Fashion has always evolved with technology, from the first sewing machines to digital design tools and smart factories. Today, the pace and scope of this evolution are transforming the apparel industry. Modern technologies are redefining how brands produce and deliver clothing by supporting greater creativity, precision, and efficiency. This article explores the innovations behind that shift and how they help businesses adapt to changing demands in a more-connected global market.

What Are Major Technologies in the Apparel Industry?

The major technologies in the apparel industry are advanced tools, sensors, software, and machinery that optimize the design, manufacturing, and sale of clothing. Robotic sewing machines, predictive analytics systems, virtual design software, and enterprise integrations all exemplify this convergence of fashion and technology. These technologies aim to address longstanding challenges, such as inefficient production, high return rates, inaccurate trend forecasting, and environmental waste.

Key Takeaways

- Automation, AI, and integrated software systems connect design, production, logistics, and go-to-market processes for more seamless apparel operations.

- Fashion brands use personalized recommendations and omnichannel shopping to provide a more consistent and engaging customer experience.

- These and other innovations present new challenges, including data privacy concerns and ethical considerations.

Apparel Industry Technology Explained

The use of technology in the apparel industry traces its roots back to the invention of the sewing machine in the 19th century. The sewing machine took clothing assembly from an individual craft to a repeatable operation, which lowered costs, established consistency, and made fashionable garments accessible to a wider population. It also contributed to the growth of textile mills, which further accelerated production at scale.

The mid-20th century saw the introduction of automated production lines, which launched the rise of industrial garment manufacturing. These systems dramatically increased output and reliability and drove down reliance on manual labor. Around the same time, the development of synthetic fibers, such as nylon and polyester, brought new levels of durability and versatility to textile design. Later, computer-aided design (CAD) systems revolutionized the creative process by allowing designers to build detailed digital prototypes and experiment with new patterns before making a single sample.

Fast-forward to the 21st century: AI, robotics, 3D printing, and integrated software systems have reshaped how apparel brands create products and bring them to market—as well as how consumers experience fashion. Online storefronts and social platforms have become digital runways, with augmented reality (AR) creating more engaging and personalized shopping experiences. The fashion industry’s digital transformation has led to faster design cycles, more environmentally friendly production methods, and new business models, all of which are essential factors for brands in a competitive global market.

The 12 Technologies Changing the Fashion Industry

From AI-driven forecasting to on-demand manufacturing, technology is upending every stage of fashion production and distribution. Each of the following technologies plays a distinct role in improving efficiency, creativity, and sustainability while expanding what apparel companies can offer to consumers.

The Benefits of Technology in the Apparel Industry

| Technology | Benefits |

|---|---|

| AI | Optimizes inventory, automates operations |

| Smart textiles | Collect biometric data |

| Digital design | Reduces sampling costs and material waste |

| Sustainable fabrics | Lower environmental impacts |

| Augmented reality | Enhances retail and online shopping experiences |

| Robotics and automation | Increase production speed and precision |

| Smart factories | Improve efficiency and visibility |

| Virtual fashion | Expands brand reach into digital environments |

| 3D printing | Supports custom, localized production |

| On-demand manufacturing | Eliminates excess inventory |

| Ecommerce and omnichannel experiences | Creates consistency across digital and physical channels |

| Integrated software systems | Centralize data and operations management |

-

Artificial Intelligence

AI recognizes patterns, analyzes data, makes decisions, and automates tasks related to design, production, marketing, and sales. The fashion industry generates massive amounts of data, drawn from sensors that measure fabric properties on the production floor to CRM systems that track consumer behavior. AI learns from these data sets and acts upon them. For example, a factory could use AI-powered computer vision systems to spot stitching defects on an assembly line, allowing operators to correct errors immediately and prevent entire batches from being discarded.

Fashion brands can also use AI to more accurately forecast trends, align inventory with demand, reduce waste, and create a competitive advantage. For instance, AI can identify a rising trend toward cropped jackets weeks before competitors notice, prompting a manufacturer to increase production in time for peak demand. Additionally, AI generates personalized marketing copy and even entire ad campaigns, accompanied by customized recommendations to increase sales. And customer service teams benefit from access to up-to-date, actionable insights that allow them to resolve issues faster.

-

Smart Textiles

Smart textiles are fabrics with sensors, conductive fibers, or microchips that collect and transmit information. These materials are woven into or coated onto clothing, where they can detect body temperature, heart rate, motion, and other environmental conditions. They then communicate that data to connected devices for analysis. Athletic apparel can measure exertion levels, for example, and winter jackets can adjust insulation automatically as the temperature changes. In healthcare applications, smart fabrics can monitor a patient’s vital signs discreetly.

Smart textiles rely on flexible, durable electronics that remain comfortable while being worn. These materials open up entirely new business models for apparel companies in the area of interactive, data-enabled clothing. For instance, a brand could develop an entire line of smart clothing that connects to a mobile app, thus promoting repeat purchases and fostering brand loyalty.

-

Digital Design

Digital designers use software to virtually create and test clothing prior to making physical samples. 3D modeling and CAD tools build digital twins of fabrics and garments and simulate their fit on avatars. Their physics simulations accurately depict the way garments drape and move, allowing designers to make refinements as needed. This lessens the time and cost associated with development and cuts down on material waste.

Design, supplier, and merchandising teams can collaborate remotely using digital design tools, which accelerates innovation. Brands can create more styles and react to trends faster. By holding virtual try-ons or style meetings before cutting any fabric, they also minimize waste. In addition, digital design supports made-to-measure initiatives, using digital body scans to create personalized fits for individual customers.

-

Sustainable Fabrics

The fashion industry is responsible for up to 8% of the world’s greenhouse gas emissions, according to the United Nations. Sustainable fabrics are produced through processes that lower this environmental impact. Recycled fibers, organically grown crops, biodegradable materials, and biotechnology-based alternatives, such as lab-grown leather, all help conserve energy and water. Production improvements like waterless dyeing further contribute to these goals. A denim company, for instance, could shift to recycled cotton and enzyme-based dyeing to shrink its carbon footprint while maintaining durability and style.

Sustainable fabrics influence sourcing and supply chain strategies because brands must trace materials from origin to finished product in order to meet certification standards and government regulations. They redefine quality as a balance between performance and responsibility, which helps attract environmentally conscious consumers. The materials also demonstrate measurable progress toward circular production models, where textiles are designed for reuse, rather than disposal.

-

Augmented Reality

AR overlays digital images onto real-world views so customers can visualize how garments and accessories will look before purchasing them. Smartphone and tablet cameras or in-store smart mirrors capture body dimensions and project clothing onto the user’s image in what is called a virtual try-on. That means a shopper can stand in front of an AR mirror, or take a selfie at home, and instantly see how different jacket styles or colors look on them without physically changing clothes. This helps brands close the gap between online and in-store experiences. It also relieves uncertainty about fit, which leads to lower return rates and greater customer satisfaction.

Designers, for their part, use AR to present collections through digital fashion shows or virtual showrooms, eliminating the need for physical samples and travel. The technology has become a key part of omnichannel retail, blending convenience and personalization. By allowing customers to experience products virtually, AR improves engagement, strengthens brand loyalty, and supports more sustainable shopping behaviors.

-

Robotics and Automation

Robotics uses programmable machines to perform precise, repetitive production and logistics tasks. Robotic arms, automated sewing systems, and laser cutters on shop floors assemble garments quickly and accurately. In warehouses, autonomous robots expedite picking, sorting, packing, and other fulfillment processes.

Robotics and automation cut down on costs and safety risks. A facility equipped with automated fabric cutters and “sewbots” could run continuously, producing thousands of T-shirts per day with negligible downtime. Quality control robots can use computer vision to instantly spot stitching defects or mismatched colors, preventing expensive rework. And automation of strenuous or hazardous tasks improves working conditions. Robotics also enhances flexibility, because production can shift from one design to another with minimal reprogramming.

-

Smart Factories

Smart factories combine robotics, Internet of Things sensors, and AI analytics into interconnected production environments. Every stage—cutting, sewing, packaging—generates data that’s collected and analyzed in real time. Software platforms use this information to optimize energy use, schedule maintenance, and predict bottlenecks before they occur.

This data-driven approach gives apparel manufacturers added flexibility. Smart factories can switch quickly among product lines or adapt to custom orders without extensive retooling. By continuously monitoring equipment health, output, energy consumption, and material efficiency, they also limit downtime and waste. As the apparel industry moves toward greater transparency and traceability, this level of visibility becomes an operational advantage and a competitive differentiator.

-

Virtual Fashion

Virtual fashion involves designing and wearing clothing entirely in digital environments. Designers use computer graphics and AI to craft 3D garments for video game avatars, social media filters, AR overlays, and the metaverse. Depending on the scenario, this clothing may be realistic, such as a suit that a businessperson would wear to a meeting, or fantastical, such as a robe that moves on its own and changes color.

Virtual fashion allows brands to engage digital-native audiences and expand their presence beyond traditional retail. It also creates new revenue opportunities. Brands can sell limited-edition digital garments for customers to wear on avatars or social profiles, release collectible NFT versions of real-world items, and offer microtransactions within gaming or metaverse platforms, where users pay to customize their digital appearance.

-

3D Printing

3D printing constructs garments and accessories from digital designs. Printers deposit thermoplastics, nylon, bio-based composites, and other materials in layers to create complex shapes that would otherwise be difficult or impossible to build. For example, a footwear company could use 3D printing to create perfectly fitting midsoles derived from an athlete’s foot scan. Or a high-fashion designer can produce intricate textures without seams. This accelerates prototyping and enhances final production.

Printing only what’s needed minimizes material consumption and eliminates inventory excess. It also supports localized production, because brands can install printers in regional microfactories or even retail locations. Large-scale apparel printing is still developing, but the potential for mass customization and more sustainable manufacturing is clear.

-

On-Demand Manufacturing

On-demand manufacturing produces apparel only after an order is placed, connecting digital design platforms with automated production systems. Orders move from ecommerce sites directly to factories equipped with robotics and digital cutters. By linking digital demand directly to manufacturing capacity, this model helps brands control costs, eliminate unsold inventory, and react quickly to consumer trends. For instance, a brand could launch a new dress design online, begin production as soon as orders close, and deliver the dresses within days—all without ever holding stock.

On-demand workflows align with environmental goals by stemming waste and energy use. They also allow for greater personalization, as customers can select fabrics, colors, or sizing that fit their preferences.

-

Ecommerce and Omnichannel Experiences

Ecommerce platforms and omnichannel strategies integrate every customer touchpoint—websites, apps, stores, and social channels—into a single cohesive experience. Centralized data systems synchronize inventory, pricing, and customer profiles, which creates a consistent shopping experience across online and physical environments. For example, a customer might see a new jacket on Instagram, try it on virtually using an AR app, purchase it through the brand’s website, and pick it up at a nearby boutique.

For apparel operations, unified systems improve demand forecasting, streamline fulfillment, and reduce returns. Omnichannel strategies turn fragmented sales channels into a connected network that delivers personalization and consistency, strengthening long-term brand value.

-

Integrated Software Systems

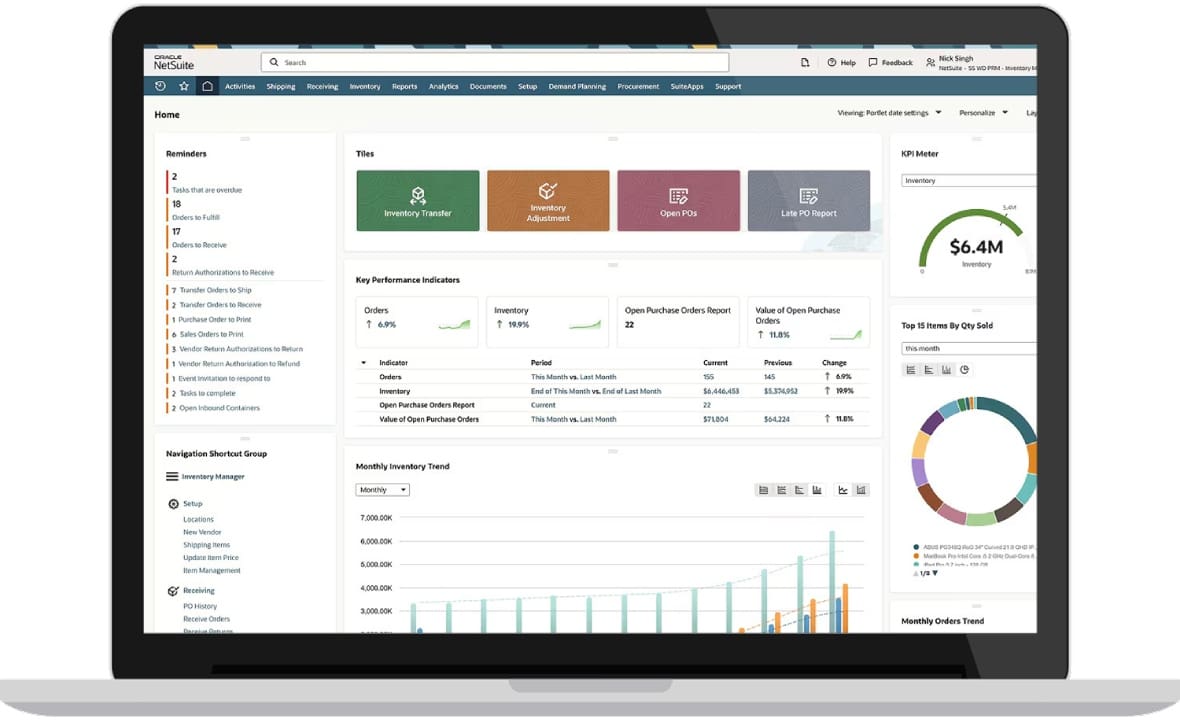

By connecting and centralizing the core functions of apparel businesses, software integrations make cohesive, data-driven organizations out of fragmented teams. ERP solutions consolidate data from design, sourcing, production, finance, and logistics systems to create a single operational backbone. They monitor costs, manage materials, and align procurement with demand forecasts, giving operations leaders consistent visibility and control. This cuts down on redundant data entry and overlapping processes, such as when multiple departments input their own purchase orders or maintain their own production schedules. Instead, teams work from the same accurate data sets, facilitating better coordination and smarter decision-making.

ERP inventory management modules optimize stock availability. They provide real-time tracking with automated reorder points, which helps prevent both overstock and stockouts. And built-in analytics improves forecasting and planning by revealing sales patterns, seasonal demand shifts, and fulfillment bottlenecks. Other integrated software includes product lifecycle management, which links design and sourcing, and supply chain management, which reports on supplier performance and compliance. Additionally, CRM platforms close the loop between operations and consumer feedback, providing valuable insights that inform planning and design improvements.

Technological Challenges and Limitations in the Fashion Industry

As transformative as they are, emerging apparel industry technologies raise significant privacy concerns and ethical considerations. Smart textiles, virtual try-on apps, and AI-powered systems collect and analyze sensitive customer data. Brands need explicit consent practices and secure retention policies to avoid compliance violations and privacy breaches that might result in penalties and damage customer trust. Sustainability claims must withstand scrutiny, with demonstrated proof of sourcing and environmental impact. Fair wages and safe conditions are still requirements, even as automation expands. And AI usage must be sure to avoid introducing or amplifying bias toward certain body types or demographics.

New technologies also come with challenges pertaining to cost control. Robotics, 3D design stacks, and enterprise software integrations incur both up-front capital expense and ongoing costs for software licensing, upgrades, maintenance, and training. Poorly scoped deployments result in companies buying overlapping tools, creating disconnected systems that amass integration debt and are costly to maintain.

Future-Forward Fashion Brands Are Powered by Modern ERP Systems

Apparel businesses must manage complex inventory and rapid style changes while scaling omnichannel operations and keeping pace with sustainability goals. Disconnected systems, manual processes, and siloed data complicate these efforts, leading to missed sales and fulfillment delays. As consumer demands continue to rise, brands need greater visibility into—and control over—inventory, order status, supplier performance, and cash flow. NetSuite Apparel ERP fuses financials, inventory, order management, supply chain, and customer engagement into one cloud platform, supporting the multifaceted needs of modern apparel companies. It optimizes seasonal planning, centralizes and automates inventory updates, and provides real-time reporting through intuitive dashboards. With these features at their disposal, fashion brands can prevent stockouts, control costs, deliver consistent customer experiences, and stay ahead of the industry’s fast-changing trends.

Unify Inventory Data Across Sales Channels With NetSuite

Technology is redefining every stage of the apparel industry, from design and sourcing to manufacturing and sales. AI, robotics, and automation improve accuracy and speed, while sustainable fabrics, digital design, and on-demand production eliminate waste and curb environmental impact. Smart factories, connected systems, and virtual experiences are changing how apparel companies operate and engage with customers. As these innovations continue to advance, the most successful brands will be those that integrate technology thoughtfully—balancing efficiency and creativity while staying focused on ethical growth.

Apparel Industry Technology FAQs

What is smart clothing technology?

Smart clothing technology refers to garments embedded with sensors or conductive fibers that interact with the wearer and their environment. These pieces can track biometric data, regulate temperature, or communicate with connected devices, merging fashion with function.

What is digital fashion?

Digital fashion is clothing created and displayed entirely in virtual environments using 3D modeling and AI tools. Designers craft these garments for avatars, enhanced photographs, or augmented reality overlays.

What is the role of technology in the apparel industry?

The role of technology in the apparel industry is to drive innovation, personalization, and sustainability. From AI-assisted design to automated production, technology helps fashion brands operate faster, smarter, and more responsibly.