Increasingly complex supply networks and shifting demand patterns are putting new pressures on inventory operations. Speed and accuracy matter more than ever, but basic management tools struggle to keep up. Businesses need the continuous visibility and tight controls that only advanced inventory management can provide. This article explains the concept and the core technologies involved.

What Is Advanced Inventory Management?

Advanced inventory management is the use of data-driven strategies and leading-edge systems to optimize stock tracking and replenishment. By aligning inventory levels with demand plans, it helps minimize carrying costs and improve availability. Advanced inventory management replaces spreadsheet-centric work with integrated, real-time platforms that inform and coordinate decisions.

Key Takeaways

- Advanced inventory management analyzes information and automates workflows to help businesses avoid stockouts and overstocks.

- Accurate forecasting, up-to-date tracking, and automatic reorder points optimize stock levels to meet demand.

- A centralized system unifies data across locations and suppliers, reducing variability and improving supply chain efficiency.

Advanced Inventory Management Explained

Guesswork around inventory often results in lost sales from stockouts and excess holding costs from overstocking. Combined, these scenarios cost global retailers $1.7 trillion in 2024. Advanced inventory management generates and acts upon precise, updated data by ingesting live signals, applying predictive models, and initiating workflows that keep products flowing. Barcode scanning and RFID capture technologies record transactions the moment work happens, and dashboards give teams a unified view of all inventory activity. This contributes to greater inventory accuracy, which is a significant challenge for many businesses. Consider this: According to CAPS Research, only 69% of companies even track inventory accuracy, and among those that do, the average rate is just 83%.

As its name implies, advanced inventory management is powered by advanced technologies. Automation handles repetitive tasks, such as reordering and allocation, while analytics refines forecasts by factoring in seasonality, promotions, and economic conditions so that managers can adjust plans before problems arise. Emerging technologies enhance these capabilities even further. AI and machine learning (ML), for example, analyze market conditions, customer behavior, weather, and social media sentiment to create more precise forecasts. Internet of Things (IoT) sensors embedded in warehouses and retail locations immediately update data about product locations and conditions, reducing spoilage. Autonomous mobile robots and drones accelerate inventory scanning, count verification, pallet moving, and other warehouse tasks. And cloud-native platforms and Inventory as a Service models expand access to live insights and ease the burden of routine replenishment.

Adoption requires careful planning, however. Budgets must weigh up-front licensing and configuration costs against long-term returns on investment. Integration with ERP and other systems demands thoughtful vendor selection, and teams need training and change management to overcome resistance. A rollout plan that minimizes disruptions and encourages user adoption raises the likelihood of success.

Advantages of Advanced Inventory Management

Stockouts, excess storage, and inaccurate counts have real financial and operational consequences. Advanced inventory management cuts down on these missteps by adding real-time data and predictive tools to everyday workflows—and then automating them. This creates smoother processes and measurable gains, as the following advantages demonstrate:

- Fewer errors: Automated capture replaces manual keying that often introduces mistakes. System-recorded and -validated transactions produce cleaner ledgers for faster issue resolution.

- Optimal stock levels: Live visibility into all locations keeps inventory aligned with demand patterns. Rule-based reordering and smart allocation prevent stockouts without tying up cash in surpluses.

- Lower costs: Reducing excess stock and wasted storage space leads to lower carrying costs. Automation replaces repetitive manual tasks, resulting in better resource use.

- Improved forecasting: Demand-planning models that factor in seasonality and market conditions generate more reliable predictions. Managers use that data to make more strategic purchasing and production decisions.

- Smarter decision-making: Accurate, current information supports more timely choices about sourcing and transfers. Dashboards identify the key metrics and actions that affect performance.

- Enhanced efficiency: Directed picking and put away, automated reordering, and barcode scanning cut back on manual touchpoints. Integration with core business platforms eliminates the need to enter data into multiple systems.

- Greater customer satisfaction: Products arrive when promised, building trust and repeat demand. Consistent availability protects revenue during promotions and seasonal peaks.

- Less risk: Greater visibility, advanced analytics, and alerts identify potential problems, such as supplier delays and demand spikes, early on. Managers can act sooner, wrangling service disruptions before they escalate.

Core Features of Advanced Inventory Management

Successful inventory management involves multiple functions working together to keep business moving forward. Demand planning matches stock levels with anticipated needs, tracking makes sure inventory is readily visible, and replenishment logic maintains flow without constant manual intervention. The following features of advanced inventory management facilitate smoother operations and more responsive supply chains.

Demand Planning and Forecasting

Strong demand forecasting forms a solid foundation for inventory decisions. Advanced inventory management distinguishes between demand planning, which predicts future needs, and daily stock control, which reacts to short-term swings. Historical sales provide a baseline, but models also account for promotions, holidays, and external conditions. ML continuously refines these forecasts, plus input from sales and operations teams adds context that raw data can’t capture, further honing the model’s outputs. For example, sales can flag an upcoming promotion, or operations can note planned factory downtime.

These insights strengthen forecasts before planners translate them into time-phased requirements that guide ordering and capacity. As a result, safety stock targets more closely reflect actual variability in demand and lead times. With this approach, companies can adjust faster during peaks and avoid slow-moving buildup of excess stock that ties up working capital during lulls.

Real-Time Inventory Tracking

Basic inventory management relies on annual physical inventory and occasional cycle counts to verify stock levels. But long gaps in between, where changes can go unnoticed, makes it difficult to respond quickly when discrepancies arise or stock levels dip too low. Advanced inventory management automatically captures transactions as they happen. Data from barcode scans, RFID tags, and IoT sensors flows into centralized dashboards, giving managers an up-to-date view of inventory at all locations. With this level of visibility, teams can reallocate stock to high-demand areas and identify slow-moving products before they tie up resources. Batch and serial tracking add another layer of control; by linking individual items to production lots or warranty records, they simplify the process of isolating products in the event of a recall.

Inventory Optimization

Advanced inventory management uses algorithms to calculate amounts of safety stock for each item and location, based on demand variability and lead times. Instead of applying a single rule for all products, the system tailors its calculations so high-volume and high-risk items receive the most coverage. Recommendations are updated as supplier performance and demand change, which, in turn, adjusts reorder points and safety stock levels.

Optimization also enhances inventory allocation. Stock is placed where it delivers the most value, avoiding duplication and supporting regional demand. Items with similar demand patterns or supply characteristics can be grouped under shared policies, making the system easier to maintain without sacrificing precision. Once these calculations are in place, workflow automation links them to replenishment.

Automated Replenishment

Manual reordering is time-consuming and introduces lag, which can result in costly line stoppages. Automated replenishment uses predefined reorder points, minimum-maximum bands, and service targets to decide when and how much to order. When stock falls below a threshold, the system generates a purchase order or transfer request. It also factors in lead times and order multiples, adjusting quantities so deliveries arrive on time and in the pack sizes or pallet loads required by suppliers. Exception alerts highlight items that deviate from plans, such as late inbound shipments. And through integrations with supplier systems, orders and confirmations are transmitted electronically without requiring clerical work. As a result, teams spend fewer resources on routine tasks and more on addressing true constraints.

Multilocation Management

A unified platform aggregates inventory across plants, distribution centers, and stores so all teams view locations and movements in the same way. Transfers become faster because available-to-move quantities—stock that is free of holds, reservations, or pending allocations—are based on actual data, rather than estimates. When demand spikes in one region, the system can redirect inventory from nearby facilities that have surplus, precluding unnecessary new purchases.

Real-time validation also expands options—such as cross-docking, where inbound shipments are redirected straight to outbound trucks, and dropshipping, where suppliers ship directly to customers—because the system can confirm supply availability before committing. Centralized reporting highlights slow-moving stock at individual sites, giving leaders time to rebalance before cash is tied up in excess. Consistent data definitions help keep disputes at bay, such as when a store counts incoming goods as “available” but headquarters still lists them as “in transit.”

Mobile Accessibility

Mobile apps let teams receive, pick, move, and count items directly from the warehouse floor, eliminating the lag between the time of writing things down and the follow-up that occurs later. Additionally, capturing data at the source speeds up transactions and cuts down on errors. Mobile scanning features help improve accuracy and make the system easier for new staff to learn, accelerating time-to-productivity. An intuitive interface lowers the learning curve and supports quicker adoption during rollout. Push alerts flag high-priority tasks, so supervisors spend less time tracking down updates. Offline modes keep work moving in low-connectivity zones, recording data locally and syncing it when network access returns. Finally, managers can review key performance indicators and exceptions from any location, preventing delays arising during travel or shift changes.

Supplier Relationship Management

Supplier relationship management (SRM) software processes purchase orders, shipment notices, and invoices electronically to avoid delays and errors. It aligns contracts with inventory policies and matches economic order quantities and service targets to reality. This tight collaboration eliminates variability, which allows businesses to decrease safety stock levels and capture cost savings.

Supplier Performance Management

Supplier performance management—which is related to, but distinct from, SRM—uses scorecards, audit reports, and spend analysis tools to measure results against mutually agreed-upon targets. These metrics allow managers to benchmark performance across the supply base and identify recurring issues with individual partners. This data may lead to discussions about creating improvement plans for certain suppliers or considering alternate sourcing to avoid customer impacts.

Examples of Advanced Inventory Management

An example of advanced inventory management is the use of predictive demand planning in retail. Say a national chain is preparing for the holiday season. It analyzes historical sales data and regional buying patterns to forecast which items will see the greatest demand spikes—and where they will see it. The system then allocates stock accordingly, keeping high-demand products on the right shelves while decreasing excess inventory and carrying costs.

In manufacturing, automated replenishment plays a central role. A producer of electronics relies on minimum–maximum thresholds and supplier integrations to keep critical components available. When stock of a specific part falls below a set level, the system creates and sends an electronic purchase order straight to the supplier. Because of direct integration with supplier lead-time data, orders arrive synced with production schedules, thereby protecting throughput and averting costly line stoppages.

Healthcare presents another compelling case. Hospitals and pharmacies use batch and serial tracking to connect individual units of medication or equipment back to their sources. When a recall occurs, advanced systems isolate exactly which products are impacted and pinpoint their locations. Staff can remove only the affected items, instead of pulling an entire category. This helps protect patient safety and minimize waste.

Technologies That Enable Advanced Inventory Management

Today’s advanced inventory management practices depend on technology as much as process. Software platforms, predictive analytics, and sensors all contribute different pieces of the puzzle. When connected, the following technologies transform raw data into accurate insights:

- Inventory management software: Inventory management platforms instantly record quantities and movements and automate reordering. AI- and ML-powered analytics support better forecasting and reporting.

- ERP software: ERP software connects inventory with finance, procurement, sales, and manufacturing. This centralized data repository minimizes duplication and keeps operational and financial views in sync.

- Artificial intelligence: AI refines forecasts, recommends reorder settings, and spots discrepancies that need attention. Predictive insights support faster responses to emerging problems.

- Smart sensors: RFID tags, barcode scanners, and IoT devices capture transactions and conditions without manual entry. Live visibility improves traceability, compliance, and performance monitoring.

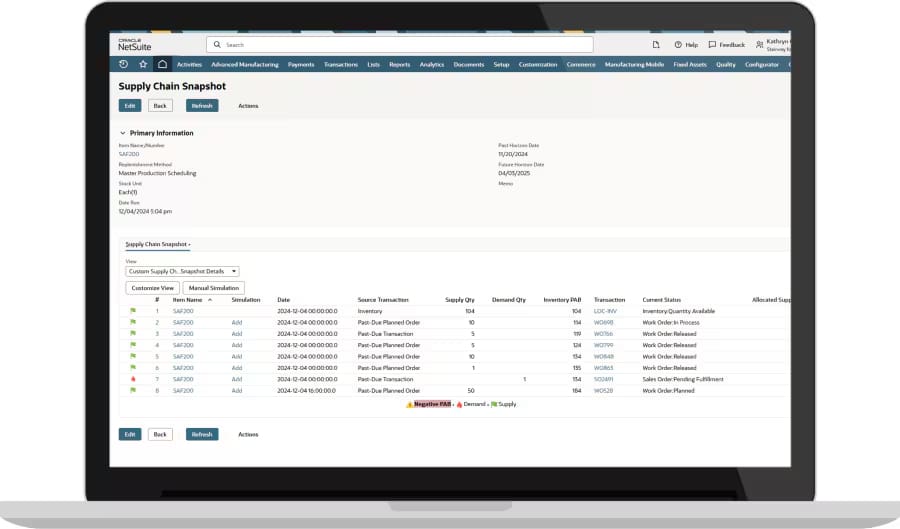

Modern Inventory Management Solutions With NetSuite

Incomplete visibility and the risks of stockouts and overstocking are constant challenges for inventory managers. They need real-time information and more efficient handling to meet rising customer expectations and overcome supply chain complexity. But isolated systems limit their ability to anticipate changes and optimize resource allocation across multiple locations. NetSuite Inventory Management addresses these challenges by centralizing all inventory activity in a single platform. Businesses gain continuous insights into stock levels in all warehouses, stores, third-party locations, and sales channels. Automated replenishment and cycle counting minimize errors and manual work, while analytics help match inventory with evolving demand. And its built-in multilocation management and mobile features mean teams spend less time dealing with shortages and more time improving fulfillment performance.

Complete Supply Chain Visibility With NetSuite

Advanced inventory management replaces guesswork and tedious manual tasks with unified data and automated workflows. In doing so, it enhances forecasting, improves supplier relationships, and cuts down on costs and waste. As AI, ERP software, and smart sensors mature, inventory managers will rely even more on predictive analytics and efficient execution. Businesses that invest in these technologies with a clear business case and strong adoption plans will be able to turn inventory management into a competitive advantage.

Advanced Inventory Management FAQs

What is AI-based inventory management?

AI-based inventory management is the use of AI and machine learning for demand forecasting, reordering, and anomaly detection. It improves planning accuracy, increases flexibility, and, in some programs, informs pricing decisions.

Why is advanced inventory management important?

Advanced inventory management is important because it reduces waste and protects against market volatility. By bringing better data to light and facilitating faster execution, it allows businesses to run with fewer surprises and a healthier cash flow.