In manufacturing, even the best products don’t sell themselves. Long sales cycles, complex quoting processes, and disconnected systems mean strong customer relationships are crucial to closing deals. That’s where manufacturing CRM software comes in. Built for the industry’s unique challenges, these systems help companies manage leads, track interactions, and coordinate efforts across sales, production, and supply chain teams.

What Is Manufacturing Customer Relationship Management (CRM)?

Manufacturing CRM is software that helps manufacturers track, analyze, and act on data about prospects, customers, and partners. It supports sales and marketing, improves forecasting, and aligns production with customer demand. Manufacturing CRM systems facilitate customer lifecycle management by providing centralized access to the information sales, marketing, and service teams need to more effectively nurture leads, close deals, and retain clients.

Key Takeaways

- Manufacturing CRM software consolidates sales, marketing, and customer service workflows on one platform.

- This improves cross-team collaboration and creates more consistency in customer interactions.

- When choosing a CRM, manufacturers must identify their operational challenges, define their technical requirements, and map out their long-term goals to find a platform that can scale with their growth.

- As CRM systems evolve, customer-focused operations are becoming more intelligent and automated using AI, the Industrial Internet of Things (IIoT), and blockchain.

Manufacturing CRM Explained

Manufacturing CRM software addresses operational and go-to-market challenges specific to the industry. Unlike general-purpose CRM strategies that focus only on sales and marketing, manufacturing CRM tools manage quoting and distribution to simplify coordination among sales, production, and supply chain teams. These systems also accommodate long, multitouch sales cycles with multiple decision-makers.

Furthermore, manufacturing CRM software integrates customer-facing activities with ERP and material requirements planning systems, providing real-time data on inventory, lead times, production schedules, and materials costs. These insights allow for more accurate, customized quoting. Manufacturing CRM systems also house searchable catalogs of product specifications, pricing, packaging options, and images to streamline direct, distributor, and dealer sales and help sales teams address questions in real time.

What Is CRM Used for in the Manufacturing Industry?

CRM software centralizes data and organizes workflows across sales, marketing, service, and production teams, ultimately improving collaboration and increasing customer satisfaction. It’s no wonder that 86% of manufacturing companies have adopted a CRM system, compared to 73% for all types of businesses. Typical users include sales representatives, who manage pipelines; marketing professionals, who nurture leads; service managers, who handle post-sale support; and account managers, who develop long-term customer relationships. Manufacturers also use CRM systems to manage distributor and dealer networks, track partner performance, share product updates, and coordinate joint marketing efforts. With this information in hand, sales managers can identify new growth opportunities, marketers can deliver consistent messaging, and production planners can more accurately forecast demand.

Meanwhile, CRM data integrated with ERP systems aligns inventory with customer needs, reducing stockouts and overproduction. ERP integration also provides real-time pricing and inventory data, which—combined with CRM’s automated quote generation, order tracking, and invoicing capabilities—improves the efficiency and accuracy of the quote-to-cash process. In customer service departments, CRM systems provide more organized and complete tracking of warranty claims and support requests for more timely responses. Product teams can analyze these detailed records to identify common problems with specific offerings and proactively add improvements to roadmaps.

Why Should Manufacturers Use CRM Software?

Manufacturing CRM software manages complex relationships, improves internal coordination, and enhances supplier communication. Additionally, centralizing data and automating routine tasks refines departmental operations and supports more personalized customer experiences. In fact, more than 40% of manufacturing companies say they have experienced an improvement in implementing repeatable business processes after implementing CRM software. Manufacturers can use CRM software to:

- Strengthen supplier relationships: Real-time visibility into order status, inventory, and production schedules demonstrates transparency, builds trust, and fosters deeper collaboration with suppliers. Manufacturing CRM systems also make it easier to coordinate shipments, resolve issues, and share updates, reducing the risks of miscommunication and delays that can strain relationships.

- Develop targeted marketing campaigns: Analyzing CRM data uncovers valuable insights that marketers can use to develop more effective campaigns. If a customer frequently orders a specific product, for example, a marketing team can create a campaign offering complementary items or bulk discounts to encourage larger orders and repeat business.

- Personalize sales experiences: More than two-thirds of manufacturers indicate that their CRM software gives them a more accurate source of information on their customers, sales, and projects. Sales reps can learn more about prospects’ and customers’ interests, demographics, and buying behaviors to generate customized recommendations that are more likely to result in closed deals and upsells. If a customer previously purchased a certain piece of machinery, for instance, sales can follow up to pitch compatible accessories.

- Increase sales efficiency: Centralized data helps eliminate sales team silos that lead to fragmented communication, missed opportunities, and lost deals. When multiple team members are working on the same opportunity, they have visibility into all previous conversations and next steps, reducing the need for time-consuming internal updates. CRM tools also automate data entry, email follow-ups, and other manual tasks, freeing sales reps to focus more on closing deals.

- Manage the whole sales funnel: Full-funnel visibility lets manufacturers track every lead interaction from first contact to conversion. Data on website activity, content engagement, and channel performance facilitates timely communication that effectively nurtures leads, such as follow-up emails to prospects lingering on product pages without completing purchases.

- Generate deeper reporting and analytics: Real-time information on orders, shipments, and client interactions help manufacturers quickly make informed decisions. Customized reporting on key metrics and trends optimizes sales efforts. For example, if a report reveals consistent product underperformance in a specific region, marketing can adjust its campaigns to boost sales, or production can reduce inventory to reduce waste.

- Turbo-charge sales: The combination of automation and unified customer data results in faster deal cycles. Sales teams can swiftly identify high-value deals to drive more sales and grow revenue without increasing head count. They can also respond to questions promptly and accurately, which strengthens relationships with prospective and existing customers alike.

- Improve scalability: Cloud-based CRM systems grow with the business, handling more users, data, and complexity as needed. By continuing to store data in the cloud and optimize workflows without disruption as operations scale, manufacturing CRM systems bolster process efficiency and support long-term growth.

- Boost customer retention: Storing contact details, demographics, and brand interaction data in one location makes it easy to nurture client relationships over time. Personalized reminders about reordering opportunities or service appointments, for example, foster loyalty and help manufacturers retain loyal customers.

Core Features of a Manufacturing CRM System

Manufacturing CRM systems combine customer-focused capabilities with tools built for complex, process-driven organizations. The following core CRM features support workflows prevalent in sales, service, and operations, which helps manufacturers increase visibility, enhance collaboration, and make data-driven decisions.

-

Marketing automation:

Marketing automation improves lead management by automatically organizing prospect data. Collecting and storing leads from multiple sources, such as trade shows and website forms, reduces the risk of missed opportunities, and lead scoring prioritizes those with the highest sales potential. From there, drip campaigns guide prospects through the buying journey with personalized messages tailored to specific audience segments. Automated campaigns also target existing customers with product updates and upsell opportunities. Real-time alerts notify sales reps when recipients engage with campaigns, ensuring prompt follow-ups. And built-in analytics track open, click-through, and conversion rates to assist marketing teams in refining their messaging.

-

Order management:

Order management features handle everything from order entry and invoice generation to shipping calculations and delivery schedules. Automating the creation, tracking, and processing of sales orders supports efficient, accurate fulfillment. Synchronizing order data with inventory and production systems lets manufacturers confirm product availability in real time and avoid costly delays. Order management capabilities can also automatically trigger work orders from sales orders, so production teams can plan output based on actual demand. Throughout the process, status tracking features give sales, production, and customer service teams full visibility into every order’s progress.

-

Customer service management:

Customer service management tools help teams respond to questions and complaints swiftly and consistently over multiple communication channels, including email, phone, social media, and websites. They enhance service quality, reduce support costs, and build stronger customer relationships. With a complete view into customer history and interactions, support teams can provide tailored assistance, develop rapport, and resolve issues more efficiently. Case management features prioritize, route, and escalate support tickets, while field service management capabilities allow manufacturers to schedule maintenance and repairs, assign technicians, and send automatic reminders. Additionally, analysis of the feedback collected throughout the process informs future product improvements.

-

Sales force automation (SFA):

SFA reduces manual tasks and improves coordination of manufacturing sales teams. By automatically capturing customer interactions—from emails to meeting notes—SFA tools keep records up to date and accessible. Lead scoring surfaces the most promising opportunities, helping reps focus their efforts. Preconfigured quote templates streamline pricing and accommodate variables, such as custom specifications and volume discounts, cutting down on delays and errors. Managers can track deal progress, forecast revenue, and spot bottlenecks using real-time dashboards. By making the sales process more transparent and better aligned with production timelines, SFA helps sales teams close more deals.

-

Partner management:

Partner relationship management features make it easier for manufacturers to work with distributors, resellers, and other channel partners. Centralized dashboards provide real-time visibility into partner performance, order history, and campaign participation. Providing access to sales tools, product information, co-branded marketing materials, and training directly through the CRM system reduces back-and-forth interactions with internal teams and enables partners to sell more effectively. Additionally, incentive-tracking tools streamline rebate and commission programs to increase partner engagement.

-

Enhanced reporting and analytics:

By turning raw data into actionable insights, reporting tools measure performance, uncover trends, improve responsiveness, and support faster, data-driven decisions. CRM dashboards track key sales, marketing, and service metrics, such as pipeline velocity and customer retention. Detailed reports reveal buying patterns, product demand, and lead behavior, resulting in more accurate forecasts and production planning. Analytics also help identify which messages, campaigns, and channels are working—and where and why prospects drop off. Social listening integrations disclose shifts in customer sentiment or brand perception so teams can respond proactively.

-

Integration with other systems:

Manufacturers with properly integrated systems keep operations running smoothly by ensuring consistent data flow, reducing manual data entry, and avoiding errors. CRM software that connects seamlessly with other systems, such as ERP, manufacturing execution, inventory management, and accounting software, supports faster decision-making and greater flexibility in responding to evolving customer and market demands. For example, with unified, real-time access to inventory levels, supplier performance, and production schedules, sales and customer service teams can provide accurate updates and set realistic expectations. Integration also optimizes order fulfillment, invoicing, logistics, and other processes by synchronizing data across multiple platforms.

Choosing the Right Manufacturing CRM

Choosing CRM software is a complex process that involves more than comparing feature lists. Manufacturers need to assess their internal challenges, technical requirements, and long-term goals to find a system that truly fits. A thoughtful, step-by-step evaluation ensures that the platform can support both current operations and future growth.

Understand Your Specific Pain Points and Goals

Begin by identifying your specific challenges, like limited visibility into distributor performance, slow quoting processes, or misalignment between sales and production. Recognizing these pain points helps prioritize CRM features that can address operational needs, such as partner management tools, automated quote generation, or ERP integration. It’s equally important to define goals and evaluate CRM systems based on their potential as long-term growth drivers, not just their surface-level functionality.

Evaluate Your System Requirements

Before implementing a new CRM system, get a clear picture of your technical specifications, regulatory requirements, and scalability needs, along with integration capabilities and cost considerations. Defining the following criteria up front helps teams make informed, confident decisions during the evaluation process:

- Security and privacy requirements: Key features to consider include user access controls, multifactor authentication, data encryption, and secure cloud hosting environments. Vendor certifications, such as SOC 2 and ISO/IEC 27001, instill additional confidence that the CRM software meets recognized security standards. Built-in audit trails and logging tools enhance internal oversight and simplify incident response when issues arise.

- Compliance requirements: For manufacturers in regulated industries, CRM platforms must support adherence to relevant compliance frameworks, such as General Data Protection Regulation in the European Union, International Traffic in Arms Regulations for defense-related exports, and ISO 9001 for quality management systems. Documentation management, audit trails, and automated reporting capabilities help reduce the burden of maintaining compliance. Some platforms also track regulatory deadlines or certification renewals, streamlining ongoing compliance efforts.

- Scalability requirements: Scalable platforms can accommodate more users, larger data volumes, and increasingly complex workflows without compromising performance. Cloud-based CRM systems are especially well suited for scaling, offering flexibility to expand functionality without major infrastructure changes. The ability for the system to support new product lines, markets, sales channels, and analytics capabilities is also crucial as business strategies evolve.

- Integration and system requirements: Compatibility with existing tools minimizes disruption during implementation, and strong API support and prebuilt connectors can speed deployment and simplify long-term maintenance. Evaluate CRM systems based on their support for specific workflows and data requirements, and consider using a checklist or scorecard to compare the integration capabilities of various vendors.

- Cost requirements: Beyond licensing and subscription fees, implementation, customization, training, and ongoing support costs also contribute to an overall CRM investment. Evaluate how pricing scales with added users and features to keep costs manageable over time, and consider cloud-based CRM tools that offer flexible pricing plans and align costs with actual usage. Estimate the ROI from faster sales cycles, higher customer retention, and other benefits to determine whether the system platform will deliver lasting value.

Identify Which Features You Need

Before investing in a CRM solution, document internal workflows and analyze how teams manage sales, customer service, inventory, and production planning. Note all inefficiencies, gaps, and recurring challenges, such as inconsistent customer records or order processing delays, and identify the functionality needed to rectify each. These insights provide the foundation for a prioritized list of CRM features.

Include industry-specific requirements, such as inventory tracking, order management, and integration with ERP and manufacturing execution systems, along with features that help achieve broader business goals, such as sales pipeline visibility, marketing automation, and advanced analytics. Clearly separate essential and secondary capabilities to focus the selection process on the most critical operational needs and avoid distractions from impressive, but unnecessary, features. Involving stakeholders from different departments ensures that the chosen CRM software will support both day-to-day manufacturing operations and long-term business growth.

Assess Potential Solutions

Conduct thorough evaluations of each potential system’s features and usability, plus its vendor’s support services and overall reputation. Training, implementation support, and other services are especially important for smooth onboarding. Consider demos or trial periods to gain hands-on experience with the software’s interface and functionality. Gather feedback from key stakeholders from the teams that will use the CRM system daily, including sales, marketing, customer service, and IT. Check case studies, testimonials, and third-party review sites for insights into how well the solution performs in real-world manufacturing organizations.

Future Trends of CRM in the Manufacturing Industry

Manufacturing CRM solutions are evolving to support more intelligent, automated, and customer-focused operations. AI plays a central role by distilling insights from siloed and underutilized data to enable predictive analytics, demand forecasting, and real-time production optimization. It also reinforces personalized outreach through emails, phone calls, and text messages for more scalable, relevant customer engagement. Low-code and no-code tools make it easier for teams to build AI-driven workflows without relying on developers, which accelerates productivity and collaboration.

Omnichannel functionality builds on these AI-driven engagement capabilities by making customer interactions more consistent across email, phone, chat, and social media. Instead of fragmented communication, manufacturers can create a unified experience, regardless of channel or team. Social CRM tools enhance this further by pulling in engagement data from online platforms, offering valuable context to use when developing marketing and sales efforts.

IIoT integration is also transforming how manufacturers use CRM data. By connecting production equipment and systems to CRM systems, manufacturers can create real-time visibility into machine health, product usage, and supply chain activity. These insights support proactive maintenance, reduce downtime, and improve customer service. Additionally, product usage data from IIoT-enabled devices can inform future product development and allow manufacturers to proactively service equipment—preventing downtime and improving the overall customer experience.

Blockchain is a complementary technology, offering secure, transparent transaction records that serve the value chain. It enhances traceability for quality control and recall management and allows manufacturers to adopt smart contracts that automate workflows, such as order fulfillment or compliance checks. These capabilities strengthen operational integrity and reinforce trust with partners and customers.

A CRM Solution Built for Manufacturers

A manufacturing CRM solution must support complex workflows, streamline order and supply chain management, and provide real-time visibility into customer and production data. It should help teams coordinate go-to-market plans, production, and logistics, ultimately improving operational efficiency and customer satisfaction. Additionally, the ability to forecast demand, manage partner relationships, and analyze performance is vital for sustained growth in a competitive industry.

NetSuite’s manufacturing CRM provides these critical functions in a unified platform, offering real-time order tracking, automated workflows, and seamless ERP integration. Its advanced tools enable manufacturers to optimize inventory, automate order fulfillment, and gain comprehensive insights into customer interactions—all within a flexible, cloud-based system that scales with your business.

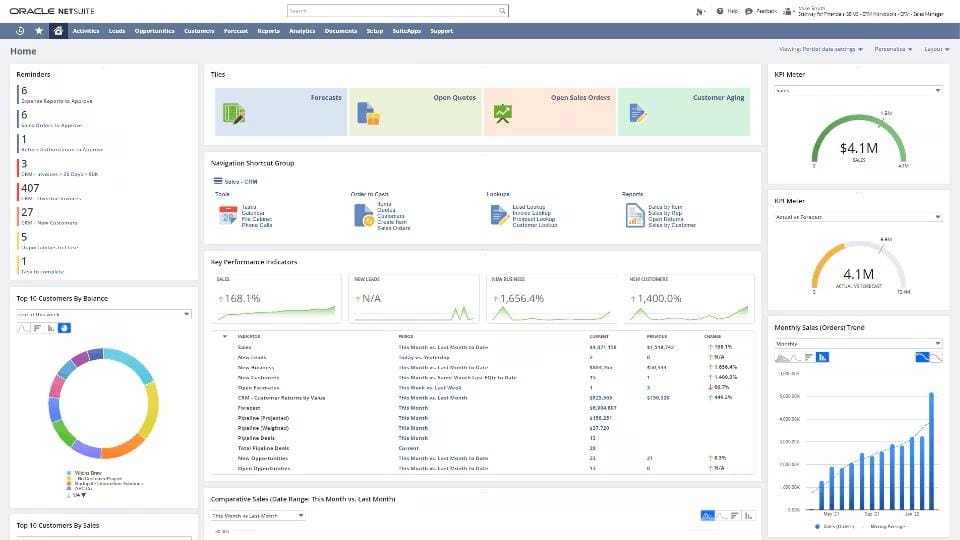

Role-Specific CRM Dashboards

Manufacturing CRM systems bring sales, marketing, and production teams together around a shared customer view, making it easier to close deals, fulfill orders, and build lasting relationships. Features such as SFA, order and partner management, and real-time reporting help manufacturers manage complexity and scale with confidence. As customer expectations continue to rise and sales cycles grow more data-driven, manufacturing CRM software will continue to evolve—from systems of record to strategic assets that drive growth.

Manufacturing CRM FAQs

What’s the difference between CRM and ERP?

The difference between CRM and ERP is that CRM systems help manage customer relationships and sales activities, while ERP systems focus on managing day-to-day business operations, such as finance, procurement, and supply chain. In manufacturing, CRM and ERP are often integrated, with CRMs supporting the front end of the customer journey and ERP systems handling the back end.

Do manufacturing companies use CRM?

Yes, manufacturing companies use CRM software to manage complex sales cycles, build stronger customer relationships, and improve data visibility for marketing, sales, and service teams. Manufacturing CRM systems also support industry-specific needs, such as partner management, order tracking, and inventory management.

Do you need a CRM solution if you have an ERP solution?

Yes, you still need a CRM solution if you have an ERP solution. While ERP handles operations like inventory and accounting, CRM focuses on improving customer-facing processes, such as sales, marketing, and support—which are especially important in manufacturing where long sales cycles and complex quoting processes benefit from strong customer relationships.