Order management is arguably the most important element of a business’s relationship with a customer because it determines how the organization responds to a customer and whether it meets their expectations. Getting this process right is essential because it directly affects customer satisfaction — and by extension, the organization’s rate of repeat business or lost sales. In addition, inefficient order management creates unnecessary costs that eat into profit margins.

What Is Order Management?

Order management refers to the processes, tools and programs built around the customer order life cycle. That life cycle includes everything from when a customer places an order through the delivery of order — and beyond, if the customer returns a purchase or sends it back for repair later, perhaps as part of a warranty program.

What Are Order Management KPIs?

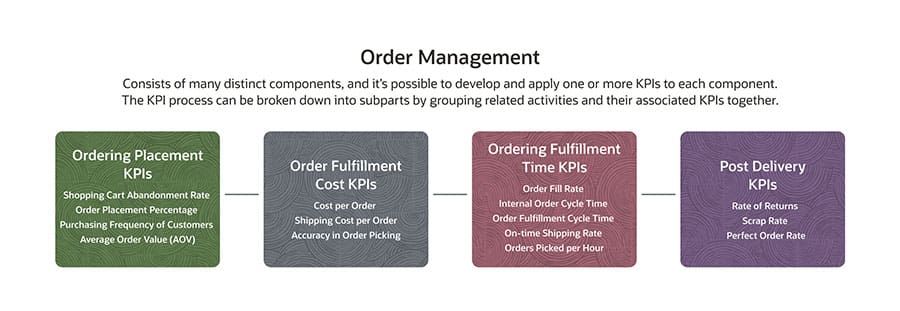

Companies can improve order management by tracking and responding to a set of order management key performance indicators (KPIs). Applying KPIs to the order management process can help businesses ensure they’re performing at an elite level at this critical stage of the customer relationship. Many companies use an order management system (OMS) to monitor these critical metrics.

KPIs can be applied to every stage of the order management process. To be actionable for operations teams, well-developed order management KPIs must be based on clear, objective metrics.

Why Are Order Management KPIs Important?

Order management deserves special attention from businesses because this is the stage of the buyer’s journey where the customer is making a purchase. Money and effort put into marketing, sales and other business functions can be squandered if a customer is dissatisfied with their order experience and decides never to purchase from the company again or even return their order.

That’s why companies scrutinize order management KPIs to gain insight into how they can optimize discrete components of the order management process, such as the time it takes to fulfill and ship orders. Digging deeper, order management KPIs can yield broader insights. For example, a company may find that it loses money when selling small volumes of a low-cost, low-margin product after accounting for shipping costs. To resolve that issue, it might require a minimum order size for those products. Order management KPIs can offer insights that drive business decisions and boost profits.

15 Order Management KPIs

Understanding the importance of order management KPIs is just the first step in improving order management processes. The real work comes in identifying the appropriate KPIs, tracking and measuring the associated metrics and understanding what they may mean for your organization so you can take the right actions in response.

Here are 15 order management KPIs to consider including in that process, divided into the following groups, based on their stage in the order management process:

- Order placement KPIs

- Order fulfillment cost KPIs

- Order fulfillment time KPIs

- Post-delivery KPIs

Order Placement KPIs

Order placement KPIs reflect the metrics related to transitioning from the sales process to the order fulfillment process. In other words, these KPIs measure different elements of the conversion from lead to customer.

-

Shopping Cart Abandonment Rate

-

Definition: The shopping cart abandonment rate is the percentage of items placed in a virtual shopping cart by an online shopper that are never purchased — in other words, they’re “abandoned.”

-

Formula: 1 – (Completed transactions / Number of shopping carts) x 100

What does it tell us? Shopping cart abandonment means the company was close to a sale but couldn’t seal the deal. This could be because customers are wary of submitting payment information on the website or because the checkout process is too long or cumbersome, among other reasons. A high shopping cart abandonment rate tells a company it needs to closely review its checkout process and look for opportunities to optimize it for usability and efficiency.

-

-

Order Placement Percentage

-

Definition: Most companies have multiple channels through which customers can submit orders, such as online, in-store or by phone. The order placement percentage measures the percentage of orders from each channel.

-

Formula: Number of sales via channel A / Total sales x 100

Order placement percentage illustrates the relative performance of a company’s sales channels. The actual percentages of sales can be compared against the expected percentages for each channel based on the forecast. Moreover, if a particular channel represents a very small percentage of sales, the company might want to look at ways to improve that channel or eliminate it to reduce costs. Alternatively, a company could study its highest-performing channels to see whether any practices contributing to the success of those channels could be applied to others.

-

-

Purchasing Frequency of Customers

-

Definition: Purchasing frequency represents the number of purchases made by an average customer over a set period of time, typically a month or a year.

-

Formula: Number of purchases in period / Number of unique customers

The purchasing frequency of customers tells companies their level of repeat business during a set period. A company might work to strengthen relationships with customers making frequent purchases through loyalty programs or even personal outreach to maintain their business long term and increase customer lifetime value.

-

-

Average Order Value (AOV)

-

Definition: The amount of revenue generated from an average order.

-

Formula: Total revenue over a time period / Number of orders

Average order value can be calculated across all sales or at the level of a specific product or category of products. Either way, knowing average order value helps a company better understand customer behavior. This insight is useful for planning pricing and/or marketing and sales strategies, for example. Any improvement in average order value is important because it can directly affect profitability.

-

Order Fulfillment Cost KPIs

Order fulfillment cannot be an afterthought. It represents a key element of the value a company provides to customers — and also a major source of additional costs. Tracking order management KPIs related to costs can help managers maintain a focus on protecting profit margins from costly order fulfillment processes.

-

Cost per Order

-

Definition: Cost per order is a measure of how much it costs to fulfill an order. This doesn’t mean the cost of the product itself, but rather the cost of labor, shipping and other expenses required to get the order to a customer.

-

Formula: Total fulfillment costs / Number of orders

A high cost per order can eat away at profit margins. In some cases, it might even cost more to fulfill an order than the customer pays for the product. If cost per order is too high, companies might consider tactics like minimum order quantities or raising the minimum basket size for free shipping to spread those costs over a greater number of units.

-

-

Shipping Cost per Order

-

Definition: Shipping cost per order is the amount it costs to deliver each package to a customer during a set period of time, usually a month or a quarter.

-

Formula: Total shipping cost for the period / Number of successful deliveries

Shipping cost per order is an element of total cost per order (No. 5) that can help a company zero in on where cost efficiencies are — or aren’t — in the business’s order management process. If shipping costs are high relative to competitors, a business may need to negotiate better deals with carriers or urge customers to consolidate orders.

-

-

Accuracy in Order Picking

-

Definition: Whether it’s a pizza or a new car, it’s frustrating when the product delivered is not what was ordered. Accuracy in order picking is a measure of how well the company prepares the right goods for delivery. Rather than let customers find mistakes, many companies have processes in place to double-check orders before they go out the door.

-

Formula: Number of orders accurately prepared to ship / Total orders picked x 100

Substandard order picking accuracy tells a company it has a challenge to address in order to remain competitive in its industry. It may be a lack of planning, organization or oversight in its warehouses, or it may signal too many manual processes that allow for human error. Automating processing and packaging efforts can help increase accuracy.

-

Order Fulfillment Time KPIs

Speedy service is generally a sign of smooth and efficient processes — and it also translates into happy customers. KPIs focusing on the time various order fulfillment processes take can identify obstacles to getting orders into the hands of customers as quickly as possible.

-

Order Fill Rate

-

Definition: Order fill rate is the percentage of orders that can be filled with existing on-hand inventory, as opposed to requiring a new order to arrive or another production run in manufacturing settings.

-

Formula: Orders fillable from inventory / Total orders x 100

Customers like getting orders quickly and having product in stock at the time they order is obviously a great way to make that happen. The ideal scenario is to have just enough inventory on hand to fulfill all new orders with minimal excess, and with enough new product flowing into inventory so that new orders aren’t delayed. Companies should be wary, though, of holding onto too much inventory because that incurs steep carrying costs and ties up cash. Order fill rate thus becomes a key variable — along with other demand planning KPIs — in a complex supply chain management challenge.

-

-

Internal Order Cycle Time

-

Definition: Lead time is the amount of time between when an order is placed and when it’s shipped. This could be a matter of hours for many consumer orders, or months for large B2B orders that are scheduled far in advance.

-

Formula: Time and date order shipped – Time and date order placed

Internal order cycle time is a great measure of the efficiency of a warehouse and communication between the warehouse and sales team. Companies that have a high internal order cycle time should bring together the key internal stakeholders in the process to brainstorm possible improvements.

-

-

Order Fulfillment Cycle Time

-

Definition: Order fulfillment cycle time measures the total time between when an order is placed and when it actually reaches a customer. It’s essentially the internal order cycle time plus shipping time.

-

Formula: Time and date order reaches customer – Time and date order placed

Getting orders into customer hands quickly is a big part of customer satisfaction. Greater speed can also be an important strategic advantage over competitors offering similar products. All else being equal, customers are likely to go with an option that can be in their hands in two days instead of a week. If lead time is low but overall customer order cycle time is high, that’s an indication that shipping carriers are causing delays.

-

-

On-time Shipping Rate

-

Definition: On-time shipping rate is the percentage of orders that ship from the company on time. While companies frequently rely on third-party carriers for shipments, they have far more control over the date a product ships from their facilities.

-

Formula: Orders shipped on time / Total orders x 100

On-time shipping rate is another way for companies to tell how well they perform order management versus their planned requirements. Often, sales contracts may have a mandatory delivery date with delays carrying penalties or constituting a breach of contract. Companies typically have the most influence over the timing of a delivery while the product is still in their possession, so getting it out the door as quickly as possible is essential.

-

-

Orders Picked per Hour

-

Definition: Orders picked per hour is the average number of orders prepared and shipped from your distribution center or warehouse per work hour.

-

Formula: Total orders picked and shipped / Total work hours

Orders picked per hour is a KPI that can directly impact the bottom line. The more orders an organization’s workforce accurately picks and ships every hour, the more cost-efficient it can be. Since inaccurate order picking increases expenses, this KPI should be tracked alongside accuracy in order picking (No. 7).

-

Post-Delivery KPIs

In most organizations, the order management process doesn’t end when an order is shipped or even when it arrives in customers’ hands. It ends only when the customer is satisfied — or, preferably, delighted. So it’s important to track KPIs such as perfect order rates, return rates and what happens to returned orders.

-

Rate of Returns

-

Definition: If an article of clothing doesn’t fit right or a piece of machinery is defective, customers will likely return it. The rate of returns measures how frequently those returns happen.

-

Formula: Number of orders returned / Total orders x 100

Returns typically mean refunds. They also mean less satisfied customers, time spent processing returns and additional shipping costs. Companies with a high rate of returns need to determine why customers are sending orders back. Returns are often due to poor product quality or poor marketing accuracy, meaning customers receive products that either don’t work or don’t match their expectations at the time they placed their order.

-

-

Scrap Rate

-

Definition: Sometimes returns can be resold to other customers. When they can’t, they often have to be discarded — in other words, scrapped.

-

Formula: Number of scrapped orders / Total number of returns x 100

High scrap rates make product returns even more costly. Not only is a sale lost, but the inventory tied to that sale is lost as well and none of the money spent producing or buying it can be recovered. Changing how items are packaged may help reduce the scrap rate if doing so can prevent damage or spoilage. For example, including transparent plastic packaging on certain products can let a customer handle a product to evaluate it for a potential return without opening it to the extent it has to be scrapped.

-

-

Perfect Order Rate

-

Definition: The perfect order rate measures how often an order is delivered without any errors.

-

Formula: Orders delivered without incident / Total number of orders x 100

While a lot can go wrong in the order management process, companies generally do an impressive job of getting it right. A typical perfect order rate is around 90%, meaning only 10% of orders have some kind of issue. One in 10 is still fairly high, though, and companies that have a perfect order rate below 90% should look closely at the more specific KPIs discussed here to pinpoint their trouble spots.

-

Tracking Order Management KPIs With NetSuite

Many products-based businesses already have an order management system (OMS) that helps them track KPIs to rigorously monitor their order management process. Companies in any industry with a supply chain — including healthcare, transportation, food service, automotive and pharmaceuticals — can benefit from an OMS.

NetSuite offers an order management solution that enables companies to manage and prioritize orders, match inventory to orders and track relevant KPIs in user-defined dashboards that display real-time data. Businesses can also optimize their distribution operations — for example, by directing order pickers to the right area of the facility for faster, more efficient fulfillment — with NetSuite's warehouse management system (WMS). NetSuite unifies these systems for order, inventory and warehouse management on a single platform, connecting processes and putting all information in one place.

No matter how much value or utility a product has, customers can still have a negative impression of a company and brand if there are issues in the order management process. This can include shipping delays, incorrect orders and returns. Even when customers are satisfied with the order management process, the company itself might be losing money due to inefficiencies in order management. By establishing, tracking and measuring order management KPIs, businesses can reimagine their order management process from a liability into an asset.

Order Management KPIs FAQs

How do you measure order fulfilment?

Order fulfillment covers a variety of individual components, from how easy it is for a customer to place an order to the time it takes for a delivery to reach that customer — and everything in between. Measuring this broad and varied process requires breaking it down into discrete components and assigning key performance indicators (KPIs) to each.

KPIs in the order fulfillment process track things like how long it takes a company to get an order ready to ship to a customer and how much it costs to ship an average order. It’s impossible to measure the overall order fulfillment process without focusing on the distinct elements of that process.

What is a good KPI in shipping?

Two of the most important shipping KPIs are internal order cycle time and on-time shipping rate. Internal order cycle time measures the amount of time between when an order is placed and when it’s shipped. Because many companies rely on third-party carriers to deliver their products, measuring internal order cycle time focuses on the aspects of order fulfillment directly under the company’s control. On-time shipping rate measures the percentage of orders shipped on schedule.