Customers today have more shopping options than ever, so to stand out from the crowd, businesses must deliver exceptional service. They must manage complex product catalogs, juggle multichannel sales, and meet growing customer demand for perfectly handled orders. This article explores what order accuracy means for modern businesses and how to measure it effectively alongside other key performance metrics. By strengthening their order accuracy through the strategies and best practices outlined below, companies can establish customer loyalty, cut costs, and increase their operational efficiencies.

What Is Order Accuracy?

Order accuracy is a key performance indicator (KPI) that measures how reliably a business delivers the correct products to its customers. More specifically, it tracks whether orders are fulfilled exactly as requested, which can include correct product specifications, packaging requirements, and delivery location and timing. Even a single error in any of these areas means an order is inaccurate. To demonstrate accuracy, orders should always be accompanied by documentation showing confirmation of successful and timely deliveries; this increases transparency for customers and provides companies with valuable data regarding the accuracy of their order fulfillment processes.

High order accuracy shows that businesses are consistently giving customers exactly what they paid for, in a timely manner. This results in positive experiences and increased trust, sales, and retention. In addition to demonstrating exceptional customer service, accurate orders can boost the bottom line by reducing costly returns, minimizing waste, maintaining efficient inventory levels, and strengthening the company’s competitive advantage, which ultimately drives long-term growth.

Key Takeaways

- Order accuracy impacts operational efficiency, profitability, and customer satisfaction.

- High order accuracy reduces errors and costly returns, while building customer loyalty.

- Fully understanding and improving order accuracy requires tracking multiple metrics, such as overall accuracy rates, returns, picking accuracy, and cycle times.

- To maintain high order accuracy, many companies deploy digital tools that make use of automation to reduce errors and streamline processes.

- Those who use these tools benefit from comprehensive training and access to clear protocols that ensure consistent execution across all teams and locations.

Order Accuracy Rate Explained

Order accuracy rate quantifies successful order fulfillment as a percentage of total orders processed. Though many companies aim for perfection, mistakes still happen. Even high-performing businesses can have order accuracy rates that fall between 96% and 98%—meaning that a well-run fulfillment center will likely miss the mark 2% to 4% of the time. But even seemingly low error rates can significantly impact customer satisfaction, operational costs, and profit margins, so companies work hard to keep the rates as low as possible.

Order accuracy rate is a holistic metric that evaluates the overall ordering and fulfillment process. It’s often analyzed alongside more granular metrics, such as the order-picking accuracy rate, which focuses only on the items that are packaged and sent to customers. By monitoring these metrics over time, companies can track the impact of any strategic process changes, identify training needs, calculate returns on technology investments, and make data-driven inventory control decisions. Business leaders can use this systematic approach to measure and enhance their operations, which, in turn, informs how they serve their customers.

How to Calculate Order Accuracy Rate

To find the order accuracy rate, first divide the number of perfect orders by the total number of orders, then multiply by 100 to convert to a percentage. A perfect order must meet all requirements, including correct items, quantities, documentation, and delivery specifications.

Order accuracy rate = (Number of perfect orders / Total orders) x 100

Alternatively, if a business wants to track its incorrect orders, it can use either of these formulas:

Order accuracy rate = ([Total orders – Number of incorrect orders] / Total orders) x 100

Order accuracy rate = (1 – [Number of incorrect orders / Total orders]) x 100

Before calculating order accuracy rate, businesses should first clearly define what constitutes an error and track all order elements consistently. This uniform approach allows analysts to show apples-to-apples comparisons across departments, locations, and product lines. Commonly identified errors include incorrect quantities or items, damaged products, incomplete documentation, and missed delivery windows.

For example, say a retailer processes 1,000 orders this month, with these results:

- 965 perfect orders

- 10 orders with missing items

- 6 orders with additional items

- 12 orders shipped to the wrong location

- 7 orders delivered late

This month’s order accuracy rate would be 96.5%, calculated thusly:

Order accuracy rate = (965 / 1,000) x 100 = 96.5%

Why Is Order Accuracy Important?

Improving order accuracy directly impacts a business’s bottom line in two primary ways: It optimizes internal operations, and it elevates the customer experience—both of which increase sales and revenue. Let’s dive deeper into these two categories through five of the major benefits they provide.

-

Reduced return rates increase cost efficiency:

Fewer order mistakes naturally lead to fewer returns, saving businesses both direct and indirect costs. Beyond the immediate expenses of return shipping and disposing of or restocking goods, inaccurate orders create hidden costs through additional operational overhead and staff burden due to the need to interact with customers, reprocess returns, and manage replacement orders. According to the National Retail Federation’s 2023 Consumer Returns in the Retail Industry report, returns amounted to $743 billion in merchandise, which translates to 14.5% of total sales. By emphasizing high order accuracy, companies can avoid these unnecessary expenses and redirect those resources toward growth initiatives.

-

Precise inventory levels prevent overstocks and stockouts:

Accurate orders allow inventory teams to develop reliable counts by ensuring that the right products leave the warehouse in the correct quantities, creating real-time visibility into what’s been sent to customers and what remains to be sold. When orders are consistently accurate, internal data is more likely to reflect actual stock levels, especially when sales software is integrated with inventory management systems. This precision reduces carrying costs and results in more effective inventory planning, helping businesses avoid frustrating and costly overstocks and stockouts.

-

Accurate orders improve customer satisfaction and encourage customer loyalty:

When customers consistently receive exactly what they ordered on time, they’re more likely to return for future purchases and recommend the company to others. Conversely, inaccurate orders can damage customer relationships and prompt disparaging reviews and negative word of mouth that deter new customers. High order accuracy contributes to a business’s positive reputation, which often leads to increased customer order size and lifetime value, competitive advantages, and growth.

-

Fewer order errors reduce operational waste:

Every incorrect order has the potential to add significant delays to the fulfillment process. Beyond the steps involved in the return itself, staff must spend time responding to customers, investigating errors, managing replacement orders, and updating inventory records. These activities waste labor hours and can cause increased shipping costs, inventory discrepancies, and documentation errors. By maintaining high order accuracy, businesses can free up their workforce for more productive tasks and minimize unnecessary operational costs.

-

Improved order accuracy informs forecasting and planning:

Reliable and timely order data helps companies make informed and forward-thinking decisions about inventory management, staffing levels, marketing strategies, and quality control processes. When order fulfillment consistently matches what was ordered, forecasters can better predict seasonal trends and other factors that influence demand. This kind of data-driven approach empowers decision-makers to proactively plan resource and inventory allocations and meet expected demand more effectively.

Order Accuracy Obstacles and Challenges

Although businesses strive for high order accuracy, they face many obstacles that can impact performance. Understanding these common roadblocks helps companies develop targeted solutions for overcoming them and maintaining a competitive edge. Here are the chief challenges that can affect order accuracy rates.

-

Human errors in manual order processing:

Manually entering data and processing orders inevitably leads to mistakes, especially on complex orders or during peak seasons. Even experienced staff can misread product codes or set incorrect quantities, and these errors can compound throughout the order fulfillment process, affecting inventory counts, shipping documentation, and customer satisfaction. Implementing order processing systems that have automated features, such as barcode scanning, can significantly reduce these human errors and speed up the order fulfillment process.

-

Complicated product catalogs:

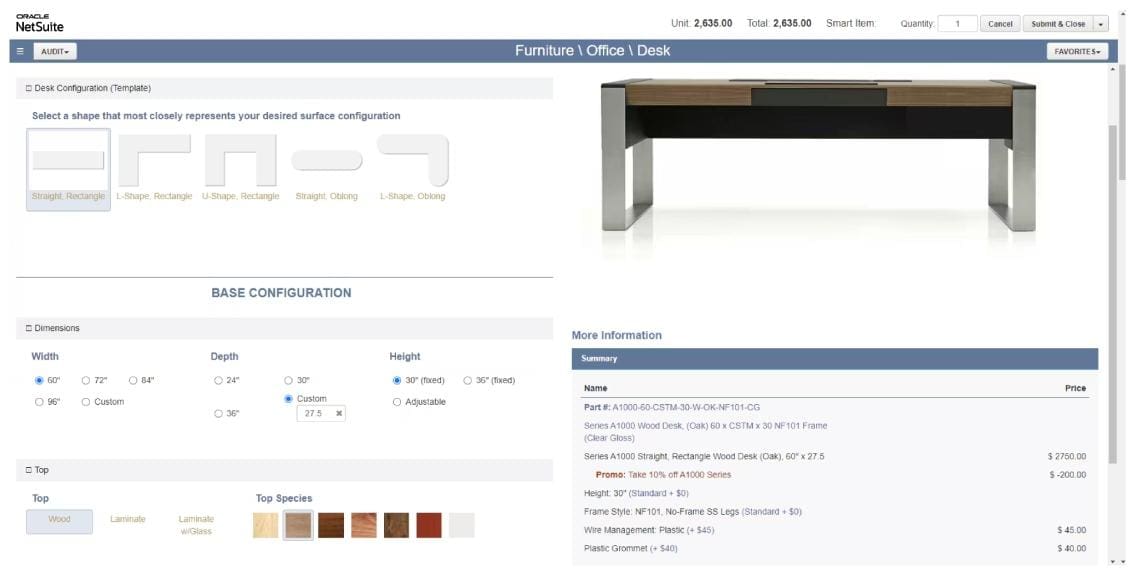

Companies with large or complex product catalogs filled with similar items, multiple variations, or frequently changing specifications face increased risk of picking and processing errors. When goods have similar names, codes, or appearances, staff may select incorrect items, especially for new product lines or during rushed periods. Businesses should develop clear product categorization systems that leverage digital catalog management tools, such as configure, price, quote (CPQ) features with detailed product images and specifications, to aid staff as they navigate complex inventories.

-

Poor communication:

Communication breakdowns among sales, warehouse, shipping, and customer service teams often are at the root of order mistakes. Without clear protocols and efficient information sharing, important order details may be lost in translation or misinterpreted, leading to incorrect deliveries or missed components. By centralizing order information in a shared digital platform or dashboard, businesses can give all teams access to the same, up-to-date order details and specifications.

-

Software limitations:

Outdated, limited, or poorly integrated software systems often create data silos and processing bottlenecks. When systems don’t communicate effectively, manual workarounds become necessary, creating workflow inconsistencies that make it difficult to track order accuracy. Modern, integrated software solutions connect all aspects of order fulfillment to eliminate these bottlenecks and provide real-time visibility into order status and accuracy.

How to Measure Order Accuracy

When assessing order accuracy, businesses should go beyond the standard order accuracy rate formula and regularly monitor multiple KPIs to develop a comprehensive view of the ordering process. While the overall order accuracy rate is important, supporting metrics can highlight specific areas for improvement and measure the impact of any process changes. Here are seven essential measurements that contribute to order accuracy.

Return Rate

Return rate measures the percentage of orders that customers send back, calculated with this formula:

Return rate = (Returned orders / Total orders) x 100

A high return rate may indicate underlying accuracy issues in the order fulfillment process, while a low rate suggests effective quality control measures. However, different industries have varied views on high and low rates, as some businesses make preference-based returns a core part of the customer experience. For example, a clothing retailer might encourage online customers to try multiple sizes before making a selection and then return the rest, creating a higher—but healthy—return rate. Because of this, some companies may not include preference-based returns in their return rate calculations.

Order Picking Accuracy

This metric tracks how accurately warehouse staff select inventory using this calculation:

Order picking accuracy = (Accurately picked orders / Total orders) x 100

This KPI helps identify errors that occur during the picking process, rather than during the initial order or final delivery phase. These errors often arise from unclear product locations, similar-looking items, or inadequate training. If order picking accuracy is decreasing, businesses might consider improving their warehouse processes and giving staff additional training.

Average Shipping Time

Even if a business ships the right items, a late delivery may still count against order accuracy. Average shipping time can be calculated with a modified version of the way a basic average is derived:

Average shipping time = Sum of all orders’ shipping times / Total orders

If a company is overpromising on delivery times, staff may have to rush processing or pay expedited shipping to meet deadlines, resulting in mistakes and higher costs. By tracking shipping speeds and making adjustments over time, sales teams can set realistic expectations that balance speed with accuracy. To reduce shipping time, many businesses rely on transportation management software or partner with third-party logistics providers to optimize their shipping processes and increase delivery speeds.

Order Error Rate

The order error rate tracks the percentage of orders that contain a particular error. Unlike the overall order accuracy rate, the order error rate is calculated for one specific error type at a time, such as incorrect quantity or shipping label mistake, using this formula:

Order error rate = (Orders with chosen error type / Total orders) x 100

Analysts use this KPI to identify quality-control patterns found in different parts of the order fulfillment process. This allows managers to prioritize targeted improvements in the areas that are likely to produce the best returns.

Order Fill Rate

Order fill rate measures the percentage of orders that are shipped complete and on time, calculated as:

Order fill rate = (Number of complete orders / Total orders) x 100

Though similar to order accuracy, fill rate zeroes in on whether all requested items were available and shipped when promised, rather than being delayed or put on backorder. Low fill rates often indicate bottlenecks caused by inventory issues or unreliable suppliers. To strengthen fill rates, businesses can implement supplier management and warehouse solutions to govern appropriate stock levels and develop stronger supplier relationships.

Order Fulfillment Cycle Time

This metric tracks the time between order placement and final delivery with this formula:

Average order fulfillment cycle time = Total time between order placement and delivery of all orders / Total orders

This metric spotlights delays or choke points that might force rushed processing and create errors. Cycle times are best viewed in context over time, as some goods take longer to produce, such as complex or heavily customized products, and therefore have longer order fulfillment times. At the same time, short cycle times may signify quick order processing, but if speed is sacrificing accuracy, businesses should adjust or slow down their fulfillment methods to make sure customers are getting consistently accurate and high-quality orders. If cycle times are increasing, it may indicate inefficient processes or resource constraints, whereas consistent or decreasing cycle times usually suggest well-organized fulfillment operations.

Inventory Turnover Rate

Though it doesn’t directly measure accuracy, inventory turnover rate reveals how effectively companies fulfill orders relative to total inventory counts. It shows how quickly inventory moves through the warehouse, calculated like this:

Inventory turnover rate = (Cost of goods sold / Average inventory value) x 100

High turnover rates can pressure staff to rush order processing, while low rates may indicate stagnant or dead stock that’s less likely to sell. A business should carefully consider all factors, such as shelf life, seasonality, expected demand, and carrying costs, when determining optimal turnover rate.

Best Practices to Improve Order Accuracy

To achieve high order accuracy, businesses should implement proven strategies that address common fulfillment challenges in their industries and pivot as market conditions evolve. Let’s examine eight essential ways companies can reduce errors and improve their order fulfillment processes.

- Automate manual processes to help reduce human errors: By replacing manual data entry with automated systems, including checkpoints where order accuracy is verified through quality control checks, such as barcode scans or weight validation, businesses can reduce costs and errors while speeding up order processing time. Many of these systems also include tracking features that automatically notify both internal staff and customers about order status and delivery updates.

- Optimize inventory management procedures: Organization systems with clearly designated storage locations and regular cycle counts give businesses a realistic view of what items are in stock, where they’re located, and when they can be delivered. To secure this level of transparency, many companies deploy digital tools, such as inventory management software and warehouse robots, to preserve accurate stock levels and automatically flag discrepancies.

- Invest in employee training and cross-training: Comprehensive training on proper procedures and equipment usage can help employees support reliable deliveries for customers and keep orders moving on schedule. Managers and trainers should regularly update training content as processes evolve and the business adopts new practices and technology. Additionally, cross-training employees helps secure smooth transitions during staff changes or busy periods and can uncover untapped potential among staff.

- Strengthen communication among teams: Standardized communication protocols and centralized platforms allow teams to share order information without adding unwanted burdens, such as interrupting workflows in progress or contributing to redundant manual data entry. When establishing lines of communication, ensure that all authorized teams have access to the same, real-time order data to prevent misunderstandings and delays.

- Review order fulfillment process for bottlenecks: Regularly analyzing each step of the fulfillment process allows analysts to pinpoint slowdowns and error-prone areas, and make actionable suggestions about how to ease these bottlenecks. Then, managers can use these analyses to implement targeted improvements where they’ll have the most impact, such as on warehouse reorganization or automated order prioritization.

- Mine customer feedback for improvement opportunities: When customers return goods or report issues, businesses should collect and organize that data to identify patterns relevant to order accuracy issues. This feedback, combined with surveys, reviews, and social media comments/posts, can inform new best practices that will directly address customer pain points.

- Solicit internal and vendor feedback for operational improvements: When planning process changes, managers should gather input from frontline workers, including warehouse staff, customer service teams, and suppliers. These perspectives often reveal practical solutions that may be missed by data alone. Additionally, this collaboration makes employees feel heard and appreciated in their workplace, which increases morale.

- Identify technology opportunities and plug any software gaps: Even systems that seem to be running well may have unseen integration issues or missing capabilities that can impact order accuracy. Robust software solutions, such as dedicated customer relationship management (CRM), CPQ, or enterprise resource planning (ERP) systems, can break down data silos and connect all aspects of order fulfillment, providing real-time visibility into the process.

Optimizing Order Accuracy Rate With CPQ Software

Complex product configurations and pricing structures often lead to costly order errors that impact the customer experience. NetSuite CPQ software enables businesses to maintain high order accuracy through automated tools and seamless integration with existing CRM and ERP systems, which upholds order accuracy from the start. From the first customer contact, NetSuite CPQ’s guided selling and dynamic automated pricing features help sales teams offer customers the right products and configurations, as well as automatically generating consistent and accurate quotes.

NetSuite CPQ integrates inventory and profitability data to automatically generate sales orders and bills of materials with exact specifications, eliminating manual data entry errors that can result in fulfillment mistakes. This provides pertinent staff with real-time inventory visibility that minimizes the possibility of issuing quotes for unavailable items or backordered goods, especially important for multichannel and ecommerce customers. With NetSuite’s scalable solution, sales teams sustain high order accuracy rates as the business grows.

Maintaining high order accuracy is a critical way for businesses to build a loyal base of repeat customers, reduce costs, and drive sustainable growth. With the right combination of technology, training, and well-planned processes, companies can significantly cut down on order errors while creating a more reliable and efficient fulfillment process. But success requires adopting a systematic approach that identifies specific challenges, implements targeted solutions, monitors impact, and adjusts strategies over time. As operations grow and market conditions evolve, this ongoing commitment to improving order accuracy empowers fulfillment teams to adapt to new trends and stay competitive, while continually offering high-quality goods and services to their customers.

Order Accuracy FAQs

What is a good order accuracy rate?

Most high-performing companies achieve consistent order accuracy rates of 96% to 98%. While 100% accuracy would be the ideal, achieving absolute perfection is rare due to the complexity of order fulfillment processes, human error, and external events outside of a business’s control, such as weather events or supply shortages. Thus, there’s no uniformly accepted “good” rate, as competitive order accuracy rates may vary with business type and industry.

Is order accuracy the same as order picking accuracy?

No, order accuracy and order picking accuracy measure different aspects of the fulfillment process. Order picking accuracy tracks how correctly items are selected from inventory and packaged for shipment to customers. Order accuracy is a broader metric that encompasses the entire fulfillment process beyond picking, including packing, shipping, delivery timing, and documentation accuracy. High order picking accuracy contributes to, but doesn’t guarantee, high overall order accuracy.

When is an order generated in CPQ?

In configure, price, quote (CPQ) software, an order is generated after a business approves a quoted price and the customer agrees to it, triggering the system to automatically create a sales order with the quote’s exact specifications, quantities, and pricing. This process supports order accuracy by eliminating manual data entry and automatically matching the quote to what ultimately is ordered.