compliance with applicable standards. Because incomplete or missing paperwork delays shipments and triggers legal and compliance risks, a 100% target is common, particularly in regulated industries.

How to Improve Supplier Performance

To improve supplier performance, adopt a structured approach to combining proactive communication and ongoing evaluation in a culture of accountability. By following the steps described below, manufacturers can develop stronger partnerships and effectively address problems.

-

Set Clear Communication Standards

Standardizing communication formats to achieve clear documentation keeps manufacturers and suppliers aligned and facilitates fast issue resolution. Outline expectations, response timelines, and preferred channels—such as supplier portals, shared dashboards, or dedicated messaging platforms—to centralize communications and curb confusion. Consider using request-for-bidding tools so buyers and suppliers can respond in real time, negotiate more effectively, and reach better outcomes in complex sourcing situations. Schedule regular check-ins to promote transparency and collaboration.

-

Solve Problems Collaboratively

Working with suppliers to address performance issues is more successful than assigning blame and making unilateral demands. When a problem arises, clearly explain it and its business impact. Then, work with the supplier to define a successful resolution and invite them to contribute their expertise to the problem-solving process. Outline the specific tasks and timelines needed to achieve the desired outcomes and assign responsibilities accordingly. This kind of collaborative approach demonstrates commitment, builds trust, and creates growth opportunities for both parties.

-

Establish Mutual Goals

Shared goals keep manufacturers and suppliers aligned toward the same outcomes. They also position suppliers as strategic partners, resulting in more collaborative, accountability-driven, and high-performing relationships. Begin by identifying realistic KPIs that reflect shared priorities and each company’s unique role in the supply chain. Clearly communicate these goals and obtain buy-in to keep suppliers motivated and committed. Review these metrics regularly and adjust them as needed to keep performance on track.

-

Leverage Analytics to Gain Insight

Track KPIs to get a clear picture of each supplier’s overall performance. Use scorecards and automated systems to collect and organize this data and review it regularly to identify both high and low performers. Advanced analytics tools offer predictive insights, scenario models, and instant alerts, which support better sourcing decisions and faster responses to performance issues. They also uncover new opportunities and hidden risks, empowering procurement teams to make timely, informed decisions that promote better business outcomes.

-

Provide Regular Feedback

Schedule performance reviews at regular intervals to satisfy specific business needs. For example, a manufacturer might hold quarterly performance reviews with most suppliers to discuss overall delivery and quality trends, but meet monthly with critical component suppliers to address immediate production scheduling issues. Provide feedback based on accurate data, acknowledging progress while highlighting areas for improvement. Encourage suppliers to share their perspectives and respond to this feedback. Troubleshoot ongoing concerns and decide on next steps. Remember to keep criticism constructive to preserve healthy relationships.

-

Document Progress

Detailed records, including reviews, improvement plans, and all related correspondence, hold manufacturers and suppliers accountable for performance management. They measure the effectiveness of improvement efforts, reinforce expectations, and adjust goals in response to changing conditions. Clear documentation also informs future sourcing decisions and aids in compliance audits, contract negotiations, and the handling of disagreements. Use supplier scorecards and digital platforms that standardize the process through templates for tracking KPIs, automating data entry, and storing all documentation in an accessible, organized system.

-

Set Up a Site Visit

Schedule site visits to evaluate supplier operations firsthand by touring facilities, observing production processes, assessing quality control practices, and monitoring compliance with labor and safety regulations. Site visits verify that reported and actual performance align, which builds mutual trust. In-person meetings also create opportunities for open conversations about emerging concerns and potential process improvements, further strengthening the relationship. For strategic and high-risk suppliers, regular site visits play an especially valuable role in maintaining performance and minimizing supply chain disruptions.

-

Give Positive Reinforcement for Positive Performance

Recognizing strong performance motivates suppliers and deepens partnerships. In particular, formal incentive programs with well-defined criteria and rewards encourage continued success by offering bonuses, larger contract volumes, or public recognition. Review these programs over time to make sure they continue to incentivize partners and stay aligned with business needs. Thank-you notes and other simple acknowledgments are also effective in letting vendors know their work is appreciated. Suppliers that feel noticed and valued are more likely to meet or exceed expectations.

-

Address Underperformance Directly

It’s equally important to note when suppliers aren’t meeting expectations. Rapid, thoughtful correspondence signals a commitment to high standards and protects the supply chain from underperformance. Start by analyzing data and soliciting feedback to understand the causes. Work with the supplier to create a performance improvement plan that details the steps required to get back on track. Set deadlines and lay out the consequences if problems persist, such as slashing order volumes or finding other vendors. Offer assistance where possible, but be prepared to take this more decisive action, if needed, to keep the business moving forward.

How Does Technology Assist in Improving Supplier Performance?

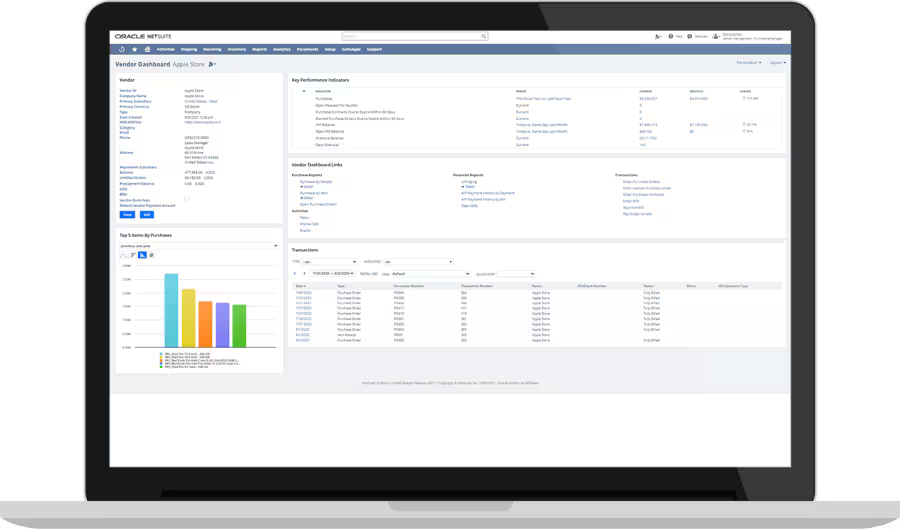

Technology helps improve supplier performance by streamlining the monitoring, analysis, and management of vendor activities. Automated data collection cuts down on manual errors and facilitates accurate, consistent tracking of performance metrics through dashboards and scorecards. Centralizing supplier data in one platform supports better informed procurement decisions and data-driven performance evaluations.

Online portals for sharing progress updates and improvement plans foster transparency between buyers and suppliers, leading to stronger partnerships and faster issue resolution. Real-time monitoring and alerting mitigate regulatory and financial risks. And integration with ERP and procurement systems helps deliver consistent, up-to-date data flows across the company.

Empower Supplier Excellence With NetSuite for Manufacturers

Manufacturers face persistent SPM challenges. Manual processes, data silos, and fragmented communication channels can result in inconsistent quality, production delays, increased costs, and missed opportunities for improvement. To avoid these pitfalls, manufacturers need tools that bring clarity, accountability, and agility to their supplier relationships.

NetSuite’s manufacturing cloud ERP solution addresses these challenges by providing a unified platform for managing every aspect of supplier performance via real-time dashboards, automated workflows, and integrated analytics. Manufacturers can monitor supplier KPIs, streamline collaboration, and track compliance efforts from a single system, with robust reporting that supports better sourcing decisions. By centralizing supplier data and processes, NetSuite empowers manufacturers to build stronger, more resilient supply chains.

NetSuite Streamlines Supplier Performance Management

SPM requires clear communication, measurable goals, and consistent follow-through. Strong relationships are built on collaboration, data-driven decision-making, and regular feedback. Technology plays a key role by improving visibility, enabling faster responses to difficulties, and supporting data-driven performance evaluations. Businesses that take an objective, proactive approach are more likely to see suppliers meet expectations and contribute to long-term success.

Improving Supplier Performance FAQs

How do you manage an underperforming supplier?

Manage an underperforming supplier by identifying the root causes of the issue, developing a clear improvement plan with timelines and responsibilities, and maintaining open communication throughout the process. If progress stalls, document each step, communicate potential consequences, and prepare to cut back orders or seek alternative suppliers, if necessary.

What are two ways to evaluate supplier performance?

Two ways to evaluate supplier performance are using scorecards to track KPIs and conducting regular performance reviews. These methods provide objective insights that drive continuous improvement for both buyers and suppliers.

How do you build and maintain strong supplier relationships?

Build and maintain strong supplier relationships by setting clear communication standards, collaborating on problem-solving, and aligning on mutual goals. Regular feedback, site visits, and recognition for positive performance reinforce trust and sustain long-term partnerships.

What are five key considerations for developing supplier performance management?

Five key considerations for developing supplier performance management are establishing clear performance expectations, consistently monitoring agreed-upon metrics, providing timely and constructive feedback, documenting all progress and communication, and using technology to enhance visibility and streamline processes.