In the movie “Planes, Trains and Automobiles,” the main characters needed all three types of transportation and endured seemingly endless hours of frustration to get home for Thanksgiving. Imagine their families trying to figure out where they were at any given moment. Businesses might experience a similar level of frustration if they didn’t have a transportation management system (TMS) to provide a complete and transparent view of their goods along the supply chain, whether they’re shipping raw materials to a production plant or finished goods to a customer. A TMS is also instrumental for efficient carrier selection, route planning and automated billing, which together can reduce costs and increase customer satisfaction.

What Is a Transportation Management System (TMS)?

A transportation management system (TMS) helps businesses plan, monitor and execute the physical movement of goods from one location to another, whether by land, air or sea. Typically part of a broader supply chain management system, TMS software centralizes all transportation-related processes so managers can select the best mode — or modes — of delivery, track where their goods are en route to their destinations, reroute shipments and analyze performance via key performance indicators (KPIs), steps that can lead to procedural improvements. TMS software can also automate and unify traditionally paperwork-heavy tasks, such as trade compliance documentation and billing.

Key Takeaways

- A transportation management system plays a critical role in managing the physical movement of goods along a supply chain and ensuring their timely delivery.

- A TMS helps businesses optimize routes, choose carriers and monitor performance using key performance indicators.

- There are three types of TMSs: single mode, multimodal and intermodal.

Transportation Management Systems Explained

A TMS is a logistics platform that concentrates on the movement of freight once it leaves a location, such as a store or warehouse. In fact, it often works in conjunction with related systems used for procurement, order management, warehouse management (WMS) and enterprise resource planning (ERP). Depending on their needs, some companies focus on only one carrier or type of transportation — such as truck, train, boat or plane — while others work with a combination of carriers and types.

A TMS manages three primary forms of transportation: single mode, multimodal and intermodal.

- Single mode: Involves one carrier and one type of transportation — typically, trucks. Single mode is often used by small or centralized companies that don’t have a far-reaching customer base.

- Multimodal: Involves multiple means of transportation but provided via a single carrier. Subcarriers may be used, but only one primary carrier is under contract.

- Intermodal: Involves multiple carriers and multiple types of transportation. This method requires the most oversight.

How Does a TMS System Work?

A TMS is, for all practical purposes, a comprehensive database that contains all necessary carrier details, from pricing to travel time to weight limits to vehicle space — everything a business needs to plan, execute and optimize deliveries. The depth of data that is captured will depend on a company’s specific needs and the complexity of its shipments. For example, a grocery distributor may seek to prioritize temperature control, while a manufacturer that orders components from many sources may prioritize support for multiple carriers. These variations will impact software selection.

A TMS is often integrated with an ERP and a WMS. The ERP manages orders as they are placed, WMS software coordinates order fulfillment, and the TMS handles the aspects related to shipping and receiving. The more closely connected these systems are, the more effective the communication will be among the different departments. This leads to a smoother order-fulfillment operation, while trimming costs and order delays.

Why a TMS Is Important

Gartner estimates that the worldwide market for transportation management systems will crack $2.1 billion by the end of 2024, marking a nearly 60% increase over 2019's $1.32 billion valuation. This degree of growth underscores how integral transportation management systems have become in the timely delivery of physical products to different points along the supply chain.

A TMS provides day-to-day and big-picture visibility into a business’s logistics operations and performance — insight that informs planning, pivoting and communicating with customers and carriers. This, in turn, can lead to growth in sales and revenue because satisfied customers are more likely to buy again. By connecting to carrier systems, the TMS can cull detailed information, such as updated shipping costs, that can help the business minimize its expenditures and possibly pass savings on to customers, while also positioning the company to expand more easily into larger markets — including international trade — while minimizing costs.

A TMS also centralizes communications among the different parties involved in the logistics process, which makes for smoother coordination and collaboration. And automated functionality, particularly relating to billing and documentation, makes for more efficient operations that free up administrative staff so they can focus instead on expanding the business’s interests.

Internally, a TMS improves manufacturing by giving warehouses more transparent data for incoming orders, enabling them to better allocate inventory and replenish stock. In addition, a TMS grants distributors more control over when and how goods will be delivered, while analysis of KPI data provided by the TMS can help identify areas ripe for improvement.

Who Uses Transportation Management Systems?

Historically, large manufacturers, distributors, retail operations and third-party logistics providers have been the main users of transportation management systems. But now that less-expensive, cloud-based TMS solutions are available, smaller companies also have begun to rely on them. Indeed, any business that regularly ships or receives goods — such as construction companies and hospitals — can be a candidate for a TMS.

Test Drive NetSuite Today

Key Features of a Transportation Management System

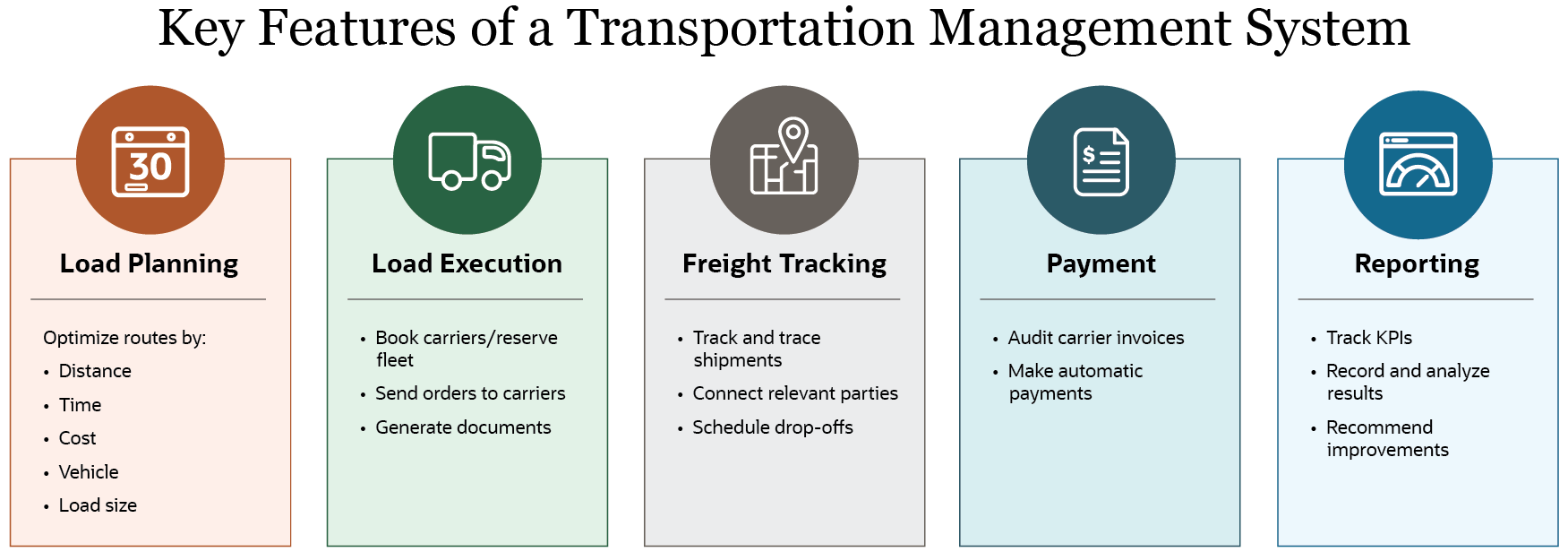

A TMS oversees the complete transportation life cycle of a shipment, also called a load. Key software features include load planning and execution, freight tracking, payment and reporting.

Load Planning

Load planning involves more than just picking a delivery route, which is not to minimize the importance of a TMS’s ability to analyze routes for cost/distance and evaluate multileg carrier routes to save money and time. A TMS can also help optimize space in a vehicle to ensure that the right modes of transportation and carriers are matched with the right shipments. Load planning also factors in trade regulations and tariffs.

Load Execution

Load execution involves — and, with a TMS, automates — freight tendering, which, much like a request for proposal, is the process of soliciting carrier bids for a transportation project. It also includes reserving carriers and notifying an internal fleet when the business’s load plan is set to decrease the time between order placement and fulfillment. Bills are automatically generated, and much of the document-heavy work associated with shipping large loads, including the complex system of international importing and exporting, also gets taken care of, creating a faster and more accurate recording process.

Freight Tracking

The ability to track and trace shipments in real time through various supply chain touchpoints is a critical TMS feature, especially in regard to preserving solid customer relationships and tracking carrier performance. Tracking data can also be used to schedule and manage accurate dock/yard appointments, preventing delivery bottlenecks and reducing the time drivers spend waiting in line to drop off their shipments.

Payment

A TMS can automate the payment process to ensure that a business pays its shipping bills on time, thereby strengthening carrier relationships and avoiding late fees. The system also provides managers with easy access to historical payment data for specific carriers, goods or periods of time, which is helpful for auditing purposes and to inform future decision-making.

Reporting

A TMS can monitor KPIs about carrier and shipping effectiveness — such as average delivery time, the number of damaged orders and freight bill accuracy — to uncover areas that need improvement and to replicate successful outcomes. For example, if loads delivered by truck are consistently arriving past the due dates promised to customers, that could indicate a need to consider a new carrier and/or transportation method.

TMS Functionalities

A TMS manages a company’s transportation functions by streamlining and managing the shipping process so that goods arrive at their destinations in a timely manner and in expected shape. Naturally, different types of businesses have different requirements, so it’s important for businesses to determine what they do and don’t require in a system. For example, a domestic company that sells nonperishable goods may not need a TMS that integrates with high-speed air shipments or expensive, temperature-controlled freight options.

That said, across the board, there are several important functionalities to look for:

Planning and Decision-Making

A TMS gathers, stores and filters shipping data from thousands of carriers so that businesses can carefully evaluate prices, plan routes and select carriers. Some common selection criteria are: lowest cost, quickest shipping time, highest performance and customer choice. Route selection can be evaluated by such factors as how many stops drivers must make or the number of drivers needed to complete a delivery. A TMS can follow specific parameters to rank the efficiency of a given carrier or route and provide recommendations aligned with what is most important to the business.

Transportation Plan Execution

This is the point at which the shipping plan is set in motion. The business can use its TMS to procure carriers, generate required order documents, track the movement of goods going out the door and settle freight bills. Many businesses use their TMS to handle custom pricing rules, such as discounts and tariffs, and ensure compliance with local regulations along the delivery route to prevent complications that could increase costs and delay order fulfillment.

Transportation Follow-Up

Transportation follow-up tracks everything between initial shipping and final delivery. A TMS typically provides automatic updates when certain checkpoints are reached — for example, when a package clears customs — or if there’s a change in estimated transit time. For example, inclement weather or a vehicle malfunction might add a day to delivery time; if that happens, the business can proactively inform its customers, who are likely to appreciate the outreach.

Measurement

As goods move along their shipping routes, the TMS collects performance data that helps managers see what is working well and where improvements can be made throughout the supply chain. Potential fixes might include tweaking how a truck is packed, finding a new carrier or investing in a larger fleet of delivery trucks.

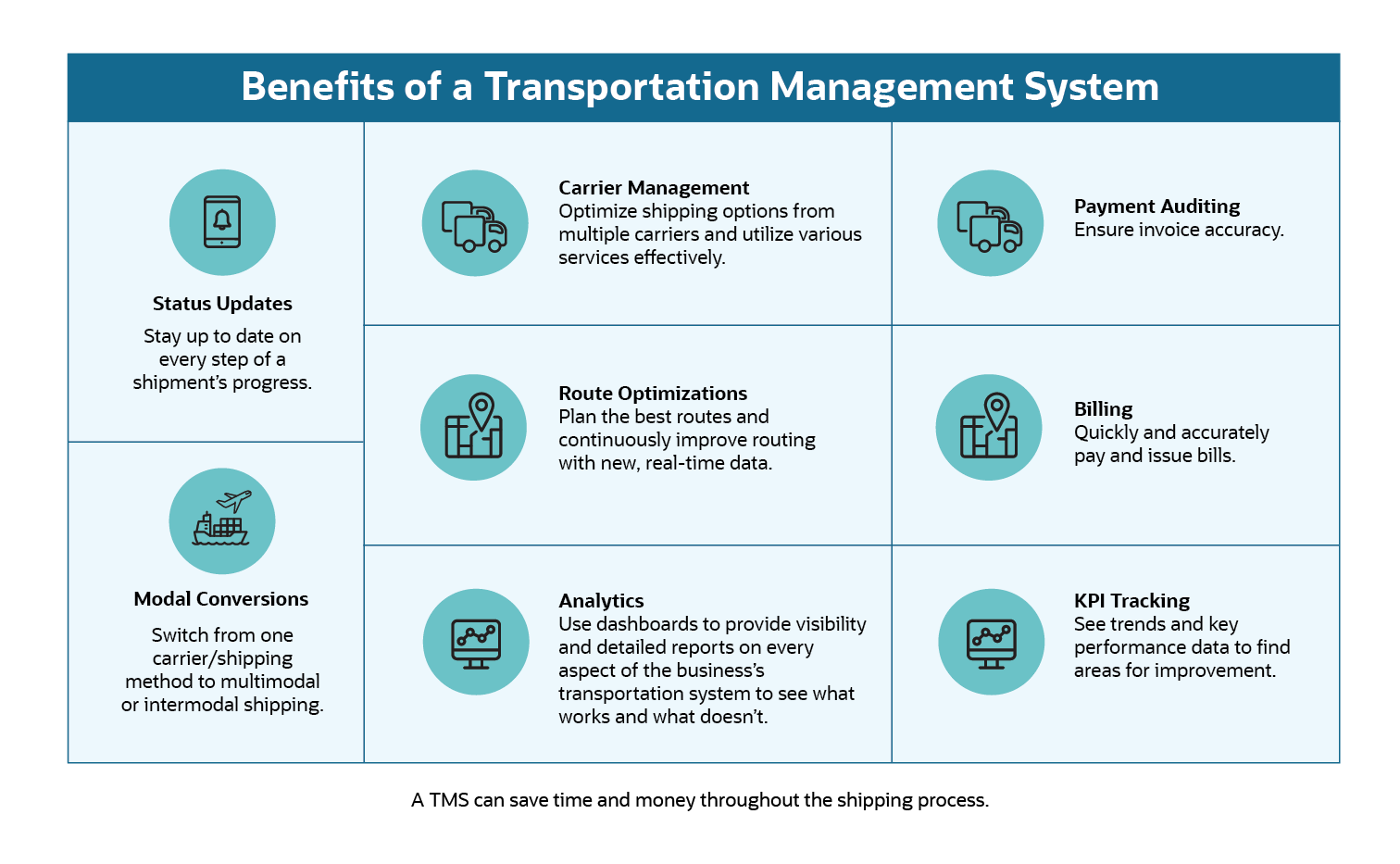

Benefits of a Transportation Management System

TMS pricing varies widely depending on how the solution is deployed, the number of users and a variety of other factors. But for any business that relies heavily on shipping, the solution provides plenty of value in terms of cost savings (in shipping and administration, to name two), process efficiencies, faster deliveries and customer satisfaction. Here are some additional benefits:

Route Optimizations

TMS platforms armed with artificial intelligence and machine learning are able to continuously optimize delivery routes in real time. This helps carriers plan and reroute shipments, if necessary, and stops them from accruing increased costs from unexpected tolls, longer labor hours and higher fuel costs.

Carrier Management

The more carriers and transportation modes a company uses, the more complicated it becomes to manually manage logistics. A scalable TMS provides overall visibility across increasing numbers of carriers, and down to the carrier level as well, as it tracks freight whereabouts and carrier efficiency.

Modal Conversions

It’s not uncommon for a shipment to require several carriers and transportation methods to reach its intended destination. For example, items being sent from overseas may begin their travels on a ship or airplane and then be transferred to a truck and/or train to continue their journey. This can be a very time-consuming task, if not handled by a TMS; turning the planning over to a TMS can be reassuring, especially to companies new to the multimodal or intermodal shipping transportation world.

Status Updates

Some businesses need only a simple confirmation when a package has been picked up or delivered. However, when shipping items such as refrigerated goods, or for time-sensitive deliveries, companies may require more advanced technology — such as Internet of Things (IoT) devices — to gain real-time data such as the package’s current location or temperature of its contents. With a TMS, companies will not only be able to track their shipments, but they’ll also have the ability to keep customers informed, especially in the case of a delay.

Payment Auditing

Overpayments can easily throw off a business’s budget, while underpayments could damage trusted carrier relationships. Many TMS solutions automatically audit invoices and cross-reference them with original purchase orders and delivery receipts. This helps ensure that the billing amount is accurate, which in turn saves time and cuts down on administrative costs.

Billing

Transportation management systems often handle a complex billing process called settlement. For some goods, certain criteria — such as proof of delivery — must be met before a customer’s payment is remitted. TMS software automatically generates freight bills at the appropriate time or notifies relevant parties when invoices should be sent out. A TMS also can be used to track when payments are made and when orders are marked as complete.

KPI Tracking

Common TMS KPIs include percentage of goods picked up and delivered on time per carrier, truck turnaround time and freight bill accuracy. Analysis of these KPIs helps businesses evaluate carrier performance, identify trends and pinpoint areas in need of improvement — all of which can lead to cost savings, efficient use of resources and happier customers.

Analytics

Broadly speaking, TMS software collects and analyzes data from throughout the supply chain to provide a wealth of insights that can lead to new efficiencies — like optimizing less-than-truckload (LTL) shipments or minimizing fuel on multileg trips. For example, a company with four deliveries for four different locations may have multiple delivery paths to choose from. Comparing the fuel efficiency of a single truck going from A to B to C to D with that of a truck going first from A to B and then two more trucks departing from B — one to C and the other to D — can be a time-consuming and difficult process. TMS software can run this kind of complex analysis quickly and more accurately. TMS analytics can also help predict future customer demand and guide decision-making, such as choosing whether or not to reallocate inventory to where demand is expected to be greatest.

What’s the Difference Between a TMS and a WMS?

A warehouse management system (WMS) oversees daily warehouse operations, including inventory management, order fulfillment and storage optimization; once goods are packed and loaded for shipping, the transportation management system (TMS) takes over. Both systems are typically integrated with a business’s enterprise resource planning (ERP) system. If these systems are not properly integrated, communication between the warehouse and shipping carriers can lag, and inefficiencies, such as cluttered loading bays and poorly packed trucks, can delay customers’ orders and decrease profitability.

NetSuite Delivers Transformative Results for Transportation and Logistics

NetSuite Enterprise Resource Planning (ERP) helps businesses manage their transportation and logistics needs, replacing disparate, aging systems with a cloud-based platform that integrates key business functions, such as order management, warehouse management and accounting — all of which have a role related to the physical movement of products along the supply chain. NetSuite automates much of the routine but time-consuming paperwork required when transporting goods, with real-time tracking capabilities that help ensure that deliveries are on schedule or rerouted, if necessary. The better a company can manage its transportation and logistics operations, the more satisfied their customers awaiting their shipments will be, leading to repeat buyers and increased profitability.

Businesses with growing shipping needs are turning to transportation management systems to help plan, execute and manage the process. TMS software can save businesses time and money by providing analyses of carrier costs and shipping routes, as well as by automating much of the complicated paperwork associated with freight, so that businesses can more easily expand into new territories or sample new shipping methods. In addition, a TMS platform can streamline billing and carrier payments, as well as track and report on KPIs that can help managers improve workflow and gain new efficiencies.

#1 Cloud ERP

Software

Transportation Management System FAQs

What is transportation management?

Transportation management controls the process of shipping physical goods or supplies from one location to another. This could be raw materials being delivered to a warehouse, intermediate stops in the supply chain or a good’s final delivery directly to a customer.

What is transport logistics?

Transport logistics involves planning and managing strategies involved in freight. Transport logistics includes data for tracking goods along a delivery route and timing deliveries.

What is multimodal transportation?

Multimodal transportation involves using a single carrier to provide multiple methods of transportation, such as rail, truck, air or boat.

What is intermodal transportation?

With intermodal transportation, multiple carriers provide multiple types of transport. For businesses selling goods with a variety of shipping requirements — say, refrigeration needed for some products but not others — multiple carriers may be needed to satisfy different needs. Multiple carriers also may be used for multileg shipping plans, with goods being swapped from one carrier to the next over the course of the route.

What are examples of transportation management systems?

Transportation management systems are software solutions that help plan shipping routes, compare carrier rates, track KPIs and more. They are primarily used by companies with large shipping operations, but cloud-based solutions have made TMS platforms more accessible to smaller businesses as well.

What is the main objective of TMS?

The main objective of a TMS is to make a business’s shipping operations perform as efficiently as possible, ensuring fast delivery and minimizing costs. KPI analysis can help the business move toward those goals.

How much does a TMS system cost?

A TMS’s cost varies according to the features offered. Small systems without many features are more affordable than more advanced systems that offer features such as multimodal and intermodal shipments, temperature regulation and instant track-and-trace updates for shipments.