It’s a common frustration for manufacturers: Materials and finished products that should contribute to revenue instead end up in the trash can, eroding profitability. Whether resulting from damaged components, excess material, or failed final inspections, scrap adds unnecessary costs to production. And in an era of volatile prices and economic uncertainties, business leaders must seize every opportunity to lower costs yet maintain quality—and keep that scrap heap as small as possible.

Manufacturing scrap may seem like a cut-and-dried concept, but there are many ways for manufacturers to analyze it, depending on the issues they hope to uncover and how they plan to address the ones they find. This article provides decision-makers with a road map to understand the ins and outs of scrap rates—and reducing waste.

What Is Scrap Rate?

Scrap rate measures the percentage of manufacturing materials—raw materials, components, finished products—that fail to meet quality standards and must be discarded. It is a useful key performance indicator (KPI) that helps manufacturing companies track production efficiency, identify quality control issues, manage material costs, and spur process improvements. By tracking scrap rate over time, businesses can see where waste is increasing and take steps to minimize it.

Different manufacturers define “scrap” in different ways. Some count only the finished products that are tossed; others include defective raw materials or ordinary production waste. It’s important to reach consensus on this before calculating and reviewing the scrap rate metric.

Key Takeaways

- Scrap rate measures the percentage of unusable materials discarded during procurement, normal manufacturing processes, and final quality checks.

- Scrap rate analysis helps businesses identify waste, control costs, maintain quality standards, and support sustainability efforts across their operations.

- Manufacturers can lower scrap rates by improving processes, maintaining equipment, and implementing strategic quality control measures.

Scrap Rate Explained

Manufacturing scrap falls into two main categories: planned and unplanned. Planned scrap results from standard production processes, consisting of metal shavings from machining or excess fabric from cutting patterns, for example. Because it follows predictable patterns, planned scrap can be accounted for when companies plan their production processes. Unplanned scrap, on the other hand, results from defects, errors, or quality issues, such as components damaged during assembly or finished products that fail quality testing. These kinds of unpredictable losses contribute to fluctuating scrap rates and can indicate quality control or process shortcomings.

Scrap can pop up in any stage of production, but its impact on a company’s scrap rate and overall profitability depends on when it happens. From a manufacturing accounting perspective, raw material scrap tends to wield the least financial harm, since it doesn’t yet include accumulated labor and overhead expenses. Scrap that occurs later in production, however—such as during work-in-progress or finished goods stages—packs a bigger financial punch because it impinges on the costs for materials, labor, machine time, and overhead. While simple material scrap can often be recycled or sold, disposing of or repurposing complex components may require additional processing steps. Recovering costs can be especially challenging for high-value materials, as fluctuating commodity prices can make resale or recycling unpredictable. For example, over the past two decades, iron and steel scrap prices have repeatedly spiked to record highs before losing a significant percentage of those gains, according to data from the Federal Reserve Bank of St. Louis.

Some scrap is unavoidable, so why do manufacturers track the scrap rate? They use it to help identify trends over time and areas in need of improvement. Inventory management, product redesign, equipment recalibration, and workforce training all play a role in minimizing scrap and stabilizing scrap rates. However, reducing scrap isn’t necessarily a top priority among manufacturers—indeed, some tolerate a marginally higher than usual scrap rate in exchange for increased production speeds that boost overall output and revenue. Because trade-offs like this do exist, scrap rate targets should always be analyzed within a manufacturer’s broader context of industry, product, and overall production strategy.

What Is Scrap Rate Used For?

Scrap rate data helps businesses better understand their manufacturing process. In addition to its value as a basic waste-tracking metric, scrap rate can be a key to operational efficiency. By analyzing their scrap rate over a period of time, companies can set benchmarks that help optimize production speed, quality, and waste. Here are five specific ways businesses use scrap rate.

- Determine optimal production schedules: Set acceptable waste targets based on expected output and production speeds. If scrap rates rise above this threshold, it may indicate that increased production speed is revealing quality defects, equipment strain, or procedural errors not apparent at lower speeds. In such cases, businesses should conduct deeper process analyses or adjust expectations.

- Establish quality control checks: Monitor scrap rate throughout production workflows to reveal where waste and defects occur most frequently. Implement quality control checks at or before the location of these problem areas to increase accuracy and reduce manufacturing waste.

- Justify equipment upgrades: Excess waste from machinery may indicate the need for repairs, upgrades, or replacements. Scrap rate data can prioritize equipment investments for a sizable impact on reducing waste.

- Set inventory reorder points: Analyze average scrap rates alongside production schedules to time material reorders and prevent shortages or excess stock. Setting acceptable parameters can reduce carrying costs without hindering the company’s ability to sustain production schedules and meet demand.

- Strengthen supplier and outsourcing decisions: If low-quality materials are contributing to excessive scrap, it may be time to reassess vendors or invest in higher-quality components. Or, if scrap is primarily resulting from specific production steps that require lacking resources to improve, outsourcing to specialized partners may provide a cost-effective solution.

Who Uses Scrap Rates?

Scrap rate is a useful metric for both front-line managers responsible for daily operations and upper-level decision-makers shaping long-term strategy. Here’s how different teams use this KPI.

- Production line managers monitor daily scrap rates to maintain and adjust processes and uphold quality standards.

- Procurement teams use historical scrap data to negotiate supplier contracts, establish quality expectations, and set safety stock levels.

- Financial controllers incorporate scrap projections into cost analyses, forecasts, and budgets.

- Engineering teams use scrap rates to refine product designs and minimize waste-prone features and components.

- Senior management integrates scrap rate analyses into strategic planning to justify investments in equipment, training, and process improvements.

Scrap Rate Formula

The scrap rate formula calculates the percentage of materials or goods that fail to meet quality standards, relative to the total amount produced or used. This calculation helps manufacturers quantify waste and track changes over time, so manufacturers often calculate scrap rate for specific production runs, time periods, or product lines to identify trends and problem areas. Though scrap rate can be measured in different ways, it always begins with the following general formula:

Scrap rate = (Scrapped material / Total material) × 100

The general formula provides an overall scrap rate, but analysts can modify it to measure scrap by mass, product count, or value:

Scrap rate by mass = (Mass of scrapped material / Total mass of material) × 100

Scrap rate by product count = (Number of scrapped products / Total number of products) × 100

Scrap rate by value = (Value of scrapped material / Total value of material) × 100

How Do You Calculate Scrap Rate?

A methodical approach to calculating scrap rate can provide consistent measurements across production periods and departments. This consistency allows manufacturers to track trends, benchmark efficiency, and identify problems that might otherwise be missed by informal monitoring. Scrap rate is calculated in four steps.

-

Total the Number of Scrapped Items

First, count all materials or products that failed to meet quality standards or were discarded during the manufacturing process. This includes scrap coming from receiving, manufacturing, and final quality control. The measurement unit employed should match business needs—units, mass, finished products, or value.

- If a company buys raw materials by weight, it makes sense to track scrap by mass.

- If materials are purchased in discrete units, unit-based scrap may be appropriate.

- If different materials have different costs per unit, measuring scrap by value can help companies prioritize waste reduction efforts with the greatest financial impact.

-

Tabulate the Total Number of Units

Next, determine the total amount of material used during the measurement period, including both successfully produced and scrapped portions. This can be measured in units, mass, or value, depending on the need. Regardless of the measurement used, total material is calculated by adding up starting inventory and received materials, then subtracting ending inventory.

Getting a full picture involves:

- Reviewing production logs and batch records to track all materials or products processed.

- Checking raw material usage against procurement orders and inventory levels.

- Confirming finished product counts using final production reports or quality control records.

-

Insert the Values Into the Formula

Once these values are identified, it’s time to plug them into the first part of the scrap rate formula:

Scrap rate = (Scrapped material / Total material)

For instance, if a manufacturer scrapped 80 units out of 2,000 total units, the calculation would be:

Scrap rate = (80 / 2,000) = 0.04

-

Multiply by 100 to Get Scrap Rate

To express the result as a percentage, multiply the resulting decimal by 100. This final figure represents the proportion of materials that did not contribute to sellable goods during the period. In the example above, a scrap rate of 0.04 becomes 4% (0.04 × 100).

What happens next depends on the business’s policies and the nature of the materials. Scrap may be returned, recycled, repurposed, or discarded based on feasibility and cost.

Note that there isn’t a single “good” scrap rate to shoot for. Acceptable levels hinge on production methods, material costs, business goals, and industry standards. Generally, manufacturers will try to minimize scrap rate without hindering output, quality, and cost efficiency.

Example Scrap Rate Calculation

A hypothetical manufacturer, Twin Pants, produces denim jeans and tracks its scrap rate using the mass-based option. During the previous quarter, the company recorded:

- 10,000 kg of denim processed

- 120 kg of defective material identified during quality inspection

- 250 kg of unusable fabric from pattern cutting

- 80 kg of damaged fabric from handling and machinery issues

Using the mass-based scrap rate formula, the company’s scrap rate for the quarter was:

Scrap rate by mass = (Mass of scrapped material / Total mass of material) × 100

Scrap rate by mass = ([120 kg + 250 kg + 80 kg] / 10,000 kg) × 100

Scrap rate by mass = (450 kg / 10,000 kg) × 100 = 4.5%

For comparison, Twin Pants’s scrap rate was 3% and 4% in the prior two quarters. To identify why scrap is rising and determine how to reverse this upward trend, front-line managers evaluated cutting and material-handling processes and compared them to overall production metrics. By finding which processes contributed most to its total waste, the company was able to target specific remedies, namely, optimizing pattern layouts to reduce excess fabric waste and upgrading to more precise cutting equipment.

Benefits of Calculating Scrap Rate

Consistently tracking something as seemingly simple as scrap rate can provide manufacturers with valuable insights into production efficiency and total manufacturing cost. Regular analysis of this metric can help optimize raw material usage, improve budgeting, strengthen quality control, and enhance resource allocation, among other benefits. Here’s how.

- Reduced material waste: Tracking scrap rates for each manufacturing step gives companies the insight needed to refine material strategies for minimizing waste, improving storage methods, or adjusting ordering quantities and timing. It also makes it easier to accurately log scrap components, which can lead to more efficient disposal processes, such as selling or recycling unused raw materials to reduce the financial impact of waste.

- Improved budgeting: Forecasting scrap rates allows financial teams to create more accurate cost projections and production budgets. By anticipating scrap levels, businesses can better estimate true production costs, including procurement and carrying costs, and set appropriate prices and revenue goals to maintain profitability.

- Increased quality control: High scrap rates frequently indicate quality issues lurking in materials, processes, finished products, or a combination of the three. By monitoring scrap rates across production stages, manufacturers can proactively implement quality checks at key points and measure their outcomes on rework, waste reduction, and customer satisfaction.

- Better resource allocation: Scrap rate analyses help companies prioritize projects, maintenance schedules, and capital investments by spotlighting where the most waste is accumulating. For instance, if one department consistently generates the highest scrap rates, managers can provide targeted training to help staff reduce waste in their day-to-day tasks, ultimately increasing profit margins.

What Causes a High Scrap Rate?

Several common factors contribute to high scrap rates in manufacturing operations, but their ramifications can vary greatly by industry and business type. It’s important to address the root causes of elevated scrap levels to avoid wasting company resources on temporary fixes that only mask symptoms.

- Bloated procedures: Outdated or poorly designed workflows increase handling and errors while contributing to waste. Every extra handoff, redundant step, or unnecessary layer of process complexity creates another opportunity for defects and damage to occur.

- Machine issues: Aging machinery, worn-out tools, and misaligned equipment often produce defective output caused by wear and improper calibration.

- Poor quality materials: Substandard components and unreliable suppliers can raise both direct material costs and scrap rates, as imperfections emerge and output must be discarded. Materials that don’t meet specifications may fail during manufacturing or result in defective finished products.

Tips to Lower Scrap Rate

Successfully reducing scrap rate often involves a combination of both immediate tactical changes and adoption of long-term strategies. For example, switching to a higher-quality supplier may reduce waste quickly, while implementing supply chain management software can bring long-term waste reduction through ongoing vendor analyses and procurement enhancements. The following tips can help companies build a comprehensive waste reduction strategy.

- Optimize internal processes: Automate repetitive production tasks to reduce errors and inefficiencies. Minimize unnecessary movement of materials by mindfully arranging workstations or using conveyor systems. Implement modern technology, such as artificial intelligence-assisted defect detection and real-time production monitoring, to refine workflows and improve efficiency.

- Maintain equipment: Establish regular maintenance schedules, precise calibration procedures, and timely equipment upgrades to minimize defects and scrap. Real-time performance and machinery monitoring software can detect issues early and increase machine efficiency. A proactive, data-driven approach can also alleviate downtime and extend equipment life, in addition to improving production consistency.

- Improve quality assurance: Source materials from reliable, high-quality suppliers and enforce strict quality benchmarks to avoid defects. Proactive inspection and testing protocols can cut down on the likelihood of producing subpar goods, as well as reducing scrap, limiting costly rework and stemming customer dissatisfaction.

- Improve material storage: Set appropriate storage policies and inventory levels, especially for perishable, temperature-sensitive, or fragile goods. Effective storage management and turnover analysis help prevent waste, ensure that materials are available when needed, and avoid excess carrying costs from unused or dead stock.

- Increase employee training: Offer ongoing, hands-on training to make sure staff follow proper procedures and can spot and prevent waste. Effective training should include onboarding of new hires and continuing education for established employees, as even veteran workers can harbor unrealized ingrained inefficiencies.

Optimize Manufacturing Output With NetSuite

As manufacturing operations become more complex, tracking waste becomes harder—which means inefficiencies can accumulate and create a major financial drag. These drawbacks are exacerbated by manual tracking methods and siloed databases that lack the visibility business leaders need to identify and reduce waste before it affects the bottom line.

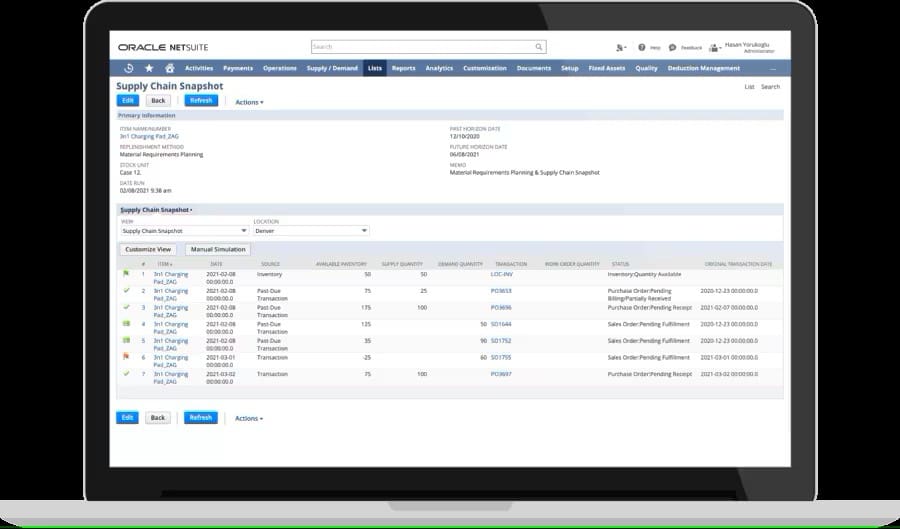

Enter NetSuite for Manufacturing, which provides comprehensive scrap rate tracking and analysis to help companies get to the root causes of inefficiencies. By taking advantage of the software’s built-in quality control features and automated data collection tools, manufacturers can set benchmarks and monitor every production stage through intuitive, real-time dashboards.

NetSuite’s specialized manufacturing software integrates with procurement, order management, supply chain, shop floor, and inventory management modules to create end-to-end transparency into the entire production process. And because it is a cloud-based platform, manufacturers can securely access critical data from anywhere—the warehouse, factory, central office, or on the go—to enable faster decision-making and more efficient operations.

Manage Your Supply Chain With NetSuite

Scrap rate is an essential metric that helps manufacturers cut waste, control costs, and maintain quality output. However, effectively managing this KPI requires decision-makers to have a deep understanding of their production processes. To lower scrap rates, businesses need a comprehensive strategy that includes systematic waste tracking, root cause analysis, and both short- and long-term corrective actions. Though it may be impossible to eliminate scrap entirely, the right combination of process improvements, quality control measures, and technology solutions can give companies the edge they need to build a more sustainable, profitable, and less wasteful operation.

Scrap Rate FAQs

Why is monitoring scrap rate important?

Scrap rate tracking helps manufacturers find inefficiencies, control costs, and uphold quality standards across production. Regularly monitoring scrap rate allows businesses to spot concerning trends early and take corrective action before they affect customers. Additionally, ongoing analysis helps managers measure the success of waste reduction initiatives.

What is an acceptable scrap rate?

Acceptable scrap rates vary by industry, business size, manufacturing process, and product. While some industries might consider 2% to 3% acceptable, others might be able to operate efficiently with rates above 5%. It’s important to establish and update benchmarks that are based on specific operations and industry standards.

What is a negative scrap rate?

In manufacturing terms, a negative scrap rate is generally not a meaningful concept. It would mean more usable material was created than was input, implying a measurement error or poorly calibrated equipment. However, the term “negative scrap value” describes a situation where the cost of disposing of an asset or material exceeds the value of its parts or materials, leading to a net loss when the unwanted asset or scrap is sold or discarded.