Many businesses are feeling the squeeze on warehouse capacity as rising demand, tighter delivery deadlines, and complex inventory needs strain their existing space. Often, the issue isn’t a lack of square footage but poor utilization caused by inefficient layouts, underused vertical areas, or outdated technology. The result: congestion, slower operations, increased labor costs, and added expenses from overflow storage or missed delivery windows.

To improve efficiency and reduce costs, businesses must aim to accurately calculate usable warehouse capacity—accounting for obstructions, aisle widths, and safety requirements. Once that data is available, businesses should implement smart strategies to maximize every inch, which may involve redesigning layouts, using more vertical space, consolidating SKUs, and updating warehouse management systems.

What Is Warehouse Capacity?

Warehouse capacity refers to the total amount of usable space within a warehouse that can be allocated for storing inventory, which may include raw materials and finished goods. Understanding this measurement helps businesses make smarter decisions about layout and storage methods, as well as making sure the facility is neither overfilled nor underused.

To calculate warehouse capacity, start by measuring the facility’s total square footage, then subtract areas used for non-storage purposes—offices, restrooms, loading docks. Multiply the remaining usable space by the maximum safe stacking height to determine the total storage capacity.

Key Takeaways

- Nearly one-third of warehouses are operating at or above the industry-recommended capacity limit.

- Fire codes require a certain clearance around sprinkler heads, fire extinguishers, and emergency exits.

- High-bay pallet racking systems allow businesses to stack more inventory vertically, increasing the building’s total storage capacity.

- An increasing number of businesses are updating their warehouse management systems to take advantage of real-time inventory tracking, faster order fulfillment, and improved labor productivity.

Warehouse Capacity Explained

Warehouse capacity is essentially how much inventory a warehouse can safely and efficiently hold at any given time.

Many warehouses operate at or above the industry-recommended limit of 85% capacity—a threshold set to prevent slow picking, restocking delays, and diminished ability to respond to shifts in customer demand. In a 2024 survey by Peerless Research Group, 30% of warehouse officials estimated their warehouse utilization during peak periods to be between 85% and 100%—suggesting that many may have been grappling with efficiency, safety, and bottleneck concerns. Notably, 37% cited the storage area as the most congested part of their facility, far exceeding any other section. And 62% reported leasing additional warehouse space during peak periods in the past five years to accommodate inventory overflow.

Merely expanding or building new facilities isn’t always the answer to space limitations. With rising real estate costs and limited land availability, more organizations are seeking to optimize the existing nooks and crannies of their spaces. Technologies, such as advanced warehouse management systems (WMSs) and automated storage and retrieval systems, are helping businesses reconfigure layouts and improve the flow of goods to maximize storage capacity and reduce labor costs.

Types of Warehouse Capacity

Businesses can determine their warehouse capacity in three main ways. Each type of warehouse capacity offers a different perspective into how much inventory a facility can realistically manage. Understanding the differences in these capacity types can help businesses improve their usage of space and reach smarter operational decisions:

- Theoretical capacity: The absolute maximum amount of inventory a warehouse could hold if every inch of space were filled, wall to wall and floor to ceiling. It does not account for real-world constraints like aisles, offices, equipment, and mandated safety requirements, so it’s best thought of as a starting point.

- Working capacity: The amount of space realistically available for storage after accounting for practical limitations, such as product size and weight, aisle space, equipment, and staff movement. It also subtracts areas that can’t be used for storage, such as docks, staging zones, and office space.

- Utilized capacity: The percentage of available storage space that’s actually in use at a given time. For example, if a warehouse has 100,000 cubic feet of working capacity and is storing 75,000 cubic feet of goods, its utilized capacity is 75%. Tracking this metric helps determine whether a facility is overcrowded or underused, which is useful for guiding inventory intake decisions.

How to Calculate Warehouse Capacity

Calculating the capacity of a warehouse entails measuring its physical dimensions to ascertain how much inventory a business can realistically store and how efficiently the company is using the space. The following steps calculate the storage capacity of a warehouse, along with the corresponding formulas:

-

Determine Your Total Warehouse Space

Start by measuring the total floor area of your warehouse in square feet. This includes all areas under the roof, including both storage and non-storage spaces, such as break rooms and staging areas.

The formula is:

Total warehouse space = Length x Width

-

Calculate the Usable Space

Not every part of a warehouse can be used for inventory storage, of course. To determine your usable space, subtract all non-storage areas from the total warehouse space. These may include:

- Offices

- Reception and administrative areas

- Restrooms and locker rooms

- Break rooms and meeting rooms

- Maintenance and equipment rooms

- Staging areas

- Loading docks

The formula is:

Usable space = Total warehouse space – Non-storage space

-

Calculate the Maximum Stack Height

The maximum stack height is the tallest point at which products or pallets can be safely and legally stacked within the warehouse. This limit is influenced by local fire codes, which often require a uniform clearance below sprinkler heads across the entire storage area. Structural limits and safety ratings of pallet racks and shelving also affect how high you can stack, though weight limits are not part of the height calculation itself.

To calculate maximum stack height, measure the distance from the floor to the lowest overhead obstruction, such as sprinklers, lights, or beams, and subtract any required safety clearance. The formula is:

Maximum stack height = Floor-to-lowest obstruction height – Required clearance

-

Calculate the Total Warehouse Capacity

After determining the usable floor area and maximum stack height, it’s time to calculate the total warehouse capacity in cubic feet. This figure represents the maximum theoretical volume of space available for storage within the usable footprint of a warehouse. It does not account for shelving, racking, or product types—just the physical limits of the space itself.

The formula is:

Total warehouse capacity = Usable space x Maximum stack height

Example of a Warehouse Capacity Calculation

Let’s say a retailer wants to calculate the total capacity of its warehouse. The first step is to measure the total warehouse space. In this case, the warehouse is 500 feet long by 300 feet wide.

Total warehouse space = 500 feet x 300 feet = 150,000 square feet

Next, the retailer calculates the usable space by subtracting non-storage areas (offices, loading docks, aisles, etc.) from the total space. In this example, the non-storage areas add up to 30,000 square feet.

Usable space = 150,000 square feet – 30,000 square feet = 120,000 square feet

Then, the retailer calculates the maximum stack height by measuring the distance from the floor to the lowest obstruction from the ceiling, subtracting the required safety clearance. The distance from the floor to the lowest sprinkler head is 20 feet, and the fire code requires a 2-foot clearance below the sprinkler head for safety.

Maximum stack height = 20 feet – 2 feet = 18 feet

At this stage, it’s also important to check racking and shelving limits. If the racking system is only rated to safely stack up to 17 feet, that becomes the true height limit—even if more vertical space is available. Let’s say that’s the case in this example. So, while the theoretical maximum is 18 feet, the retailer’s actual stack height is 17 feet, because of the racking system limitations.

Maximum usable stack height = 17 feet

Finally, to calculate the total warehouse capacity, multiply the usable warehouse space by the maximum usable stack height.

Total warehouse capacity = 120,000 square feet x 17 feet = 2,040,000 cubic feet

This figure represents the total volume of warehouse space available to the retailer for storage, based on real-world constraints.

Considerations for Calculating Warehouse Capacity

While measuring the raw square footage and height of a warehouse is a good starting point, it’s also important to account for constraints that reduce how much space can be realistically used for storage. The following considerations can help businesses make more accurate capacity estimates and design layouts while optimizing safety and usage:

- Obstructions: Structural and mechanical elements, such as columns, support beams, stairwells, lighting fixtures, and HVAC equipment, reduce usable vertical and horizontal space. These obstructions can interfere with racking layouts and limit how high or how densely goods can be stored.

- Storage dimensions and storage levels: The dimensions of pallets, bins, storage units, and stored items directly affect how much space is needed and how high inventory can be stacked. Bulky or irregularly shaped goods, such as furniture or construction machinery, can limit stacking height and storage density, for instance.

- Types of storage: Storage methods, such as pallet racks, shelving, bulk floor stacking, and automated systems, affect how efficiently space can be used. Pallet racks allow high stacking of heavy loads but require wider aisles to accommodate forklifts. Bulk floor stacking maximizes floor use but can limit stacking height and access to inventory. Automated systems often increase both vertical and horizontal capacity by using robotics to move goods through high-density layouts.

- Aisle widths: Aisles must allow safe, efficient movement for workers and equipment, but wider aisles reduce available storage space. For example, 12-foot aisles may support quicker picking and fulfillment, but an 8-foot-aisle layout will offer more storage space—the final decision will involve a trade-off between capacity and productivity.

- Equipment limitations: The forklifts, pallet jacks, automated guided vehicles, and other equipment in use will dictate how high and how densely the company can store goods. A standard forklift might require 12-foot aisles and reach 15 feet high, whereas specialized narrow-aisle lift trucks may need less space and can access higher racks.

- Safety requirements: Safety regulations often require clearance zones that reduce storage space. Fire codes generally mandate at least 18 inches of clearance below sprinkler heads, specified distances from overhead lighting, and unobstructed access to emergency exits, fire extinguishers, electrical panels, and ventilation systems.

Tips for Maximizing Warehouse Space

Expanding the square footage of a warehouse isn’t always economically feasible, so it’s important for companies to find creative ways to maximize the space they already have. In fact, a 2025 AutoStore report shows 27% of business leaders say optimizing their existing space is a key priority in the year ahead. By rethinking warehouse layouts, developing new storage processes, and using advanced technology, businesses can significantly improve warehouse space utilization. Here are some of the most effective strategies to optimize warehouse space.

Leverage Vertical Space

Some warehouses strategically fail to build as high as possible upward. Taking full advantage of vertical space in a warehouse is a great way to increase storage capacity without expanding the facility’s footprint. This is especially effective in high-rent areas, where horizontal expansion is costly and real estate is scarce. Installing high-bay pallet racking systems or mezzanines allows businesses to stack more inventory without using more floor space, be it clothing, canned goods, paper products, or lumber.

The benefit is even more pronounced with automated storage and retrieval systems, which use robotic shuttles or cranes to access goods at heights that would be difficult or time-consuming to reach manually. These systems not only maximize vertical capacity but also reduce labor demands and speed up inventory handling.

Redesign Warehouse Layout

Many warehouses suffer from awkward layouts that generate not only wasted space but also bottlenecks and slow order fulfillment. In fact, a recent survey found that 26% of warehouse professionals cited outdated layouts as a major operational issue.

Warehouse simulation tools and computer-aided-design software can help businesses create more efficient warehouse layouts that support faster picking, smoother flow of materials, and strategic zoning—while reclaiming underused space. Common designs, such as U-shaped, I-shaped, and L-shaped layouts, help separate inbound and outbound goods to reduce congestion, for instance. Similarly, switching from traditional wide-aisle racking to narrow-aisle systems can boost storage density by up to 25%.

It’s also important to remember that a warehouse layout design shouldn’t be set in stone. Businesses should regularly review and refine the layout to be sure the space will adapt to changing inventory needs over time.

Optimize Slotting

Storing goods in random spots or keeping items in the same place year-round can waste space and increase picking times—especially when storage locations aren’t intuitive, or when low-demand items occupy prime locations. Warehouse slotting optimization uses data analysis to assign products to ideal locations based on demand, size, and picking frequency. Placing high-turnover items in easy-to-reach areas and slower-moving stock in less accessible zones can go a long way toward reducing congestion, for instance.

Companies can also use analytics tools to examine historical order patterns and current market trends to anticipate demand and adjust storage accordingly. Seasonal products, like holiday decorations, might be rotated into prime picking zones ahead of peak demand months and then moved back to harder-to-reach areas once the season ends.

Consolidate SKUs

If customers aren’t buying certain products in high numbers, why reserve precious warehouse space for them? Businesses should regularly analyze sales data, turnover rates, and customer demand to assess which stock-keeping units (SKUs) are unpopular, redundant, or too similar to faster-moving products—and consider phasing them out.

For example, a retailer might carry multiple brands of nearly identical black T-shirts. If two brands far outsell the rest, it might be time to drop the low performers to reduce clutter and make space available for higher-demand, higher-margin items.

Consider Cross-Docking

Some businesses might be able to reduce—or even eliminate—the need for warehouse storage by keeping their products in transit. Cross-docking accomplishes that. Products are unloaded from inbound trucks and immediately loaded onto outbound vehicles, bypassing the storage stage entirely.

Cross-docking works best for products in consistently high demand or with short shelf lives, since it minimizes the time goods spend sitting in storage. Perishable goods, including fresh produce, dairy products, and meat, are ideal candidates because they need to move quickly to avoid spoilage. Retailers like Walmart, Target, and Amazon use cross-docking for fast-moving inventory, coordinating inbound shipments with outbound routes using real-time data and advanced logistics software.

Update Your Warehouse Management System (WMS)

When a business relies on an outdated WMS, it often lacks the timely data and insights needed to manage inventory effectively, use vertical space, or efficiently alter layouts. An upgraded WMS enables real-time inventory tracking by capturing product movement through the warehouse; it also speeds up order fulfillment by optimizing picking routes and helps teams work more efficiently because of task automation. It also provides data that informs decisions such as sales trends driving storage locations to maximize space and reduce congestion.

Moreover, as real estate costs rise and available warehouse space becomes harder to find in some areas, more companies are turning to WMS upgrades as a cost-effective way to stretch existing capacity and boost productivity. Indeed, the global WMS market size was estimated at $2.8 billion in 2024 and is projected to expand at a compound annual growth rate of nearly 20% in the next five years, to reach roughly $8.4 billion by 2030, according to Grand View Research.

Considerations for Growing and Scaling Warehouse Capacity

When planning a warehouse, many business leaders focus only on their current space needs, overlooking the importance of planning for future growth. Without that foresight, they risk ending up with a facility that’s too small or too rigid to scale with demand.

Planning for growth begins with choosing the optimal location and facility design. Look for a site that not only supports immediate operations—one that provides sufficient proximity to transportation routes and suppliers, for example—but also allows for future physical expansion. Ideal sites may feature adjacent land for construction or the ability to lease additional space as needed.

If possible, steer away from fixed warehouse layouts that may create obstacles as the business evolves. Instead of permanently installed racking or narrow aisles, consider modular layouts and flexible systems. Mobile racking, for example, lets you adjust aisle width and storage density to accommodate seasonal demand. Scalable mezzanines can expand vertical capacity without altering the building’s footprint. And open floor plans without too many permanent fixtures can make it easier to eventually introduce automation without requiring major renovations.

Technology also plays a role in efficient scaling. A modern, cloud-based WMS should support increasing SKU volume, automated picking methods, integration with robotics, and AI-powered analytics. With the right tools in place, businesses are better prepared to manage growing operations, even at multiple sites, without incurring a full system overhaul.

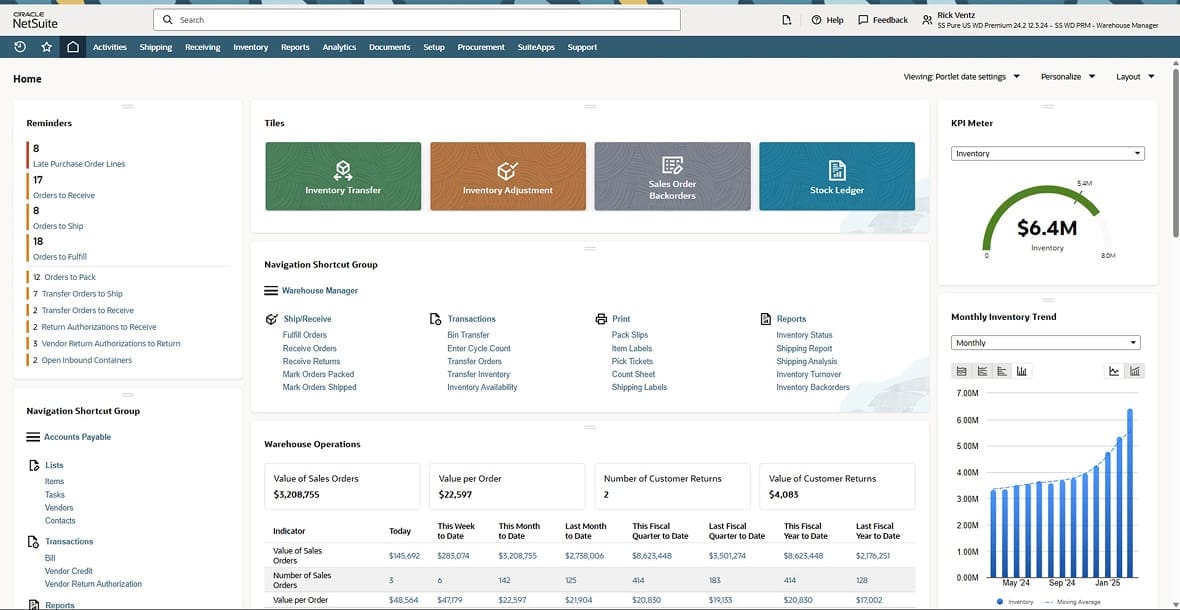

Get Real-Time Warehouse Visibility With NetSuite WMS

NetSuite Warehouse Management provides real-time visibility that allows businesses to track inventory as it enters, moves within, and leaves the warehouse. The NetSuite WMS mobile application increases efficiency and reduces human error with direct interfaces for a wide variety of daily tasks, such as receiving, putaway, picking, and packing. In addition, NetSuite’s WMS can support smarter use of storage space by accounting for such factors as storage capacity and product velocity. With NetSuite, warehouses can optimize inventory and operations to power new opportunities for savings and revenue.

NetSuite WMS

Congested aisles. Slow fulfillment. Inventory errors. These problems are often the result of warehouses operating at or above recommended utilization levels—not necessarily because they lack space, but because they don’t maximize the space they have. The first step in overcoming these challenges is accurately calculating warehouse capacity for a clear picture of how much inventory the business can safely and efficiently manage at any given time. That insight drives business action, such as redesigning layouts, capitalizing on vertical space, reslotting according to demand, and embracing scalable WMS tools to get the most out of existing square footage.

Calculating Warehouse Capacity FAQs

What is the formula for calculating warehouse capacity?

The formula for calculating warehouse capacity is:

Total warehouse capacity = Usable space x Maximum stack height

Usable space subtracts non-storage space, such as offices, restrooms, loading bays, and administrative areas, from the total square footage of the warehouse. Maximum stack height is how high goods can be safely stored, taking into account safety regulations pertaining to sprinklers, lighting fixtures, and other overhead obstructions.

How do you determine warehouse space requirements?

To determine warehouse space requirements, start by estimating the amount of inventory to be stored. Then, measure the usable storage area by subtracting non-storage zones—such as offices and aisles—from the total square footage. Consider how high items can safely be stacked vertically and be sure to leave enough room for equipment movement, staff access, and safety clearances.

How full should a warehouse be?

The industry-recommended capacity limit of a warehouse is 85%, which allows for the flexible movement of stock.

How do you calculate the warehouse occupancy rate?

To calculate the warehouse occupancy rate, use this formula:

Occupancy rate (%) = (Utilized space / Total usable storage space) x 100